- DL manuals

- Wascomat

- Scrubber

- WS3 230-340-470-670 H

- Instruction Handbook Manual

Wascomat WS3 230-340-470-670 H Instruction Handbook Manual

Summary of WS3 230-340-470-670 H

Page 1

08100226gb w asher- e xtractors ws3 230-340-470-670 h wsb3 230-340-470-670 h instruction handbook.

Page 2: Table of Contents

Notice date page 01201055 instruction handbook general instructions general ..................................................... 1/1 precautions for use ................................... 1/2 environmental information ........................ 1/3 preliminary instructions .............................

Page 3: 1. General

Notice date page 01201055 instruction handbook 0300 1 1 1. General identification plate general instructions the machines described in this handbook have a washing capacity of 229, 338, 467 or 668 litres according to their type. They are washer-extractors designed to meet the most severe requirement...

Page 4: 1. General

Notice date page 01201055 instruction handbook 1199 2 1 1. General 1 2 3 4 5 6 7 8 9 0 during a wash : "pause" key. Before and after a wash, and during programming : "move back key". By pressing this key repeatedly you can move backwards through the menus you have navigated through. This will always...

Page 5: 1. General

Notice date page 01201055 instruction handbook 1298 3 1 1. General a very high working safety level of the machine is achieved thanks to a continuous monitoring and built-in safety devices. Even the compound textile fabrics can be washed at a high temperature with no crumpling risk thanks to a speci...

Page 6: 2. Precautions For Use

Notice date page 01201055 instruction handbook 0700 1 2 2. Precautions for use precautions for use . The machine should not be used by children. . The machine is designed for "water washing" of textile only. . This machine is for professional use and must be used exclusively by qualified personnel. ...

Page 7: 3. Environmental

Notice date page 01201055 instruction handbook 0401 1 3 3. Environmental information environmental information concerned by providing the end user with useful and necessary environmental information, we wish to precise : . Data about energetic consumptions, wastes (atmospheric and liquid) and sound ...

Page 8: 4. Preliminary

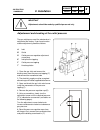

Notice date page 01201055 instruction handbook a flash of lightning with an arrow at its end displayed inside an equilateral tri- angle, warns the user about the pres- ence of uninsulated "dangerous cur- rent" sufficient in intensity to cause electrocution. An exclamation mark inside an equi- latera...

Page 9: 4. Preliminary

Notice date page 01201055 instruction handbook 1199 2 4 4. Preliminary instructions safety the mechanical and electrical installation of the machine should only be done by qualified personnel. Caution do not use the machine unless it is plugged into a correctly earthed power socket com- plying with ...

Page 10: 4. Preliminary

Notice date page 01201055 instruction handbook 1101 3 4 4. Preliminary instructions the use and handling of chemical products such as detergent, chlo- rine, acids, antiliming agents etc... May create hazards for health and environment ; the following precautions should be taken. - do not breathe the...

Page 11: 4. Preliminary

Notice date page 01201055 instruction handbook 1298 4 4 4. Preliminary instructions distributor letter chemical system responsibility disclaimer the following policy should be considered and understood as a warranty/disclaimer to customers operating textile care installations where liquid supply (ch...

Page 12: 5. Locking and

Notice date page 01201055 instruction handbook 1298 1 5 5. Locking and tagging procedure locking and tagging procedure 1 2 3 4 a red insert at the beginning of this instruction handbook schematically shows the locking and tagging procedure described below. If you wish, you can detach this insert and...

Page 13: 6. Handling

Notice date page 01201055 instruction handbook 1298 1 6 6. Handling 1/ lifting with handling straps lifting in that case can only be done with handling straps (minimum capacity 1000 dan) which bear weight of the machine. Nota : in order to avoid bending of the machine's casings, make sure to place t...

Page 14: 6. Handling

Notice date page 01201055 instruction handbook 1298 2 6 d0603 2/ lifting with a fork-lift truck this can be carried out from the front or back, at the centre of the machine. Caution you should never handle the machine in its longitudinal side (any other than shown on the drawing below) with a fork-l...

Page 15: 6. Handling

Notice date page 01201055 instruction handbook 1298 3 6 6. Handling 74 03 21 46 caution in order to avoid any bend- ing of casings, you should never climb and stand on top of the machine. 4/ lifting with a jack lifting in this case can only be done with a jack (minimum capacity 500 dan) which can be...

Page 16: 7. Packing - Weight

Notice date page 01201055 instruction handbook 0102 1 7 7. Packing - weight packing packing dimensions in mm/inch size a size b size c washer extractor type 230 standard 1180/46.5 1230/48.4 1840/72.4 washer extractor type 230 barrier 1180/46.4 1230/48.4 1840/72.4 washer extractor type 340 standard 1...

Page 17: 8.Technical

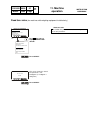

Notice date page 01201055 instruction handbook front view top view right view left view example of drain connection 0999 1 8 8.Technical characteristics 07100081 washer extractor type 230 standard 8 7 0 /3 4 .2 5 ” 8 7 0 /3 4 .2 5 ” 1 6 1 0 /6 3 .3 8 ” 1 6 1 0 /6 3 .3 8 ” > 1 m/40” > 1 m/40” > 1 m/4...

Page 18: 8.Technical

Notice date page 01201055 instruction handbook 0102 2 8 washer extractor type 230 standard diagram no. 07100081 8.Technical characteristics heating gas electric steam thermic fluid characteristics Ø cage --------------------------- 770 mm (30.31")-------------------- cage length --------------------...

Page 19: 8.Technical

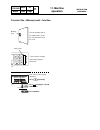

Notice date page 01201055 instruction handbook 0999 3 8 07100083 washer extractor type 340 standard top view example of drain connection front view right view left view 8.Technical characteristics j 8 7 0 /3 4 .2 5 ” 8 7 0 /3 4 .2 5 ” 1 6 1 0 /6 3 .3 8 ” 1 6 1 0 /6 3 .3 8 ” > 1 m/40” > 1 m/40” > 1 m...

Page 20: 8.Technical

Notice date page 01201055 instruction handbook washer extractor type 340 standard diagram n°. 07100083 0201 4 8 8.Technical characteristics heating gas electric steam thermic fluid characteristics Ø cage --------------------------- 770 mm (30.31")-------------------- cage length --------------------...

Page 21: 8.Technical

Notice date page 01201055 instruction handbook 0999 5 8 07100085 washer extractor type 470 standard top view example of drain connection front view right view left view 8.Technical characteristics j 1565/61.61” 1565/61.61” h1-h2 n n' h3 h1 h4 h2 h3-h4 f-d-e j k g 1 7 1 0 /6 7 .3 2 ” j 150/5.9” n e j...

Page 22: 8.Technical

Notice date page 01201055 instruction handbook washer extractor type 470 standard diagram no. 07100085 0102 6 8 8.Technical characteristics heating gas electric steam thermic fluid characteristics Ø cage --------------------------- 770 mm (30.31")-------------------- cage length --------------------...

