- DL manuals

- Waters

- Security Sensors

- 432

- Operator's Manual

Waters 432 Operator's Manual

Summary of 432

Page 1

Waters 432 conductivity detector operator’s guide 34 maple street milford, ma 01757 71500043202, revision a.

Page 2

Notice the information in this document is subject to change without notice and should not be construed as a commitment by waters corporation. Waters corporation assumes no responsibility for any errors that may appear in this document. This document is believed to be complete and accurate at the ti...

Page 3

Note: when you use the instrument, follow generally accepted procedures for quality control and methods development. If you observe a change in the retention of a particular compound, in the resolution between two compounds, or in peak shape, immediately determine the reason for the changes. Until y...

Page 4

Caution: use caution when working with any polymer tubing under pressure: • always wear eye protection when near pressurized polymer tubing. • extinguish all nearby flames. • do not use tefzel tubing that has been severely stressed or kinked. • do not use tefzel tubing with tetrahydrofuran (thf) or ...

Page 5

Precauzione: prestare attenzione durante le operazioni con i tubi di polimero sotto pressione: • indossare sempre occhiali da lavoro protettivi nei pressi di tubi di polimero pressurizzati. • estinguere ogni fonte di ignizione circostante. • non utilizzare tubi tefzel soggetti a sollecitazioni ecces...

Page 7

Caution: the user shall be made aware that if the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired. Attention : l’utilisateur doit être informé que si le matériel est utilisé d’une façon non spécifiée par le fabricant, la prote...

Page 8

Caution: to protect against fire hazard, replace fuses with those of the same type and rating. Attention : remplacez toujours les fusibles par d’autres du même type et de la même puissance afin d’éviter tout risque d’incendie. Vorsicht: zum schutz gegen feuergefahr die sicherungen nur mit sicherunge...

Page 9

Caution: to avoid possible electrical shock, disconnect the power cord before servicing the instrument. Attention : afin d’éviter toute possibilité de commotion électrique, débranchez le cordon d’alimentation de la prise avant d’effectuer la maintenance de l’instrument. Vorsicht: zur vermeidung von ...

Page 10

Commonly used symbols direct current courant continu gleichstrom corrente continua corriente continua alternating current courant alternatif wechselstrom corrente alternata corriente alterna protective conductor terminal borne du conducteur de protection schutzleiteranschluss terminale di conduttore...

Page 11

Frame or chassis terminal borne du cadre ou du châssis rahmen- oder chassisanschluss terminale di struttura o telaio borne de la estructura o del chasis caution or refer to manual attention ou reportez-vous au guide vorsicht, oder lesen sie das handbuch prestare attenzione o fare riferimento alla gu...

Page 12

Caution, risk of electric shock (high voltage) attention, risque de commotion électrique (haute tension) vorsicht, elektroschockgefahr (hochspannung) precauzione, rischio di scossa elettrica (alta tensione) precaución, peligro de descarga eléctrica (alta tensión) caution, risk of needle-stick punctu...

Page 13

Fuse fusible sicherung fusibile fusible electrical power on sous tension netzschalter ein alimentazione elettrica attivata alimentación eléctrica conectada electrical power off hors tension netzschalter aus alimentazione elettrica disattivata alimentación eléctrica desconectada commonly used symbols...

Page 14

432 conductivity detector information intended use the waters ® 432 conductivity detector can be used for in-vitro diagnostic testing to analyze many compounds, including diagnostic indicators and therapeutically monitored compounds. When you develop methods, follow the “protocol for the adoption of...

Page 15

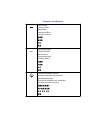

Table of contents 15 preface ....................................................................................... 23 chapter 1 introduction ...................................................................................... 26 chapter 2 installing the detector ....................................

Page 16

Table of contents 16 chapter 3 operating the detector .................................................................... 56 3.1 controls and indicators ......................................................... 56 3.2 startup and shutdown .......................................................... 6...

Page 17

Table of contents 17 appendix a specifications ................................................................................... 87 appendix b spare parts....................................................................................... 90 appendix c ion chromatography methods ..................

Page 18

Table of contents 18 c.2 alkali and alkaline earth cations, ammonium, and amines........................................................................ 103 c.2.1 preparing eluent .................................................... 104 c.2.2 preparing standards ........................................

