185df backwashing filters carbon—taste and odor(acf) multimedia (mmf) nextsand (ultramf) neutralizer (nnf) owners manual revision # 0 revision date feb 28,2015 54825 followthe installation instructions carefully. Failure to install the unit properly voids the warranty. Before you begin installation,...

Safety guide check and comply with your provincial / state and local codes. You must follow these guidelines. Use care when handling the filter tank. Do not turn upside down, drop, drag or set on sharp protrusions. The system works on 12 volt-60 hz electri- cal power only. Be sure to use only the in...

Proper installation this water filter system must be properly installed and located in accordance with the installation instructions before it is used. Do not install or store where it will not be exposed to temperatures below freezing or exposed to any type of weather. Water freezing in the system ...

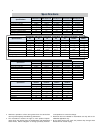

Specifications continuous operation at flow rates greater than the service flow rate may affect capacity and efficiency performance. The manufacturer reserves the right to make product improve- ments which may deviate from the specifications and descriptions stated herein, without obligation to chan...

Before starting installation tools, pipe, and fittings, other materials pliers screwdriver teflon tape razor knife two adjustable wrenches additional tools may be required if modifi- cation to home plumbing is required. Plastic inlet and outlet fittings are included with the filter. To maintain full...

Place the filter tank as close as possible to the pressure tank (well system) or water meter (city water). Place the filter tank as close as possible to a floor drain, or other acceptable drain point (laundry tub, sump, standpipe, etc.). Connect the filter to the main water supply pipe before the wa...

Sizing requirements water pressure the water system must have a pump big enough to deliver the recommended backwash rate with a minimum pressure at the inlet of the filter of 30 psi. If the existing system can- not do this, it must be upgraded to do so. Whenever possible, the water system should be ...

1. If your hot water tank is electric, turn off the power to it to avoid damage to the element in the tank. 2. If you have a private well, turn the power off to the pump and then shut off the main wa- ter shut off valve. If you have municipal water, simply shut off the main valve. Go to the faucet, ...

Filter installation 9.

System start-up 1. Plug the valve into an approved power source. 2. When power is supplied to the control, the screen will display “initializing wait please” while it finds the service position. 3. Start an immediate manual regeneration. The valve will immediately start moving to the backwash positi...

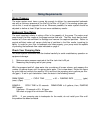

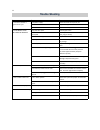

The table below can be used to help deter- mine the frequency of regeneration for multi- media and taste & odour filters. Use this ta- ble as a guide since individual circumstances will require more or less frequent regenera- tions. This can be adjusted by the home owner to suite their individual ne...

Control operation during a power failure in the event of a power failure, the valve will keep track of the time and day for 48 hours. The programmed settings are stored in a non-volatile memory and will not be lost during a power failure. If power fails while the unit is in regeneration, the valve w...

Automatic raw water bypass during regeneration the regeneration cycle can last 30 minutes after which filtered water service will be re- stored. During regeneration, un-filtered water is automatically bypassed for use in the household. Hot water should be used as little as possible during this time ...

Maintenance care of your system to retain the attractive appearance of your new water filter, clean occasionally with mild soap solution. Do not use abrasive cleaners, ammonia or solvents. Never subject your sof- tener to freezing or to temperatures above 100°f. Maintenance of your new water filter ...

Loading the media pak place the distributor tube back down the center of the tank. Note: the top of this tube should be plugged with a rag or cork to prevent media from entering. Pour the bag of coarse gravel into the tank, and then pour the bag of fine gravel into the tank. It is important that the...

Replacing drain line flow control (dlfc) 1. Remove the red clip that secures the drain line elbow. 2. Remove the blfc washer from the elbow fitting. 3. Reassemble using the reverse procedure. 16.

A a a b d f e a c replacement part number part description dwg # quantity 60010020 3/4" npt elbow a 2 60010019 1" npt straight a 2 60010023 3/4" npt straight a 2 60010079 valve coupling inlet b 1 60010101 valve coupling outlet (meter side) c 1 60010025 plastic secure clip d 2 60010046 bypass ss clip...

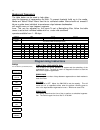

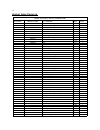

Valve repair parts list replacement part number part description replacement part number part description 60010127 injector set #0000 black 60010129 85he upflow piston assembly 60010126 injecttor set #000 grey 60010171 85he downflow piston assembly 60010035 injector set #00 violet 60010130 85he seal...

185he control valve (downflow) replacement part number mfg part number part description dwg # quantity 5056087 screw-m5x12(hexagon) a01 3 5056088 screw-m5x16(hexagon with washer) a02 2 5056047 end plug retainer a03 1 5031016 bnt85he piston rod a04 1 5056097 piston pin a05 1 5031015 bnt85he quad ring...

Power head exploded view 20

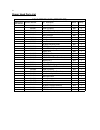

185he power head (downflow) replacement part number mfg part number part description dwg # quantity 5056084 screw-st3.5x13 b01 10 5010037 screw-st2.9x10 b02 9 13000416 screw-st3.5x25 b03 1 5031007 bnt85he piston rod guide plate b04 1 5056510 motor-12v/2rpm b05 1 5030014 motor power cable 1 11700005 ...

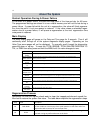

Trouble shooting issue possible cause possible solution 1. No power supply. Check electrical service, fuse, etc. 2. Defective circuit board. Replace faulty parts. 3. Power failure. Reset time of day. 1. By‐pass valve open. Close by‐pass valve. 2. Electrical service to unit has been interrupted assur...

Warranty watergroup warrants that your new water filter is built of quality material and workmanship. When properly installed and maintained, it will give years of trouble free service. Seven year complete parts guarantee watergroup will replace any part which fails within 84 months from date of man...