Page 23: 8.Technical

Notice date page 01201055 instruction handbook 0999 7 8 8.Technical characteristics 07100087 washer extractor type 670 standard front view right view left view top view example of drain connection j 200078.74” 200078.74” h1-h2 h6 h6 h5 h5 h3 h1 h4 h2 h3-h4 1 7 1 0 /6 7 .3 2 ” j 150/5.9” n 915/36” n ...

Page 24: 8.Technical

Notice date page 01201055 instruction handbook 0102 8 8 8.Technical characteristics heating gas electric steam thermic fluid characteristics Ø cage --------------------------- 770 mm (30.31")-------------------- cage length ----------------------------- 1500 mm (59") ------------------- cage volume ...

Page 25: 8.Technical

Notice date page 01201055 instruction handbook 0999 9 8 07100082 washer extractor type 230 barrier top view example of drain connection front view right view left view 8.Technical characteristics 1 7 1 0 /6 7 .3 2 ” > 1 m/40” 55/2.16” 40/1.57” 1 0 0 /3 .9 3 ” Ø 7 5 /3 ” 150/5.9” > 1 m/40” 1055/41.53...

Page 26: 8.Technical

Notice date page 01201055 instruction handbook washer extractor type 230 barrier diagram no. 07100082 0102 10 8 8.Technical characteristics heating gas electric steam thermic fluid characteristics Ø cage --------------------- 770 mm (30.31") ------------------- cage length --------------------- 520 ...

Page 27: 8.Technical

Notice date page 01201055 instruction handbook 0999 11 8 07100084 washer extractor type 340 barrier top view example of drain connection front view right view left view 8.Technical characteristics > 1 m/40” > 1 m/40” 1285/50.59” 1285/50.59” h1-h2 h3-h4 n m h3 h1 h4 h2 r p o p 1315/51.77” f-d-e j k g...

Page 28: 8.Technical

Notice date page 01201055 instruction handbook washer extractor type 340 barrier diagram no. 07100084 0102 12 8 8.Technical characteristics heating gas electric steam thermic fluid characteristics Ø cage --------------------- 770 mm (30.31") ------------------- cage lenght ----------------------- 76...

Page 29: 8.Technical

Notice date page 01201055 instruction handbook 0999 13 8 07100086 washer extractor type 470 barrier top view example of drain connection front view right view left view 8.Technical characteristics 1565/61.61” 1565/61.61” h1-h2 h3-h4 n h3 h1 h4 h2 o p 1595/62.79” f-d-e j k g 1 7 1 0 /6 7 .3 2 ” j j 1...

Page 30: 8. Characteristics

Notice date page 01201055 instruction handbook washer extractor type 470 barrier diagram no. 07100086 0102 14 8 8. Characteristics techniques heating gas electric steam thermic fluid characteristics Ø cage --------------------- 770 mm (30.31") ------------------- cage length ----------------------- ...

Page 31: 8.Technical

Notice date page 01201055 instruction handbook 0999 15 8 8.Technical characteristics 07100088 washer extractor type 670 barrier top view example of drain connection front view right view left view h1-h2 h3-h4 h3 h1 h4 h2 o p 2030/79.92” 1 6 2 5 /6 3 .9 7 ” 1 7 1 0 /6 7 .3 2 ” j j 150/5.9” n e j k f ...

Page 32: 8.Technical

Notice date page 01201055 instruction handbook 0120 16 8 8.Technical characteristics heating gas electric steam thermic fluid characteristics Ø cage --------------------- 770 mm (30.31") ------------------- cage length ----------------------- 1550 mm (59") ------------------- cage volume -----------...

Page 33: 8. Characteristics

Notice date page 01201055 instruction handbook 8. Characteristics techniques 0102 17 8 d0267 label of energetic performance (gas heating only) the global output hg of the gas heated washer-extractor is determinated according to a stand- ardised method and shall not be lower than 50 %. This output mi...

Page 34: Unpacking

Notice date page 01201055 instruction handbook you should have found an instruction handbook and keys to open the machine casings, in the machine. Depending on its destination, the washer extractor is delivered bare or may be placed on a transport pallet and/or packed with plastic film. In some case...

Page 35: Working Place Lighting

Notice date page 01201055 instruction handbook working place lighting the lighting should be designed so as to avoid eye strain for the operator ; it should be uniform without any glare, and should be sufficient to detect any hazards. The average lighting value on the working place recommended by th...

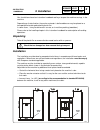

Page 36: Mechanical Installation

Notice date page 01201055 instruction handbook mechanical installation setting of the "gripsol" bolsters preparation of the ground and machine : - degrease carefully the ground and the soles of the machine. Preparation of the "gripsol" bolsters : - soak the bolsters in hot water during 5 minutes, th...

Page 37: 9. Installation

Notice date page 01201055 instruction handbook 9. Installation 0102 4 9 instructions to fit the safety flanges position the safety flanges (a) crosswise (one in the front and the other at the back of the sole). Mark the place of the drilling hole for the fixing pin (b) and drill the holes for fixing...

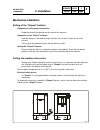

Page 38: 9. Installation

Notice date page 01201055 instruction handbook 9. Installation 0599 5 9 instructions to fit the filling angles (barrier machines only) two angles (a and b) allow to fill the the soles ends. Assemble each filling angle with screws and nuts to the sole ends which are next to the parti- tion wall, in t...

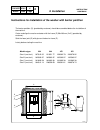

Page 39: 9. Installation

Notice date page 01201055 instruction handbook 100 5 0 1 0 0 o p r r p o d a c b instructions for installation of the washer with barrier partition the barrier partition (o) (provided by customer) should be assembled before the installation of the machine. Centre and align the washer-extractor with ...

Page 40: Waters Connections

Notice date page 01201055 instruction handbook waters connections washer extractors are assembled in standard execution with two waters inlet. One hot water and one hard water. On option, a third water inlet (soft) is possible. The hereunder example sketch shows the connection of the machine to the ...

Page 41: Steam Connection

Notice date page 01201055 instruction handbook steam connection for transport reasons, the steam electrovalve is dismantled and placed in the cardboard box supplies. The inlet pipe to the machine has to be fit with a manual stopping valve to ease installation and maintenance. Connect the steam elect...

Page 42: 9. Installation

Notice date page 01201055 instruction handbook tow winden only on type xxx 4 holes to countersink steam diffuser adjusting the diameter for drilling the steam diffuser according to the pressure machine 1 bar 2 bar 3 bar 4 bar 5 bar 6 bar (standard pressure) 230 Ø x mm Ø x mm Ø x mm Ø x mm Ø x mm Ø x...

Page 43: Drain Connection

Notice date page 01201055 instruction handbook drain connection the machine's exhaust sleeve outside diameter is of 75 mm (3"). Depending of your installa- tion, it might be fit on the left or right side of the machine. Adapt and connect the rubber bend (h) to the machine's exhaust sleeve and to the...