Page 19

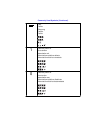

List of figures 19 1-1 waters 432 conductivity detector ................................................. 26 1-2 flow cell schematic ...................................................................... 28 2-1 rear panel .................................................................................

Page 20

List of figures 20 c-2 calibration curves for chloride, fluoride, and bromide ............... 95 c-3 calibration curves for nitrite and nitrate ...................................... 96 c-4 calibration curves for sulfate and phosphate .............................. 96 c-5 100-ml injection .............

Page 21

List of tables 21 1-1 limiting equivalent conductance of ions in water at 25 °c ......... 29 2-1 power cord wire identification ..................................................... 33 2-2 nominal operating voltage...................................................... 34 2-3 i/o signal descriptions ...

Page 22

List of tables 22 a-5 communications ........................................................................... 89 b-1 spare parts ................................................................................... 90 c-1 required instrumentation .......................................................

Page 23

23 preface the waters 432 conductivity detector operator’s guide details the procedures for unpacking, installing, operating, maintaining, and troubleshooting the 432 conductivity detector. It also includes appendixes listing specifications and spare parts and describing validation support. This gui...

Page 24

24 documentation on the web related product information and documentation can be found on the world wide web. Our address is http://www.Waters.Com . Related adobe acrobat reader documentation for detailed information about using adobe ® acrobat ® reader, see the adobe acrobat reader online guide. Th...

Page 25

25 notes notes call out information that is helpful to the operator. For example: note: record your result before you proceed to the next step. Attentions attentions provide information about preventing damage to the system or equipment. For example: cautions cautions provide information essential t...

Page 26

26 1 chapter 1 introduction features the waters ® 432 conductivity detector ( figure 1-1 ) is specifically designed to be integrated into chromatographic systems. The following features contribute to its performance in measuring the conductivity of column eluents: • unique 5-electrode flow cell desi...

Page 27

Introduction 27 1 method of operation this section discusses the method of operation of the 432 detector. Additional descriptive information appears in these sections: • section 2.4.1, i/o signal descriptions • section 3.1, controls and indicators • appendix a, specifications measurement technique t...

Page 28

28 1 figure 1-2 flow cell schematic ion detection theory the conductance of a solution of known concentration can be calculated using the following equation: g = measured conductance of the solution, in siemens (1 s = ohm − 1 ) c = concentration in equivalents per 1000 cm 3 k = length/area of cell (...

Page 29

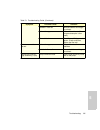

Introduction 29 1 1. Henry h. Bauer et al., eds. “instrumental analysis,” allyn and bacon, boston (1978), p. 115. Reprinted with permission from the publisher. Table 1-1 limiting equivalent conductance of ions in water at 25 °c cations l + anions λ — h + 349.8 oh − 198.6 li + 38.6 f − 55.4 na + 50.1...

Page 30

Selecting the installation site 30 2 chapter 2 installing the detector this chapter guides you through the following steps in preparing the 432 detector for operation in a chromatographic system: • selecting an installation site that satisfies the detector’s power and environmental requirements • un...

Page 31

Installing the detector 31 2 required space the 432 detector requires bench space that measures approximately: • 10 inches (25 cm) high • 14 inches (34 cm) wide • 24 inches (60 cm) deep power requirements the 432 detector requires: • one properly grounded ac voltage outlet. • correct voltage and fus...

Page 32

Ac power connection 32 2 inspection inspect all items. If you find any damage or discrepancy, immediately contact the shipping agent and waters. For more information about the instrument warranty, refer to waters licenses, warranties, and support. If the shipment is complete and undamaged, record th...

Page 33

Installing the detector 33 2 figure 2-1 rear panel the 432 detector can be adapted to operate within two voltage ranges at 50 or 60 hz. Table 2-2 describes these voltage ranges and the fuse value that is appropriate to each. Table 2-1 power cord wire identification wire (usa) wire (international) co...

Page 34

Ac power connection 34 2 required material you need a flat-blade screwdriver to perform this procedure. Procedure to change the operating voltage setting: 1. Remove the power cord from its connector on the rear panel of the controller and pry open the power connector cover with a flat-blade screwdri...

Page 35

Installing the detector 35 2 2.4 i/o signal connections the 432 detector is usually installed as an integral part of a data collection system. You can control the 432 detector either locally from the keypad on the front panel or remotely from a powerline™ controller, such as the waters 600s. This se...

