- DL manuals

- Water Furnace

- Heat Pump

- 500A11 5 Series

- Installation Manual

Water Furnace 500A11 5 Series Installation Manual - Electrical Connections Cont.

15

5 SERIES 500A11 INSTALLATION MANUAL

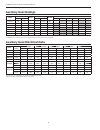

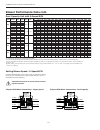

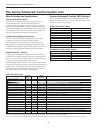

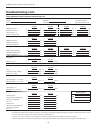

Pump Power Wiring

See Figure 14 for electrical connections from control box

to pumps.

FC1/FC2 style flow centers with fixed speed pumps

connect to PB1 in the control box. If using a variable speed

pump it should be connected to L1 and L2 on the AXB.

Figure 14: Pump Wiring 208-230/60/1

R

Y1

C

W

O

G

L

24VAC (Hot)

24VAC (Common)

Compressor (1st Stage)

Aux. Heat

Reversing Valve

Blower Relay

System Monitor

Microprocessor Controller

Thermostat Connection

Y2

Compressor (2nd Stage)

Electrical Connections cont.

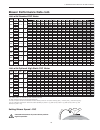

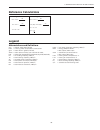

Electronic Thermostat Installation

Position the thermostat subbase against the wall so that

it is level and the thermostat wires protrude through

the middle of the subbase. Mark the position of the

subbase mounting holes and drill holes with a 3/16-inch

bit. Install supplied anchors and secure base to the wall.

Thermostat wire must be 8-conductor (4 or 5 counductor

for communicating thermostats), 20-AWG (minimum)

wire. Strip the wires back 1/4-inch (longer strip lengths

may cause shorts) and insert the thermostat wires into

the connector as shown. Tighten the screws to ensure

secure connections. The thermostat has the same type

connectors, requiring the same wiring. See instructions

enclosed in the thermostat for detailed installation and

operation information. The W1 terminal on TPCM32U03

and TPCM32U04 communicating thermostats may be

hard wired to provide aux/emergency heat in the event

communication is lost between the thermostat and the

ABC microprocessor.

NOTE: Aurora Base Control (ABC) DIP switch SW2-7 is

required to be in the “OFF” position for the control to

operate with FaultFlash or ComforTalk thermostats. SW2-7

in the “ON” position configures the control to operate with

typical thermostats (continuous lockout signal). There

must be a wire connecting Y2 on the Aurora controller

to 2nd stage compressor on the thermostat for proper

operation. SW2-7 DIP switch position is not relevant with

communicating thermostats.

Figure 15a: Thermostat Wiring (Y1 Style Signals)

C

P7

P1

–

R

W

C 24VAC (Common)

R 24VAC (Hot)

B- Communication

W1 (Optional)

Microprocessor Controller

Thermostat Connection

+

A+ Communication

TPCM32U03/TPCM32U04

Monochrome Thermostats

C

P7

–

R

C 24VAC (Common)

R 24VAC (Hot)

DX- Communication

Microprocessor

Controller

Thermostat

Connection

+

DX+ Communication

TPCC32U01

Color Touchscreen

Thermostat

Figure 15b: Thermostat Wiring (Communicating Style Signals)

External

Loop Pump(s)

208-230/60/1

1/2 hp Max

PB1

CB

Optional External

Variable Speed Loop

Pump (ex. Magna Geo)

208-230/60/1

Summary of 500A11 5 Series

Page 1

Im2500an 02/13 installation information water piping connections hot water generator connections electrical startup procedures troubleshooting preventive maintenance 5 series 500a11 ins tallation manual geothermal heat pump • r-410a refrigerant • 1, 1.5, 2, 2.5, 3, 3.5, 4, 5, 6 ton single speed • 2,...

Page 3: Table of Contents

5 series 500a11 installation manual table of contents model nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 general installation information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

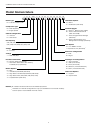

Page 4: Model Nomenclature

4 5 series 500a11 installation manual 1 n 2 d 3 v 4-6 049 7 g 8 1 9 1 10 1 11 c 12 t 13 l 14 0 15 a 16 n model type n = 5 series water-to-air compressor type d = dual capacity s = single speed cabinet configuration v = vertical h = horizontal unit capacity 012, 018, 022, 026, 030, 036, 038, 042, 048...

