- DL manuals

- WaterCare

- Water Dispenser

- CSE-TW

- Owner's manual

WaterCare CSE-TW Owner's manual

Summary of CSE-TW

Page 1

For models: • tc1-tw • tc2-tw • cse-tw • csp-tw • cserc-tw • csprc-tw totalcare ® , caresoft elite ® and caresoft pro ® series twin water softeners and conditioners.

Page 2: Table of Contents

Table of contents preinstallation instructions for dealers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 bypass valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 installation . . . . . . . . . . . . . . . . ....

Page 3

Preinstallation instructions for dealers: 3 the manufacturer has preset the water treatment unit’s sequence of cycles, cycle times, salt dose, exchange capacity and salt dose refill time . The dealer should read this page and guide the installer regarding hardness, day override, time of regeneration...

Page 4: Bypass Valve:

The bypass valve is typically used to isolate the control valve from the plumbing system’s water pressure in order to perform control valve repairs or maintenance . The 1” full flow bypass valve incorporates four positions, including a diagnostic position that allows a service technician to have pre...

Page 5: Installation:

General installation & service warnings the control valve, fittings and/or bypass are designed to accommodate minor plumbing misalignments . There is a small amount of “give” to properly connect the piping, but the water softener is not designed to support the weight of the plumbing . Do not use vas...

Page 6

6 plumbing system first and then attach the nut, split ring and “o” ring . Heat from soldering or solvent cements may damage the nut, split ring or “o” ring . Solder joints should be cool and solvent cements should be set before installing the nut, split ring and “o” ring . Avoid getting solder flux...

Page 7: Programming Procedures:

7 1. Set time of day: programming procedures: note: the manufacturer has preset the unit so that the gallons between regenerations will be automatically calculated after the hardness is entered . Step 1 – press next and + simultaneously for 3 seconds . Step 2 – hardness:set the amount of hardness in...

Page 8

8 step 4 – immediate regeneration:the manufacturer has set the regeneration to occur when zero gallons remain . When this occurs, the standby tank will switch into service and provide treated water while the tank requiring regeneration will start this process . Press next to go to step 5 . Press reg...

Page 9

9 operating displays and instructions: 1 . General operation:when the system is operating, one of five displays may be shown and will alternate with the installing dealer’s name and phone number (if set) for future service . Pressing next will alternate between the displays . 1 . Current time of day...

Page 10

5 . Power loss and battery replacement: the transformer comes with a 15 foot power cord and is designed for use with the control valve; the transformer should only be used in a dry location . In the event of a power outage, the control valve will remember all settings and time of day . If an extende...

Page 11: Start-Up Instructions:

11 flushing of system: to flush the system of any debris and air after installation is complete, please perform the following steps: 1 . Rotate bypass handles to the bypass mode (see fig. 2 of page 4) . 2 . Turn on inlet water and check for leaks in the newly installed plumbing . 3 . Fully open a co...

Page 12: Troubleshooting Guide:

12 problem cause correction 1. No display on pc board a . No power at electric outlet a . Repair outlet or use working outlet b . Control valve power adapter not plugged into outlet or power cord end not connected to pc board connection b . Plug power adapter into outlet or connect power cord end to...

Page 13

13 7. Control valve does not regenerate automatically but does when the correct button(s) is depressed and held. A . Bypass valve in bypass position a . Turn bypass handles to place bypass in service position b . Meter is not connected to meter connection on pc board b . Connect meter to three pin c...

Page 14

14 troubleshooting guide cont’d: 12. Control valve fails to draw in regenerant a . Injector is plugged a . Remove injector and clean or replace b . Faulty regenerant piston b . Replace regenerant piston c . Regenerant line connection leak c . Inspect regenerant line for air leak d . Drain line restr...

Page 15

15 problem cause correction 16. E3, err – 1003, err – 103 = control valve motor ran too long and was unable to find the next cycle position a . Motor failure during a regeneration a . Check motor connections then press next and regen buttons for 3 seconds to resynchronize software with piston positi...