Page 36

I/o signal connections 36 2 figure 2-3 i/o terminal strip table 2-3 i/o signal descriptions terminal pairs function rec (+ and –) recorder output – a 10-mv full-scale analog output signal appears on these terminals. The measurement range is determined by the product of the base range and sensitivity...

Page 37

Installing the detector 37 2 required material to connect cables to the i/o terminals, use a small flat-blade screwdriver. Other rear panel connections and dip switch in addition to the i/o terminal strip, the rear panel also contains the following items: • ieee-488 connector –communication bus for ...

Page 38

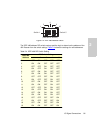

I/o signal connections 38 2 figure 2-4 ieee-488 address switch the ieee-488 address dip switch employs positive logic to determine the address of the 432 detector from the switch settings. Table 2-4 shows the settings for valid addresses. Table 2-4 ieee-488 dip switch setting ieee-488 address dip sw...

Page 39

Installing the detector 39 2 powerline operation under powerline control, the 432 detector is recognized as a 431 detector and it retains the functionality of the 431 detector with the following differences: • the balance field on the detector setup page of the powerline controller affects the integ...

Page 40

I/o signal connections 40 2 empower and millennium 32 are menu-driven applications specifically designed by waters for chromatographers. Use the software to: • acquire data • process data • generate and print reports • store information (or data) in a central area and share this information with use...

Page 41

Installing the detector 41 2 note: to prevent damage to the unit, always disconnect the power cord at either the wall outlet or the power supply before you attach or remove the power connection to the bus sat/in module. The bus sat/in module does not have a power switch. Connecting the bus sat/in mo...

Page 42

I/o signal connections 42 2 figure 2-6 bus sat/in to bus lac/e connections ac to dc converter i/o distribution por t (9-pin) of bus lac/e card i/o distribution box connect sat/in to port 1 on the i/o distribution box modified modular jack connections i/o distribution cable pwr data bcd sat/in module...

Page 43

Installing the detector 43 2 connecting the bus sat/in module to the 432 detector the bus sat/in module connects to the 432 detector as shown in figure 2-7 . Refer to the procedure following the figure and table 2-5 for complete details. Figure 2-7 bus sat/in to 432 detector connections to connect t...

Page 44

I/o signal connections 44 2 3. Connect the event in terminals of the channel you chose in the previous step to the inject start output signal of the waters alliance ® solvent delivery system or the waters 717plus (or equivalent) autosampler. 4. Remove the ieee-488 cable from the rear panel of the 43...

Page 45

Installing the detector 45 2 use the signal to start a waters 746 data module by connecting a signal cable to the module’s data cable ( table 2-7 ). 2.4.5 chart recorder connections to connect the 432 detector to a chart recorder: 1. Attach the recorder cable (see appendix b, spare parts ) to the 43...

Page 46

I/o signal connections 46 2 2.4.7 auto zero input connections the voltage at the recorder and integrator outputs is set to the user-selected balance offset level when a contact closure occurs between the auto zero terminals. This section describes how to connect the 432 detector to the following dev...

Page 47

Installing the detector 47 2 before you can generate an auto-zero from an alliance separations module, you must configure the auto-zero signal at the 432 detector front panel. The default auto-zero signal is low. Figure 2-8 alliance separations module connections to the 432 detector auto-zero on inj...

Page 48

Making fluidic connections 48 2 before you can generate a chart mark from an alliance separations module, you must configure the chart mark signal at the front panel. The default chart mark signal is low. Figure 2-9 alliance separations module connections to the 432 detector chart mark on inject 2.5...

Page 49

Installing the detector 49 2 this section will guide you through each of these procedures. Figure 2-10 fluid connections cutting stainless steel tubing you need the following tools to cut stainless steel tubing: • a file with cutting edge • two cloth- or plastic-covered pliers to cut the tubing: 1. ...

Page 50

Making fluidic connections 50 2 cutting polymeric tubing waters chromatography systems are supplied with a tubing cutter (similar to the one in figure 2-11 ) to facilitate cutting polymeric tubing. This section presents the recommended procedure for using the tubing cutter. Note: to avoid bandspread...

Page 51

Installing the detector 51 2 figure 2-12 ferrule and compression screw assembly connecting to the 432 detector to make connections at the column outlet and detector inlet, and at the detector outlet: 1. Install a compression screw and then a ferrule on the length of 0.009-inch tubing from the column...

