- DL manuals

- WaterFurnace

- Heat Pump

- Envision NSW018 series

- Installation information

WaterFurnace Envision NSW018 series Installation information

Summary of Envision NSW018 series

Page 1

Im1006wn 08/13 installation information water piping connections electrical data startup procedures preventive maintenance ns w ins tallation manual geothermal hydronic heat pump 1.5 to 6 tons.

Page 3: Table of Contents

Nsw installation manual table of contents model nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 general installation information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4: Model Nomenclature

4 nsw installation manual model nomenclature all envision series product is safety listed under ul1995 thru etl and performance listed with ahri in accordance with standard 13256-1. The envision series is also energy star ® rated. N s w 050 * 1 0 r c 3 4-6 7 8 9 10 11 model n – envision hydronic hea...

Page 5

5 nsw installation manual safety considerations installing and servicing air conditioning and heating equipment can be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should install, repair or service heating and air conditioning equipment. Wh...

Page 6: Water Quality

6 nsw installation manual general nsw water-to-water heat pumps may be successfully applied in a wide range of residential and light commercial applications. It is the responsibility of the system designer and installing contractor to ensure that acceptable water quality is present and that all appl...

Page 7: Field Connected Water Piping

7 nsw installation manual to-water heat exchanger (see pressure drop table for water flow and pressure drop information). Normally about 3 gpm flow rate per ton of cooling capacity (2.25 gpm per ton minimum) is needed. Both source as well as load fluid piping must be at least as large as the unit co...

Page 8: Potable Water Systems

8 nsw installation manual field connected water piping cont. Earth coupled systems with flow center once piping is completed between the unit, flow center and the earth loop, final purging and charging of the loop is needed. A flush cart (at least a 1.5 hp or 1.12 kw pump) is needed to achieve adequ...

Page 9: Potable Water Systems Cont.

9 nsw installation manual notes: 1) unions and valves must be installed so that acid flushing of the heat exchanger is possible. 2) route thermistor wires to nsw. Remove yellow thermistor wires on tb 3 and 4 from control box and connect thermistor wires from geothermal storage tank. Set the pump sam...

Page 10: Hydronic Section

10 nsw installation manual hydronic section general guidelines are shown below for component selection and design/installation criteria for the piping system. Local codes supersede any recommendations in this manual. Shut off/flow regulation valves use full port ball valves or gate valves for compon...

Page 11: Hydronic Section Cont.

11 nsw installation manual hydronic section cont. Synergy3d thermostat open the screw 2 turns only in the end of the pump motor (if grundfos ® pumps are used) to allow trapped air to be discharged and to ensure the motor housing has been flooded. Route thermistor wires to nsw. Remove yellow thermist...

Page 12: Accessories and Options

12 nsw installation manual accessories and options earth loop pump kit (field installed) a specially designed one or two-pump module provides all liquid fl ow, fi ll and connection requirements for independent single unit systems (230/60/1 only). The one-pump module is capable of 20 feet of head at 16...

Page 13

13 nsw installation manual 30° 30° to geo 59˝ dip tube w/1˝ x 3˝ nipple approx. 1˝ t & p valve from geo 1˝ x 3˝ nipple primary anode 39˝ - 80 gallon 42˝ - 119 gallon 3/4˝ cold inlet 52˝ dip tube 3/4˝ hot outlet w/14˝ secondary anode height optional “to geo” connection shipped with 1-1/2˝ pipe plug i...

Page 14: Electrical Data

14 nsw installation manual nsw control box load pump fuse block transformer run capacitor (single phase only) ground lug load pump relay terminal board power block terminal power strip optional intellistart compressor contactor power block intellistart only source pump fuse block source pump relay r...

Page 15: Electrical Data Cont.

15 nsw installation manual electrical data cont. 208 volt operation all 208-230 volt units are factory wired for 230 volt operation. To convert the unit from a 230v unit to a 208v unit follow these steps: 1. Remove the blue transformer wire from terminal l2 on the compressor contactor and secure the...

Page 16: Wiring Schematics

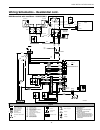

16 nsw installation manual wiring schematics for all nsw 208/230 volt single-phase units, the circulator wiring is as shown in the illustrations below. The internal relay and fusing allow for external pumps no larger than .5 horsepower. The external loop pump connections mentioned in this manual inc...

