Waterous Floto-pump IL1330 Operation & Maintenance Manual

Read through the safety and operating

instructions carefully before using your

Waterous Floto- pump.

Table of Contents

Important Information

1

. . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Instructions

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning Decals

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation

5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

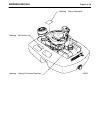

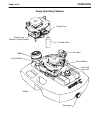

Pump Operating Features

5

. . . . . . . . . . . . . . . . . . . . . . . .

Fuel Mixture

6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting the Engine

6

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stopping the Engine

6

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Compression Release Valve

7

. . . . . . . . . . . . . . . . . . . .

Carburetor Adjustment

8

. . . . . . . . . . . . . . . . . . . . . . . . .

General Operating Hints

9

. . . . . . . . . . . . . . . . . . . . . . . .

Storage

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ordering Repair Parts

9

. . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting

10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

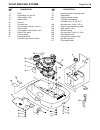

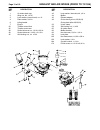

Pump Repair Parts

11

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Float and Fuel System

12

. . . . . . . . . . . . . . . . . . . . . . . .

Exhaust and Air Intake

Prior to 7/21/06

13

. . . . . . . . . . . . . . . . . . . . . . . . . . .

After 7/21/06

14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

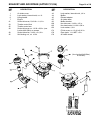

Engine (Starter and Ignition)

16

. . . . . . . . . . . . . . . . . . .

Engine (Carburetor and Power Head)

17

. . . . . . . . . . .

Warranty

18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All content in this instruction is property of the Waterous Company. Instructions subject to change without

Waterous Company 125 Hardman Avenue South, South St. Paul, Minnesota 55075 USA (651) 450-5000

Instructions subject to change without notice.

Visit us at www.waterousco.com

Form No.

F-2210

Issue Date

02/08/94

Rev. Date

10/01/07

Floto-pump

E

Standard and High Pressure Models

Operation & Maintenance