Page 52

Making fluidic connections 52 2 installing the pulse dampener to achieve the best performance from the 432 detector in a chromatographic system with a non-waters pump, breeze™ software, or waters hplc 515 pump, you must install the pulse dampener kit supplied in the startup kit. The pulse dampener i...

Page 53

Installing the detector 53 2 figure 2-13 pulse dampener 2.6 passivating the system passivating the system removes potential contamination from the wetted surfaces of all system components. Perform passivation on a new system, and subsequently, whenever you suspect that contamination may have occurre...

Page 54

Verifying the detector 54 2 to passivate the system: 1. Replace the column with a union fitting. 2. If the system is not new, flush it thoroughly with astm type i reagent water to remove any residual solvents or salts. 3. Connect the power cord to the 432 detector and plug the other end into an ac p...

Page 55

Installing the detector 55 2 verify the detector when any of these conditions apply: • when you replace the flow cell • to verify accuracy • when you make adjustments calibration procedure note: you need solution of 1 mm potassium chloride (kcl) to calibrate the detector. Note: waters suggests one o...

Page 56

Controls and indicators 56 3 chapter 3 operating the detector this chapter contains: • a description of front panel controls and displays • procedures for starting up, shutting down, and long-term storage • recommended operating practices 3.1 controls and indicators figure 3-1 illustrates the contro...

Page 57

Operating the detector 57 3 power switch the power switch (located in the lower-right corner of the front panel) controls power to the 432 detector. Upon startup, an initialization routine verifies the data in rom memory, tests ram memory function, and checks for any internal leakage or an eluent co...

Page 58

Controls and indicators 58 3 note: three keys (balance, sensitivity range, and the numeral 1) perform an alternate function when they are preceded by the shift key. Table 3-1 key descriptions key function remote key: toggles between local and remote operating modes. In remote mode, the light above t...

Page 59

Operating the detector 59 3 response key: sets the response time constant of the 432 detector to optimize signal-to-noise ratio. Use the up and down keys or the numeric keypad to choose setting 1 (fast, 0.25 sec) for very narrow peaks, setting 2 (standard, 0.5 sec), or setting 3 (slow, 1.0 sec) to d...

Page 60

Controls and indicators 60 3 beep function you can set the 432 detector to beep when a key is pressed and/or an error condition is detected. Use the clear key to stop an error alarm. For a continuing error condition, the error message remains after the beep is cleared. To set the beep function, foll...

Page 61

Operating the detector 61 3 3.2 startup and shutdown startup procedure perform the following procedure to start the 432 detector. Typically, this procedure is done at the beginning of each workday. Note: this procedure assumes that the flow cell has stabilized at the selected temperature (minimum 2 ...

Page 62

Operating recommendations 62 3 long-term storage if the 432 detector is to be removed from a system for storage or if the system itself is to be stored for a long time, flush the detector/system with 100% water, then 100% hplc-grade methanol. Leave the methanol in the system after shutdown. If you a...

Page 63

Operating the detector 63 3 polarity signal polarity depends on eluent conductivity. If necessary, press the polarity key to obtain peaks rather than dips. Eluent handling replace your eluent reservoir filter regularly. When you analyze cations, use an all-plastic eluent reservoir filter. Filter and...

Page 64

Fundamental considerations 64 4 chapter 4 performing ion analysis this chapter provides essential information about ion analysis techniques. Two representative columns serve as typical examples: the waters ic-pak a for anions and the ic pak c m/d for cations. The following topics are discussed: • fu...

Page 65

Performing ion analysis 65 4 adsorption cartridges produce astm type i reagent water, and are recommended for ion chromatography applications. Do not use hplc-grade water or distilled water. Containers use plastic to contain all anion and cation samples, cation standards, and cation eluents. When yo...

Page 66

Fundamental considerations 66 4 carbonate absorption, connect a soda lime (ascarite ® ) tube ( figure 4-1 ) to the eluent bottle as follows: 1. Insert a 3/4-inch (2-cm) piece of glass wool in one end of a polyethylene tube with end fittings. Attach the end fitting. 2. Fill the tube with soda lime (a...

Page 67

Performing ion analysis 67 4 figure 4-1 soda lime tube sample preparation sample preparation is very important in ion analysis. Contact the waters technical services department, if you need assistance. End fittings glass wool soda lime polypropylene tube reagent bottle pump inlet line.