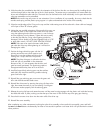

Page 16: Service Instructions:

Release locking tabs from each side to remove back plate. 16 transfer cap assemblies service instructions 1 . The backplate of the control valve must first be removed to allow access to the transfer cap assembly . 2 . Hold slight downward pressure on the top left corner of the backplate while using ...

Page 17

17 14 . With the outlet disc assembled to the shaft, the orientation of the shaft to inlet disc can be assured by installing the set with the through hole on the outlet disc at the 6 o’clock position . The easiest way to reassemble is to remove both disc drives and assemble the outlet side first . T...

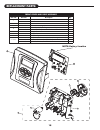

Page 18: Replacement Parts:

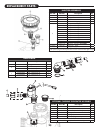

Replacement parts: 18 4 1 2 3 5 6 7 front cover and drive assembly item no. Part no. Description qty. 1 cv3837-01xb totalcare cover 1 cv3837-01 caresoft pro cover 1 2 cv3107-1 motor 1 3 cv3106-1 drive bracket & spring clip 1 4 cv4050wb pc board (used on chlorine generator models) 1 cv4062wx pc board...

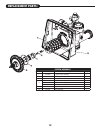

Page 19: Replacement Parts:

19 replacement parts: 4 2 3 5 1 14 piston assembly item no. Part no. Description qty. 1 cv3005 1” spacer stack assembly 1 2 cv3004 drive cap assembly 1 3 cv3135 o-ring 228 1 4 cv3011 1” piston assembly downflow 1 cv3011-01 1” piston assembly upflow 1 cv3407 1 .25” piston assembly downflow 1 5 cv3174...

Page 20: Replacement Parts:

20 replacement parts: see pages 22-23.

Page 21: Replacement Parts:

21 replacement parts: twin transfer item no. Part no. Description qty. 1 cv3470 screw, bhc 1/4-20 x 1 ss 12 2 cv3724 washer, flat ss 1/4 12 3 cv4005-01 t1 transfer cap assembly 1 4 cv4029 o-ring 236 2 5 cv4015 t1 transfer spring 2 6 cv4014 t1 transfer spring support 2 7 cv4036 t1 rotor disk assembly...

Page 22: Replacement Parts:

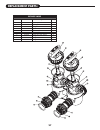

1 2 3 6 4 5 22 injector assemblies item no. Part no. Description qty. 1 cv3176 injector cap 1 2 cv3152 o-ring 135 1 3 cv3177-01 injector screen 1 4 cv3010-1z injector assembly plug 1 5 cv3010-1a a injector assembly, black 1 cv3010-1b b injector assembly, brown cv3010-1c c injector assembly, violet c...

Page 23: Replacement Parts:

Drain line assembly 3/4” item no. Part no. Description qty. 1 ch4615 elbow locking clip 1 2 cpkp10ts8-bulk optional insert, 5/8” tube 1 3 cv3192 optional nut, 3/4” drain elbow 1 4 cv3158-02 drain elbow, 3/4” npt with o-ring 1 5 cv3163 o-ring 019 1 6 cv3159-01 dlfc retainer assembly 1 7 cv3162-007 0 ...

Page 24: Replacement Parts:

24 water meter & meter plug item no. Part no. Description qty. 1 cv3151 nut, 1” qc 1 2 cv3003 meter assembly, includes items 3 & 4 1 3 cv3118-01 turbine assembly 1 4 cv3105 o-ring 215 1 5 cv3003-01 meter plug assembly 1 replacement parts:.

Page 25: Replacement Parts:

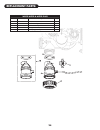

Replacement parts: 1 2 3 4 5 6 7 8 10 2 3 4 5 6 1 9 11 brine tank assembly item no. Part no. Description qty. 1 cg2191-76 brine tank cover, injection molded watercare 1 cg2180 brine tank cover, standard 1 2 ch1095-01 optional 18” diameter salt grid 1 ch1080 optional 24” diameter salt grid 1 3 cg2183...

