- DL manuals

- WaterCare

- Water Dispenser

- UCS-1044

- Installation Instructions & Owner's Manual

WaterCare UCS-1044 Installation Instructions & Owner's Manual

Summary of UCS-1044

Page 1

For models: • ucs-844 • ucs-948 • ucs-1044 • ucs-1054 • ucs-1248 • ucs-1354 caresoft series ® metered water softeners.

Page 2: Table of Contents

Your caresoft pro series water conditioners are precision built, high quality products. These units will deliver conditioned water for many years to come, when installed and operated properly. Please study this manual carefully and understand the cautions and notes before installing. This manual sho...

Page 3

3 preinstallation instructions for dealers: the manufacturer has preset the water treatment unit’s sequence of cycles, cycle times, salt dose, exchange capacity and salt dose refill time. The dealer should read this page and guide the installer regarding hardness, day override, time of regeneration,...

Page 4: Bypass Valve:

4 the bypass valve is typically used to isolate the control valve from the plumbing system’s water pressure in order to perform control valve repairs or maintenance. The 1” full flow bypass valve incorporates four positions, including a diagnostic position that allows a service technician to have pr...

Page 5: Installation:

5 general installation & service warnings the control valve, fittings and/or bypass are designed to accommodate minor plumbing misalignments. There is a small amount of “give” to properly connect the piping, but the water softener is not designed to support the weight of the plumbing. Do not use vas...

Page 6

6 7. Installing ground: to maintain an electrical ground in metal plumbing of a home’s cold water piping (such as a copper plumbing system), install a ground clamp or jumper wiring. Note: if replacing an existing softener, also replace the ground clamps/wire. If removing a softener, replace the pipi...

Page 7: Programming Procedures:

7 1. Set time of day: programming procedures: time of day should only need to be set after extended power outages or when daylight saving time begins or ends. If an extended power outage occurs, the time of day will flash on and off indicating that the time should be reset. Step 1 – press clock . St...

Page 8

8 5 6 step 5 – regeneration minutes: set the minutes using + or — buttons. Press next to exit installer programming. Press regen if you need to return to the previous step. To initiate an immediate manual regeneration, press and hold the regen button for three seconds. The system will begin to regen...

Page 9

1. General operation: when the system is operating, one of three displays may be shown. Pressing next will alternate between the displays. One of the displays is always the current time of day. The second display shows the current treated water flow rate through the system in gallons per minute. The...

Page 10

5. Error message: if the word “error” and a number are alternately flashing on the display record the number and contact the dealer for help. This indicates that the control valve was not able to function properly. 6. Brine tank maintenance and salt: refill the brine tank as necessary, making sure a...

Page 11: Start-Up Instructions:

11 flushing of system: to flush the system of any debris and air after installation is complete, please perform the following steps: 1. Rotate bypass handles to the bypass mode (see fig. 2 of page 4). 2. Turn on inlet water and check for leaks in the newly installed plumbing. 3. Fully open a cold wa...

Page 12

12 8. Sanitizing of unit upon installation and after service: at this time, it is advised to sanitize the softener: 1. Open brine tank and remove brine well cover. 2. Pour 1 oz. Of household bleach into the softener brine well. 3. Replace brine well cover. Note: avoid pouring bleach directly onto th...

Page 13: Troubleshooting Guide:

13 1. No display on pc board a. No power at electric outlet a. Repair outlet or use working outlet b. Control valve power adapter not plugged into outlet or power cord end not connected to pc board connection b. Plug power adapter into outlet or connect power cord end to pc board connection c. Impro...

Page 14: Troubleshooting Guide

14 7. Control valve does not regenerate automatically but does when the correct button(s) is depressed and held. For timeclock valves the buttons are ▲ & ▼ . For all other valves the button is regen. A. Bypass valve in bypass position a. Turn bypass handles to place bypass in service position b. Met...

Page 15

15 12. Control valve fails to draw in regenerant a. Injector is plugged a. Remove injector and clean or replace b. Faulty regenerant piston b. Replace regenerant piston c. Regenerant line connection leak c. Inspect regenerant line for air leak d. Drain line restriction or debris cause excess back pr...

Page 16: Troubleshooting Guide

16 16. E3, err – 1003, err – 103 = control valve motor ran too long and was unable to find the next cycle position a. Motor failure during a regeneration a. Check motor connections then press next and regen buttons for 3 seconds to resynchronize software with piston position or disconnect power supp...

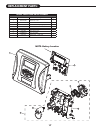

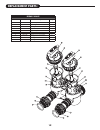

Page 17: Replacement Parts:

17 front cover and drive assembly item no. Part no. Description qty. 1 cv3837-01 caresoft ® cover 1 2 cv3107-1 motor 1 3 cv3106-1 drive bracket & spring clip 1 4 cv3851wn pc board 1 5 cv3110 drive gear, 12 x 36 3 6 cv3109 drive gear cover 1 7 cv3002cc drive assembly - cv3186 transformer, 110v-12v 1 ...