Page 68

Configuring the system 68 4 as a general rule, to analyze a sample of completely unknown ionic concentration, initially prepare at least a 1:100 dilution and inject 100 µ l. For best results, injections should contain a total anion concentration of no more than 300 ppm for the ic-pak a column or a t...

Page 69

Performing ion analysis 69 4 pulse dampener if your system uses a non-waters pump or a waters pump with breeze software, such as the hplc 515, use a pulse dampener (supplied in the startup kit) to achieve the best performance from the 432 detector. Install the pulse dampener between the pump and the...

Page 70

Standards for ion analysis 70 4 transfer the eluent to a precleaned plastic container, introducing the least possible amount of bubbles in the process. The waters in-line degasser is recommended for continuous online degassing. 4.3.1 preparing anion eluent this section presents the procedure for the...

Page 71

Performing ion analysis 71 4 storing standards for accurate quantitative results, do not store standards beyond the approximate periods listed in table 4-1 . Be aware that shelf-life depends on many factors and may be significantly shorter than shown here. Cation standards must be stored in properly...

Page 72

Standards for ion analysis 72 4 2. Place each salt in a separate plastic100-ml volumetric flask and dilute to the mark with astm type i reagent water. Each concentrate contains 1000 ppm of the anion. 3. Combine the amounts listed in table 4-3 in a 100-ml volumetric flask with astm type i reagent wat...

Page 73

Performing ion analysis 73 4 • 1-cc disposable plastic syringe – pharmaseal ® stylex ® disposable syringe with a luer slip ® tip, or equivalent. • autoinjector or manual injector with 100- µ l loop – ion chromatography commonly uses a 100- µ l injection volume. When you use a fixed loop, overfill a ...

Page 74

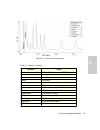

Standards for ion analysis 74 4 figure 4-3 chromatogram of a 7-anion standard 4.4.3 preparing cation standards this section presents the procedure for preparing an 8-cation standard. If a simpler standard suffices, follow this procedure selecting only those salts that you want in the standard. For a...

Page 75

Performing ion analysis 75 4 (mol. Wt. Salt / mol. Wt. Cation) = g salt if you choose to use other salts, be sure to avoid any combinations that will form a precipitate. 2. Place each salt in a separate plastic1-l volumetric flask and dilute to the mark with reagent-grade water. Each concentrate con...

Page 76

Standards for ion analysis 76 4 4.4.4 injecting cation standards required materials to inject the standard, obtain the following materials: • 0.1 mm edta/ 3 mm hno 3 cation eluent – refer to section 4.3.2, preparing cation eluent . • 1-cc disposable plastic syringe – pharmaseal ® stylex ® disposable...

Page 77

Performing ion analysis 77 4 figure 4-4 chromatogram of an 8-cation standard.

Page 78

Routine maintenance 78 5 chapter 5 maintenance this chapter contains information about maintaining the 432 detector and troubleshooting charts to help you isolate and correct problems. 5.1 routine maintenance this section contains information designed to help you maintain the 432 detector. Routine m...

Page 79

Maintenance 79 5 2. Pry open the power connector cover with a screwdriver. 3. To change the ac power fuses, pull out each fuse holder as though opening a drawer. Spare fuses are included in the system startup kit. For ordering information, see appendix b, spare parts . 4. Table 2-2 on page 34 lists ...

Page 80

Routine maintenance 80 5 refer to appendix b, spare parts , to order a replacement flow cell. The following tools are required to replace the flow cell: • phillips-head screwdriver • 5/16-inch open-end wrench • knife or flat-blade screwdriver 1. Unplug the 432 detector from the power source, and com...

Page 81

Maintenance 81 5 figure 5-2 flow cell assembly pin upper plate screws upper plate of cell block insulation cell block cover pin connector flow cell cell mounting bracket screws cell mounting bracket cell block pin holder pin holder.

Page 82

Cleaning the detector exterior 82 5 5.2 cleaning the detector exterior to clean the outside of the 432 detector, use only a soft lint-free paper or cloth dampened with mild soap and water. 5.3 troubleshooting this section contains troubleshooting charts to help you isolate and correct problems with ...

Page 83

Maintenance 83 5 startup diagnostics the 432 detector performs startup diagnostics that check the internal memory (both ram and rom), and the associated processing circuitry. Power supply the following factors can adversely affect the operation of the 432 detector: • power surges • line spikes • tra...