Page 5

5 5 series 500a11 installation manual warning: before performing service or maintenance operations on a system, turn off main power switches to the indoor unit. If applicable, turn off the accessory heater power switch. Electrical shock could cause personal injury. Installing and servicing heating a...

Page 6

6 5 series 500a11 installation manual general installation information cont. Insulate supply plenum and use at least one 90 elbow to reduce noise electrical disconnect flexible duct collar threaded rods line voltage ball v alves hose kits to line power to thermostat hanging brackets (included) build...

Page 7

7 5 series 500a11 installation manual general installation information cont. :stb @wuvb !&bv`sorsr @]rpg]bvs`a 6sf pg]bvs`a eoavs` dwp`obw]\ 7a]zob]` 0]zbo\r :]qyeoavs` 1 4 / /w`1]wz 2 0 /w`1]wz ! " " ! Hanger dimensions model hanger kit part number unit hanger dimensions a b c d single speed 012 in...

Page 8

8 5 series 500a11 installation manual the swivel connector prior to attempting any connection. The rubber seals are shipped attached to the waterline. To make the connection to a ground loop system, mate the brass connector (supplied in ck4li connector kit) against the rubber gasket in the swivel co...

Page 9

9 5 series 500a11 installation manual 1/2'' pitch drain 1.5 in. 1.5 in. Pvc tube stub pvc coupling vent (if needed) pvc tube stub 1/8 in. Per foot note: check dimensional data for actual pvc sizes. Figure 6: unit pitch for drain figure 5: horizontal drain connection low water coil limit set the free...

Page 10

10 5 series 500a11 installation manual figure 7: closed loop ground source application note: for closed loop systems with antifreeze protection, set sw2-1 to the “loop” (15°f) position. (refer to the dip switch settings table in the aurora control section.) once piping is completed between the unit,...

Page 11

11 5 series 500a11 installation manual typical open loop piping is shown below. Always maintain water pressure in the heat exchanger by placing water control valves at the outlet of the unit to prevent mineral precipitation. Use a closed, bladder-type expansion tank to minimize mineral formation due...

Page 12

12 5 series 500a11 installation manual to maximize the benefits of the hot water generator a minimum 50-gallon water heater is recommended for higher demand applications, use an 80-gallon water heater or two 50-gallon water heaters connected in a series as shown below. Two tanks plumbed in a series ...

Page 13

13 5 series 500a11 installation manual hot water generator startup 1. Turn the hot water generator switch to the “on” position. The hot water generator switch will allow the hot water generator pump to be enabled or disabled by the service technician or homeowner. 2. Close the drain valve to the wat...

Page 14: Electrical Connections

14 5 series 500a11 installation manual general be sure the available power is the same voltage and phase as that shown on the unit serial plate. Line and low voltage wiring must be done in accordance with local codes or the national electric code, whichever is applicable. Unit power connection conne...

Page 15: Electrical Connections Cont.

15 5 series 500a11 installation manual pump power wiring see figure 14 for electrical connections from control box to pumps. Fc1/fc2 style flow centers with fixed speed pumps connect to pb1 in the control box. If using a variable speed pump it should be connected to l1 and l2 on the axb. Figure 14: ...

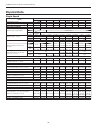

Page 16: Auxiliary Heat Ratings

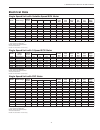

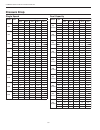

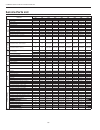

16 5 series 500a11 installation manual auxiliary heat ratings auxiliary heat electrical data model supply circuit heater amps min circuit amp fuse (usa) fuse (can) ckt brk 208 v 240 v 208 v 240 v 208 v 240 v 208 v 240 v 208 v 240 v eas(h)4 single 13.7 15.8 17.9 20.5 20 20 20 20 20 20 eam(h)5 single ...

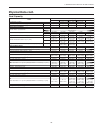

Page 17: Electrical Data

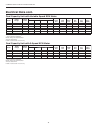

17 5 series 500a11 installation manual electrical data * with optional 1 hp ecm motor ** with optional intellistart ® rated voltage of 208/230/60/1 all fuses class rk-5 hacr circuit breaker in usa only single speed unit with variable speed ecm motor model rated voltage voltage min/max compressor hwg...

