Summary of XP

Page 1

Xp passthrough dishwasher service manual.

Page 2

Warning before installation and commissioning, you must read the safety instructions and warnings carefully and all the warning labels attached to the equipment. Important failure to comply (even partially) with the instructions given in this manual will invalidate the product warranty and relieves ...

Page 3: Contents

Contents safety instructions ...........................................................................................................................................................................4 installation.........................................................................................

Page 4: Safety Instructions

Safety instructions warning equipment contains dangerous voltages and can be hazardous if installed or operated incorrectly. Non-compliance with warnings or failure to follow the instructions contained in this manual can result in loss of life, severe personal injury or serious damage to property. I...

Page 5: Installation

Installation warning installer must be suitably qualified and ensure compliance with all codes and standards including as/nzs3500.1. Failure to comply even partially with installation instructions may void the warranty. Positioning unpack machine, check for damage and complete delivery. Install mach...

Page 6

Service manual xp-2 6 revision 1c.

Page 7

Service manual xp-2 7 revision 1c.

Page 8: Installation Checklist

Installation checklist check ok / notes delivery supplied complete no transit damage position level and stable on sound, waterproof, self draining floor water isolator valve fitted accessible, all fittings sound, no leaks dcvs fitted (washtech only) correct direction temperature 65 ± 5°c flow rate m...

Page 9: Maintenance Checklist

Maintenance checklist check ok / notes installation – use installation checklist on previous page to check all services, operator training and chemical issues services water, power, drain etc. Operator trained / has instructions chemicals squeeze tube checked – replacement recommended every 6 months...

Page 10: Dishwashing Procedures

Dishwashing procedures for best results note: these are general instructions to assist in getting the best performance from washtech dishwashers – some comments and / or illustrations may not apply to every unit. Installation read the operator manual. Correct installation, including an adequate supp...

Page 11: Dishwashing Procedures

Dishwashing procedures for best results drying single tank commercial dishwashers do not have a drying cycle. However, the machines do rinse at high temperatures which promote fast drying particularly when drying agents are used. We recommend prompt removal of the rack from the machine - leave the r...

Page 12: Troubleshooting Chart

Troubleshooting chart problem possible causes remedy (check/adjust/replace) filling not filling water supply valve shut water supply valve door switch faulty door switch solenoid valve faulty solenoid valve rinse lines blocked rinse pump, solenoid valve filter pressure switch faulty pressure switch ...

Page 13: Troubleshooting Chart

Troubleshooting chart problem possible causes remedy (check/adjust/replace) drainage flooding drain waste blocked drain waste leaks leak from pumps seal failure pump seal leak from hoses hose damage hoses hose clamp loose hose clamps splash from door wash arm end caps missing end caps wash jets bloc...

Page 14: Xp Operating Instructions

Xp operating instructions start up fit drain upstand, wash pump filter, scrap tray and shut door. Turn wall power switch on and select any cycle (1, 2 or 3). Power light glows red and machine fills automatically. Wash ready light (water symbol) glows amber when wash tank is ready. Rinse ready light ...

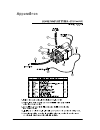

Page 15: Components

Components warning all service/repair work must be carried out by qualified personnel only. Location and access 1. Rinse tank 2. Rinse safety thermostat 3. Rinse heating element 4. Test switch 5. Detergent pump 6. Rinse thermostat 7. Wiring tray 8. Detergent prime switch 9. Door switch relay 10. Hea...

Page 16: Timer

Timer part number 32822 function provides an automatic timing sequence of the wash, rinse, detergent and rinse aid injection stages in a dishwashing cycle. Description the electromechanical timer has a main drive motor and gearbox which produce a full rotation of the seven cams in 180 seconds. The a...

Page 17: Rinse Thermostat

Rinse thermostat part number 3020 function controls the rinse heating elements and prevents operation of machine if the rinse temperature is below that required. Description the rinse thermostat is a specially calibrated 3 pole capillary type temperature operated device. The thermostat does not have...

Page 18: Wash Thermostat

Wash thermostat part number 30201 function controls the wash element description the wash thermostat is a single pole capillary type device. It has a single changeover contact and a rotating shaft for a manual temperature adjustment. Factory default setting is 65°c. Contact switching capacity: 16(4)...

Page 19: Solenoid Valve

Solenoid valve part number 3342 function controls flow of water into machine during filling of wash tank and final rinsing. Description electromagnetically operating water valve for use with cold and hot water. Diagram replacement disconnect the wires from the solenoid connectors. Remove hot water s...

Page 20: Pressure Switch

Pressure switch part number 600 30308 function controls filling of wash tank and protects wash elements. Description the pressure switch is attached to the pressure bell. As the water level in the wash tank rises air is trapped in the bell and increasing pressure is transmitted to the pressure switc...