Page 84

Troubleshooting 84 5 2. If the results of previous runs are available, compare the current system operation with the system operation before you identified the problem. For example, if your system usually runs at a certain pressure with a certain method: • is the system pressure in the same range, o...

Page 85

Maintenance 85 5 12. Allow the detector to stand overnight (>12 hours) with temperature on and with methanol in the flow cell. 13. Repeat steps 5 through 9. Table 5-1 troubleshooting guide symptom possible cause solution noisy baseline pulse dampener not installed see “installing the pulse dampener”...

Page 86

Troubleshooting 86 5 bubbles in flow cell remove bubbles and degas the solvent. Solvent changeover wait until baseline stabilizes (purge autosampler a few times). Flow cell leak check flow cell fittings and tighten. If leak continues, replace the flow cell. Detector cannot be zeroed solvent changeov...

Page 87

Specifications 87 a appendix a specifications this appendix includes information on: • operational specifications • mechanical specifications • environmental specifications • electrical specifications • communications table a-1 operational specifications condition specification drift less than 0.05 ...

Page 88

Specifications 88 a operating pressure 70 psi maximum height 9.4 inches (23.8 cm) length 21 inches (53.3 cm) width 11.5 inches (29.2 cm) weight 17.7 pounds (8 kg) table a-3 environmental specifications condition specification operating temperature range 4 to 35 °c (40 to 95 °f) operating humidity 20...

Page 89

Specifications 89 a b. Over voltage category ii – pertains to instruments that receive their electrical power from a local level such as an electrical wall outlet. C. Pollution degree 2 – a measure of pollution on electrical circuits, which may produce a reduction of dielectric strength or surface r...

Page 90

Spare parts 90 b appendix b spare parts the parts listed in table b-1 are spare parts recommended for installation by you, the customer. Any parts that are not listed may require installation by a trained service representative. Order a supply of the parts listed in table b-1 to keep in stock for us...

Page 91

Ion chromatography methods 91 c appendix c ion chromatography methods this appendix provides information about: • general-purpose anion analysis using conductivity and uv detection • alkali and alkaline earth cations, ammonium, and amines c.1 general-purpose anion analysis using conductivity and uv ...

Page 92

Ion chromatography methods 92 c figure c-1 common anion standards table c-1 analysis conditions condition value column ic-pak a/hr (part number 026765) eluent borate/gluconate containing 12% accn back conductivity 240 ± 20 µ s degas continuous flow rate 1 ml/min. Backpressure 1200 ± 200 psi temperat...

Page 93

Ion chromatography methods 93 c c.1.1 preparing eluent 1. Add 20 ml of lithium borate/gluconate concentrate and 120 ml of hplc-grade acetonitrile (accn) into a 1-liter volumetric flask (see section c.1.13, preparing lithium borate/gluconate 50x stock concentrate , for concentrate preparation). 2. Di...

Page 94

Ion chromatography methods 94 c c.1.4 empower data processing method table c-2 ic processing method using peak apex for retention time process values integration peak width = 30.0 minimum area = 3000 inhibit intg. = 0 to 2 min. Threshold = 10 to 25 minimum height = 150 calibration averaging = none u...

Page 95

Ion chromatography methods 95 c c.1.5 method validation this validation design is abstracted from astm/epa validation. It has been used to validate all anion analysis methods. Many of the methods using this validation design are linear above 50 ppm. C.1.6 method linearity figure c-2 calibration curv...

Page 96

Ion chromatography methods 96 c figure c-3 calibration curves for nitrite and nitrate figure c-4 calibration curves for sulfate and phosphate no 2 r 2 = 0.9999 no 3 r 2 = 0.9992 so 4 r 2 = 0.9999 po 4 r 2 = 0.9992.

Page 97

Ion chromatography methods 97 c c.1.7 quantitation precision quantitation precision is the percent rsd of analyte peak area at each concentration. Data is based on seven replicate injections of the validation standards. C.1.8 method detection limits figure c-5 100- µ l injection table c-4 quantitati...

Page 98

Ion chromatography methods 98 c based on this representative chromatogram using a 100- µ l injection, the estimated detection limits, as ppb, at three times signal to noise (s/n) are as follows: • fluoride = 50 • chloride = 25 • nitrite = 50 • bromide = 75 • nitrate = 75 • phosphate = 125 • sulfate ...

