- DL manuals

- Water

- Heat Pump

- 700A11 7 Series

- Installation Manual

Water 700A11 7 Series Installation Manual

Summary of 700A11 7 Series

Page 1

Im2700an 06/13 installation information water piping connections hot water generator connections electrical startup procedures troubleshooting preventive maintenance 7 series 7 00a11 ins tallation manual geothermal heat pump • r-410a refrigerant • 3, 4, 5 ton variable speed 700a11 c us.

Page 3: Table of Contents

7 series 700a11 installation manual table of contents model nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 general installation information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4: Model Nomenclature

4 7 series 700a11 installation manual model nomenclature n 1 2 3 4-6 7 8 9 model type n – 7 series water-to-air compressor type v – variable speed cabinet configuration v – vertical h - horizontal unit capacity (mbtuh) 036, 048, 060 vintage * - factory use only voltage 1 – 208-230/60/1 hot water gen...

Page 5

5 7 series 700a11 installation manual warning: before performing service or maintenance operations on a system, turn off main power switches to the indoor unit. If applicable, turn off the accessory heater power switch. Electrical shock could cause personal injury. Installing and servicing heating a...

Page 6

6 7 series 700a11 installation manual caution: do not use rods smaller than 3/8-inch diameter since they may not be strong enough to support the unit. The rods must be securely anchored to the ceiling. General installation information cont. Insulate supply plenum and use at least one 90 elbow to red...

Page 7

7 7 series 700a11 installation manual or compound. Check to ensure that the rubber seal is in the swivel connector prior to attempting any connection. The rubber seals are shipped attached to the waterline. To make the connection to a ground loop system, mate the brass connector (supplied in ck4li c...

Page 8

8 7 series 700a11 installation manual 1/2'' pitch drain 1.5 in. 1.5 in. Pvc tube stub pvc coupling vent (if needed) pvc tube stub 1/8 in. Per foot note: check dimensional data for actual pvc sizes. Figure 6: unit pitch for drain figure 5: horizontal drain connection low water coil limit set the free...

Page 9

9 7 series 700a11 installation manual figure 7: closed loop ground source application note: for closed loop systems with antifreeze protection, set sw2-1 to the “loop” (15°f) position. (refer to the dip switch settings table in the aurora control section.) once piping is completed between the unit, ...

Page 10

10 7 series 700a11 installation manual typical open loop piping is shown below. Always maintain water pressure in the heat exchanger by placing water control valves at the outlet of the unit to prevent mineral precipitation. Use a closed, bladder-type expansion tank to minimize mineral formation due...

Page 11

11 7 series 700a11 installation manual to maximize the benefits of the hot water generator a minimum 50-gallon water heater is recommended for higher demand applications, use an 80-gallon water heater or two 50-gallon water heaters connected in a series as shown below. Two tanks plumbed in a series ...

Page 12

12 7 series 700a11 installation manual hot water generator startup 1. Turn the hot water generator switch to the “on” position. The hot water generator switch will allow the hot water generator pump to be enabled or disabled by the service technician or homeowner. 2. Close the drain valve to the wat...

Page 13: Electrical Connections

13 7 series 700a11 installation manual general be sure the available power is the same voltage and phase as that shown on the unit serial plate. Line and low voltage wiring must be done in accordance with local codes or the national electric code, whichever is applicable. The compressor has no inter...

Page 14: Electrical Connections Cont.

14 7 series 700a11 installation manual electrical connections cont. Electronic thermostat installation position the thermostat subbase against the wall so that it is level and the thermostat wires protrude through the middle of the subbase. Mark the position of the subbase mounting holes and drill h...

Page 15: Auxiliary Heat Ratings

15 7 series 700a11 installation manual model kw stages btu/h min cfm model compatibility 208v 230v 208v 230v 036 048 060 eal(h)10 7.2 9.6 2 24,600 32,700 1100 • • • eal(h)15 10.8 14.4 3 36,900 49,100 1250 • • • eal(h)20 14.4 19.2 4 49,200 65,500 1500 • • air flow level for auxiliary heat (aux) must ...