Page 44: Air Vent Connection

Notice date page 01201055 instruction handbook air vent connection the air vent of the drum opens on the top of the machine. Remove the upper casing protecting the water inlets to reach the air intake sleeve, then connect the bent hose to this opening. Connect the air vent, to the outside of the lau...

Page 45: 9. Installation

Notice date page 01201055 instruction handbook 9. Installation 0102 12 9 d0651 machine type units a length of exchanger mm/inch 1110/43.7" b dimension of output exchanger mm/inch 1040/41" c dimension of evacuation pipe mm/inch 645/25.39" d evacuation of burn gas mm/inch Ø 125/5" e exchanger bottom o...

Page 46: 9. Installation

Notice date page 01201055 instruction handbook 9. Installation 0102 13 9 connection of the evacuation pipe of the gas exchanger. Fresh air inlet to allow the gas exchanger to work at ist best, it is important that the laundry air inlet passes throught an opening from the outside. The fresh air arriv...

Page 47: 9. Installation

Notice date page 01201055 instruction handbook 9. Installation 0102 14 9 installation of the exhaust of burn gas - connect the whole set of pipes on your cheminey pipe, that is to say : - 1 aluminium pipe (a) lenght 500 mm (20") on the exchanger. -1 t-square (b) pipe + 1 regulator (c). -1 aluminium ...

Page 48: 9. Installation

Notice date page 01201055 instruction handbook 9. Installation 0499 15 9 gas connection caution the installation, connection and gas arrival adjustments for the machine must be done by qualified personnel only. The customer must install a filter and a manual stop valve on the supply side of the mach...

Page 49: 9. Installation

Notice date page 01201055 instruction handbook 9. Installation 0800 16 9 d0291 the gas exchanger is adjusted at the plant to be suitable for the kind of gas specified on the order. If you have to supply your machine with gas in a family different from the gas for which your machine was adjusted, pro...

Page 50: 9. Installation

Notice date page 01201055 instruction handbook 9. Installation 0499 17 9 p f d0290 d0034 important adjustments should be made by qualified personnel only. Adjustement and chesking of the outlet pressure the gas outlet pressure of the electrovalve is adjusted at the factory. If you have to make anoth...

Page 51: 9. Installation

Notice date page 01201055 instruction handbook 9. Installation 0300 18 9 legend of symbols used i: machine working with only one gas family ii: machine working with two gas families 1: 1 st family : caol gas or town gas (for information : not used here) 2: 2 nd family : natural gas 3 : 3 th family :...

Page 52: 9. Installation

Notice date page 01201055 instruction handbook 9. Installation 0102 19 9 table of correspondences - washer-extractor 230 category type working Ø of pressure at heat consumption consumption of gas supply hi injectors injectors emission mn in vn in index pressure in mm in mm h 2 o qn in kw kg/h (hi)**...

Page 53: 9. Installation

Notice date page 01201055 instruction handbook 9. Installation 0102 20 9 table of correspondences - washer-extractor 470 category type working Ø of pressure at heat consumption consumption of gas supply hi injectors injectors emission mn in vn in index pressure in mm in mm h 2 o qn in kw kg/h (hi)**...

Page 54: 9. Installation

Notice date page 01201055 instruction handbook check-out before leaving, put the appliance into operation and allow to run a complete cycle. Watch to ensure that all burner system components function correctly. Important tightness test after installation the gas leak test is performed as follows : 1...

Page 55: Liquid Detergents Connection

Notice date page 01201055 instruction handbook caution liquid detergents are particularly aggressive. We advise you to use only products with ph lower than 9 in order to avoid the machine's rubbers from being attacked. Dilute imperatively all of your detergents before letting them flow into the mach...

Page 56: 9. Installation

Notice date page 01201055 instruction handbook 9. Installation 1101 23 9 caution the running of detergents must be independent from the running of the machine. The control information of detergents must imperatively be relayed. Connection scheme of liquid detergents we advise you to use one of the t...

Page 57: 9. Installation

Notice date page 01201055 instruction handbook washer-extractor electricity power supply caution prior to use, the washer-extractor should be plugged into a correctly earthed power socket complying with the standards in force. Safety the electrical installation of the machine must be undertaken by q...

Page 58: 9. Installation

Notice date page 01201055 instruction handbook connect the power supply cable on the machine main switch. Connect the 3 phases on the main switch (see marks l1, l2, l3) and connect the earth wire on the earth terminal (pe) of this main switch. (check operation, see chapter no. 10). Pass the power su...

Page 59: 9. Installation

Notice date page 01201055 instruction handbook measure the power supply voltage at the transformer primary with a voltmeter be- tween the transformer 0 and 400 volts terminals. - if the voltage is equal to 400 volts, do not touch the transformer connection which must be as shown in the adjacent figu...

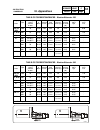

Page 60: Table 1

Notice date page 01201055 instruction handbook the feeder cable sections mentioned in our literature are given only as a guide. To obtain a value perfectly suited to your own application and which takes account of the different correction factors in respect of your plant, refer to the tables below. ...

Page 61: Table 4

Notice date page 01201055 instruction handbook table 4 (b2, c and e correction factors for cable grouping) b2 c e number seated in wall fixing cable of cables cable duct or cable trough tray 1 1.00 1.00 1.00 2 0.80 0.85 0.87 4 0.65 0.75 0.78 6 0.57 0.72 0.75 9 0.50 0.70 0.73 the total current includ...

Page 62: 9. Installation

Notice date page 01201055 instruction handbook caution before putting the machine into service, it is compulsory to remove the 4 transport locks fitted. Remove of the transport locks fitted to do so, remove the front and rear casings, then the fixing screws of the transportation bridles (b). Keep th...

Page 63: Operating Inspection

Notice date page 01201055 instruction handbook operating inspection before putting the machine into service, carry out the working tests. The operating inspection must be done by an approved technician. Manual operation the procedure for operating the various machine functions manually is described ...

Page 64: 10. Operating

Notice date page 01201055 instruction handbook 1298 2 10 automatic operation • check that the external switch or switches are switched on and that the manual valves for water and steam (if the machine has steam heating) are open. • run one of the machine's built-in (standard) with heating. • check t...

Page 65: 11. Machine

Notice date page 01201055 instruction handbook 11. Machine operation 0999 1 11 emergency stop the emergency stop must be unblocked, if not the machine will not work (to unblock, turn the red button to the right). If the machine for some reason has to be stopped, abnormal or dangerous running, press ...

Page 66: 11. Machine

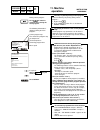

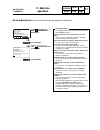

Notice date page 01201055 instruction handbook 0499 2 11 the control board on the loading side includes the following : indicator (1) light = "power on". Key (2) "cage positioning". Key (3) "door unblocking". Emergency stop (4). Indicator (5) light = "drum door opening". Key (6) "cage positioning". ...

