Waterous 80-P Operation Manual - Figure(S)

F-1031, Section 2416

Page 2 of 23

Warnings, Cautions, and Notes

Warning

A warning alerts you to a procedure, practice or condition that may result in death or long

term injury to personnel or destruction of equipment.

Caution

A caution alerts you to a procedure or condition that may result in serious

damage to equipment or its failure to operate as expected

Note: A note points out important information. Failure to read the note may not result in physical

harm to personnel or equipment. It may waste time and money.

Disclaimer:

These instructions are guidelines only and in no way meant to be definitive. During installation, standard safety precautions and

equipment should be used where appropriate. Because the tools used and the skill/experience of the installer can vary widely, it is impossible to

anticipate all conditions under which this installation is made, or to provide cautions for all possible hazards. Proper installation is the

responsibility of the purchaser. All bolts, setscrews, and belts must be checked prior to start-up AND after the initial operation. Damages due to

poor installation are the responsibility of the installer.

Figure(s)

Figure 1 Manual Auto-sync panel ................................................................................................................ 3

Figure 2 CE 55 G ......................................................................................................................................... 7

Figure 3 Wye Strainer ................................................................................................................................. 10

Figure 4 Wye-strainer installed, with cleanout valve ................................................................................. 10

Figure 5 Clean Strainer .............................................................................................................................. 10

Figure 6 Dirty Strainer ................................................................................................................................ 10

Figure 7 80-SP ........................................................................................................................................... 19

Figure 8 Basic CAFS Schematic ............................................................................................................... 20

Figure 9 Air Schematic w/ Manual Auto-sync ............................................................................................ 21

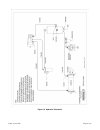

Figure 10 Hydraulic Schematic .................................................................................................................. 22