Page 18: Electrical Data Cont.

18 5 series 500a11 installation manual dual capacity unit with variable speed ecm motor model rated voltage voltage min/max compressor hwg pump fla ext loop fla blower motor fla total unit fla min circ amp max fuse/ hacr mcc rla lra lra** 026 208-230/60/1 197/253 18.2 11.6 58.3 21.0 0.4 5.4 4.0 21.4...

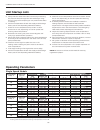

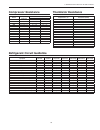

Page 19: Blower Performance Data

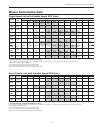

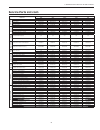

19 5 series 500a11 installation manual single speed unit with variable speed ecm motor model max esp airflow speed settings 1 2 3 4 5 6 7 8 9 10 11 12 018 0.50 300 400 500 600 700 800 875 950 1025 1125 g l h aux 022 0.50 400 500 600 700 800 900 1000 1100 1200 g l h aux 030 0.50 400 500 600 700 800 9...

Page 20

20 5 series 500a11 installation manual ecm speed info 1 ▶ 2 ◀ g 3 4 5 6 7 8 9 10 11 12 option ◀▶ enter ◙ ecm speed info 1 2 g ▶ 3 ◀ lo 4 5 6 7 8 9 10 11 12 option ◀▶ enter ◙ ecm speed info 1 2 g 3 lo 4 5 ▶ 6 ◀ hi 7 8 9 10 11 12 option ◀▶ enter ◙ ecm speed info 1 2 g 3 lo 4 5 6 hi 7 8 9 ▶10 ◀ aux 11 ...

Page 21

21 5 series 500a11 installation manual 5-speed ecm constant torque motors the 5-speed ecm is a ‘constant torque’ ecm motor and delivers air flow similar to a psc but operates as efficiently as an ecm motor. Because it’s an ecm motor, the 5-speed ecm can ramp slowly up or down like the ecm motor. The...

Page 22

22 5 series 500a11 installation manual l g n c high voltage connections 3/16 in. 1 2 3 4 5 g - blue y1 - red aux - gray c - black l - orange g - green n - brown low voltage connections 1/4 in. L g n c 1 2 3 4 5 aux - gray g - blue y1 - red y2 - tan c - black l - orange g - green n - brown high volta...

Page 23

23 5 series 500a11 installation manual psc blower motor body high low medium b l o w e r s p e e d w ir e unit with standard psc motor model motor spd blower size motor hp airflow (cfm) at external static pressure (in. Wg) 0 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.60 0.70 0.80 0.90 1.00 ...

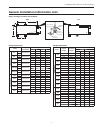

Page 24: Vertical Dimensional Data

24 5 series 500a11 installation manual left return right return front top 2ft [61cm] primary service access top a d e h f k j i g 1.9in [4.8cm] 1.9in [4.8cm] m r q n o l r n o l p q right side b c b left side s t s t c top air discharge vertical top flow model overall cabinet water connections elect...

Page 25

25 5 series 500a11 installation manual 2ft [61cm] primary service access left side right side b c s t b c s t left return right return r q l n o p a front d e f g h i j k 1.90 (4.7 cm) 1.70 (4.3 cm) 1 2 3 4 5 right bottom discharge floor foot print r o n l m left bottom discharge floor foot print q ...

Page 26

26 5 series 500a11 installation manual rear view left return side view right return side view left return rear view right return front c c c c a a a b b d e h f g i j k l l m n m n p o q q r r s s t t 1.90 1.90 rear air discharge verti- cal rear discharge models overall cabinet water connections ele...

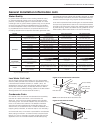

Page 27: Horizontal Dimensional Data

27 5 series 500a11 installation manual 2ft [61cm] primary service access b c 2.1in [5.4cm] h l o n m s r q p mount (2) hanger brackets as shown to allow access to filter as shown lr unit (rr unit on opposite side—same dimensions) side dishcarge view end view top view a s front view d e f g k j i 1.9...

