- DL manuals

- Water Furnace

- Heat Pump

- 502W12

- Installation Manual

Water Furnace 502W12 Installation Manual

Summary of 502W12

Page 1

Im2517wn 03/13 installation information water piping connections electrical data microprocessor control startup procedures preventive maintenance 5 series 50 2w12 ins tallation manual c us 5 serie ll l high temp hydronic geothermal heat pump • r-134a refrigerant • 7 ton dual capacity 502w12.

Page 3: Table of Contents

5 series 502w12 installation manual table of contents model nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 general installation information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4: Model Nomenclature

4 5 series 502w12 installation manual model nomenclature all 5 series 502w12 product is safety listed under ul1995 thru etl and performance listed with ahri in accordance with standard 13256-2. The 5 series 502w12 is also energy star rated. 1-3 nhw 4-6 084 7 h 8 1 9 8 10 0 11 a 12 b 13-14 ss 15 a mo...

Page 5

5 5 series 502w12 installation manual safety considerations installing and servicing air conditioning and heating equipment can be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should install, repair or service heating and air conditioning e...

Page 6: Field Connected Water Piping

6 5 series 502w12 installation manual general each unit is equipped with captive 1-1/4 in. [31.8 mm] fpt water connections to eliminate ‘egg-shaping’ from use of a backup wrench. For making the water connections to the unit, a teflon tape thread sealant is recommended to minimize internal fouling of...

Page 7

7 5 series 502w12 installation manual field connected water piping cont. Open loop well water systems installation of an open loop system is not recommended unless water quality guidelines are met. Earth coupled systems all supply and return water piping should be insulated to prevent excess condens...

Page 8: Typical Application Piping

8 5 series 502w12 installation manual typical application piping load pump hydronic load source out p/t ports ball valve dielectric unions dielectric unions waterfurnace 5 series 502w12 note: * a 30 psi pressure relief valve (part no: srv30) should be used in hydronic applications. 1-1/2˝ fpt expans...

Page 9: Water Quality

9 5 series 502w12 installation manual the following table outlines the water quality guidelines for unit heat exchangers. If these conditions are exceeded, a secondary heat exchanger is required. Failure to supply a secondary heat exchanger where needed will result in a warranty exclusion for primar...

Page 10: Dimensional Data

10 5 series 502w12 installation manual 1= /:b3@ a3@d713/113aa =>b7==e d=:b/53 %&9 =>b7= b=>e/b3@ 1= :7 !&9 :=ed=:b/53 %&9 1=a ab/>=a7b3 =4e/b3@:7 6/a473:2=>b7= b=03ae7b1632 1= =>b7= !!$ ##& " & "# # & #& $ % $ :=/2 a=c@13 ab/ =>b7= e/b3@:7 >@7;/@g a3@d713 /113aa :=/2 a=c@13 1= /:b3@ a3@d713/113aa =>...

Page 11: Electrical Data

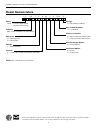

11 5 series 502w12 installation manual figure 1 - control box 208 or 230 volt switch (if applicable) power supply (field line voltage connection) compressor contactor (cc-a) compressor contactor (cc-b) field low voltage connections fx10 control board fx10 expansion board run capacitor transformer co...

Page 12: Wiring Schematics Cont.

12 5 series 502w12 installation manual wiring schematics cont. 208-230/60/1 sfs lfs es johnson fx-10 5vdc ai3 35 36 37 38 + - ai5 - + ai4 - + ai6 ai2 ai1 5vdc 5vdc led - - - + + + 24v ac 24v ac com ground 39 40 41 pwm2 pwm2 com pwm1 42 43 44 45 46 47 48 24vac com di12 di11 di10 di9 di8 di7 49 50 51 ...

Page 13: Wiring Schematics Cont.

13 5 series 502w12 installation manual wiring schematics cont. 208-230/60/1 cont. 24v t ransformer pb1 2 3 1 1 2 3 4 5 7 8 9 10 6 11 12 13 16 15 14 17 20 19 18 a black red 208v blue 230v black/white yellow yellow yellow yellow yellow (24) y1 comp 1 lc1 comp a alarm rs not used x2 do-7 r 24vac ss do-...

Page 14: Wiring Schematics Cont.

14 5 series 502w12 installation manual wiring schematics cont. 208-230/60/1 with intellistart sfs lfs es johnson fx-10 5vdc ai3 35 36 37 38 + - ai5 - + ai4 - + ai6 ai2 ai1 5vdc 5vdc led - - - + + + 24v ac 24v ac com ground 39 40 41 pwm2 pwm2 com pwm1 42 43 44 45 46 47 48 24vac com di12 di11 di10 di9...

Page 15: Wiring Schematics Cont.

15 5 series 502w12 installation manual wiring schematics cont. 208-230/60/1 with intellistart cont. 24v t ransformer pb1 2 3 1 1 2 3 4 5 7 8 9 10 6 11 12 13 16 15 14 17 20 19 18 a black red 208v blue 230v black/white yellow yellow yellow yellow yellow (24) y1 comp 1 lc1 comp a alarm rs not used x2 d...

Page 16: Wiring Schematics Cont.

