- DL manuals

- Water Right

- Water Filtration Systems

- ECLIPSE WRO-35

- Installation, operation & service manual

Water Right ECLIPSE WRO-35 Installation, operation & service manual

Tested and Certifi ed by NSF International against

NSF/ANSI Standard 58 for the reduction of the claims

specifi ed on the Performance Data Sheet.

E C L I P S E

Reverse Osmosis

Drinking Water Sys tem

from Water-Right

Sold and serviced

by authorized

Water-Right dealers.

Installation, Operation & Service Manual

WRO-35

R.O. Drinking

Water System

Summary of ECLIPSE WRO-35

Page 1

Tested and certifi ed by nsf international against nsf/ansi standard 58 for the reduction of the claims specifi ed on the performance data sheet. E c l i p s e reverse osmosis drinking water sys tem from water-right sold and serviced by authorized water-right dealers. Installation, operation & servi...

Page 2

Table of contents page section i. Introduction ...................................................................................3 section ii. Specifications ................................................................................4 section iii. Preparation .....................................

Page 3

3 section i. Introduction your new reverse osmosis (r.O.) drinking water system uses a combination of fi ltration tech nol o gies to reduce unwanted contaminants in a water supply. The following steps combine to give you the best in clear sparkling drinking water: mechanical filtration/activated car...

Page 4

4 section ii. Specifications table a – qualified system per for mance because the performance of an r.O. Mem brane is highly dependent upon pressure, temperature and tds, the following should be used for com par i son purposes only. U.S. Metric membrane production 1 35 ± 7 gpd (106–159 lpd) membrane...

Page 5

5 section iii. Preparation a. Major system components the following components comprise the r.O. Drinking water system. (refer to fig. 1, below for general system layout.) • an r.O. Manifold assembly. • housings and housing o–rings. • a drinking water holding tank. • a dispensing faucet with water q...

Page 6

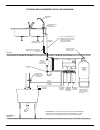

6 optional wro-35 basement installation diagram holding tank shutoff valve (open position) drinking water holding tank dispensing faucet reverse osmosis membrane housing activated carbon module sediment/ carbon module in-line activated carbon post filter product (3/8" blue) drain (1/4" black) r.O. M...

Page 7

7 b. Tools recommended for installation the following tools will cover most of the in stal la tion sites encountered: 1. 3 / 8 " variable speed electric drill. 2. Extension work light with outlet. 3. Safety glasses. 4. 1¼" porcelain hole cutter kit. 5. 1¼" greenlee hole punch and 1 / 8 " and ½" meta...

Page 8

8 section iv. Installation steps all plumbing should be done in accordance with state and local plumbing codes. Note: some codes may require installation by a licensed plumber; check with the local plumbing authority prior to installation. In restricted under–sink areas, it may be easier to install ...

Page 9

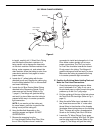

9 mounting surface, 1¼" drill hole slotted washer cl 3/8" polytube quick connect fitting 3/8" blue polytube water quality monitor cable water quality monitor connector water quality monitor cable plastic spacer 7/16" washer 7/16" hex nut 7/16" stud note: assemble slotted washer, 3/8" polytube quick ...

Page 10

10 •from the top of the counter place the stud, tubing and water quality monitor connector cable through the mounting hole. See figure 2b, page 9. •from the bottom of the counter top slide the slotted washer between the counter top and the plastic spacer with the open end towards the tubing. Tighten...

Page 11

11 to the dispensing faucet. Route to the tubing to the drain clamp and trim to length. Note: when cutting the polytubing make clean, square cuts, failing to do so could result in poor con nec tions and possible leaks. Caution: the lowest point of the line should be the point of connection to the dr...

Page 12

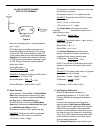

12 3/8" drain clamp assembly to length, carefully slit ¼" black drain tubing end that has the blue drain restrictor in it being careful not to damage the hose barb on the drain restrictor. Remove restrictor from tubing, make a square cut, and reinsert the drain restrictor. Allow the tubing to relax,...

Page 13

13 and seal it in place. Make sure the tubing is pressed all the way in to create a pressure tight connection. F. Start up 1. Installing the modules and membrane and sanitizing the holding tank. •open the dispensing faucet by lifting the black handle and close the holding tank shut–off valve (the ha...

Page 14

14 prefi lter and post fi lters. B. Changing modules this r.O. System contains modules which must be replaced at regular intervals to maintain proper performance. Use only factory approved modules. All individuals should take adequate precautions when changing the fi lters, including wearing protect...

Page 15

15 they are not exactly equal, in most dis cus sions ppm = mg/l.) r.O. Membranes are rated by the amount of dissolved solids that are rejected. This rating is a ratio of the tds in the feed water to the tds in the product water and is reported as percent rejection. If the feed water contained 100 pp...

Page 16

16 dissolved minerals in the water and can be ap prox i mat ed by 1 psig for each 100 ppm of tds example: a feed water with 1500 ppm of tds would exert a backward pressure of about 15 psig on the membrane. Net pressure differential = feed water pressure – holding tank pressure – osmotic pressure the...

Page 17

17 estimated water production rate feed water in gallons per day (gpd) and liters per day (lpd) for line pressure of: 40 psig 50 psig 60 psig 70 psig 80 psig 90 psig 100 psig temp tds* (280 kpa) (345 kpa) (414 kpa) (483 kpa) (552 kpa) (621 kpa) (690 kpa) °f °c mg/l gpd lpd gpd lpd gpd lpd gpd lpd gp...

Page 18

18 section vii. Trouble shooting guide problem possible cause so lu tion open valve or unclog. Replace modules. Feed water pressure must be above 40 psig. See feed water operating limits. Correct cause of fouling, replace membrane. Replace post filter. Empty water from holding tank, and with the fau...

Page 19

19 correct plumbing. Clear or replace drain restrictor. Clear or replace air gap faucet.. Repair or replace the aso valve com po nents. Flush with several full tanks of product water. An increase in feed water tds will give a corresponding increase in product water tds. Replace filter. Clean, fl ush...

Page 20

20 notes:.

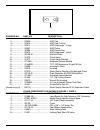

Page 21

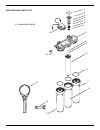

21 made in usa exploded view & parts list 1 2 3 4 5 6 7 8 9 10 11 12 13 14 17 19 18 15 16 21. Nitrate/nitrite test kit.

Page 22

Drawing no. Part no. Description 1.................... S2009................................ Self tapping screw 2.................... S2005................................ Aso cap 3.................... S2013................................ Aso cap o–ring 4.................... S2011.....................

Page 24

Form no. S1474–01wr updated 06/03 1900 prospect court appleton, wi 54915 phone: 920-739-9401 1-800-777-1426 fax: 920-739-9406 © 1998 water-right, inc. All rights reserved. Eclipse™ r.O. Drinking water system five/one year limited warranty what does this warranty cover? This warranty covers any defec...