Page 16: Blower Performance Data

16 7 series 700a11 installation manual ecm speed info 1 ▶ 2 ◀ g 3 4 5 6 7 8 9 10 11 12 option ◀▶ enter ◙ ecm speed info 1 2 g ▶ 3 ◀ lo 4 5 6 7 8 9 10 11 12 option ◀▶ enter ◙ ecm speed info 1 2 g 3 lo 4 5 ▶ 6 ◀ hi 7 8 9 10 11 12 option ◀▶ enter ◙ ecm speed info 1 2 g 3 lo 4 5 6 hi 7 8 9 ▶10 ◀ aux 11 ...

Page 17: Vertical Dimensional Data

17 7 series 700a11 installation manual left return right return front top 2 ft [61 cm] primary service access top a d e h f i k j g 1.9in [4.8cm] 1.9in [4.8cm] m r q n o l r n o l p q right side b c b left side s t s t c top air discharge vertical top flow model overall cabinet water connections ele...

Page 18

18 7 series 700a11 installation manual 2 ft [61 cm] primary service access left side right side b c s t t b c s left return right return r q l n o p a front d e f g h j k i 1.90 (4.7 cm) 1.70 (4.3 cm) 1 2 3 4 5 right bottom discharge floor foot print r o n l m left bottom discharge floor foot print ...

Page 19

19 7 series 700a11 installation manual rear air discharge rear view left return side view right return side view left return rear view right return front c c c c a a a b b d e h f g j k i l m n m n p o q q r r s s t t 1.90 in. [4.8 cm] 1.90 in. [4.8 cm] 2 ft [61 cm] primary service access verti- cal...

Page 20: Horizontal Dimensional Data

20 7 series 700a11 installation manual 2 ft [61 cm] primary service access b c 2.1in [5.4cm] h l o n m s r q p mount (2) hanger brackets as shown to allow access to filter as shown lr unit (rr unit on opposite side—same dimensions) side dishcarge view end view top view a s front view d e f g i k j 1...

Page 21: Physical Data

21 7 series 700a11 installation manual model variable speed 036 048 060 compressor (1 each) variable speed scroll factory charge r-410a, oz [kg] vertical 95 [2.69] 120 [3.40] 140 [3.96] factory charge r-410a, oz [kg] horizontal 95 [2.69] 136 [3.85] 148 [4.19] ecm blower motor & blower blower motor t...

Page 22

22 7 series 700a11 installation manual aurora advanced vs control aurora advanced vs control system is a complete residential and commercial comfort system that brings all aspects of the hvac system into one cohesive module network. The aurora advanced vs control features the aurora base control (ab...

Page 23

23 7 series 700a11 installation manual add on control feature kits (field or factory installed) description aurora advanced vs geo energy monitoring kit monitors real time power consumption of compressor, blower, aux heat and pump. Requires thermostat tpcm32u04 or tpcc32u01. Standard refrigeration m...

Page 24

24 7 series 700a11 installation manual loop temperature in cooling mode, loop temperatures may be too low to allow proper heating of water. The control will monitor water and refrigerant temperatures to determine if conditions are satisfactory for heating water. Vs drive and envelope control the vs ...

Page 25

25 7 series 700a11 installation manual home automation 2 – e24 ha2 with a closed dry contact signal, this input will cause an alarm and alert code 24 to indicate on the stat or flash on abc. The aid tool will allow configuration of this input between the following selections: • no action • home auto...

Page 26

26 7 series 700a11 installation manual variable speed ecm configuration mode the control is placed in the variable speed ecm configuration mode by holding the push-button switch sw1 for 5 to 10 seconds, the high, low, and g variable speed ecm speeds can be selected by following the led display light...

