- DL manuals

- Water Furnace

- Heat Pump

- envision 2 compact

- Installation Manual

Water Furnace envision 2 compact Installation Manual

Summary of envision 2 compact

Page 1

Im1022an 01/13 installation information water piping connections hot water connections electrical startup procedures troubleshooting preventive maintenance compact water source/geothermal heat pump • r-410a refrigerant • commercial 0.75-6 ton en vision 2 c ompact ins tallation manual s.

Page 3: Table of Contents

Envision 2 compact installation manual table of contents model nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 general installation information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

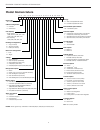

Page 4: Model Nomenclature

4 envision 2 compact installation manual model nomenclature 1-2 nb 4-6 036 7 t 8 l 9 0 10 0 11 0 12 c 13 a 14 n 15 a 16 n 17 1 21-22 ss 18 a 19 1 20 0 23 a 3 v model type nb = envision 2 compact cabinet configuration v = vertical h = horizontal unit capacity single speed 009, 012, 015, 018, 024, 030...

Page 5

5 envision 2 compact installation manual warning: before performing service or maintenance operations on a system, turn off main power switches to the indoor unit. If applicable, turn off the accessory heater power switch. Electrical shock could cause personal injury. Installing and servicing heatin...

Page 6: Vertical Dimensional Data

6 envision 2 compact installation manual vertical dimensional data 1 2 8 3 4 access panel air coil air coil side air coil side air coil 5 power supply 1 in (25.4 mm) knockout low voltage 1/2" (12.7 mm) knockout condensate 3/4 in pvc glue socket front front right view - right return left view - left ...

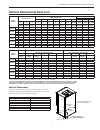

Page 7

7 envision 2 compact installation manual vertical dimensional data cont. Vertical models overall cabinet water connections electrical knockouts 6 7 8 1 2 3 4 5 j k l a b c d e f g h loop knockout 1/2 in. Cond 1/2 in. Cond 1 in. Cond width depth height* in out hwg in hwg out cond- ensate water fpt hw...

Page 8: Horizontal Dimensional Data

8 envision 2 compact installation manual horizontal dimensional data right return end discharge left return end discharge end discharge end discharge side discharge side discharge right return left return front front cmp cmp ap ap condensate "x" pvc size condensate "x" pvc size rr front view blower ...

Page 9

9 envision 2 compact installation manual horizontal dimensional data cont. Horizontal models overall cabinet water connections electrical knockouts 1 2 3 j k a b c d e h loop 1/2 in. Cond 1 in. Cond width depth height* in out condensate water fpt low voltage power supply 009-012 in. 22.5 35.0 17.2 1...

Page 10: Installing Horizontal Units

10 envision 2 compact installation manual installing horizontal units remove and discard the compressor hold down shipping bolt located at the front of the compressor mounting bracket prior to setting the unit in place. Horizontal units are available with side or end discharge. Note: left (right) re...

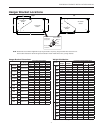

Page 11: Hanger Bracket Locations

11 envision 2 compact installation manual hanger bracket locations b c a h e d g f left d e f g right vibration isolator w asher hex nuts (not supplied) bolt and lockwasher 3/8” threaded rod (not supplied) compressor section compressor section air handler section air handler section h note: model si...

Page 12: Duct System

12 envision 2 compact installation manual an air outlet collar is provided on vertical top flow units and all horizontal units to facilitate a duct connection. A flexible connector is recommended for discharge and return air duct connections on metal duct systems. Uninsulated duct should be insulate...

Page 13: Water Quality

13 envision 2 compact installation manual in ground water situations where scaling could be heavy or where biological growth such as iron bacteria will be present, a closed loop system is recommended. The heat exchanger coils in ground water systems may, over a period of time, lose heat exchange cap...

Page 14

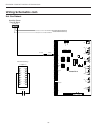

14 envision 2 compact installation manual typical open loop piping is shown below. Always maintain water pressure in the heat exchanger by placing water control valves at the outlet of the unit to prevent mineral precipitation. Use a closed, bladder-type expansion tank to minimize mineral formation ...

Page 15

15 envision 2 compact installation manual the heat reclaiming hot water generator coil is of vented double-wall copper construction and is suitable for potable water. To maximize the benefits of the hot water generator a minimum 50-gallon water heater is recommended. For higher demand applications, ...

Page 16

16 envision 2 compact installation manual caution: never operate the hwg circulating pump while dry. If the unit is placed in operation before the hot water generator piping is connected, be sure that the pump wires are disconnected from the contactor. Hot water generator connections cont. Hot water...

