- DL manuals

- Waters

- Water Pump

- 600

- User Manual

Waters 600 User Manual

Summary of 600

Page 1

Waters 600e multisolvent delivery system user’s guide 34 maple street milford, ma 01757 wat174-02tp, revision 3 view more waters manuals at www.Chromatography.Co.

Page 2

Notice the information in this document is subject to change without notice and should not be construed as a commitment by waters corporation. Waters corporation assumes no responsibility for any errors that may appear in this document. This document is believed to be complete and accurate at the ti...

Page 3

Note: when you use the instrument, follow generally accepted procedures for quality control and methods development. If you observe a change in the retention of a particular compound, in the resolution between two compounds, or in peak shape, immediately determine the reason for the changes. Until y...

Page 4

Caution: use caution when working with any polymer tubing under pressure: • always wear eye protection when near pressurized polymer tubing. • extinguish all nearby flames. • do not use tubing that has been severely stressed or kinked. • do not use nonmetallic tubing with tetrahydrofuran (thf) or co...

Page 5

Attenzione: prestare attenzione durante l’utilizzo dei tubi di polimero pressurizzati: • indossare sempre occhiali da lavoro protettivi nei pressi di tubi di polimero pressurizzati. • estinguere ogni fonte di ignizione circostante. • non utilizzare tubi soggetti che hanno subito sollecitazioni ecces...

Page 7

Caution: the user shall be made aware that if the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired. Attention : l’utilisateur doit être informé que si le matériel est utilisé d’une façon non spécifiée par le fabricant, la prote...

Page 8

Caution: to protect against fire hazard, replace fuses with those of the same type and rating. Attention : remplacez toujours les fusibles par d’autres du même type et de la même puissance afin d’éviter tout risque d’incendie. Vorsicht: zum schutz gegen feuergefahr die sicherungen nur mit sicherunge...

Page 9

Caution: to avoid possible electrical shock, disconnect the power cord before servicing the instrument. Attention : afin d’éviter toute possibilité de commotion électrique, débranchez le cordon d’alimentation de la prise avant d’effectuer la maintenance de l’instrument. Vorsicht: zur vermeidung von ...

Page 10

Commonly used symbols direct current courant continu gleichstrom corrente continua corriente continua alternating current courant alternatif wechselstrom corrente alternata corriente alterna protective conductor terminal borne du conducteur de protection schutzleiteranschluss terminale di conduttore...

Page 11

Frame or chassis terminal borne du cadre ou du châssis rahmen- oder chassisanschluss terminale di struttura o telaio borne de la estructura o del chasis caution or refer to manual attention ou reportez-vous au guide vorsicht, oder lesen sie das handbuch prestare attenzione o fare riferimento alla gu...

Page 12

Caution, risk of electric shock (high voltage) attention, risque de commotion électrique (haute tension) vorsicht, elektroschockgefahr (hochspannung) attenzione, rischio di scossa elettrica (alta tensione) precaución, peligro de descarga eléctrica (alta tensión) caution, risk of needle-stick punctur...

Page 13

Fuse fusible sicherung fusibile fusible electrical power on sous tension netzschalter ein alimentazione elettrica attivata alimentación eléctrica conectada electrical power off hors tension netzschalter aus alimentazione elettrica disattivata alimentación eléctrica desconectada commonly used symbols...

Page 14

United states – fcc emissions notes this device complies with part 15 of the fcc rules. Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired...

Page 15

600e pump information intended use when you develop methods, follow the “protocol for the adoption of analytical methods in the clinical chemistry laboratory,” american journal of medical technology, 44, 1, pages 30–37 (1978). This protocol covers good operating procedures and techniques necessary t...

Page 17: Table Of Contents

Table of contents xvii preface ......................................................................................................................... Xxv chapter 1 introduction ................................................................................................................. 1 1.1 ...

Page 18

Xviii table of contents chapter 3 preparing your 600e system for operation .................................................. 27 3.1 sparging eluents.............................................................................................. 28 3.2 priming the pump....................................

Page 19

Table of contents xix 4.5 setting up dissolution control ....................................................................... 76 4.6 setting up the detectors ................................................................................. 76 4.6.1 accessing the detector setup screen ...............

Page 20

Xx table of contents 6.2 creating an event table ................................................................................ 111 6.2.1 documenting the event table ......................................................... 112 6.2.2 programming the event table .......................................