Page 67: Automatic Operation

Notice date page 01201055 instruction handbook 0499 3 11 automatic operation preparation sort the linen according to the instructions mentioned on the care labels. Empty the pockets and clasp the slide fasteners. • position the cage doors in front of the drum door thanks to the key "cage positioning...

Page 68: 11. Machine

Notice date page 01201055 instruction handbook 0200 4 11 6 • block the cage (b) by rotating it manually to the front and rear so that the upper door stops on the blocking straps (c). • never press the doors in (a) to rotate the cage. • load the linen in the cage. Be careful to distribute it correctl...

Page 69: Dosage of The Detergents

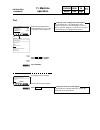

Notice date page 01201055 instruction handbook 0999 5 11 7 dosage of the detergents pour the detergents in the containers ac- cording to the program. P1 : powder product (prewash) p2 : powder product (wash) l1 : liquid product (ex : chlorine) l2 : liquid product (ex : neutralizer) l3 : liquid produc...

Page 70: To Run A Wash Program

Notice date page 01201055 instruction handbook 1298 6 11 to run a wash program the « move back » function each press of the « move back » key moves you back one menu, in reverse order. By pressing this key repeatedly you can return to this menu at any time : if you find you are in the wrong place, o...

Page 71: 11. Machine

Notice date page 01201055 instruction handbook 1298 7 11 use the numeric key to enter the program number. Press select. If you have entered a wrong number… enter the correct number to overstrike the earlier one. Note: you must always enter three digits, even when the number is really only a one or t...

Page 72: 11. Machine

Notice date page 01201055 instruction handbook 1298 8 11 nom du programme delayed start time (hrs:mins) 2 delayed start use the numeric keys to enter a time (max. 24 hrs). This parameter appears on the right of the display. Press start. 3582 delayed start delayed start means that the machine will no...

Page 73: 11. Machine

Notice date page 01201055 instruction handbook 1298 9 11 during a wash program : press to make the machine pause during the wash program. Two ways of pausing during a wash program there are two ways of pausing during a wash program : 1 by pressing . 2 as an additional function. This is described in ...

Page 74: 11. Machine

Notice date page 01201055 instruction handbook 0102 10 11 to start a wash program from the program library waht is the program library ? The program library lists all wash programs, both user and standard programs, showing their program numbers and a description, for example : 1 my own 40°c (104°f) ...

Page 75: 11. Machine

Notice date page 01201055 instruction handbook 1298 11 11 4031 select library via menu you can also select the program library via the option "go to the menu". Then select "wash program library". 3590 to select a program from the pcu program labrary : press pcs. If there is a memory card in the pcu ...

Page 76: 11. Machine

Notice date page 01201055 instruction handbook 1298 12 11 if you want to see the description of the program : press text . 3582 delayed start delayed start means that the machine will not start the wash program until the time entered has elapsed. This function allows you, for example, to load the ma...

Page 77: 11. Machine

Notice date page 01201055 instruction handbook 1298 13 11 3584 to change parameters in the current program step during program operation the display will look like this (see section « to start the wash program »). You can alter the following parameters : prewash, main wash, rinse, drain, soak, rinse...

Page 78: 11. Machine

Notice date page 01201055 instruction handbook 1298 14 11 rapid advance during program operation the display will look this (see section « to start the wash program »). Check that « rapid advance » is highlighted. To terminate a program before it has finished select rapid advance and press select. A...

Page 79: 11. Machine

Notice date page 01201055 instruction handbook 0999 15 11 11. Machine operation show weight (for machines with weighing equipment installed only) during program operation, the display will look like this (see section "to start the wash program"). Show weight the actual weight is shown in large digit...

Page 80: 11. Machine

Notice date page 01201055 instruction handbook 0999 16 11 11. Machine operation during program operation, the display will look like this (see section "to start the wash program"). No water reduction the wash load is weighed during the program and the water level is adjusted automatically according ...

Page 81: 11. Machine

Notice date page 01201055 instruction handbook 0999 17 11 pause two ways of pausing during a wash program note that you must be in normal wash mode to be able to pause in this way. If, for example, you are using "manual functions", you will have to exit that first before you can use pause. There are...

Page 82: 11. Machine

Notice date page 01201055 instruction handbook 0999 18 11 manual operation during a program 3585 during program operation the display will look this (see section « to start the wash program »). Two types of manual operation there are two types of manual operation, which should not be confused : • ma...

Page 83: 11. Machine

Notice date page 01201055 instruction handbook 0999 19 11 use the cursor key to select the function. Press select. 3679 manual functions during a wash program water/drain (see section "water/drain") allows manual operation of all water valves and the drain valve. Highest extraction speed (see sectio...

Page 84: 11. Machine

Notice date page 01201055 instruction handbook 0999 20 11 to access this function, see instructions in section « manual operation ». Water level in drum. 3680 press open. The function will be activated for as long as you press and hold this key. The function ceases as soon as you release the key. Pr...

Page 85: 11. Machine

Notice date page 01201055 instruction handbook 0999 21 11 maximum extraction speed press select. To limit the program’s highest extraction speed this function allows you to modify the highest extraction speed allowed during the program. Example : assume that the highest speed in the program is 1000 ...

Page 86: 11. Machine

Notice date page 01201055 instruction handbook 0999 22 11 press select. Motor on after wash motor to rotate after program has ended if you answer yes (y) : the motor will continue to rotate in alternative directions after the program has ended. This prevents creasing of the load. When the program ha...

Page 87: 11. Machine

Notice date page 01201055 instruction handbook 0999 23 11 detergent signals and water flushing press open. The function will be actived for as long as you press and hold this key. The function ceases as soon as you release the key. 3684 press exit. Detergent signals and water flushing flush water : ...

Page 88: 11. Machine

Notice date page 01201055 instruction handbook 0999 24 11 text pressing ”text” displays more information the text displayed is a description of the wash program selected. This text description is inserted when a new wash program is created. This procedure is described fully in the programming manual...

Page 89: 11. Machine

Notice date page 01201055 instruction handbook 0999 25 11 to change the wash program after program operation has commenced during program operation the display will look this (see section « to start the wash program »). 3694 to change the wash program after program operation has commenced you can ch...

Page 90: 11. Machine

Notice date page 01201055 instruction handbook 0999 26 11 to change temperature scale °c/°f during program operation the display will look this (see section « to start the wash program »). To change temperature scale °c/°f this function changes the temperature scale used for all temperatures display...

Page 91: 11. Machine

Notice date page 01201055 instruction handbook 0999 27 11 auto restart what is auto restart ? Auto restart means that the same program will be repeated one or more times, according to the number set. The program will restart immediately, and the door will remain locked. If you have set auto restart,...

Page 92: Manual Operation

Notice date page 01201055 instruction handbook 0999 28 11 manual operation to select manual operation 3589 if this menu is not currently displayed : press repeatedly. Two types of manual operation there are two types of manual operation, which should not be confused : • manual operation when no prog...

