Waterous PB18 Series Operation Instructions Manual

Read through the safety information and

operating instructions carefully before

using your Waterous Fire Pump.

Table of Contents

Safety Instructions

1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning and Operating Decals

4

. . . . . . . . . . . . . . . . . . . . . . .

Preparation Before Operation

5

. . . . . . . . . . . . . . . . . . . . . . . .

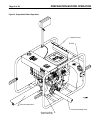

Operation Controls

6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation and Maintenance

7

. . . . . . . . . . . . . . . . . . . . . . . . . .

Starting the Engine

7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Priming Pump

7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating the Pump

8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pumping from Hydrant or Relay

8

. . . . . . . . . . . . . . . . . . . . . . . .

Pumping from Draft

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Maintenance

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Maintenance

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Maintenance

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spark Arresting Muffler

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine and Pump Repair

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Repair

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Repair

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

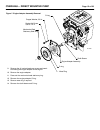

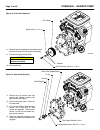

Overhaul Instructions - Direct Mounted Pump

10

. . . . . . . .

Priming Tube Removal

10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Volute Body Removal

10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impeller Removal

11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Seal Removal

11

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Adapter Assembly Removal

12

. . . . . . . . . . . . . . . . . . . .

Overhaul Instructions - Geared Pump

13

. . . . . . . . . . . . . . .

Volute Body Removal

13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impeller Removal

13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Case Cover Removal

14

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Impeller Shaft Assembly

14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Gear Removal

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Case Removal

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Seal Assembly

16

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection

17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impeller Wear

17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Seal

17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Seals

17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ball Bearings, Gears and Needle Bearing

17

. . . . . . . . . . . . . . .

Reassembling and Testing Pump

18

. . . . . . . . . . . . . . . . . . . .

Direct Mounted Pump

18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Geared Pump

18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing

18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting

19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All content in this instruction is property of the Waterous Company. Instructions subject to change without

Waterous Company 125 Hardman Avenue South, South St. Paul, Minnesota 55075 USA (651) 450-5000

Instructions subject to change without notice.

Visit us at www.waterousco.com

Form No.

F-2523

Issue Date

09/04

Rev. Date

05/08/12

PB18 Series

Portable Pumps

Operation, Maintenance

and Overhaul Instructions