Page 17: Wiring Schematics Cont.

17 nsw installation manual wiring schematics cont. Transformer low v o lt a g e ter m in al s t r ip fuse blocks lo w v o lt a g e the r m o st at conne c t io ns p2 shut down c not used c p1 g w o r c y1 y2 lo control box 13p003b relay (field supplied) sl1 in sl1 out control box compressor contacto...

Page 18

18 nsw installation manual wiring schematics - residential nsw heating only - 208-230/60/1 transformer note 1 red 208v black com compressor unit power supply cc t1 l1 t2 tan brown blue g c r s black red blue factory low voltage wiring legend switch - high pressure switch - low pressure relay coil fi...

Page 19

19 nsw installation manual wiring schematics - residential cont. Nsw reversible with intellistart - 208-230/60/1 transformer note 1 red 208 v compressor unit power supply cc t1 l1 t2 brown g c r s blue 24v microprocessor control test pin hp hp cc cg hi lo c lp lp r cc cg hi lo c lp lp r hp lp black/...

Page 20: External Control

20 nsw installation manual y1 = compressor call r = 24vac c g w1 l x1 y2 o y1 w2 s x2 r control box typical aquastat secondary unit (sl=1) aquastat wiring for dedicated heating or cooling unit y1 = compressor call o = reversing valve call r = 24vac note: jumper wire must be moved to terminals 5 & 6....

Page 21: External Control Cont.

21 nsw installation manual staging with primary/secondary mode staging is only possible with dedicated heating or cooling units. Reversible units cannot be staged. Staging can be accomplished with primary/secondary modes or by using an aquastat. The first stage must be setup as a primary unit. All o...

Page 22

22 nsw installation manual converting to a dedicated cooling unit procedure to convert a heating only unit to a cooling only unit all non-reversible nsw units are built at the factory as dedicated heating units. Follow the procedures below to make the unit a dedicated cooling unit. 1. Shut off all p...

Page 23: Unit Startup

23 nsw installation manual unit startup before powering unit check the following: • high voltage wiring is correct and matches the nameplate. • fuses, breakers and wire size are correct. • piping is completed and water system has been cleaned and flushed. • air is purged from the closed loop system....

Page 24

24 nsw installation manual standard board - control features anti short cycle time the anti short cycle time consists of a three minute minimum “off” time plus a randomly chosen 0-2 minute additional “off” delay. The random delay is chosen by the control after each compressor shut down. The 3-5 minu...

Page 25

25 nsw installation manual fault. If the fault activity ceases while the system is inactive, the fault code is cleared from the display and operation is permitted. High temperature compressor operation will be disabled when the control senses an entering load side water temperature of 130° f regardl...

Page 26

26 nsw installation manual the control panel allows you to access the service menu on the unit. The control panel has three 7-segment led screens that display the: • water temperature • configuration menu there are six (6) led indicators that indicate when the secondary output is active or the unit ...

Page 27

27 nsw installation manual standard control - panel confi guration cont. Remote aquastat secondary mode (y1) in secondary mode the compressor output is determined by an external aquastat. The compressor shall engage 10 seconds after the y1 call has been received. The compressor shall de-activate 10 s...

Page 28: Reference Calculations

28 nsw installation manual reference calculations legend and notes heating calculations: lwt = ewt - he gpm x c* cooling calculations: lwt = ewt + hr gpm x c* he = c* x gpm x (ewt - lwt) hr = c* x gpm x (lwt - ewt) note: * c = 500 for pure water, 485 for brine. Abbreviations and definitions elt = en...

Page 29

29 nsw installation manual ahri/iso 13256-2 performance ratings english (ip) units note: all ratings based upon 208v operation. Model capacity modulation flow rate water loop heat pump ground water heat pump cooling 86°f source 53.6°f load heating 68°f source 104°f load cooling 59°f source 53.6°f lo...

Page 30: Operating Limits

30 nsw installation manual operating limits heating with high source temperatures heating water with a water to water unit using high source temperatures can lead to operating conditions that fall outside of the system operating range. The condition occurs when the loop (source) temperature exceeds ...