Page 21

Table of contents xxi 7.4.3 stopping flow ................................................................................. 144 7.4.4 modifying gradient, event, and detector tables ........................... 145 7.4.5 modifying the method table .........................................................

Page 22

Xxii table of contents 10.1.3 entering parameter values into the gradient table ........................ 179 10.1.4 editing the gradient table .............................................................. 180 10.2 creating an event table ................................................................

Page 23

Table of contents xxiii appendix b eluent considerations .......................................................................................... 207 b.1 eluent compatibility with the 600e system ................................................. 207 b.2 clean eluent ..................................

Page 24

Xxiv table of contents.

Page 25

Xxv preface the waters 600e multisolvent delivery system user’s guide describes the features and use of the waters ® 600e multisolvent delivery system. This guide also includes information on the use of these systems with other waters components, including autosamplers, detectors, and computer contr...

Page 26

Xxvi appendix a contains 600e system specifications. Appendix b describes eluent cosiderations. Appendix c contains the analysis plan and file sheet. Related documentation waters licenses, warranties, and support: provides software license and warranty information, describes training and extended su...

Page 27

Xxvii notes notes call out information that is helpful to the operator. For example: note: record your result before you proceed to the next step. Attentions attentions provide information about preventing damage to the system or equipment. For example: cautions cautions provide information essentia...

Page 28

Xxviii.

Page 29

Waters 600e system overview 1 chapter 1 introduction this chapter introduces you to the waters ® 600e multisolvent delivery system. It describes the system and each individual system module. 1.1 waters 600e system overview the waters 600e system is a high-performance liquid chromatography (hplc) mul...

Page 30

2 introduction – linear change – four convex gradient curves – four concave gradient curves • system control of powerline detectors and autoinjectors through ieee-488 interface • rs-232 serial communications interface for connection to optional integrator • optional shelf unit to house system module...

Page 31

Waters 600e system modules 3 1.2 waters 600e system modules this section discusses the major modules of the waters 600e system: • waters 600 controller • waters 600e pump 1.2.1 waters 600 controller the waters 600 controller ( figure 1-2 ) automatically controls the eluent gradient, the flow rate, c...

Page 32

4 introduction figure 1-2 waters 600 controller front panel the 600 controller rear panel ( figure 1-3 ) provides connection terminals and communication ports for operation with external devices. Figure 1-3 waters 600 controller rear panel.

Page 33

Waters 600e system modules 5 screw terminals the 600 controller rear panel contains the following screw terminals: • pressure • chart • inject • stop flow • hold • s1 through s4 (event switches) • aux +12 v pressure/chart function as output terminals (10 mv full scale analog signals). Located on the...

Page 34

6 introduction • hold output switch - transmits a signal from the 600 controller to an external device when the controller receives a: – stop flow signal – hold screen key signal – pressure limit error – pump flow rate error event switches/aux +12 v four ttl-compatible connectors (s1 through s4) on ...

Page 35

Waters 600e system modules 7 figure 1-4 waters 600e pump (front view) figure 1-5 600e pump rear panel.

Page 36

8 introduction eluent blending the gradient proportioning valve blends up to four eluents or buffers in any combination. It produces predictable gradient segments regardless of eluent compressibility and system backpressure. Eluent selection and proportioning take place on the low-pressure (intake) ...

Page 37

Powerline controller features 9 1.3 powerline controller features powerline controller description use the powerline controller configuration when you want to control other devices from the 600e system over the ieee-488 bus. The powerline controller is the default configuration for the waters 600 co...

Page 38

10 introduction • program tables that define the varying percentage composition of the eluent, the flow rate, and the time range for each phase of the gradient operation. You develop tables for gradient programs and programmed events and save them in memory. • create multi-method programs that link ...

Page 39

Options and accessories 11 automatic switching valves allow automatic column selection, large-volume sample injection, or flow-path diversion. 746 data module the waters 746 data module (integrator) provides documentation of powerline system programs, a permanent annotated chromatographic record, an...

Page 40

12 introduction.

Page 41

Powering up the system 13 chapter 2 basic operation this chapter introduces you to the operation of the waters 600e multisolvent delivery system. This chapter assumes that you are using the system with other waters system components. 2.1 powering up the system before you begin this section provides ...