Page 93: 11. Machine

Notice date page 01201055 instruction handbook 0999 29 11 manual operation when no program is running motor/door (see section "motor/door") lock/unlock door. Switch motor on/off (normal drum action). Water and drain valves (see section "water/ drain") operation of drain valve and all water valves. H...

Page 94: 11. Machine

Notice date page 01201055 instruction handbook 0999 30 11 water filling : press open. The function will be activated for as long as you press and hold this key. The function ceases as soon as you release the key. Press select. Drain (a toggle function) : press y/n to toggle the function from yes (y)...

Page 95: 11. Machine

Notice date page 01201055 instruction handbook 0102 31 11 use the numeric key to enter the temperature the water is to be heated do. Actual temperature temperature selected press start. Heating will now begin. If you wish, you can cancel heating before the set temperature is reached : access this fu...

Page 96: 11. Machine

Notice date page 01201055 instruction handbook 0999 32 11 to access this function, see instructions in section « to select manual operation ». Detegent signals and water flushing press select. Press open. The function will be activated for as long as you press and hold this key. The function ceases ...

Page 97: 11. Machine

Notice date page 01201055 instruction handbook 0999 33 11 this page is left blank on purpose. 11. Machine operation.

Page 98: At The End of The Wash

Notice date page 01201055 instruction handbook 0599 34 11 at the end of the wash for your safety, the door can only be open after 40 seconds. Standard machines • position the cage doors in front of the drum door with key "cage positioning". • press the "door unblocking" key. • open the unloading doo...

Page 99: Statistics

Notice date page 01201055 instruction handbook 0999 35 11 if this menu is not currently diplayed : press repeatedly. Statistics to select "statistics" 3589 press select. 3691 press to highlight « go to the menu ». Press select. Press five times… … to highlight « statistics ». 11. Machine operation r...

Page 100: 11. Machine

Notice date page 01201055 instruction handbook 0999 36 11 the statistics function the statistics function gives you access to the following information : total run time hours : shows the total operating time for the machine since it was installed. Total trip run time hours : this register records th...

Page 101: 11. Machine

Notice date page 01201055 instruction handbook 0999 37 11 if the menu is not currently displayed : press repeatedly. 3589 statistics registers which can be reset to zero the following registers in the statistics function can be cleared (reset to zero) : • total trip run time hours. • hours since las...

Page 102: 11. Machine

Notice date page 01201055 instruction handbook the service mode may only be used by authorised personnel, because all safety interlocks are disabled when it is in use. 3693 press select. Now you can choose either to clear/reset a register or to adjust the weighing equipment. Press select. 4042 to pr...

Page 103: 11. Machine

Notice date page 01201055 instruction handbook 0999 39 11 both counters can be reset in the same way. If you do not want to reset the register : press any key other than select. If you want to reset the register : press select. First you have a chance to change your mind. Time counter « service time...

Page 104: 11. Machine

Notice date page 01201055 instruction handbook 0999 40 11 number of washes for program in timer or memory card you can reset program in both timer and the memory card (if inserted) : write from which program number you want to clear wash programs. Press so that "clear wash program counter in pcs" or...

Page 105: 11. Machine

Notice date page 01201055 instruction handbook 0999 41 11 press erase. If you do not want to reset the register : press on any button except select. If you want to reset the register : press select. Do you want to change your mind ? Now the numbers of washes toy haves marked are erased. If you want ...

Page 106: 11. Machine

Notice date page 01201055 instruction handbook 0999 42 11 11. Machine operation scale adjustments (for machines with weighing equipment installed only) 4777 service program make a choice : service program clear counter clear service counter clear wash counter in pcs clear wash counter in memory card...

Page 107: 11. Machine

Notice date page 01201055 instruction handbook 0999 43 11 11. Machine operation press select. 4778 4779 service program make a choice : reset scale to zero reset tare to zero tare scale set tare to a certain value read tare value calibrate the scale reset scale to zero reset tare to zero tare scale ...

Page 108: 11. Machine

Notice date page 01201055 instruction handbook 0999 44 11 11. Machine operation this screen shows that the stored tare parameter has been cleared. 4780 4781 service program make a choice : reset scale to zero reset tare to zero tare scale set tare to a certain value read tare value calibrate the sca...

Page 109: 11. Machine

Notice date page 01201055 instruction handbook 0999 45 11 11. Machine operation press ò twice to highlight "tare scale". 4782 4783 service program make a choice : reset scale to zero reset tare to zero tare scale set tare to a certain value read tare value calibrate the scale reset scale to zero res...

Page 110: 11. Machine

Notice date page 01201055 instruction handbook 0999 46 11 11. Machine operation 4784 service program make a choice : reset scale to zero reset tare to zero tare scale set tare to a certain value read tare value calibrate the scale reset scale to zero reset tare to zero tare scale set tare to a certa...

Page 111: 11. Machine

Notice date page 01201055 instruction handbook 0999 47 11 11. Machine operation 4787 service program make a choice : reset scale to zero reset tare to zero tare scale set tare to a certain value read tare value calibrate the scale reset scale to zero reset tare to zero tare scale set tare to a certa...

Page 112: 11. Machine

Notice date page 01201055 instruction handbook 0999 48 11 11. Machine operation 4789 service program make a choice : reset scale to zero reset tare to zero tare scale set tare to a certain value read tare value calibrate the scale reset scale to zero reset tare to zero tare scale set tare to a certa...

Page 113: 11. Machine

Notice date page 01201055 instruction handbook 0999 49 11 11. Machine operation (for machines with weighing equipment installed only) 4792 1 2 3 4 5 6 7 8 9 0 fill drum with calibration weight enter weight in hg and press select scale adjustments calibrate the scale 4791 scale adjustments done ! Pre...

Page 114: 11. Machine

Notice date page 01201055 instruction handbook 0999 50 11 11. Machine operation (for machines with weighing equipment installed only) 4791 scale adjustments done ! Press select calibrate the scale 4795 reset scale from calibration mode and press select scale adjustments calibrate the scale restore t...

Page 115: 11. Machine

Notice date page 01201055 instruction handbook 0999 51 11 11. Machine operation zero calibration (for machines with weighing equipment installed only) 4796 service program make a choice : reset scale to zero reset tare to zero tare scale set tare to a certain value read tare value calibrate the scal...

Page 116: 11. Machine

Notice date page 01201055 instruction handbook 0999 52 11 11. Machine operation read version number (for machines with weighing equipment installed only) 4799 service program make a choice : reset scale to zero reset tare to zero tare scale set tare to a certain value read tare value calibrate the s...

Page 117: 11. Machine

Notice date page 01201055 instruction handbook 0700 53 11 11. Machine operation d0793 functions "on/off" and "servo-control pause" by exterior signals description during a programme, an on/off function and a servo-control pause can be used to vary the heating or the starting of a machine in comparis...

