- DL manuals

- Water Boss

- Water Dispenser

- 700

- Owner's Manual And Installation Manual

Water Boss 700 Owner's Manual And Installation Manual

Summary of 700

Page 1

M m o o d d e e l l s s 7 7 0 0 0 0 , , 9 9 0 0 0 0 , , a a n n d d 9 9 5 5 0 0 o o w w n n e e r r ’ ’ s s m m a a n n u u a a l l a a n n d d i i n n s s t t a a l l l l a a t t i i o o n n g g u u i i d d e e v v e e r r s s i i o o n n 7 7 . . 3 3.

Page 2: 10 Year Limited Warranty

10 year limited warranty to whom warranty is extended this warranty is issued to the original owner at the original location site and is not transferable to other sites or to subsequent owners of the system. To place the equipment under warranty, the warranty registration card must be completed and ...

Page 3: Contents

Contents general information .......................................................................................................................................4 getting maximum efficiency from the appliance............................................................................................

Page 4: General Information

Waterboss softener owner’s manual 12/2/2010 4 general information congratulations on choosing a superior waterboss ® water treatment appliance! Soon you and your family will be enjoying clean, clear water. Use this guide to attain the maximum benefit from your appliance. Keep it handy for a referenc...

Page 5: Efficiency Statements

Waterboss softener owner’s manual 12/2/2010 5 getting maximum efficiency from the appliance to achieve the maximum benefit and performance from this appliance, familiarize yourself with this manual and the appliance. 1. The salt level should always be at least 1/3 full. Refill the salt when the leve...

Page 6

Waterboss softener owner’s manual 12/2/2010 6 checklist before installation refer to this checklist before installation. Water quality—if the water supply contains sand, sulfur, bacteria, iron bacteria, tannins, algae, oil, acid, or other unusual substances, consider pre-treating the water to remove...

Page 7: Precautions

Waterboss softener owner’s manual 12/2/2010 7 checklist before installation, cont. Water temperature—not less than 40° or greater than 120°f (4.4°–48.9°c). Drain—drain the appliance to an appropriate drain, such as a floor drain or washer drain that will comply with all local and state plumbing code...

Page 8

Waterboss softener owner’s manual 12/2/2010 8 installation steps and start-up procedures the water softener is capable of treating a combination of undesirable constituents (such as iron, dirt, sediment, chlorine, and/or lead) in water. See specifications for the capabilities of your appliance. Inst...

Page 9

Waterboss softener owner’s manual 12/2/2010 9 installation steps and start-up procedures, cont. G. For most installations, install the appliance after the pressure tank and any water filter appliance or water meter and before the water heater unless otherwise recommended. Contact the helpline for fu...

Page 10

Waterboss softener owner’s manual 12/2/2010 10 installation steps and start-up procedures, cont. Step 5 connect gravity overflow connection the overflow line drains away excess water should the tank fill with too much water or the appliance malfunction. A. Attach the overflow elbow and check that it...

Page 11

Waterboss softener owner’s manual 12/2/2010 11 installation steps and start-up procedures, cont. Step 7 flush lines a. Place the appliance in the bypass position. (see figure 6.) b. Turn on the main water supply. C. Open the nearest cold water faucet to flush the plumbing of any excess soldering flu...

Page 12

Waterboss softener owner’s manual 12/2/2010 12 installation steps and start-up procedures, cont. Step 11 add water to the brine cabinet a. Add 2 gallons (7.6 l) of water to the brine cabinet. After the first regeneration, the appliance will automatically refill the correct amount of water into the b...

Page 13: Bypass Valve

Waterboss softener owner’s manual 12/2/2010 13 bypass valve your appliance is equipped with a bypass valve. The bypass valve can isolate the appliance should the appliance malfunction or leak. It can also permit the use of untreated water for watering plants, shrubs, or lawns. The bypass is located ...

Page 14: Four-Button Controller

Waterboss softener owner’s manual 12/2/2010 14 four-button controller this appliance features a four-button controller with an lcd display. The controller can be used to view the appliance’s status, perform regenerations, and change settings. The controller must be set up correctly for the appliance...

Page 15

Waterboss softener owner’s manual 12/2/2010 15 four-button controller, cont. Button function set used to set customer settings change used to change customer settings power clean (700 and 900 only) activates/deactivates the powerclean™ feature, which is a service/maintenance step for water supplies ...

Page 16: Setting The Controller

Waterboss softener owner’s manual 12/2/2010 16 setting the controller step 1 determine the controller setting number a. For municipal water, call the water department to determine the hardness and ph of your water supply. B. For well water, use the hardness test strips provided with your appliance o...

Page 17: Advanced Customer Settings

Waterboss softener owner’s manual 12/2/2010 17 advanced customer settings most customers will want to use the factory default settings, so no changes are necessary. However, you can reset the controller settings if the factory default settings are not suitable for your needs. Note: be sure to check ...

Page 18

Waterboss softener owner’s manual 12/2/2010 18 advanced customer settings, cont. Step 3 set gallons or liters display reads “gallons (or liters) x 100.” to set gallons or liters a. Press change to toggle between gallons and liters. Choosing “gallons” sets the controller to english units, and choosin...

Page 19: Optional Plumbing Procedures

Waterboss softener owner’s manual 12/2/2010 19 optional plumbing procedures this section provides information on plumbing with copper fittings and with plastic pipe. Hard plumbing the bypass with copper fittings do not use qest fittings for hard plumbing with copper fittings. When preparing the male...

Page 20

Waterboss softener owner’s manual 12/2/2010 20 optional plumbing procedures, cont. Plastic (pvc/cpvc) pipe joining procedures to ensure reliable joint integrity when using solvent cement for pvc/cpvc plumbing, follow these recommendations: a. Cutting—the pipe must be cut square to allow for the prop...