Page 42

14 basic operation powering up a 600e system when used with a data system this section contains the powerup sequence to follow when using the 600e system with a data system (empower or millennium ® chromatography manager). Note: the 600 controller must be in the gradient controller configuration to ...

Page 43

Powering up the system 15 note: you cannot run methods or method sets, or use the quickset control window unless all devices on the ieee-488 bus that are assigned to a system on the empower or millennium chromatography manager are powered up and calibrated. Note: you do not need to power up instrume...

Page 44

16 basic operation 2.1.2 powering up the stand-alone 600e system this section contains the powerup sequence to follow when using the 600e system with the stand-alone gradient controller configuration. To power up your stand-alone system: 1. Power up all external equipment (chart recorder, injector)....

Page 45

Using the controller front panel 17 diagnostic failure on powerup if any of the tests fail, a failure message appears as follows: • if the controller or pump fails the diagnostic test, the powerup screen indicates the failed test. • if a detector or an autoinjector fails the diagnostic test, the fai...

Page 46

18 basic operation displays screen-specific help. The specific function for a given screen key appears at the bottom of the screen above the key. Figure 2-3 waters 600 controller front panel 2.3.1 keypad the waters 600 controller main keypad (see figure 2-3 ) includes: • cursor movement keys - move ...

Page 47

Using the controller front panel 19 2. Type a value for the selected parameter. Press the help screen key to display the allowable range for the field. 3. Press enter. The system checks the new value to see if it is the correct type of entry and within the proper range. • if the entry is acceptable,...

Page 48

20 basic operation gradient controller keys in gradient controller mode, function keys access different screens: 2.3.3 screen keys screen key description screen keys are the five unlabeled keys directly below the display screen. Their functions are indicated by labels that appear on the bottom of th...

Page 49

Comparing controller types 21 figure 2-4 shows the location of the clear line screen label relative to the screen key. Figure 2-4 clear line screen key 2.4 comparing controller types use this section to help you determine which controller configuration best fits your needs. This section describes: •...

Page 50

22 basic operation 2.4.1 powerline controller configuration this section includes: • powerline controller description • powerline controller operation when to use powerline mode use powerline mode to: • control external powerline devices (such as, autosamplers, detectors and integrators) from the wa...

Page 51

Comparing controller types 23 powerline operation the powerline controller provides product-specific setup and operating parameters for powerline detectors and autoinjectors. Detector parameters inlude: • detector filter constant • autozero (except for 431/432 detector) • polarity • absorbance units...

Page 52

24 basic operation • method table - a time-based program that contains up to 48 individual steps. Each step accesses a set of gradient/event/detector tables. You can program the method table to automatically: – apply multiple separation methods to a sample set – equilibrate the system for a specifie...

Page 53

Powering down the system 25 operation the gradient controller provides storage for 15 sets of tables. Each set of tables consists of a gradient table and an event table that run together during gradient operation. The gradient and event tables can each contain a maximum of 15 operational steps. You ...

Page 54

26 basic operation.

Page 55

27 chapter 3 preparing your 600e system for operation this chapter contains procedures for preparing your waters 600e multisolvent delivery system for operation. You perform some of these procedures only once (the first time you operate the system). You must perform other procedures every time you u...

Page 56

28 preparing your 600e system for operation eluent considerations when purging the waters 600e system: • always wear safety glasses when working with eluents. • before operation, always check for miscibility with the previous eluent used, or change eluents. • if organic and aqueous buffers are used ...

Page 57

Sparging eluents 29 during pump operation, sparge all active reservoirs at a reduced rate (for example, 30 ml/min) with helium to: • maintain pump performance with blended eluents • prevent accumulation of dissolved air in the eluents note: a sparge rate of 50 ml/min is recommended for gradients inv...

Page 58

30 preparing your 600e system for operation enabling sparging to enable sparging for the reservoirs containing eluent: 1. Move the cursor to the reservoir to sparge field for the first reservoir that contains eluent (a, b, c, or d). 2. Type 1 and press enter. This enables the reservoir for sparging....

Page 59

Priming the pump 31 3.2 priming the pump priming is necessary to ensure proper pump operation. Priming involves: • initiating flow • drawing off eluent • purging air from the pump heads when to prime prime the pump when: • starting up the system for the first time • adding fresh eluent to the system...