Page 21: Wash Pump

Wash pump part number 600 30299 function pumps water from the wash tank to the wash arms providing a recirculating wash cycle. Description electric pump zf 320v sx power: hp 0.93 kw 0.68 voltage: 230 v 50hz amperes: 3.0 a capacitor: 12.5 uf speed 2800 rpm protection: ip 20 hm min: 1.0 m hm max: 12.3...

Page 22: Detergent Pump

Detergent pump part number 600 30094 function when fitted the pump automatically injects detergent into wash tank during filling of the machine and at the start of each wash cycle. Description fixed flow peristaltic pump pg1.5 voltage: 230 v 50hz pressure: 0.1 bar flow rate: 1.5 l/h (0.42 ml/sec) ma...

Page 23: Rinse Aid Injector

Rinse aid injector part number 600 30324 function adjustable flow rate hydraulic rinse pump for rinse-aid chemical dosing description the injector works by using the water pressure in the rinse line. The pressure in the input line causes the suction of a determined amount of chemical for each cycle....

Page 24: Assembly Diagrams

Plan a perspective view parts list item part number description qty 1 32822 timer4907dv(180/6 sec)3 cycle 1 2 3035 switch single pole biased black 2 3 8816 ms rh brass 3/16 x 3/4 1 4 8151 nut hx brass 3/16" pressed 1 5 3229 terminal strip 12 way 1 6 3020 3 pole thermostat 1 7 8800 ms pan pozi zp m4x...

Page 25

Exploded view parts list qty description part number item 1 xp (3) control panel 208 20006 1 1 xp control label 208 70001 2 2 temp gauge rectangular 58x25 600 90080 3 1 lens & neon assy (green) 12mm 600 30163 4 1 lens & neon assy (red) 12mm 600 30161 5 2 lens & neon assy (amber) 12mm 600 30162 6 1 k...

Page 26

Service manual xp-2 26 revision 1c.

Page 27

Service manual xp-2 27 revision 1c.

Page 28

Service manual xp-2 28 revision 1c.

Page 29

Exploded perspective view a perspective view b c front view a parts list qty description part nu item 1 m2 (3) door 326 20025 1 1 m2(3) door upper infill 326 20024 2 2 m2 door slide 326 30004 3 2 m2(3) door strip spacer 326 20007 4 4 hank bush 304 ss m5 600 80016 5 4 m5 x 12 ss truss head screw 600 ...

Page 30

Perspective view inside door j bolt assembly parts list qty description part number item 1 m2 (3) pass-through door assy 326 10007 1 3 m5 x 12 ss truss head screw 600 80017 2 1 assy me/m2 (3) door handle 326 10037 3 1 passthrough door mount gasket 400 90120 4 1 m5 x 12 ss button head cap screw 600 8...

Page 31

Perspective view 326 10011 16/09/2013 3-d m2 \ xp rackslide assy rev parts list qty description part number item 1 m2(3) rack slide sub assy mk2 326 10012 1 2 m5 x 25 ss hex hd setscrew 600 80094 3 2 nut nyloc m5 s/s 600 80060 4 2 nut ss 304 hex m8 600 80023 5 1 al rack slide guide 351 20060 6 2 m8x...

Page 32

Service manual xp-2 32 revision 1c.

Page 33

Service manual xp-2 33 revision 1c.

Page 34: Spare Parts

Spare parts description part no cabinet & door control panel 208 20006 control panel label 208 70001 door switch magnet 600 30182 spring door 27 x 735 x 5 326 30019 controls & indicators contactor 600 30337 auxiliary contact 600 30339 cord set 15 600 30452 door reed switch 600 30183 door switch rela...

Page 35: Spare Parts

Spare parts description part no pumps & solenoids detergent pump 1.5 l/h 600 30094 dual check valve assembly 400 10132 rinse aid injector 600 30324 solenoid valve 3342 wash pump zf 320v sx 600 30299 wash pump capacitor 12.5 mf 3892 wash tank components drain upstand 400 10144 pressure bell 400 90135...

Page 36

Service manual xp-2 36 revision 1c.

Page 37

Service manual xp-2 37 revision 1c.

Page 38

400 90144 19/11/2013 1-g drain pump kit 0440031 - xp/al3/al8/pw1 rev drain pump kit 0440031 qty description part number item 1 switch c/rinse rold spco 600 30102 1 4 hose clamp ass16 2 1 p clip 600 30173 3 1 hose drain 2.5m 600 60105 4 1 drain pump 600 60102 5 1 ms hx ss 304 m6 x 12 88461 6 1 washer...

Page 39: Revisions

Revisions manual revisions revision revision from change status date serial no: description 1a 10/08/13 133088 1b 19/11/13 add drain pump retrofit kit 1c 10/12/13 134202 add auxiliary contact service manual xp-2 39 revision 1c.

Page 40

Information supplied in this manual is copyright. No part of this work may be reproduced or copied in any form or by any means, electronic or mechanical without the express permission of the author / publisher..