Page 27

27 7 series 700a11 installation manual lockout – when locked out, the blower will operate continuously in “g” blower speed setting. The alarm output (alm) and lockout output (l) will be turned on. The fault type identification display led1 (red) shall flash the fault code. To reset lockout condition...

Page 28

28 7 series 700a11 installation manual have the cooling airflow adjustment applied. In all cooling operations, the reversing valve directly tracks the o input. Thus, anytime the o input is present, the reversing valve will be energized. Blower (g) - the blower will start immediately upon receiving a...

Page 29

29 7 series 700a11 installation manual status led (led1, r ed) abc a ction aid t ool displa y and his tory int elliz one2 and thermos tat displa y r ed f ault led led flash c ode * l ock out r eset/ r e m ove f ault c ondition summary abc gr een status led abc r ed f ault led abc & axb basic f aults...

Page 30

30 7 series 700a11 installation manual cc2 factory fault alg alm ls es acc c status aurora tm base control rv – k1 cc2 cc – k2 cc hi – k3 fan – k4 alarm – k5 acc – k6 acc no acc nc o/b c r lo g y1 y2 w dh 3a-fuse o/b c r lo g y1 y2 w dh lo g hi ccg cc fg f r hp hp lp fp2 fp2 fp1 rev rev cfm pwm ecm ...

Page 31: Operation Logic

31 7 series 700a11 installation manual operation logic heating mode when the variable speed controls determine that heating is needed in the space the blower will be turned on, the compressor will be ramped to speed 6 and the loop pump will be started. The compressor will continue to run at speed 6 ...

Page 32: Wiring Schematics

32 7 series 700a11 installation manual wiring schematics aurora variable speed note 7 note 6 violet(14) transformer 24v ecm blower motor p12 p11 2 3 4 5 1 green 16 1 12 15 10 pw m c1 c2 r g 3 3 cf m to p2 on electric heat board t rv cc hp condensate black(10) black(09) blue(08) blue(07) lp black bla...

Page 33: Wiring Schematics Cont.

33 7 series 700a11 installation manual wiring schematics cont. Aurora variable speed cont. 02/14/13 97p842-01a pb2 violet blue with optional ' ea' series 2 3 he1 ts1 he2 ts2 he3 ts3 he4 ts4 pink yellow black gray pink yellow black gray gray yellow pink black pink yellow black gray green p9 er1 er2 e...

Page 34: Wiring Schematics Cont.

34 7 series 700a11 installation manual wiring schematics cont. Aurora variable speed drive/eev wiring unit power 208-230/60/1 l2 l1 cc t1 t2 g t t compressor ambient discharge line temp suction pressure discharge pressure black brown blue black brown blue red red black black ma ste r 1 2 3 eev2 1 2 ...

Page 35: Wiring Schematics Cont.

35 7 series 700a11 installation manual aurora variable speed drive/eev wiring cont. Wiring schematics cont. T1 t3 t2 red black su ct io n t em p km 2 1 2 eev o ut pu t km 9 1 2 3 4 gn d s2 12 v d c x1 x2 y1 danfoss eev control po w er km 4 1 2 3 4 r b+ a- c leav in g a ir t em p (l a t ) km 3 1 2 gn...

Page 36: Unit Startup

36 7 series 700a11 installation manual unit startup before powering unit, check the following: note: remove and discard the compressor hold down shipping bolt located at the front of the compressor mounting bracket. • high voltage is correct and matches nameplate. • fuses, breakers and wire size cor...

Page 37: Unit Startup Cont.

37 7 series 700a11 installation manual configuring the sensor kits configuring the sensor kits the aurora advanced control allows refrigeration, energy, and performance monitoring sensor kits. These kits can be factory or field installed. The following description is for field activation of a factor...

