Waterous CS Series Operation And Maintenance

Waterous Company 125 Hardman Avenue South, South St. Paul, Minnesota 55075 USA (651) 450-5000

Instructions subject to change without notice.

Visit us at www.waterousco.com

Section

2115

Form No.

F-1031

Issue Date

12/14/95

Rev. Date

10/11/04

CS Series Centrifugal

Fire Pumps

Section

2115

Form No.

F-1031

Issue Date

12/14/95

Rev. Date

05/11/12

CS Series Centrifugal

Fire Pumps

Operation and Maintenance

Read through the safety information and

operating instructions carefully before using

your Waterous Fire Pump.

Table of Contents

Safety Information

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Components

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options

3, 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

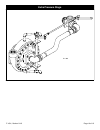

Water Flow Diagram

5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drain Locations

5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Instructions:

Transmission

6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pumping from Water Tank

6

. . . . . . . . . . . . . . . . . . . . . . .

Pumping from Hydrant or in Relay

7

. . . . . . . . . . . . . . . .

Pumping from Draft

8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Extra Pressure Stage (CSH Models)

9, 10

. . . . . . . . . . .

Maintenance:

Corrosion Protection

Optional Zinc Intake Screens

11

. . . . . . . . . . . . . . . .

Optional Zinc Anodes

11

. . . . . . . . . . . . . . . . . . . . . .

Lubrication

12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Packing

12-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vacuum Test

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overheat Protection Manager (OPM)

15

. . . . . . . . . . . . .

Butterfly Valve (BFV)

15

. . . . . . . . . . . . . . . . . . . . . . . . . . .