Page 60

32 preparing your 600e system for operation • open the slide-out drawer. Disconnect the fluid tubing at the column inlet. See the waters 600e multisolvent delivery system installation and maintenance guide, section 2.3.1, installing a column. Disconnecting the fluid line avoids introducing air into ...

Page 61

Priming the pump 33 drawing off eluent once you have initiated flow, draw off eluent as follows: 1. Move the cursor to the %a field for the first eluent and type 100 in the new column. Press enter. 2. Type 0 and press enter for the remaining eluent composition fields. 3. Attach the priming syringe t...

Page 62

34 preparing your 600e system for operation 3. Move the cursor to the flow field and press 10. Press enter. This sets the flow rate to 10 ml/min for eluent reservoir a. 4. Rotate the inlet manifold valve handle fully counterclockwise to the draw position (see figure 3-3 ). Draw off some eluent, rota...

Page 63

Flushing the system 35 4. Flush for 2 to 5 minutes. 5. If your system backpressure fluctuates more than 100 psi (7 kg/cm 2 ) once the system has reached the operating flow rate, prime the system again as described in section 3.2, priming the pump . 6. If the column in the system has been used before...

Page 64

36 preparing your 600e system for operation 3. Install a union in place of the column during system flush. 4. Place the rest of the system back in the flow path by closing the reference valve. 5. Flush the complete system, including detectors (see section 3.4.1, flushing the system fluid lines ). 3....

Page 65

Flushing the system 37 5. Fully insert the syringe needle into the injector port. 6. Gently discharge the contents of the syringe to completely fill the sample loop and expel any old or intermediate eluent from the injector vent tube. This step replaces the eluent in the sample loop with fresh eluen...

Page 66

38 preparing your 600e system for operation 3.5 equilibrating the system to equilibrate the system, set the following initial parameters on the direct control screen (see figure 3-2 ): • flow rate • eluent composition • sparge rate • aufs • sensitivity note: when using the millennium chromatography ...

Page 67

Equilibrating the system 39 procedure to equilibrate the system: 1. Press the direct function key to access the direct control screen (see figure 3-2 ). Sparging 2. If desired, set the sparging conditions as follows: a. Move the cursor to the sparge field. B. Type in the maintenance rate for your el...

Page 68

40 preparing your 600e system for operation b. Type in the desired flow rate value (0 to 20 or 45 ml/min). Press enter. The pump immediately begins operating at the new flow and eluent composition conditions. Setting powerline detector parameters 5. Set the powerline detector parameters as necessary...

Page 69

Changing eluents 41 3.6 changing eluents this section outlines the recommended procedures for changing eluents in the waters 600e system. The procedures include: • adding fresh eluent • changing between incompatible eluents eluent compatibility all eluents are compatible with the 600e system. Howeve...

Page 70

42 preparing your 600e system for operation • always wear safety glasses when working with eluents. • if your column is not compatible with an eluent, disconnect the column and replace the column in line with a union. • if organic eluents and aqueous buffers are used together, make certain that salt...

Page 71

Changing eluents 43 • changes involving two miscible eluents can be made immediately, without an intermediate eluent. • to prevent eluent contamination, use the same container to prepare, supply, and store an eluent. Once a container is used for one eluent, it should not be used for any other eluent...

Page 72

44 preparing your 600e system for operation 3. Prime and flush the system with intermediate eluent using the procedures described in section 3.2, priming the pump , and section 3.4, flushing the system . 4. Flush the system with 20 to 40 ml of eluent at a flow rate of 2.0 ml/min for 10 to 20 minutes...

Page 73

45 chapter 4 setting powerline controller operating parameters this chapter contains the information you need to set the operating parameters for the powerline modules using the 600 controller. The operating parameters apply to all controller operations, whether you are running a direct-control or a...

Page 74

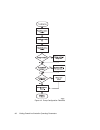

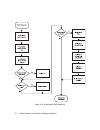

46 setting powerline controller operating parameters screen layout figure 4-1 illustrates the relationship of the screens associated with the waters 600 controller in its powerline configuration. See figure 4-1 when you set powerline parameters in preparation for a run. Figure 4-1 powerline controll...

