- DL manuals

- Waterline

- Ventilation Hood

- FW100.2BL

- User Manual

Waterline FW100.2BL User Manual

User Manual for your

FW60.2BL/SS 60 cm cooker hood

FW70.2BL/SS 70 cm cooker hood

FW90.3BL/SS 90 cm cooker hood

FW100.2BL/SS 100 cm cooker hood

NOTE

:

This User Instruction Manual contains important

information, including safety & installation points, which will

enable you to get the most out of your appliance. Please keep it

in a safe place so that it is easily available for future reference; for

you or any person not familiar with the operation of the appliance.

DD 30/10/09

Summary of FW100.2BL

Page 1

User manual for your fw60.2bl/ss 60 cm cooker hood fw70.2bl/ss 70 cm cooker hood fw90.3bl/ss 90 cm cooker hood fw100.2bl/ss 100 cm cooker hood note : this user instruction manual contains important information, including safety & installation points, which will enable you to get the most out of your...

Page 2

3 contents page environmental note 4 important safety information 5 – 7 specifications of your cooker hood 8 – 12 fw60.2bl/ss 8 fw70.2bl/ss 9 fw90.3bl/ss 10 fw100.2bl/ss 11 optional extras (all models) 11 - 12 using your cooker hood 12 - 13 before first use 12 to use your cooker hood 12 - 13 cleanin...

Page 3

Environmental note note: before discarding an old appliance, switch off and disconnect it from the power supply. Cut off and render any plug useless. Cut the cable off directly behind the appliance to prevent misuse. This should be undertaken by a competent person. Conformity to w.E.E.E. Directive 4.

Page 4

Important safety information your safety is of the utmost importance to us. Please make sure that you read this instruction booklet before attempting to install or use the appliance. If you are unsure of any of the information contained in this booklet, please contact the advice line. Important: any...

Page 5

O the edges of the cooker hood are sharp – be mindful of this as you handle your appliance, especially during installation and cleaning. Do not clean in behind the grease filters! O if the room where the cooker hood is to be used contains a fuel burning appliance such as a central heating boiler the...

Page 6

O remember that when in extraction mode, your cooker hood is removing air from your room. Ensure that proper ventilation measures are being observed. O note: your cooker hood is designed to remove cooking odours from the room and not steam. O warning - always ensure that the cooker hood has been dis...

Page 7

Specifications of your cooker hood fw60.2bl/ss product dimensions height: 700* mm – 1080 mm width: 600 mm depth: 500 mm dimensions of chimney section: 170 mm x 221 mm your stainless steel cooker hood is fitted with : o high extraction tangential motor o push button control operation o 3 speeds o 2 m...

Page 8

Fw70.2bl/ss product dimensions height: 700* mm – 1080 mm width: 700 mm depth: 500 mm dimensions of chimney section: 165 mm x 222 mm your stainless steel cooker hood is fitted with : o high extraction tangential motor o push button control operation o 3 speeds o 2 metallic grease filters o 2 lights e...

Page 9

Fw90.3bl/ss product dimensions height: 700* mm – 1080 mm width: 900 mm depth: 500 mm dimensions of chimney section: 170 mm x 221 mm your stainless steel cooker hood is fitted with : o high extraction tangential motor o push button control operation o 3 speeds o 3 metallic grease filters o 2 lights e...

Page 10

Fw100.2bl/ss product dimensions height: 700 mm* – 1080 mm width: 1000 mm depth: 500 mm dimensions of chimney section: 170 mm x 221 mm your stainless steel cooker hood is fitted with : o high extraction tangential motor o push button control operation o 3 speeds o 3 metallic grease filters o 2 lights...

Page 11

O available from the spares department on telephone number (01235) 437244. Using your cooker hood before first use important: this process must be followed before the cooker hood is used for the first time. O you should use a good quality stainless steel cleaner and polish on all of the stainless st...