Page 26: Replacement Parts:

26 replacement parts: although no tools are necessary to assemble or disassemble the valve, the service wrench, (shown in various positions on the valve) is available to aid in assembly or disassembly . Service wrench - cv3193-02 in/out head (for tank b) item no. Part no. Description qty. Cd1400 119...

Page 27: Replacement Parts:

Replacement parts: bypass valve item no. Part no. Description qty. 1 cv3151 nut, 1” quick connect 2 2 cv3150 split ring 2 3 cv3105 o-ring 215 2 4 cv3145 bypass rotor, 1” 2 5 cv3146 bypass cap 2 6 cv3147 bypass handle 2 7 cv3148 bypass rotor seal retainer 2 8 cv3152 o-ring 135 2 9 cv3155 o-ring 112 2...

Page 28

28 installation fitting assemblies: interconnect fitting assembly (up to 10” tanks) item no. Part no. Description qty. Cv4017-01 interconnect kit for tanks up to 10” 1 1 cv3151 nut, 1” qc 4 2 cv3150 split ring 4 3 cv3105 o-ring 215 4 4 cv4017 interconnect fitting 2 interconnect fitting assembly (12”...

Page 29

1” pvc male npt elbow item no. Part no. Description qty. Cv3007 1” pvc male npt elbow assembly 2 1 cv3151 nut, 1” quick connect 2 2 cv3150 split ring 2 3 cv3105 o-ring 215 2 4 cv3149 fitting 2 3/4” & 1” pvc solvent elbow item no. Part no. Description qty. Cv3007-01 3/4” & 1” pvc solvent elbow assemb...

Page 30

30 1-1/4” & 1-1/2” pvc solvent item no. Part no. Description qty. Cv3007-07 1-1/4” & 1-1/2” pvc solvent assembly 2 1 cv3151 nut, 1” quick connect 2 2 cv3150 split ring 2 3 cv3105 o-ring 215 2 4 cv3352 fitting 2 1-1/4” & 1-1/2” brass sweat item no. Part no. Description qty. Cv3007-09 1-1/4 & 1-1/2” b...

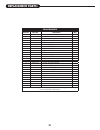

Page 31

Totalcare twin specifications: 31 cycle times (in minutes) 1 all totalcare water conditioners are pre-factory set at medium salting . Note: influent waters must be at least 3 gpg hardness and 80 tds . A calcite or corosex unit may be needed for correct operation . 2 combined iron and manganese remov...

Page 32

32 caresoft elite and caresoft pro twin specifications: 1 all water softeners are factory preset at medium salting . Note: influent waters must be at least 3 gpg hardness and 80 tds . A calcite or corosex unit may be needed for correct operation . Capacity will be reduced by the gallons used during ...

Page 33

33 watercare ® water conditioner limited warranty congratulations. You have purchased one of the finest water treatment systems available. In the unlikely event of a problem due to defects in material and workmanship, water-right ® proudly warrants our watercare water conditioners to the original ow...

Page 34: Quick Reference Guide:

34 manual regeneration note: for softeners, if brine tank does not contain salt, fill with salt and wait at least two hours before regeneration . If you need to initiate a manual regeneration immediately, press and hold regen until valve motor starts (typically 3 seconds) . Error if the display togg...

Page 35

35 adjust hardness, days between regeneration, time of regeneration and alarm buzzer for initial set-up or to make adjustments, please complete the following steps . 1 . Accessed by pressing next and + button simultaneously 2 . Adjust hardness using + and — buttons 3 . Press next 4 . Adjust days bet...

Page 36

© 2014 watercare all rights reserved. Lit-wc tw man envink 9/14 250 1900 prospect court • appleton, wi 54914 phone: 920-739-9401 • fax: 920-739-9406.