Page 75

Setting up the 600 as a powerline controller 47 4.1 setting up the 600 as a powerline controller this section describes how to use the pump configuration screen to configure the waters 600 controller as a powerline controller. It includes procedures for: • configuring the controller type • communica...

Page 76

48 setting powerline controller operating parameters figure 4-2 pump configuration flowchart.

Page 77

Setting up the 600 as a powerline controller 49 exiting the pump configuration screen do one of the following: • press the configure screen key to save the parameter values displayed on the screen. The system reboots and displays the powerup screen. Pressing the configure screen key also aborts a ru...

Page 78

50 setting powerline controller operating parameters 2. Check the controller type field. If the type field contains: • w600e powerline controller - skip the rest of this section and proceed to section 4.1.2, selecting an integrator . • w600e gradient controller - proceed to step 3. 3. Press the setu...

Page 79

Setting up the 600 as a powerline controller 51 figure 4-5 gradient controller pump configuration screen 5. Move the cursor to the unit type field. Note: press the help screen key to display the available controller configuration options. 6. Type 1 to select the powerline controller configuration. P...

Page 80

52 setting powerline controller operating parameters accessing the pump configuration screen 1. Press the set up function key from the powerline controller powerup screen. The powerline controller pump setup screen appears ( figure 4-6 ). Figure 4-6 powerline controller pump setup screen 2. Press th...

Page 81

Setting up the 600 as a powerline controller 53 the function parameter on the pump configuration screen ( figure 4-7 ) identifies the module connected to the rs-232 interface. This module can be either the: • 745b data module • 746 data module table 4-1 lists the default rs-232 communication paramet...

Page 82

54 setting powerline controller operating parameters 5. If you do not want to select or change the report type, press the configure screen key to save your selections. The controller reboots and returns to the powerup screen. 6. Proceed with the following sections: • section 4.2, verifying that powe...

Page 83

Setting up the 600 as a powerline controller 55 figure 4-8 example of a short report (first injection).

Page 84

56 setting powerline controller operating parameters figure 4-8 example of a short report (first injection) (continued).

Page 85

Setting up the 600 as a powerline controller 57 figure 4-9 example of an abridged report (first injection).

Page 86

58 setting powerline controller operating parameters figure 4-9 example of an abridged report (first injection) (continued).

Page 87

Setting up the 600 as a powerline controller 59 figure 4-10 example of a full report (all injections).

Page 88

60 setting powerline controller operating parameters figure 4-10 example of a full report (all injections) (continued).

Page 89

Verifying that powerline devices are active 61 4.2 verifying that powerline devices are active verify that powerline devices are active only if you will be using a powerline autoinjector (717plus autosampler) or a powerline detector (410 refractive index, 431/432 conductivity, 486 tunable absorbance...

Page 90

62 setting powerline controller operating parameters active powerline devices the system configure screen indicates which powerline devices are active on the ieee-488 bus. This screen displays device boxes that include the device names and ieee addresses of all powerline devices that the system reco...

Page 91

Setting up the 600e pump 63 4.3 setting up the 600e pump this section describes how to access and use the pump setup screen in powerline control mode. It includes the following information: • accessing the pump setup screen • setting pump setup screen parameters • exiting the pump setup screen pump ...

Page 92

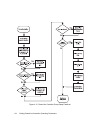

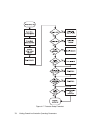

64 setting powerline controller operating parameters figure 4-12 powerline controller pump setup flowchart.

Page 93

Setting up the 600e pump 65 4.3.1 accessing the pump setup screen 1. Press the set up function key from any screen except the powerline controller pump configuration screen. The powerline controller pump setup screen appears ( figure 4-13 ). 2. If you are at the powerline controller pump configurati...

Page 94

66 setting powerline controller operating parameters 4.3.2 setting pump setup parameters this section describes the pump parameters on the pump setup screen (see figure 4-13 ) and provides procedures for setting each parameter. The pump setup parameters are: • reservoirs to sparge • pump col. Temp. ...

Page 95

Setting up the 600e pump 67 pump col. Temp. Heater limit defines the high-temperature limit for the optional column heater. The upper limit of the heater module is on the module label. Note: to prevent damage to the column, the heater module shuts down when the temperature exceeds the programmed lim...