Page 31: Flow Rates

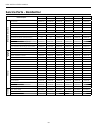

31 nsw installation manual load flow rates model minimum load flow rate normal load flow rate maximum flow rate 018 3.0 5.0 7.0 025 4.0 7.0 9.0 040 5.0 10.0 12.0 050 8.0 15.0 17.0 060 9.0 18.0 20.0 075 10.0 19.0 21.0 5/15/09 flow rates source flow rates model minimum open loop flow rate minimum clos...

Page 32: Operating Parameters

32 nsw installation manual operating parameters heating mode entering load temp (°f) entering source temp (°f) suction pressure (psig) discharge pressure (psig) superheat (°f) subcooling (°f) 60 20 52-67 195-227 8-16 5-15 30 67-82 208-235 7-14 6-14 50 95-113 216-245 7-14 6-12 70 124-144 225-255 8-19...

Page 33: Antifreeze Correction

33 nsw installation manual antifreeze correction catalog performance can be corrected for antifreeze use. Please use the following table and note the example given. Antifreeze correction example antifreeze solution is propylene glycol 20% by weight for the source and methanol 10% for the load. Deter...

Page 34

34 nsw installation manual troubleshooting guideline for refrigerant circuit the chart below will assist in determining if measurements taken at the unit are within factory specifications and aid in accurate diagnosis (symptom) and repair. The chart is general in nature and represents whether a symp...

Page 35: Heating Cycle Analysis

35 nsw installation manual heating cycle analysis acqbw]\ 2waqvo`us 1][^`saa]` @d a]c`qs 1]of 42 mmmmmm>a7+mmmmmma/b4 mmmmmm4 mmmmmm>a7+mmmmmma/b4 mmmmmm4 mmmmmm4:w_cwr:w\s c\wb/[^2`oe :w\sd]zbous :]]^( =^s\ 1z]asr acpq]]zw\u ac^s`vsob 2]\]bobboqv`st`wus`o\buocusac\zsaao^`]pzs[waaca^sqbsr 3\bs`...

Page 36

36 nsw installation manual check one start up/check-out for new installation t troubleshooting problem:___________________________________ t 1. Flow rate in gpm (source side heat exchanger) water in pressure: a.______ psi water out pressure: b.______ psi pressure drop = a - b c.______ psi convert pr...

Page 37: Troubleshooting

37 nsw installation manual troubleshooting should a major problem develop, refer to the following information for possible causes and corrective steps: compressor won’t run 1. The fuse may be blown or the circuit breaker is open. Check electrical circuits and motor windings for shorts or grounds. In...

Page 38: Troubleshooting Cont.

38 nsw installation manual troubleshooting cont. Display failure diagnostic dc freeze detection thermistor is closed (shorted) replace the freeze detection thermistor (clip-on thermistor) do freeze detection thermistor is open verify that the freeze detection thermistor is secured properly in the bo...

Page 39: Preventive Maintenance

39 nsw installation manual preventive maintenance 1. Keep all air out of the water lines. An open loop system should be checked to ensure that the well head is not allowing air to infiltrate the water line. Lines should always be airtight. 2. Keep the system under pressure at all times. In open loop...

Page 40: Service Parts - Residential

40 nsw installation manual service parts - residential part description 018 025 040 050 060 075 208-230/60/1 208-230/60/1 208-230/60/1 208-230/60/1 208-230/60/1 208-230/60/1 r efriger ation c omponents compressor 34p657-01 34p568-05 34p621-01 34p580-01 34p616-01 34p614-01 compressor capacitor 16p002...

Page 41: Notes

41 nsw installation manual notes.

Page 42: Revision Guide

42 nsw installation manual revision guide pages: description: date: by: 4 updated nomenclature to new format 09 aug 2013 ds 14 updated electrical data 09 aug 2013 ds 31 updated compressor resistances 09 aug 2013 ds 4 updated nsw018 revision level 09 may 2013 ds 12 updated load side pump kits 09 may ...

Page 44

Manufactured by waterfurnace international, inc. 9000 conservation way fort wayne, in 46809 www.Waterfurnace.Com ©2013 waterfurnace international, inc., 9000 conservation way, fort wayne, in 46809-9794. Waterfurnace has a policy of continual product research and development and reserves the right to...