Page 17: Electrical Connections

17 envision 2 compact installation manual 208 volt operation all 208/230 units are factory wired for 230 volt operation. For 208 volt operation, the red and blue transformer wires must be switched on terminal strip ps. Caution: when installing a unit with a variable speed ecm blower motor in 460/60/...

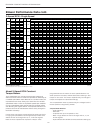

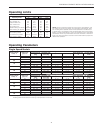

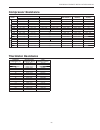

Page 18: Electrical Data

18 envision 2 compact installation manual electrical data psc motor model rated voltage voltage min/max compressor blower motor fla total unit fla min circ amp max fuse/ hacr breaker mcc rla lra lra** single speed 009 208-230/60/1 187/253 6.4 4.1 21.0 n/a 0.6 4.7 5.7 10/15 265/60/1 238/292 6.7 4.3 2...

Page 19: Electrical Data Cont.

19 envision 2 compact installation manual electrical data cont. 5-speed ecm motor model rated voltage voltage min/max compressor blower motor fla total unit fla min circ amp max fuse/ hacr breaker mcc rla lra lra** single speed 015 208-230/60/1 187/253 9.7 6.2 29.0 n/a 4.1 10.3 11.9 15 265/60/1 238/...

Page 20: Electrical Data Cont.

20 envision 2 compact installation manual electrical data cont. Caution: when installing a unit with a variable speed ecm blower motor in 460/60/3 voltage, a neutral wire is required to allow proper unit operation. Variable speed ecm motor model rated voltage voltage min/max compressor blower motor ...

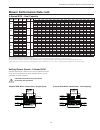

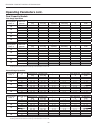

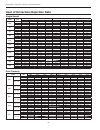

Page 21: Blower Performance Data

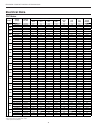

21 envision 2 compact installation manual blower performance data standard psc motor model blower spd blower size motor hp airflow (cfm) at external static pressure (in. Wg) 0 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.60 0.70 0.80 0.90 1.00 009 h 6 x 8 1/10 480 450 440 420 410 380 360 340 ...

Page 22

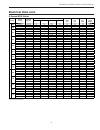

22 envision 2 compact installation manual blower performance data cont. About 5-speed ecm constant torque motors the 5-speed ecm is a ‘constant torque’ ecm motor and delivers air flow similar to a psc but operates as efficiently as a variable speed ecm motor. Because it is an ecm motor, the 5-speed ...

Page 23

23 envision 2 compact installation manual blower performance data cont. Caution: disconnect all power before performing this operation. Setting blower speed - 5-speed ecm 5-speed ecm blower motors have five (5) speeds of which three (3) are selectable on single speed and four (4) are selectable on d...

Page 24

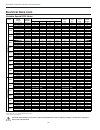

24 envision 2 compact installation manual blower performance data cont. Variable speed ecm motor single speed model max esp blower size motor hp airflow dip switch settings 1 2 3 4 5 6 7 8 9 10 11 12 015 0.50 9 x 7 1/2 300 400 500 600 700 l m h 018 0.50 9 x 7 1/2 300 400 500 600 700 800 l m h 024 0....

Page 25

25 envision 2 compact installation manual the abc board’s yellow config led will flash the current variable speed ecm blower speed selections for low, med, and high continuously with a short pause in between. The speeds can also be confirmed with the aid tool under the setup/ecm setup screen. The va...

Page 26: Wiring Schematics

26 envision 2 compact installation manual wiring schematics aurora control 460/60/3 variable speed ecm 97p818-08 3/19/12 thermistor relay coil switch - condensate overflow switch - high pressure switch - low pressure polarized connector factory low voltage wiring factory line voltage wiring field lo...

Page 27: Wiring Schematics Cont.

27 envision 2 compact installation manual wiring schematics cont. Aurora base control 460/60/3 5-speed ecm with reheat slow flash fast flash flash code status led (led1, green) configuration led (led2, yellow) fault led (led3, red) status led (led1, green) normal mode control is non-functional test ...

Page 28: Wiring Schematics Cont.

28 envision 2 compact installation manual wiring schematics cont. Fx10 control 460/60/3 5-speed ecm relay coil capacitor w/ bleed resistor switch - condensate overflow switch - high pressure switch - low pressure polarized connector factory low voltage wiring factory line voltage wiring field low vo...

Page 29: Wiring Schematics Cont.

29 envision 2 compact installation manual wiring schematics cont. Fx10 control 460/60/3 5-speed ecm cont. Compressor t1 t2 t3 l2 l3 cc t2 t3 l1 t1 note 9 disconnect neutral ground l1 l1 l2 l2 l3 l3 g green (93) yellow red black l1 l2 l3 phase guard monitor (pgm) note 10 black (7) white (8) red (9) b...

