- DL manuals

- Water Factory Systems

- Water Filtration Systems

- SQC3 Series

- Owner's Manual

Water Factory Systems SQC3 Series Owner's Manual

Summary of SQC3 Series

Page 1

Sqc series owner's manual this manual is for the installation, operation, and maintenance of the water factory systems ™ sqc3 and sqc4 series reverse osmosis (ro) drinking water appliance ™ installer: leave with homeowner..

Page 3: Safety Information

Safety information read, understand and follow all safety information contained in these instructions prior to instal- lation and use of the sqc series reverse osmosis (ro) drinking water appliance. Retain these instructions for future reference. Intended use: the water factory systems™ sqc series r...

Page 4

To reduce the risk associated with property damage due to water leakage: • read and follow useinstructionsbeforeinstallationanduseofthissystem. • installationanduse must comply with all state and local plumbing codes. • protect from freezing,removefiltercartridgewhentemperaturesareexpectedtodropbelo...

Page 5

Introduction this manual explains the installation, operation and maintenance of the water factory systems ™ sqc series reverse osmosis (ro) drinking water appliances. Please read each section of this manual carefully. The specific model chosen should be appropriate for the local water conditions an...

Page 6

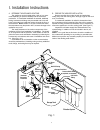

A. Determinetheappliancelocations the appliance can be located under a sink or in a base- ment depending on space availability and the customer’s preference. If a basement installation is selected, additional tubing, hardware and fittings may be needed and a hole will have to be made from inside the...

Page 7

C. Preparetheapplianceforinstallation open the shipping carton and remove the components. Check to see that all of the installation parts are present. They should include the filtration assembly, storage tank, faucet, installation hardware, ro membrane, cartridges and tubing. Check to see that the a...

Page 8

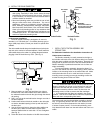

E. Mountthefaucet undercounter installations generally require that the faucet’s built-in air gap be used. In basement installations, the built-in air gap does not have to be used if one is provided elsewhere on the drain line. For basement installations without an air gap module see installation in...

Page 9

F. Installstemadapterwith1/4”feedwater tubeoutlet important notes • for basement installations, the existing orange feed water tubing may have to be longer to reach the faucet adapter. 1) open faucet and turn off cold water supply to relieve pres- sure. 2) locate the cold water stem on the underside...

Page 10

H. Installthedrainconnection important notes • before starting this procedure, inspect the condition of the drain piping, especially in older homes where the traps and tailpieces can be deceptively thin and frail. If they are in poor condition, it is wise to inform the customer that the condition sh...

Page 11

J. Makethetubingconnections with all of the components in place, the tubing connections can be made. When routing the tubing between the compo- nents, several guidelines should be observed. • tubingrunsshouldgenerallyfollowthecontourofthe cabinet rather than interfere with the cabinet storage area. ...

Page 12

9 m. Flushtheapplianceofthepreservative andchecktheoperation 1) with the tank valve closed (the tank should still contain the sanitizing solution at this point), open the faucet (set the faucet handle in the “up” position) and feed water valve. Water should begin to drip from the faucet within sever...

Page 13

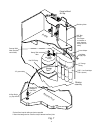

10 fig. 7 (floor) faucetwithout airgap 3/8”blue tubing* forrefrigera- tor icemaker or water dispenser hookup, tee into tubing faucetadapter cold water supplypipe 3/8”yellow tubing* storage tank** 1/4”greentubing airgapdevice (e.G.Gap-a-flow) laundrysink, standpipe or floordrain (basement floor) stor...

Page 14

11 o. Appendixforbasementinstallations the following variations are generally required for basement installations: install the drain connection for basement installations, the drain saddle is generally not used. Instead, the ro reject line (sfc tubing) is routed so that it drains into a laundry sink...

Page 15

P. Installationtroubleshooting problem: leak at the drain saddle. Possible cause: drain saddle not clamped tightly enough. Solution: tighten the drain saddle screws evenly and firmly. Problem: leak at the fittings threaded connection. Possible cause: fitting is improperly taped or not ` tightened su...

Page 16

A. Importantwaterqualityassurance requirements reverse osmosis drinking water appliances contain treat- ment components that are critical for the effective reduction of total dissolved solids (tds) as well as inorganic chemical con- taminants. Water factory systems ™ strongly recommends that the use...

Page 17

How to replace the ro membrane cartridge 1) close the cold water supply shut off valve. Lift up on the faucet handle to drain the tank. Wait five (5) minutes for the filtration assembly to completely depressurize. 2) make sure that there is some slack in the red sfc tubing connected to the fitting a...

Page 18

How to sanitize the storage tank and filtration system sanitizing the storage tank generally requires: • common household bleach (5.25% non-scented) • eye dropper or plastic oral syringe 1) close the cold water feed valve and lift up on the faucet handle to empty the water in the storage tank. It sh...

Page 20

3m purification inc. 400 research parkway meriden, ct 06450, u.S.A. Tel (800) 733-1199 (203) 237-5541 fax (203) 203-8701 www.3mpurification.Com www.Waterfactorysystems.Com please recycle. Printed in u.S.A. Water factory system is a trademark of 3m company used under license. 3m is a trademark of 3m ...