Page 118: Memory Card

Notice date page 01201055 instruction handbook 0999 54 11 memory card general introduction 3605 a memory card is a plastic card, the size of a credit card, with an electronic memory chip inside it. This memory card is capable of storing 10 to 15 wash programs of normal size. If the programs are most...

Page 119: 11. Machine

Notice date page 01201055 instruction handbook 1 2 3 4 5 6 7 8 9 0 0999 55 11 3589 if this menu is not currently displayed : press repeatedly. Card reader 3606 turn the memory card so its memory chip is at the far end, and on the left of the card... ...Then insert the memory card into the program co...

Page 120: 11. Machine

Notice date page 01201055 instruction handbook 0999 56 11 3596 press select. Press three times… … to highlight « memory card ». 11. Machine operation menu make a choice : wash program library program library programming mode programming mode settings 1 settings 1 memory card memory card service mode...

Page 121: 11. Machine

Notice date page 01201055 instruction handbook 0999 57 11 “the "memory card" functions run wash program straight from memory card (see section "to run a wash program straight from a memory card") a wash program can be run from the memory card, without first being copied to the washer extractor. The ...

Page 122: 11. Machine

Notice date page 01201055 instruction handbook 0999 58 11 to run a wash program straight from a memory card press select. Program name to run a program from the memory card in broad terms, the program control unit has two different memories. One is a ”program memory” where all its wash programs are ...

Page 123: 11. Machine

Notice date page 01201055 instruction handbook 0999 59 11 note that restricted-use pro- grams on a memory card cannot be copied. To copy a program from memory card to the machine's program control unit press select. What is a restricted-use program ? A wash program which has been created on a pc can...

Page 124: 11. Machine

Notice date page 01201055 instruction handbook 0999 60 11 choose 1 or 2 : 1 if you want to give the program a different program number (from the one it had on the memory card : use the numeric keys to enter the new program number, the press select. 2 if the existing number is suitable : press select...

Page 125: 11. Machine

Notice date page 01201055 instruction handbook 0999 61 11 to copy a program from the program control unit to a memory card what happens when a program is copied ? Both the memory card and the program control unit have memory chips capable of storing wash programs. The chip on the memory card can hol...

Page 126: 11. Machine

Notice date page 01201055 instruction handbook 0999 62 11 3623 choose 1 or 2 : 1 if you want to give the program a different program number (from the one it had on the machine) : use the numeric keys to enter the new program number, then press select. 2 if the existing number is suitable : press sel...

Page 127: 11. Machine

Notice date page 01201055 instruction handbook 0999 63 11 11. Machine operation to delete a program on a memory card 3626 press select. The program will now be deleted from the memory card. This takes between 5 and 51 seconds. If you want to delete more programs: continue in the same way as describe...

Page 128: 11. Machine

Notice date page 01201055 instruction handbook 0999 64 11 11. Machine operation to delete all programs on a memory card 4519 if you change yor mind and do not want to delete the entire memory card : press any key other than select. Note that restricted-use programs on a memory card cannot be copied....

Page 129: 11. Machine

Notice date page 01201055 instruction handbook 1100 65 11 11. Machine operation weighing equipment (optional equipment) description the weighing equipment comprises the following units : • a scale unit located • four load cells, one in each corner of the frame • wiring the weight of the wash load is...

Page 130: 11. Machine

Notice date page 01201055 instruction handbook 1100 66 11 11. Machine operation reset to zero menu line showing actual weight 2 weight display mode normal mode 3651 3 4775 run a wash program go to the menu clarus control fig. 2 fig. 3 after a power-cut when the supply is restored after a power- cut,...

Page 131: 11. Machine

Notice date page 01201055 instruction handbook 1100 67 11 11. Machine operation resetting the weighing equipment if the display does not show the weight (in an empty machine) as zero after a program, the weighing equipment can be reset to zero using the tar key. For a description of the functions us...

Page 132: 11. Machine

Notice date page 01201055 instruction handbook 1100 68 11 11. Machine operation checking accuracy of weighing equipment display twice a year you need to check that the weighing equipment is displaying the accu- rate weight, with the aid of an object of known weight. If the weighing equipment does no...

Page 133: 11. Machine

Notice date page 01201055 instruction handbook 1100 69 11 11. Machine operation 4 4807 5 4872 1000- 1330 280- 650 228 0- 2600 20 20 - 23 50 58 0- 88 0 83 0- 113 0 17 30 - 20 50 15 00 - 18 30 123 0- 153 0 dead load a b load cell fig. 4 fig. 5 install the new load cell as indicated by arrow on side of...

Page 134: 11. Machine

Notice date page 01201055 instruction handbook 1100 70 11 11. Machine operation to replace the scale unit • remove the machine’s side panel. • disconnect the six connectors to the scale unit. • remove the scale unit. • install the new scale unit, assembly in reverse order of disassembly. • check tha...

Page 135: 11. Machine

Notice date page 01201055 instruction handbook 1100 71 11 11. Machine operation um scale unit cel load cells connectors 230 v voltage feed x9-cpu communication with cpu board c1-c4 load cells component locations fig. 7 7 cel p0842-4822-4822bis c1 c2 c3 c4 230 v x9-cpu um.

Page 136: 11. Machine

Notice date page 01201055 instruction handbook 1100 72 11 11. Machine operation 8 4804 weight-totalling board board connectors board connectors dead load selector 1 1 1 1 2 2 2 2 3 3 3 3 4 4 4 4 5 5 5 5 1000 - 1330 28 0- 65 0 22 80- 260 0 2 0 20 - 2 3 5 0 5 8 0 - 8 80 830 - 11 30 17 30 - 20 50 1 5 0...

Page 137: 11. Machine

Notice date page 01201055 instruction handbook 1100 73 11 11. Machine operation • if more than one load cell is faulty, the faulty cells can be identified using a multimeter on the scale unit weight-totalling board to check each cell in turn, as follows : - remove the four screws on the scale unit c...

Page 138: 11. Machine

Notice date page 01201055 instruction handbook 9 4807 dead load selector scale unit connectors, load cells connector, cpu communication connector, power supply calibration switch 1000- 1330 280- 650 228 0- 2600 20 20 - 23 50 58 0- 88 0 830 - 113 0 1 730 - 2 050 15 00 - 18 30 123 0- 153 0 dead load 1...

Page 139: 11. Machine

Notice date page 01201055 instruction handbook 1100 75 11 11. Machine operation information in display : function no allowed. Probable cause : a function has been selected in the program which cannot be carried out. Fault-finding procedure : • check that the function in question is switched on under...

Page 140: 11. Machine

Notice date page 01201055 instruction handbook 0401 76 11 11. Machine operation traceability for quality control : as a quality control option, all washer- extractors can be equipped for traceability to comply with haccp method. Haccp (hazards analysis critical control points) is a very well known q...

Page 141: 11. Machine

Notice date page 01201055 instruction handbook 0401 77 11 11. Machine operation a- open the transparent cover with the key b- delicately raise the needle (1) c- unscrew the central nut (2) d- remove the old disk (3) e- put the new disk and center it carefully on the shouldered axis f- slide the edge...