Page 30: Wiring Schematics Cont.

30 envision 2 compact installation manual wiring schematics cont. Hot gas reheat johnson fx-10 5vdc ai3 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 + - ai5 - + ai4 - + ai6 ai2 ai1 5vdc 5vdc led - - - + + + 24v ac 24v ac c om gr ou nd 39 40 41 pwm2 pwm2 com pwm1 42 43 44 45 46 47 48 24vac com di1...

Page 31

31 envision 2 compact installation manual controls - aurora base control aurora ‘base’ control note: refer to the aurora base control application and troubleshooting guide and the instruction guide: aurora interface and diagnostics (aid) tool for additional information. Control features software abc...

Page 32

32 envision 2 compact installation manual cycle with blower - the accessory relay will cycle with the blower output. Cycle with compressor - the accessory relay will cycle with the compressor output. Water valve slow opening - the accessory relay will cycle and delay both the blower and compressor o...

Page 33

33 envision 2 compact installation manual over/under voltage shutdown - an over/under voltage condition exists when the control voltage is outside the range of 18 vac to 30 vac. If the over/under voltage shutdown lasts for 15 minutes, the lockout and alarm relay will be energized. Over/under voltage...

Page 34

34 envision 2 compact installation manual cc2 factory fault alg alm ls es acc c status aurora tm base control rv – k1 cc2 cc – k2 cc hi – k3 fan – k4 alarm – k5 acc – k6 acc no acc nc o/b c r lo g y1 y2 w dh 3a-fuse o/b c r lo g y1 y2 w dh lo g hi ccg cc fg f r hp hp lp fp2 fp2 fp1 rev rev cfm pwm e...

Page 35: Controls - Fx10 (Optional)

35 envision 2 compact installation manual optional fx10 microprocessor and bas interface the fx10 is a microprocessor based control that not only monitors and controls the heat pump but also can communicate any of this information back to the building automation system (bas). This means that not onl...

Page 36

36 envision 2 compact installation manual lockout mode lockout mode can be activated by any of the following fault signals: refrigerant system high pressure, refrigerant system low pressure, freeze detection, and condensate overflow. When any valid fault signal remains continuously active for the le...

Page 37

37 envision 2 compact installation manual compressor fixed on delay time the compressor fixed on delay time will ensure that the compressor output (b02) is not enabled for 90 seconds after the control receives a call to start the compressor. This delay is adjustable from 30 – 300 seconds over a bas ...

Page 38

38 envision 2 compact installation manual fx10 user interface (mui) physical layout power led led 1 led 4 escape (esc) button return button alarm led led 8 up arrow right arrow left arrow down arrow alarm led - indicates a lock-out or a bad freeze sensor power led - shows fx processor is operational...

Page 39

39 envision 2 compact installation manual controls - fx10 (optional) cont. Mui menu navigation for single compressor - envision 2 series water-to-air welcome info status temps outputs settings maint alarms alm-history water source heat pump profxenv-xx _/_/__ info run mode auto eff occup’y occ y1 in...

Page 40: Unit Startup

40 envision 2 compact installation manual • high voltage is correct and matches nameplate. • fuses, breakers and wire size correct. • low voltage wiring complete. • piping completed and water system cleaned and flushed. • air is purged from closed loop system. • isolation valves are open, water cont...

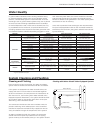

Page 41: Operating Limits

41 envision 2 compact installation manual operating limits operating limits cooling heating (°f) (°c) (°f) (°c) air limits min. Ambient air 45 7.2 45 7.2 rated ambient air 80 26.7 70 21.1 max. Ambient air 100 37.8 85 29.4 min. Entering air 50 10.0 40 4.4 rated entering air db/wb 80.6/66.2 27/19 68 2...

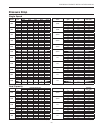

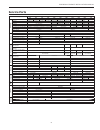

Page 42: Operating Parameters Cont.

42 envision 2 compact installation manual operating parameters cont. Dual capacity models first stage operation entering water temp °f water flow gpm/ton cooling -- no hot water generation suction pressure psig discharge pres- sure psig superheat subcooling water temp rise °f air temp drop °f db 30 ...

Page 43: Pressure Drop

43 envision 2 compact installation manual pressure drop single speed model gpm pressure drop (psi) valve gpm cv pressure drop (psi) 30°f 50°f 70°f 90°f 110°f 009 1.5 1.9 1.8 1.7 1.6 1.5 1/2 in. 1.5 9.6 0.02 2.0 3.5 3.4 3.2 3.1 3.0 2.0 9.7 0.04 3.0 6.9 6.5 6.3 6.0 5.7 3.0 9.9 0.09 4.0 12.0 11.4 11.0 ...