Page 96

68 setting powerline controller operating parameters 4. Move the cursor to the high field. 5. Enter a high-pressure limit value within the range 51 to 6000 psi (3.6 to 420 kg/cm 2 ). 6. Press enter. Chart out determines which signal is available at the chart out terminal on the rear panel of the con...

Page 97

Setting up the 600e pump 69 to determine the flow factor for your application: 1. Set the flow rate at 1.0 ml/min. 2. Measure the actual flow rate. 3. If the actual flow rate is less than or greater than 1.0 ml/min, type a flow factor value to compensate for the difference. The valid range is 0.950 ...

Page 98

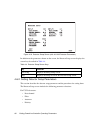

70 setting powerline controller operating parameters sample method table for example, your method table may appear as shown in figure 4-14 . Figure 4-14 example of a method table if you want to equilibrate your system 12 hours from now and start on vial 15, type the following in the autostart field:...

Page 99

Setting up the autoinjector 71 4.3.3 exiting the pump setup screen 1. Press any one of the following screen keys to select another screen: • next setup - displays the autoinjector setup screen • system config - displays the system configuration screen • pump config - displays the pump configuration ...

Page 100

72 setting powerline controller operating parameters figure 4-15 autoinjector setup flowchart.

Page 101

Setting up the autoinjector 73 4.4.1 accessing the autoinjector setup screen you set up the autoinjector through the autoinjector setup screen. To access the autoinjector setup screen ( figure 4-16 ): 1. Press the set up key to display the pump setup screen ( figure 4-13 ). 2. Press the next setup s...

Page 102

74 setting powerline controller operating parameters 4.4.2 setting autoinjector setup parameters this section describes the autoinjector setup parameters and the procedures for setting them. Syringe draw rate controls the rate at which the autoinjector draws the sample from the vial. The slow rate i...

Page 103

Setting up the autoinjector 75 to set the auto standards parameter: 1. Move the cursor to the auto stds field. 2. Type 0 (no, default) to turn off auto standard sequencing, or type 1 (yes) to select auto standard sequencing. Press enter. 3. If you typed 1 in step 2, enter values for the following pa...

Page 104

76 setting powerline controller operating parameters 4.5 setting up dissolution control use the dissolution setup screen to coordinate the collection and transfer of dissolution samples from a hanson transfer controller into the wisp 712d autoinjector sample vials. Accessing the dissolution setup sc...

Page 105

Setting up the detectors 77 using multiple detectors you may use up to three powerline detectors in the system at one time: • two uv/vis absorbance detectors (two waters 486 detectors, two channels of a waters 490e detector, or one 486 and one 490e channel) and • one refractive index (ri) detector (...

Page 106

78 setting powerline controller operating parameters figure 4-17 detector setup flowchart.

Page 107

Setting up the detectors 79 4.6.1 accessing the detector setup screen to access the detector setup screen ( figure 4-18 ): 1. Press the set up function key to display the pump setup screen (see figure 4-13 ). 2. Press the next setup screen key to display the autoinjector setup screen (see figure 4-1...

Page 108

80 setting powerline controller operating parameters figure 4-19 detector setup screen (with 431/432 detector parameters) in addition to the parameters shown on the screen, the detector setup screen displays the screen keys described in table 4-4 . Table 4-4 detector setup screen keys 4.6.2 setting ...

Page 109: Data Chan

Setting up the detectors 81 for ri detectors (waters 410): • data channel • filter • autozero • polarity • internal cell temperature • temperature of external heaters 1 and 2 for conductivity detectors (waters 431/432): • data channel • filter • polarity • balance data chan assigns an identifying nu...

Page 110

82 setting powerline controller operating parameters 2. Type a value: • for a uv detector, between 0.1 and 99.99 (seconds). (the default is 1 second). Press enter. • for an ri detector, 0.2 (default), 1.0, 3.0, or 10.0. Press enter. • for a 431/432 conductivity detector, slow (1.0 sec.), std (0.5 se...

Page 111

Setting up the detectors 83 cell temp sets the internal oven temperature of the 410 detector and defines an alarm to be set at 5 °c above that temperature. To set the cell temp parameter: 1. Move the cursor to the cell temp field for det #3. 2. Type a value between 30 and 50 (°c) to set a temperatur...

Page 112

84 setting powerline controller operating parameters.