Page 28: Physical Data

28 5 series 500a11 installation manual single speed model single speed 012 018 022 030 036 042 048 060 070 compressor (1 each) rotary scroll factory charge r-410a, oz [kg] vertical 42 [1.19] 40 [1.13] 62 [1.76] 80 [2.26] 84 [2.38] 92 [2.60] 100 [2.83] 120 [3.40] 150 [4.25] factory charge r-410a, oz ...

Page 29: Physical Data Cont.

29 5 series 500a11 installation manual dual capacity model dual capacity 026 038 049 064 072 compressor (1 each) copeland ultratech, dual capacity scroll factory charge r-410a, oz [kg] vertical 60 [1.70] 82 [2.32] 93 [2.63] 128 [3.63] 138 [3.91] factory charge r-410a, oz [kg] horizontal 60 [1.70] 82...

Page 30: The Aurora™ Control System

30 5 series 500a11 installation manual aurora control features description aurora ‘base’ aurora ‘advanced’ microprocessor compressor control microprocessor control of compressor for timings with fp1, hp, lp, condensate, assignable acc relay • • advanced microprocessor features smart grid, home autom...

Page 31

31 5 series 500a11 installation manual add on control feature kits (field or factory installed) description aurora ‘base’ aurora ‘advanced’ geo energy monitoring kit monitors realtime power consumption of compressor, blower, aux heat and pump. Requires thermostat tpcm32u03, tpcm32u04, or tpcc32u01. ...

Page 32

32 5 series 500a11 installation manual aurora ‘base’ control note: refer to the aurora base control application and troubleshooting guide and the instruction guide: aurora interface and diagnostics (aid) tool for additional information. Control features software abc standard version 2.0 single or du...

Page 33

33 5 series 500a11 installation manual cycle with blower - the accessory relay will cycle with the blower output. Cycle with compressor - the accessory relay will cycle with the compressor output. Water valve slow opening - the accessory relay will cycle and delay both the blower and compressor outp...

Page 34

34 5 series 500a11 installation manual over/under voltage shutdown - an over/under voltage condition exists when the control voltage is outside the range of 18 vac to 30 vac. If the over/under voltage shutdown lasts for 15 minutes, the lockout and alarm relay will be energized. Over/under voltage sh...

Page 35

35 5 series 500a11 installation manual cc2 factory fault alg alm ls es acc c status aurora tm base control rv – k1 cc2 cc – k2 cc hi – k3 fan – k4 alarm – k5 acc – k6 acc no acc nc o/b c r lo g y1 y2 w dh 3a-fuse o/b c r lo g y1 y2 w dh lo g hi ccg cc fg f r hp hp lp fp2 fp2 fp1 rev rev cfm pwm ecm ...

Page 36

36 5 series 500a11 installation manual aurora ‘advanced’ control features the aurora ‘advanced’ control system expands on the capability of the aurora ‘base’ control (abc) by adding the aurora expansion board (axb). All of the preceding features of the aurora ‘base’ control are included. The followi...

Page 37

37 5 series 500a11 installation manual advanced communication ports communication ports p6 and p8 will provide future expansion via dedicated protocols. These are for future use. Smart grid-on peak (sg) input the 'on peak' input was designed to allow utilities to utilize simple radio controlled swit...

Page 38

38 5 series 500a11 installation manual aurora ‘advanced’ control led displays these three leds display the status, configuration, and fault codes for the control. These can also be read in plain english via the aurora aid tool. Status led (led3, green) description of operation fault led, green norma...

Page 39: Reference Calculations

39 5 series 500a11 installation manual he gpm x 500 reference calculations heating calculations: cooling calculations: lwt = ewt + lat (db) = eat (db) - lc = tc - sc s/t = hr gpm x 500 sc cfm x 1.08 sc tc lwt = ewt - lat = eat + th = hc + hw hc cfm x 1.08 legend abbreviations and definitions cfm = a...

Page 40: Wiring Schematics

40 5 series 500a11 installation manual wiring schematics aurora advanced with ecm and intellistart ext pump 1/2 hp total 208-230/60/1 pump pump g 1 2 pb1 2 1 orange(9) t t t t brown brown black red gnd out 5dc 1 2 3 white sct suc p hwhw brown(10) pink t pink hot water option refrigeration option per...