Page 44: Reference Calculations

44 envision 2 compact installation manual symptom head pressure suction pressure compressor amp draw superheat subcooling air temp. Differential water temp. Differential under charged system (possible leak) low low low high low low low over charged system high high high normal high normal/low normal...

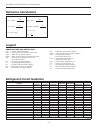

Page 45: Compressor Resistance

45 envision 2 compact installation manual compressor resistance model 208-230/60/1 265/60/1 208-230/60/3 460/60/3 575/60/3 run start run start single speed 009 3.65 - 4.19 3.75 - 4.31 3.73 - 4.27 4.45 - 5.13 n/a n/a n/a 012 3.35 - 3.85 2.80 - 3.22 3.73 - 4.27 4.45 - 5.13 n/a n/a n/a 015 2.74 - 3.16 ...

Page 46

46 envision 2 compact installation manual heat of extraction/rejection data single speed model gpm heat of extraction (he) - mbtu/h heat of rejection (hr) - mbtu/h 30°f 50°f 70°f 90°f 30°f 50°f 70°f 90°f 110°f 009 1.5 6.5 8.6 11.3 13.0 12.4 12.1 2.0 5.1 6.7 8.9 11.6 13.3 13.0 12.4 12.1 11.9 3.0 5.0 ...

Page 47: Troubleshooting

47 envision 2 compact installation manual should a major problem develop, refer to the following information for possible causes and corrective steps. If compressor won’t run: 1. The fuse may be open or the circuit breaker is tripped. Check electrical circuits and motor windings for shorts or ground...

Page 48

48 envision 2 compact installation manual check one start up/check-out for new installation ❑ troubleshooting problem:___________________________________ ❑ 1. Flow rate in gpm (coaxial heat exchanger) water in pressure: a.______ psi water out pressure: b.______ psi pressure drop = a - b c.______ psi...

Page 49

49 envision 2 compact installation manual cooling cycle analysis hot water generator - expansion valve °f air coil °f °f °f °f psi psi brine in brine out compressor discharge suction subcooling superheat reversing valve psi °f sat °f = psi = sat f f °f liquid line water to water application ° ° °f c...

Page 50: Preventive Maintenance

50 envision 2 compact installation manual water coil maintenance 1. Keep all air out of the water. An open loop system should be checked to ensure that the well head is not allowing air to infiltrate the water line. Lines should always be airtight. 2. Keep the system under pressure at all times. It ...

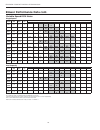

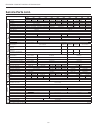

Page 51: Service Parts

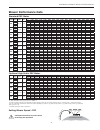

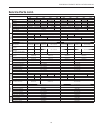

51 envision 2 compact installation manual service parts part description single speed vertical units 009 012 015 018 024 030 036 042 048 060 070 c ompr es sor compressor 208-230/60/1 34p590-01 34p591-01 34p592-01 34p593-01 34p624-01 34p582-01 34p583-01 34p578-01 34p579-01 34p580-01 34p646-01 265/60/...

Page 52: Service Parts Cont.

52 envision 2 compact installation manual service parts cont. Part description single speed horizontal units 009 012 015 018 024 030 036 042 048 060 070 c ompr es sor compressor 208-230/60/1 34p590-01 34p591-01 34p592-01 34p593-01 34p624-01 34p582-01 34p583-01 34p578-01 34p579-01 34p580-01 34p646-01...

Page 53: Service Parts Cont.

53 envision 2 compact installation manual service parts cont. Part description dual capacity vertical units dual capacity horizontal units 026 038 049 064 072 026 038 049 064 072 c ompr es sor compressor 208-230/60/1 34p640-01 34p641-01 34p642-01 34p643-01 34p644-01 34p640-01 34p641-01 34p642-01 34p...

Page 54: Notes

54 envision 2 compact installation manual notes.

Page 55: Revision Guide

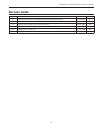

55 envision 2 compact installation manual revision guide pages: description: date: by: all updated nomenclature to reflect new variable speed ecm motor 08 jan 2013 ds all added intellistart availability for 3-phase units 08 jan 2013 ds 27 replaced wiring diagram with reheat version 08 jan 2013 ds 31...

Page 56

Manufactured by waterfurnace international, inc. 9000 conservation way fort wayne, in 46809 www.Waterfurnace.Com ©2013 waterfurnace international, inc., 9000 conservation way, fort wayne, in 46809-9794. Waterfurnace has a policy of continual product research and development and reserves the right to...