Page 12

O find the control panel, which is located at the front right of the canopy. O there are several buttons on the control panel, which perform separate functions. Important: ideally you should switch on your hood ten minutes before you start to cook, or at the very least when you begin cooking. You sh...

Page 13

The grease filters o your cooker hood is fitted with grease filters, which help to absorb grease particles and protect your kitchen & furniture from greasy residues. O these metallic filters may become inflammable if you allow them to get saturated with this greasy residue. O to prevent this fire ha...

Page 14

O refit the grease filters once they have dried. O important: let the grease filters dry thoroughly before refitting them in the cooker hood. Changing a light bulb important: before attempting to change a light bulb, you must ensure that you have disconnected the cooker hood from your mains supply. ...

Page 15

O important: defective bulbs should be replaced immediately. O if the lights still do not work, make sure that the lamps are fitted properly into their housings before you call for technical assistance. O refit the grease filters. Fitting the carbon filters (st1 carbon filters) if the appliance is b...

Page 16

O repeat this process for the second carbon filter. You need to place a carbon filter at either end of the motor. O refit the grease filters. O the carbon filters should be replaced every 3 - 6 months or if they show signs of damage. Installation important: before installation and usage read all the...

Page 17

We recommend that the appliance is connected by a qualified electrician, who is a member of the n.I.C.E.I.C. And who will comply with the i.E.E. And local regulations. The wires in the mains lead are coloured in accordance with the following uk code: blue = neutral, brown = live, green/yellow = grou...

Page 18

O select a flat surface for assembling the cooker hood. Cover that surface with a protective covering and place all cooker hood parts and fittings on to it. O rawl plugs are provided to secure the hood to most types of walls and ceilings. However a qualified technician must verify the suitability of...

Page 19

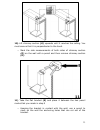

2a) the support screw holes are indicated by figure a in this drawing and the anchoring screw holes are indicated by figure b . 20 3) using a drill bit with a 6 mm diameter, make holes in the wall on the positions that you have marked in step 2. 4) insert rawl plugs into all of the holes that you ha...

Page 20

6) hang the hood onto the support screws. 7) fully tighten the support screws (a) and then screw the anchoring screws (b) through the relevant holes in the cooker hood. Fully tighten the anchoring screws into the wall. 21.

Page 21

Connecting to external ducting 8) connect the coupling to the top of the cooker hood, and then connect a 125 mm ducting hose to the coupling (please note that the ducting hose is not supplied with the appliance). O the other end of the ducting hose should be connected to a discharge outlet that is s...

Page 22

10) lift chimney section (d) upwards until it reaches the ceiling. You must ensure that it is perpendicular to the hood. O mark the side measurements of both sides of chimney section (d) on the wall with a pencil and then remove chimney section (d) . 11) take the flat bracket (e) and place it betwee...

Page 23

12) using a 6 mm drill bit, drill out two holes on the pencil markings that you made in step 11. Insert rawl plugs into the holes and then use a screwdriver to secure the fixing bracket to the wall. O refit chimney section (c) to the hood and fix it onto the hood using the two screws that are suppli...

Page 24

Completing the installation o if you are setting the appliance to recirculation mode, then you should now fit the two carbon filters. See the “fitting the carbon filters” section on page 16 - 17. O the electrical connection must correspond to the electrical requirement noted on the rating plate, whi...

Page 25

Troubleshooting important: if your cooker hood appears not to be operating properly, before contacting the customer care department, please refer to the checklist below. My cooker hood will not start. O check that the hood is connected to the electricity supply o check that the fan speed control is ...

Page 26

Important: if your appliance appears not to be operating correctly, then you should disconnect it from your mains supply and then contact customer care on telephone number (0118) 933 6918. Do not attempt to repair the appliance yourself. Please note that if an engineer is asked to attend whilst the ...

Page 27

28.

Page 28

29 united kingdom 6 bennet road, reading, berkshire rg2 0qx united kingdom customer care (0118) 933 6918.