Page 142: 11. Machine

Notice date page 01201055 instruction handbook this page ist left blank on purpose. 0401 78 11 11. Machine operation.

Page 143: 12. Safety

Notice date page 01201055 instruction handbook 0499 1 12 12. Safety safety restarting the machine after any stoppage of the machine, either due to power failure, emergency stop, motor safety, the machine can only be restarted after having pressed key "on". Outer doors all of the different parts of t...

Page 144: 12. Safety

Notice date page 01201055 instruction handbook 12. Safety 0499 2 12 drain a 'hold to run" switch allows the manual opening of the drain to empty the machine if needed (open the loading side casing to get to it). Accessibility all of the casings can be dismantled by means of a specially designed tool...

Page 145: Operating Incidents

Notice date page 01201055 instruction handbook operating incidents in order to limit the risk of failure in the electronic controls of the programming unit of the ma- chine, the machine should be earthed. Should interferences happen, the first thing to be checked is the earthing of the machine. The ...

Page 146: 13. Maintenance

Notice date page 01201055 instruction handbook water in drum - waste water collector might be blocked. - drain valve or wiring faulty. - level tube probably blocked. - level detection function on cpu pcb faulty. - air vent blocked. Error/function cause action clean waste water collector. - check dra...

Page 147: 13. Maintenance

Notice date page 01201055 instruction handbook door lock error/function cause action signal absent from door status switch, although door is locked. 1298 3 13 - transient fault. No action required. - fault in door lock switch or in wiring faulty. - the pcb is faulty. - check if the door is locked. -...

Page 148: 13. Maintenance

Notice date page 01201055 instruction handbook 13. Maintenance 0700 4 13 tangling of the linen the mechanical action during washing can lead to the tangling of large pieces such as bed sheets or table cloths. - bad programming options can be responsible of this matter : - too long washing cycle - wa...

Page 149: 14. Preventive Maintenance

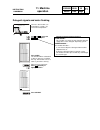

Notice date page 01201055 instruction handbook 14. Preventive maintenance 0401 1 14 d0629 12 1 3 2 10 11 4-17 9 5 10 11 8 11 13 14 12 15 18 16 6 7 caution complete the washing cycle, unload the machine and shut off the power supplies (water, gas, electricity, steam) before any maintenance or repair ...

Page 150: 14. Preventive Maintenance

Notice date page 01201055 instruction handbook monthly 4 clean the connection and the water level pipe on the drain valve (do not blow i the tube towards the cpu). 5 grease the drum bearings (2 greasing point on each bearing). Use the right pump and grease by slow and not brutal injections. Use lith...

Page 151: 14. Preventive Maintenance

Notice date page 01201055 instruction handbook 0102 3 14 colorants do not input colorant in the machine with very hot water. Very hot water react with the colorant, which creates a very corrosive solu- tion. The colorants must be input with cold water or warm water which temperature doesn’t exceed 5...

Page 152: 14. Preventive Maintenance

Notice date page 01201055 instruction handbook 1298 4 14 14. Preventive maintenance t0130gb l u b r i c a t i o n t a b l e uses rolling bearings rolling bearings assembly paste bare gears flange joints reducers with reducers with circuits and bearings bearings high (fretting chains shafts union pip...

Page 153: 15. Electric Diagrams

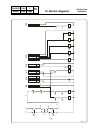

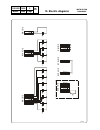

Notice date page 01201055 instruction handbook 15. Electric diagrams 0499 1 15 31100331 x1 1 9 pb r13 +p a x 11 4 l2 l 3 l1 l22 l1 2 l2 l2 1 l1 1 l4 1 l4 2 l4 3 l1 l2 3 l13 l3 v uw a1 l3 1 l3 2 l3 3 2 2 2 2 1 1 1 1 4 4 4 4 3 3 3 3 6 6 6 6 5 5 5 5 3 u v w m1 pe km 2 q1 3 uv w m2 km 1 q2 a2.

Page 154: 15. Electric Diagrams

Notice date page 01201055 instruction handbook power circuit all washer-extractor diagram no. 31100331 a1 frequency converter a2 interference filter q1 main switch q2 motor breaker km1 motion contactor km2 heating contactor r1-r2-r7-r8-r13-r14 heating element (230) r3-r9-r15 heating element (340) r4...

Page 155: 15. Electric Diagrams

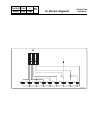

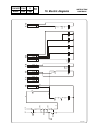

Notice date page 01201055 instruction handbook 1100 3 15 15. Electric diagrams 31100332-1 1 1 1 1 0 1 1 1 5 1 3 1 1 1 4 1 2 1 1 1 3 x1 0-1 x8 -1 x6 -1 x7 -1 x4 -1 x1 4-1 x1 4-3 x1 0-2 x8 -2 x6 -2 x7 -2 x4 -2 x7 -3 x4 -4 x4 -3 x1 4-2 x1 4-4 x1 4-5 2 2 2 2 2 3 4 3 2 4 5 x 1 0 x 8 x 6 x 7 x 4 x 1 4 k a...

Page 156: 15. Electric Diagrams

Notice date page 01201055 instruction handbook power circuit - programmer outputs all washer-extractor barrier types diagram no. 31100332-1 a3 ignitor of gas exchanger h2 possible unloading indicator ka1 unloading door lock relay ka2 loading door lock relay km1 motion contactor km2 haeting contactor...

Page 157: 15. Electric Diagrams

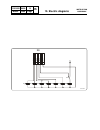

Notice date page 01201055 instruction handbook 1100 5 15 15. Electric diagrams 31100332-2 1 x 9 -1 x 9 -2 x 9 -3 x 9 -4 x 9 -5 x 9 -6 x 9 -7 x 9 -8 2 3 4 5 6 7 8 x9 y3 y6 y5 y27 y9 s18 11 y13 y26 y1 y1’.

Page 158: 15. Electric Diagrams

Notice date page 01201055 instruction handbook control circuit - programmer outputs all washer-extractor barrier types diagram no. 31100332-2 s18 manual drain switch control (optional) x9 waters connector x9 unloading door lock connector x9 products connector x9 drain connector y1 unloading door loc...

Page 159: 15. Electric Diagrams

Notice date page 01201055 instruction handbook 0700 7 15 15. Electric diagrams 31100333-1 31100333-2 1 1 a1 10 7 a2 c1 9 8 c2 1 19 20 dc 24 v dc 230 v 50 hz + - x5 -1 x 12- 1 x 13- 1 x 12- 2 x 13- 2 x5 -2 x5 -3 x5 -4 x3 -1 x5 -5 x3 -2 x5 -6 x3 -3 2 2 2 3 4 1 5 2 6 3 x5 x3 x12 x13 ka1 ka1 ka2 ka2 t2 ...