Page 38: Thermistor Resistance

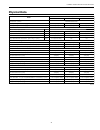

38 7 series 700a11 installation manual model gpm pressure drop (psi) 30° f 50° f 70° 90° f 110° f 36 11.5 3.40 3.20 3.00 2.80 2.60 9.0 2.70 2.60 2.40 2.20 2.10 7.0 1.65 1.55 1.45 1.35 1.25 5.5 1.10 1.00 0.90 0.85 0.75 4.5 0.68 0.64 0.60 0.55 0.51 48 13.5 4.60 4.40 4.10 3.80 3.50 10.5 2.90 2.70 2.50 ...

Page 39: Heat of Extraction/rejection

39 7 series 700a11 installation manual heat of extraction/rejection model gpm heat of extraction (mbtu/h) gpm heat of rejection (mbtu/h) 30°f 50°f 70°f 90°f 30°f 50°f 70°f 90°f 110°f 036 full load 5.5 26.4 36.6 46.2 54.5 4.5 42.2 48.3 43.1 42.6 40.4 8.0 26.7 37.7 47.8 57.6 7.0 41.9 48.8 47.0 42.5 40...

Page 40: Operating Parameters

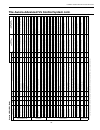

40 7 series 700a11 installation manual operating parameters model 060 - comp speed 9 (1800 cfm) entering water temp °f water flow cooling -- no hot water generation suction pressure psig discharge pressure psig superheat subcooling water temp rise °f air temp drop °f db 30 13.5 122-127 162-172 20-24...

Page 41: Troubleshooting

41 7 series 700a11 installation manual aurora control system note: refer to the aurora base control application and troubleshooting guide and the instruction guide: aurora interface and diagnostics (aid) tool for additional information. To check the unit control board for proper operation: 1. Genera...

Page 42: Troubleshooting Cont.

42 7 series 700a11 installation manual troubleshooting cont. Fp2 sensor llt ( fp1 sensor filter dryer dƵŋĞƌ compressor coax water in water out rev. Valve eev discharge line thermistor line thermistor pressure transducer discharge pressure transducer air coil blower leaving air thermistor ( wire bund...

Page 43

43 7 series 700a11 installation manual cooling cycle analysis hot water generator - electronic expansion valve air coil °f high speed high speed psi °f low speed low speed psi °f psi °f psi brine in brine out high speed high speed low speed compressor discharge suction subcooling superheat reversing...

Page 44: Troubleshooting Cont.

44 7 series 700a11 installation manual troubleshooting cont. Variable speed startup/troubleshooting form 1. Job information model # job name: loop: open / closed serial # install date: hot water generator: y / n 2. Flow rate in gpm source coax heating speed 12 heating speed 4 cooling speed 9 cooling...

Page 45: Preventive Maintenance

45 7 series 700a11 installation manual water coil maintenance 1. Keep all air out of the water. An open loop system should be checked to ensure that the well head is not allowing air to infiltrate the water line. Lines should always be airtight. 2. Keep the system under pressure at all times. It is ...

Page 46: Service Parts List

46 7 series 700a11 installation manual service parts list parts list vertical 036 048 060 c ompr es sor compressor 208-230/60/1 34p647-01 34p648-01 34p649-01 sound jacket 92p504a05 92p504a05 92p504a05 power harness 11p853-01 11p853-01 11p853-01 ecm mot or & blo w e r ecm motor 208-230/60/1 14s545-01...

Page 47: Revision Guide

47 7 series 700a11 installation manual pages: description: date: by: 9 updated primary/secondary pump wiring diagram 26 jun 2013 ds 10 updated open loop water valve information 26 jun 2013 ds 22 - 29 updated aurora controls information 26 jun 2013 ds 32 - 35 updated wiring diagram 26 jun 2013 ds 40 ...

Page 48

Manufactured by waterfurnace international, inc. 9000 conservation way fort wayne, in 46809 www.Waterfurnace.Com ©2013 waterfurnace international, inc., 9000 conservation way, fort wayne, in 46809-9794. Waterfurnace has a policy of continual product research and development and reserves the right to...