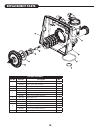

Page 18: Replacement Parts:

18 piston assembly item no. Part no. Description qty. 1 cv3005 1” spacer stack assembly 1 cv3430 1.25” spacer stack assembly 1 2 cv3004 drive cap assembly 1 3 cv3135 o-ring 228 1 4 cv3011 1” piston assembly downflow 1 cv3011-01 1” piston assembly upflow 1 cv3407 1.25” piston assembly downflow 1 5 cv...

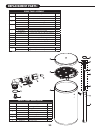

Page 19: Replacement Parts:

19 bypass valve item no. Part no. Description qty. 1 cv3151 nut, 1” quick connect 2 2 cv3150 split ring 2 3 cv3105 o-ring 215 2 4 cv3145 bypass rotor, 1” 2 5 cv3146 bypass cap 2 6 cv3147 bypass handle 2 7 cv3148 bypass rotor seal retainer 2 8 cv3152 o-ring 135 2 9 cv3155 o-ring 112 2 10 cv3156 o-rin...

Page 20: Replacement Parts:

20 injector assemblies item no. Part no. Description qty. 1 cv3176 injector cap 1 2 cv3152 o-ring 135 1 3 cv3177-01 injector screen 1 4 cv3010-1z injector assembly plug 1 5 cv3010-1a a injector assembly, black 1 cv3010-1b b injector assembly, brown cv3010-1c c injector assembly, violet cv3010-1d d i...

Page 21: Replacement Parts:

21 drain line assembly 3/4” item no. Part no. Description qty. 1 ch4615 elbow locking clip 1 2 cpkp10ts8-bulk optional insert, 5/8” tube 1 3 cv3192 optional nut, 3/4” drain elbow 1 4 cv3158-02 drain elbow, 3/4” npt with o-ring 1 5 cv3163 o-ring 019 1 6 cv3159-01 dlfc retainer assembly 1 7 cv3162-007...

Page 22: Replacement Parts:

22 water meter & meter plug item no. Part no. Description qty. 1 cv3151 nut, 1” qc 1 2 cv3003 meter assembly, includes items 3 & 4 1 3 cv3118-01 turbine assembly 1 4 cv3105 o-ring 215 1 5 cv3003-01 meter plug assembly 1 6 cv3013 optional mixing valve 1 although no tools are necessary to assemble or ...

Page 23: Replacement Parts:

23 2 3 4 5 6 7 8 10 1 9 11 safety float brine elbow item no. Part no. Description qty. 1 ch4655 474 .5 gpm flow control 1 2 cv3163 o-ring 019 1 3 ch4613 3/8” elbow cap 1 ch4612 1/2” elbow cap 1 4 ch4615 elbow locking clip 1 5 cjcpg-5pblk 3/8” compression nut 1 cjcpg-8pblk 1/2” compression nut 1 6 fp...

Page 24

24 installation fitting assemblies: 1” pvc male npt elbow item no. Part no. Description qty. Cv3007 1” pvc male npt elbow assembly 2 1 cv3151 nut, 1” quick connect 2 2 cv3150 split ring 2 3 cv3105 o-ring 215 2 4 cv3149 fitting 2 3/4” & 1” pvc solvent elbow item no. Part no. Description qty. Cv3007-0...

Page 25

25 1-1/4” & 1-1/2” pvc solvent item no. Part no. Description qty. Cv3007-07 1-1/4” & 1-1/2” pvc solvent assembly 2 1 cv3151 nut, 1” quick connect 2 2 cv3150 split ring 2 3 cv3105 o-ring 215 2 4 cv3352 fitting 2 1-1/4” & 1-1/2” brass sweat item no. Part no. Description qty. Cv3007-09 1-1/4 & 1-1/2” b...

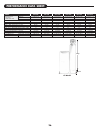

Page 26: Performance Data Sheet:

26 performance data sheet: model ucs-844 ucs-948 ucs-1044 ucs-1054 ucs-1248 ucs-1354 minimum 13,000 @ 3.4 18,000 @ 4.5 18,000 @ 4.5 27,500 @ 7.0 36,000 @ 9.0 45,000 @ 11.5 medium 16,500 @ 6.0 23,000 @ 9.0 23,000 @ 9.0 36,000 @ 15.0 46,000 @ 18.0 53,000 @ 18.0 maximum 18,500 @ 8.0 28,000 @ 15.0 28,00...

Page 27

27 watercare ® water conditioner limited warranty congratulations. You have purchased one of the fi nest water treatment systems available. In the unlikely event of a problem due to defects in material and workmanship, water-right ® proudly warrants our watercare water conditioners to the original o...

Page 28: Quick Reference Guide:

Manual regeneration note: for softeners, if brine tank does not contain salt, fill with salt and wait at least two hours before regeneration. If you need to initiate a manual regeneration, either immediately, or the same night at the preprogrammed time for regeneration (typically 2:00 am), complete ...