Page 160: 15. Electric Diagrams

Notice date page 01201055 instruction handbook control circuit - programmer inputs/outputs all washer-extractor barrier types diagram no. 31100333-1 & 2 f frequency converter interference filter h1 voltage indicator ka1 loading door lock relay ka2 unloading door lock relay ntc 1 temperature probe s1...

Page 161: 15. Electric Diagrams

Notice date page 01201055 instruction handbook 1099 9 15 15. Electric diagrams 31100341 1 2 1 1 1 3 1 3 x8/2 -1 x5/2 -1 x1 3/2-1 x1 2/2-1 x5/2 -3 x1 4/2-1 x1 4/2-3 x8/2 -2 x5/2 -2 x1 3/2-2 x1 2/2- 2 x5/2 -4 x5/2 -5 x5/2 -6 x1 4/2-2 x1 4/2-4 x1 4/2-5 2 2 2 4 5 6 2 4 5 x8 i/ o 2 x5 i /o 2 x1 2 i /o 2 ...

Page 162: 15. Electric Diagrams

Notice date page 01201055 instruction handbook inputs / outputs card no. 2 (optional) all washer-extractor diagram no. 31100341 cdc frequency converter failure safty contact (if necessary) x5 i/o 2 shunt connector x8 i/o 2 liquid products no. 13 electrovalve connector x9 i/o 2 liquid products no. 4 ...

Page 163: 15. Electric Diagrams

Notice date page 01201055 instruction handbook 1100 11 15 15. Electric diagrams 31101334-1 1 1 1 1 0 1 1 1 1 1 2 1 4 1 1 1 3 x1 0-1 x8 -1 x6 -1 x7 -1 x4 -1 x1 4-1 x1 4-3 x1 0-2 x8 -2 x6 -2 x7 -2 x4 -2 x7 -3 x4 -4 x4 -3 x1 4-2 x1 4-4 x1 4-5 2 2 2 2 2 3 4 3 2 4 5 x 1 0 x 8 x 6 x 7 x 4 x 1 4 k a 1 1 7 ...

Page 164: 15. Electric Diagrams

Notice date page 01201055 instruction handbook 1100 12 15 15. Electric diagrams power circuit - programmer outputs all washer-extractor standard types diagram no. 31101334-1 a3 ignitor of gas exchanger ka1 unloading door lock relay ka2 loading door lock relay km1 motion contactor km2 haeting contact...

Page 165: 15. Electric Diagrams

Notice date page 01201055 instruction handbook 0499 13 15 15. Electric diagrams 31101334-2 1x 9 -1 x9 -2 x9 -3 x9 -4 x9 -5 x9 -6 x9 -7 x9 -8 2 3 4 5 6 7 8 x9 y3 y6 y5 y27 y9 s18 11 y13 y26.

Page 166: 15. Electric Diagrams

Notice date page 01201055 instruction handbook 15. Electric diagrams 0499 14 15 control circuit - programmer outputs all washer-extractor standard types diagram no. 31101334-2 s18 manual drain switch control (optional) x9 waters connector x9 unloading door lock connector x9 products connector x9 dra...

Page 167: 15. Electric Diagrams

Notice date page 01201055 instruction handbook 15. Electric diagrams 0700 15 15 31101340 31100333-1 1 1 a1 10 7 a2 c1 9 8 c2 1 19 20 dc 24 v dc 230 v 50 hz + - x5 -1 x 12- 1 x 13- 1 x 12- 2 x 13- 2 x5 -2 x5 -3 x5 -4 x3 -1 x5 -5 x3 -2 x5 -6 x3 -3 2 2 2 3 4 1 5 2 6 3 x5 x3 x12 x13 ka1 ka1 ka2 ka2 t2 4...

Page 168: 15. Electric Diagrams

Notice date page 01201055 instruction handbook 15. Electric diagrams 0700 16 15 control circuit - programmer inputs/outputs all washer-extractor standard types diagram no. 31100333-1 & no. 31101340 f frequency converter interference filter h1 voltage indicator ka1 loading door lock relay ka2 unloadi...

Page 169: 15. Electric Diagrams

Notice date page 01201055 instruction handbook 15. Electric diagrams 0301 17 15 31101285.

Page 170: 15. Electric Diagrams

Notice date page 01201055 instruction handbook 15. Electric diagrams 0500 18 15 gas heating - connecting diagram all washer-extractor diagram no. 31101285 a3 ignitor and checking box b1 products of combustion pressure switch (do not change the adjustments) c1 water level detector e1 ignitor electrod...

Page 171: 15. Electric Diagrams

Notice date page 01201055 instruction handbook 15. Electric diagrams 0999 19 15 71082374 interface board "alcopo" all washer-extractor diagram no. 71082374.

Page 172: 16. Appendices

Notice date page 01201055 instruction handbook conversion of measurement units to following is a list of correspondences of the main frequently used units, to avoid the need to use measurement unit conversion tables. 16. Appendices 1199 1 16 bar : 1 bar = 100 000 pa 1 bar = 1.019 7 kg/cm² 1 bar = 75...

Page 173: Washing Symbols

Notice date page 01201055 instruction handbook washing symbols to overcome language barriers, the following are symbols used internationally to give you guidance and recommendations when washing different textiles. Washing symbol max. Washing cycle load spin temperature in °c/°f 95/203 normal 1/1 no...

Page 174: 16. Appendices

Notice date page 01201055 instruction handbook 0800 3 16 16. Appendices Ø 125 a d >0,50 m >0 ,5 0 m 0 m g g g e e e e f f f f y y z x x 10 0 80 250 260 340 635 b c 230 10 0 27 0 21 5 47 0 93 5 246 5 430 d0651 machine type units 230/340 a length of exchanger mm 910 b dimension of output exchanger mm ...

Page 175: 16. Appendices

Notice date page 01201055 instruction handbook 0800 4 16 16. Appendices evacuation duct it is recommended that a separate smoothwalled evacuation duct should be connected to each machine, providing the least possible resistance to air. Check that the shaft flow is at least twice the capacity of the ...

Page 176: 16. Appendices

Notice date page 01201055 instruction handbook 0800 5 16 16. Appendices d0409 maxi. 5 mm table of correspondences - washer-extractor 340 category type working hi Ø of ventilation pressure at heat consumption consumption of gas supply in injectors plate injectors emission mn in vn in index pressure m...

Page 177: 16. Appendices

Notice date page 01201055 instruction handbook 0800 6 16 16. Appendices table of correspondences - washer-extractor 470 category type working hi Ø of ventilation pressure at heat consumption consumption of gas supply in injectors plate injectors emission mn in vn in index pressure mj/m³ in mm positi...

Page 178: 16. Appendices

Notice date page 01201055 instruction handbook 0800 7 16 16. Appendices d0436 note : g20 (h) = natural gas, lacq type (20 mbar) g25 (l) = natural gas, groningue type (20 or 25 mbar) g30 = butane gas (28/30, 37, 50 mbar) g31 = propane gas (28/30, 37, 50 mbar).