16 5 series 502w12 installation manual wiring schematics cont. Mui wiring diagram johnson fx-10 5vdc ai3 35 36 37 38 + - ai5 - + ai4 - + ai6 ai2 ai1 5vdc 5vdc led - - - + + + 24 vac 24v ac c om gr o un d 39 40 41 pwm2 pwm2 com pwm1 42 43 44 45 46 47 48 24vac com di12 di11 di10 di9 di8 di7 49 50 51 5...

Page 17

17 5 series 502w12 installation manual tb typical t-stat 24vac 24v com comp 1 comp 2 rev valve acc 2 acc 1 alarm circuit 1 alarm circuit 2 alarm 24vac 24v com comp 1 comp 2 rev valve accessory item 1 r c y1 y2 o/b x2 x1 l lc1 lc2 r c y1 y2 b notes: 1) acc output 1 is cycled with the lead compressor ...

Page 18: Control Features

18 5 series 502w12 installation manual field wiring and control setup cont. Accessory relay setup the accessory output set to “close” upon y1 compressor call (compressor is delayed 90 sec. After y1) but can be set to “open” with y1. To change acc1: • using up and down keys, scroll to “acc 1 sel” hit...

Page 19: Control Features Cont.

19 5 series 502w12 installation manual control features cont. Basic freeze detection operation: “comp1 or comp2 freeze” alarm this alarm can be triggered by one of two detection schemes. Hard limit freeze detection if the refrigerant temperature drops below the freeze detection setpoint by 1.8°f, th...

Page 20: Sequence of Operation

20 5 series 502w12 installation manual power fail restart when the controller is first powered up, the outputs will be disabled for a random start delay time (see random start delay). The delay is provided to prevent simultaneous starting of multiple heat pumps. Once the timer expires, the controlle...

Page 21: Unit Display and Interface

21 5 series 502w12 installation manual dual stage ww input name input output name output entering load water temperature ai 1 compressor 1 do1 leaving load water temperature 1 ai 2 compressor 2 do2 source heating freeze detection 1 ai 3 reversing valve do3 source heating freeze detection 2 ai 4 acce...

Page 22

22 5 series 502w12 installation manual mui menu navigation welcome info temp stat outputs settings maint alarm_history dual stage info outputs comp1 status on comp2 status off acc1 status off stg1 status normal stg2 status normal bo7 off bo8 off bo9 off expb01 off expb02 off expb07 off expb08 off ou...

Page 23

23 5 series 502w12 installation manual menu and menu contents alarm • displays unit alarms until the unit has been reset (unit alarms can be reset by holding both the escape (esc) key and return ( ← ) key for five seconds or by power cycling the unit.) alarm history if a fault occurs the fault will ...

Page 24: Legend

24 5 series 502w12 installation manual he gpm x 500* legend reference calculations heating calculations: cooling calculations: lwt = ewt + hr gpm x 500* lwt = ewt - note: * when using water. Use 485 for 15% methanol/water or environol solution. Abbreviations and definitions: cop = coefficient of per...

Page 25: Operating Parameters

25 5 series 502w12 installation manual operating parameters heating mode entering load temp (°f) entering source temp (°f) suction pressure (psig) discharge pressure (psig) superheat (°f) subcooling (°f) 60 30 10-20 60-75 8-10 6-10 50 20-30 65-80 9-11 8-12 70 30-40 70-85 10-14 10-14 90 40-50 75-90 2...

Page 26: Thermistor Resistance

26 5 series 502w12 installation manual heat of extraction/rejection data thermistor resistance thermistor temperature resistance in ohms °f °c 5 -15 758 14 -10 789 23 -5 822 32 0 855 41 5 889 50 10 924 59 15 960 68 20 997 77 25 1035 86 30 1074 95 35 1113 104 40 1153 113 45 1195 122 50 1237 131 55 12...

Page 27: Heating Cycle Analysis

27 5 series 502w12 installation manual heating cycle analysis suction discharge compressor rv braze plate braze plate fd unit amp draw ____________ line voltage _________ loop:______ open ______ closed subcooling _______ superheat _______ entering source water ________°f entering water pressure drop...

Page 28

28 5 series 502w12 installation manual check one start up/check-out for new installation t troubleshooting problem:___________________________________ t 1. Flow rate in gpm (source side heat exchanger) water in pressure: a.______ psi water out pressure: b.______ psi pressure drop = a - b c.______ ps...

Page 29: Troubleshooting

29 5 series 502w12 installation manual should a major problem develop, refer to the following information for possible causes and corrective steps. If compressor won’t run: 1. The fuse may be open or the circuit breaker is tripped. Check electrical circuits and motor windings for shorts or grounds. ...

Page 30: Service Parts List

30 5 series 502w12 installation manual service parts list part description nhw084 r efriger ation c omponents compressor 34p632-01 compressor sound jacket 92p504a05 thermal expansion valve 33p618-01 txvs per circuit 1 filter drier 36p500b02 reversing valve with coil 33p526-05 brazed plate heat excha...

Page 31: Revision Guide

31 5 series 502w12 installation manual revision guide pages: description: date: by: 18 updated field wiring and control setup 25 feb 2013 ds 20 updated sequence of operation 25 feb 2013 ds 31 added revision guide 25 feb 2013 ds.

Page 32

Im2517wn 03/13 manufactured by waterfurnace international, inc. 9000 conservation way fort wayne, in 46809 www.Waterfurnace.Com ©2013 waterfurnace international, inc., 9000 conservation way, fort wayne, in 46809-9794. Waterfurnace has a policy of continual product research and development and reserv...