Page 41: Wiring Schematics Cont.

41 5 series 500a11 installation manual wiring schematics cont. Aurora advanced with ecm and intellistart cont. Brown transformer 24v ecm blower motor p12 p11 2 3 4 5 1 green 16 1 12 15 10 pwm c1 c2 r g 33 cfm to p2 on electric heat board t rv cc hp condensate black(10) black(09) blue(0 8) blue(07) l...

Page 42: Wiring Schematics Cont.

42 5 series 500a11 installation manual wiring schematics cont. Aurora advanced with 5-speed ecm ext pump 1/2 hp total 208-230/60/1 pump pump g 1 2 pb1 2 1 orange(9) t t t t brown brown black red gnd out 5dc 1 2 3 white sct suc p hwhw brown(10) 02/14/13 97p840-09 pink t pink hot water option refriger...

Page 43: Wiring Schematics Cont.

43 5 series 500a11 installation manual wiring schematics cont. Aurora advanced with 5-speed ecm cont. Blower current transducer (ct) transformer 24v to p2 on electric heat board t rv cc hp condensate black(10) black(09) blue(0 8) blue(07) lp black black fp2 t yellow yellow fp1 orange(02) orange(01) ...

Page 44: Wiring Schematics Cont.

44 5 series 500a11 installation manual wiring schematics cont. Aurora base with psc transformer 24v to p2 on electric heat board rv cc hp condensate black black blue blue lp t yellow yellow fp1 orange orange rv black(15) violet (14) green(11) brown(23) note 1 black/white yellow red 208v 1 c 2 4 3 2 ...

Page 45: Wiring Schematics Cont.

45 5 series 500a11 installation manual wiring schematics cont. Aurora base with psc cont. Event normal mode test mode random start delay compressor on delay compressor minimum on time compressor short cycle delay blower off delay fault recognition delay – high pressure start-up bypass – low pressure...

Page 46: Wiring Schematics Cont.

46 5 series 500a11 installation manual wiring schematics cont. Aurora base with ecm and intellistart transformer 24v ecm blower motor p12 p11 2 3 4 5 1 green 16 1 12 15 10 pwm c1 c2 r g 33 cfm to p2 on electric heat board rv cc hp condensate black black blue blue lp t yellow yellow fp1 orange orange...

Page 47: Wiring Schematics Cont.

47 5 series 500a11 installation manual wiring schematics cont. Aurora base with ecm and intellistart cont. 97p840-02 6/22/12 pb2 violet blue with optional ' ea' series 2 3 he1 ts1 he2 ts2 he3 ts3 he4 ts4 pink yellow black gray pink yellow black gray gray yellow pink black pink yellow black gray gree...

Page 48: Unit Startup

48 5 series 500a11 installation manual unit startup before powering unit, check the following: note: remove and discard the compressor hold down shipping bolt located at the front of the compressor mounting bracket. • high voltage is correct and matches nameplate. • fuses, breakers and wire size cor...

Page 49: Unit Startup Cont.

49 5 series 500a11 installation manual energy monitoring (standard sensor kit on most ‘advanced’ models) the energy monitoring kit includes two current transducers (fan and electric heat) added to the existing two compressor sensors so that the complete power usage of the heat pump can be measured. ...

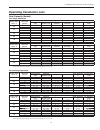

Page 50: Operating Parameters

50 5 series 500a11 installation manual operating parameters single speed models entering water temp °f water flow gpm/ton cooling -- no hot water generation suction pressure psig discharge pressure psig superheat subcooling water temp rise °f air temp drop °f db 30 1.5 115 - 125 150 - 170 20 - 35 10...

Page 51: Operating Parameters Cont.

51 5 series 500a11 installation manual operating parameters cont. Dual capacity models first stage operation entering water temp °f water flow gpm/ton cooling -- no hot water generation suction pressure psig discharge pressure psig superheat subcooling water temp rise °f air temp drop °f db 30 1.5 1...