Page 21: Assembly and Parts

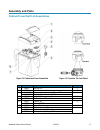

Waterboss softener owner’s manual 12/2/2010 21 assembly and parts cabinet/cover/salt lid assemblies figure 12: cabinet and cover assemblies figure 13: controller tab lock detail part # description quantity 1 54306 salt port lid 1 2 54324 valve cover assembly 1 3 54545-700 computer control assembly (...

Page 22: Assembly and Parts, Cont.

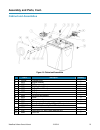

Assembly and parts, cont. Cabinet and assemblies figure 14: cabinet and assemblies part # description quantity 1 c0700a overflow elbow 1 2 54512 bypass assembly 1 3 93838 o-ring 2 4 93281 fill plug, model 950 only 1 5 93272 o-ring, model 950 only 1 6 93808 o-ring 2 7 90828 o-ring 1 8 54520 drive end...

Page 23: Assembly and Parts, Cont.

Assembly and parts, cont. Injector assembly figure 15: injector assembly part # description quantity 1 93223 injector throat 1 2 53224 injector nozzle with over-mold gasket 1 3 93806 o-ring 1 4 53235 injector cap 1 93504 all of the above parts 93223 injector throat in conjunction with the injector n...

Page 24: Assembly and Parts, Cont.

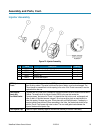

Assembly and parts, cont. Bypass assembly figure 16: bypass assembly part # description quantity 1 54512 bypass assembly (also includes items 2-6) 1 2 93860 turbine sensor/cap assembly 1 3 90809 sensor cap screw, self-tapping 1 4 54320 plastic turbine axle 1 5 90522 turbine assembly 1 6 93838 o-ring...

Page 25: Assembly and Parts, Cont.

Assembly and parts, cont. Top fill plug assembly (950) figure 17: fill plug assembly part # description quantity 1 93281 fill plug 1 2 93272 fill plug o-ring 1 93281 fill plug the fill plug (93281) seals the media access ports in the media tank. Care should be taken that the o-ring seal area is kept...

Page 26: Assembly and Parts, Cont.

Assembly and parts, cont. Drive end cap assembly figure 18: drive end cap assembly part # description quantity 1 90802 screw, self-tapping 2 2 90217 drive motor 1 3 93891 1/4" hex nut 2 4 93238 drive gear 1 5 90809 screw, self-tapping, cam cover 2 6 93219 piston slide cam cover 1 7 93217 piston slid...

Page 27: Assembly and Parts, Cont.

Assembly and parts, cont. Drive end cap assembly cont. 90217 drive motor the motor is held in place by two, 1/2-inch self-tapping screws. The screws should be “snug.” the brass pinion gear on the motor should engage the plastic drive gear (93238). The wires should be securely fastened to the control...

Page 28: Assembly and Parts, Cont.

Assembly and parts, cont. Brine valve housing assembly concave side static o-ring figure 19: brine valve housing assembly part # description quantity 1 53511 piston assembly (includes o-ring & spring) 1 2 90821 o-ring 1 3 53510 housing 1 4 90843 0.5 gpm flow control 1 5 93805 o-ring 1 6 54314 brine ...

Page 29: Assembly and Parts, Cont.

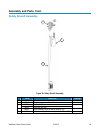

Assembly and parts, cont. Safety shutoff assembly 1 2 3 figure 20: safety shutoff assembly part # description quantity 1 54226 safety shutoff (see figure 21) 1 2 56018 float 1 3 54228 air check, 700 1 54229 air check, 900, 950 54526 entire assembly (all of the above parts)-for 700 54330 entire assem...

Page 30: Assembly and Parts, Cont.

Assembly and parts, cont. Safety shutoff valve elbow installation 3/8" nut 3/8" retainer sleeve 2 3/8" plastic gripper 3/8" plastic tube safety shutoff valve hex nut wrist pin 1/2" nut 1/2" plastic gripper 1/2" retainer sleeve 1 air check/draw tube figure 21: safety shutoff valve elbow installation ...

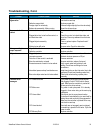

Page 31: Troubleshooting

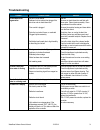

Troubleshooting problem possible cause solution no salt in brine cabinet add salt sediment in brine cabinet has plugged the brine line and air check/draw tube remove air check/draw tube and flush with clean water. Clean injector assembly. Clean any sediment from brine cabinet flow control is plugged...

Page 32: Troubleshooting, Cont.

Troubleshooting, cont. Problem possible cause solution controller not attached properly make sure the controller is pushed all the way onto the drive end cap defective magnet disk replace magnet disk foreign object in valve body remove foreign object(s) from the valve body appliance stays in regener...

Page 33: Waterboss

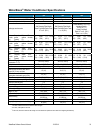

Waterboss ® water conditioner specifications 700 900 950 max compensated hardness gpg (mg/l) 70 (1,200) 90 (1,540) 35 (600) maximum ferrous iron reduction 1 10 ppm 1 10 ppm 1 0 minimum ph (standard units) 7 7 7 media type and amounts self cleaning filter media. Super fine mesh resin total– 0.7 cu. F...

Page 34: Certificates

Waterboss softener owner’s manual 12/2/2010 34 certificates.

Page 35: Notes

Notes.

Page 36: Waterboss

Waterboss ® has these third-party listings: in business since 1956 www.Waterboss.Com 4343 south hamilton road, groveport, oh 43125 litho usa ©2010 f93966 rv1210hqwi.