Page 99

Ion chromatography methods 99 c c.1.10 analyte recovery the certified performance evaluation standards were diluted 1:100 with typical drinking water. Amounts are based on a multi-point calibration. Table c-6 analyte recovery analyte f ci no 2 no 3 po 4 so 4 milford drinking water n=3, as ppm not de...

Page 100

Ion chromatography methods 100 c c.1.11 example of use figure c-6 typical drinking water, no dilution required c.1.12 using direct uv detection many anions are uv active in the range of 205 to 214 nm, such as no 2 , br, and no 3 , and the use of direct uv detection provides a degree of detector sele...

Page 101

Ion chromatography methods 101 c figure c-7 direct uv detection direct uv detection is five times more responsive for nitrite and nitrate than is conductivity detection and therefore provides lower detection limits. The chromatogram in figure c-8 of a 100-ppb anion standard demonstrates the improved...

Page 102

Ion chromatography methods 102 c the borate/gluconate eluent has some uv absorption. Use of eluents that are uv transparent, such as hydroxide and carbonate/bicarbonate, provide lower detection limits. C.1.13 preparing lithium borate/gluconate 50x stock concentrate 1. Using a 60-ml plastic syringe, ...

Page 103

Ion chromatography methods 103 c c.2 alkali and alkaline earth cations, ammonium, and amines figure c-9 1-ppm standard table c-1 required instrumentation instrument part number alliance, 2695 separations module or breeze (with column heater, seal wash, and degasser) n/a 432 conductivity detector 043...

Page 104

Ion chromatography methods 104 c c.2.1 preparing eluent 1. Add 0.029 g of edta as the free acid into a 1-liter plastic volumetric flask. 2. Dissolve in 500 ml of di water with a stirring bar for 30 min. 3. Add 30 ml of 100 mm hno 3 (or 189 µ l of concentrated hno 3 ). 4. Dilute to volume with di wat...

Page 105

Ion chromatography methods 105 c calibration curve is validated, a single-point calibration curve within the expected analyte concentration is appropriate for future calibrations. You can use this method for the analysis of rb, cs, sr, and ba. C.2.3 preparing a sample 1. Determine the expected range...

Page 106

Ion chromatography methods 106 c c.2.5 method detection limits figure c-10 25-ppb cation standard based on this representative chromatogram using a 100- µ l injection in a 2695 separations module, the estimated detection limits, as ppb, at three times signal to noise (s/n) are as follows: • lithium ...

Page 107

Ion chromatography methods 107 c • calcium = 15 you can achieve lower detection limits by using a 250- µ l injection. C.2.6 examples of use figure c-11 typical drinking water, no dilution required figure c-12 typical municipal wastewater, diluted 1:50, overlay of duplicate injections.

Page 108

Ion chromatography methods 108 c note: alkyl and alkanol amine analysis standards are between 1 and 5 ppm, 3 mm hno 3 /0.1 mm edta/3% accn. C.2.7 preparing stock reagent because it is difficult to prepare a stock eluent for this column, it is recommended to prepare fresh working eluent. To prepare s...

Page 109

Validation support 109 d appendix d validation support this appendix provides information about: • validation regulation overview • waters ® regulatory compliance support validation regulation overview federal regulatory codes require that instrumentation and automated systems used for generation, m...

Page 110

Validation support 110 d instrument maintenance chapter 5, maintenance , in the waters 432 conductivity detector operator’s guide satisfies regulatory requirements for routine instrument maintenance. Chapter 5 includes: • maintenance considerations • calibration adjustment • replacing the flow cell ...

Page 111

Index 111 i n d e x a auto base 59 auto zero 36 , 39 , 46 , 59 b balance 39 balance key 58 base range 62 base range key 58 baseline drift 85 noise 85 beep-on-error 60 beep-on-keystroke 60 bubbles, removing 84 bus lac/e connections 41 bus sat/in connections 40 c carbonate absorption, minimizing 66 ch...

Page 112

Index 112 i i n d e x k key descriptions 58 – 60 l lac/e connections. See bus lac/e connections leak alert output 36 m marker input 36 , 45 marker output 36 , 44 , 59 millennium 32 connections 39 n nitric acid eluent, preparing 70 noisy baseline, troubleshooting 85 o offset chart recorder 58 integra...

Page 113

Index 113 i i n d e x u unpacking the 432 detector 31 v validation support 109 voltage, operating 34 ranges 34 w water purity 64.