Page 52: Pressure Drop

52 5 series 500a11 installation manual single speed model gpm pressure drop (psi) 30°f 50°f 70°f 90°f 110°f 012 1.5 0.3 0.3 0.3 0.3 0.3 2.5 1.0 1.0 1.0 1.0 1.0 3.5 1.7 1.7 1.7 1.6 1.6 4.5 2.5 2.4 2.4 2.4 2.3 018 3.0 1.6 1.6 1.5 1.5 1.4 4.0 2.9 2.9 2.8 2.8 2.7 5.0 4.2 4.2 4.1 4.0 3.9 6.0 6.0 5.8 5.7 ...

Page 53: Thermistor Resistance

53 5 series 500a11 installation manual symptom head pressure suction pressure compressor amp draw superheat subcooling air temp. Differential water temp. Differential under charged system (possible leak) low low low high low low low over charged system high high high normal high normal/low normal lo...

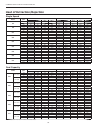

Page 54: Heat of Extraction/rejection

54 5 series 500a11 installation manual heat of extraction/rejection single speed model gpm heat of extraction (kbtuh) heat of rejection (kbtuh) 30°f 50°f 70°f 90°f 30°f 50°f 70°f 90°f 110°f 012 1.5 7.4 9.6 12.5 16.9 16.5 15.8 2.5 5.9 7.7 10.1 12.7 17.3 16.9 16.4 15.9 16.0 3.5 6.1 8.1 10.6 12.9 17.4 ...

Page 55: Troubleshooting

55 5 series 500a11 installation manual aurora control system note: refer to the aurora base control application and troubleshooting guide and the instruction guide: aurora interface and diagnostics (aid) tool for additional information. To check the unit control board for proper operation: 1. Discon...

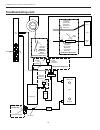

Page 56: Troubleshooting Cont.

56 5 series 500a11 installation manual troubleshooting cont. Fp2 sensor llt (liquid line heating) fp1 sensor filter dryer mu ŋer compressor coax water in water out rev. Valve txv suction line thermistor suction pressure transducer discharge pressure transducer air coil blower leaving air thermistor ...

Page 57: Troubleshooting Cont.

57 5 series 500a11 installation manual troubleshooting cont. Cooling cycle analysis hot water generator - expansion valve air coil °f psi °f psi brine in brine out brine in brine out compressor discharge suction subcooling superheat reversing valve psi °f sat °f = psi = sat f f °f liquid line water ...

Page 58: Troubleshooting Cont.

58 5 series 500a11 installation manual troubleshooting cont. Single speed/dual capacity startup/troubleshooting form 1. Job information model # job name: loop: open / closed serial # install date: hot water generator: y / n 2. Flow rate in gpm source coax load coax (water-to-water) heating cooling h...

Page 59: Preventive Maintenance

59 5 series 500a11 installation manual water coil maintenance 1. Keep all air out of the water. An open loop system should be checked to ensure that the well head is not allowing air to infiltrate the water line. Lines should always be airtight. 2. Keep the system under pressure at all times. It is ...

Page 60: Service Parts List

60 5 series 500a11 installation manual service parts list parts list single speed units 012 018 022 030 036 042 048 060 070 c ompr es sor compressor 208-230/60/1 34p591-01 34p593-01 34p581-01 34p582-01 34p583-01 34p578-01 34p579-01 34p580-01 34p646-01 run capacitor 208-230/60/1 16p002d18 16p002d19 1...

Page 61: Service Parts List Cont.

61 5 series 500a11 installation manual service parts list cont. Parts list dual capacity units 026 038 049 064 072 c ompr es sor compressor 208-230/60/1 34p640-01 34p641-01 34p642-01 34p643-01 34p644-01 run capacitor 208-230/60/1 16p002d19 16p002d20 16p002d18 16p002d31 16p002d31 sound jacket 92p504a...

Page 62: Notes

62 5 series 500a11 installation manual notes.

Page 63: Revision Guide

63 5 series 500a11 installation manual revision guide pages: description: date: by: 24-26 updated dimensional drawings 22 feb 2013 ds 40-43 updated wiring diagrams 22 feb 2013 ds all revision table added, minor formatting corrections 22 feb 2012 ds.

Page 64

Manufactured by waterfurnace international, inc. 9000 conservation way fort wayne, in 46809 www.Waterfurnace.Com ©2013 waterfurnace international, inc., 9000 conservation way, fort wayne, in 46809-9794. Waterfurnace has a policy of continual product research and development and reserves the right to...