Page 113

85 chapter 5 running powerline in direct control mode once you have familiarized yourself with your system and prepared your system according to the procedures in chapters 1 through 4, you can run your waters 600e multisolvent delivery system in the direct control mode. Direct control all direct-con...

Page 114

86 running powerline in direct control mode • familiarized yourself with basic operation and have decided upon a controller configuration ( chapter 2, basic operation ) • prepared your system as outlined in chapter 3, preparing your 600e system for operation • set operating parameters as described i...

Page 115

Setting run conditions 87 figure 5-1 direct control flowchart.

Page 116

88 running powerline in direct control mode accessing the direct control screen you set the run conditions from the direct control screen. To access the direct control screen, press the direct function key. The powerline controller direct control screen appears ( figure 5-2 ). Figure 5-2 powerline c...

Page 117

Setting run conditions 89 flow specifies the eluent flow rate. To set the flow rate: 1. Move the cursor to the flow field if necessary. 2. Type the appropriate eluent flow rate (0.00 to 20.0 or 45.00 ml/min) for the application and press enter. The system immediately sets the pump to the flow rate y...

Page 118

90 running powerline in direct control mode sparge determines the rate at which the system sparges the eluent reservoirs. To set the sparge rate: 1. Move the cursor to the sparge field. 2. Type the sparge rate value (0 to 100 ml/min). Press enter. Note: the system uses the sparge rate for all eluent...

Page 119

Setting run conditions 91 connecting external devices before setting any of the event switches, ensure that all external devices are connected to the appropriate switch terminals on the rear panel of the controller. See the waters 600e multisolvent delivery system installation and maintenance guide ...

Page 120

92 running powerline in direct control mode vial indicates the vial you wish to use for the injection. To select a vial: 1. Move the cursor to the vial field. 2. Type the vial number from which to make an injection and press enter. Valid vial numbers are 1 to 48 or 1 to 96, depending on the capacity...

Page 121

Setting run conditions 93 inj vol specifies the size of the sample you wish to inject. To select the injection volume: 1. Move the cursor to the inj vol field. 2. Type the appropriate sample value to be injected. 3. Press enter. Valid entries are 0 to 200 ml with the standard sample loop installed, ...

Page 122

94 running powerline in direct control mode 2. Press the lamp on/lamp off screen key for the desired function. The key toggles between the two functions. Waters 486 lamp status is checked at the beginning of each run. If the lamp is off at the start of a run, the system returns to idle and the error...

Page 123

Performing a direct control run 95 in addition to the parameters shown on the screen, the direct control screen displays the screen keys described in table 5-2 . The lower-left corner of the direct control screen displays a system status flag. This flag is similar to the screen keys except that it a...

Page 124

96 running powerline in direct control mode 5.2.1 setting the run time use the direct control screen (see figure 5-2 ) to set the run time parameter. Run time specifies the duration of the analysis after the injection is made. The system does not recognize another inject signal while a run is in pro...

Page 125

Performing a direct control run 97 5.2.3 equilibrating the system when the system status displays initial , the system is running with the conditions displayed on the direct control screen and with the downloaded powerline module operating parameters. The system runs at these conditions until you eq...

Page 126

98 running powerline in direct control mode 3. The autoinjector draws the sample and makes the injection. The autoinjector sends a contact closure signal to the inject input terminal on the rear panel of the controller. Using the start run screen key with a non-powerline autoinjector for methods dev...

Page 127

Running a method from the direct control screen 99 5.2.6 aborting a run 1. Press the abort screen key. The caution screen appears ( figure 5-3 ). Figure 5-3 caution screen 2. Press either the: • abort screen key to immediately abort the run • direct function key to continue running 5.2.7 changing pa...

Page 128

100 running powerline in direct control mode accessing the operate method screen to run a method from the direct control screen: 1. Press the operate method function key. The initial operate method screen appears with the current direct control flow conditions shown in the current field ( figure 5-4...

Page 129

101 chapter 6 creating powerline methods this chapter describes how to create the time-based tables required for unattended operation of the waters 600e multisolvent delivery system. You can combine these tables to compose a method. A method is a set of instructions that controls how and when a run ...

Page 130

102 creating powerline methods figure 6-1 illustrates the relationship between time-based tables and a method table. A gradient, an event, and a detector table with the same number combine to form one line of a method table. Figure 6-1 methods and tables once you create these tables, you can run the...

Page 131

Creating a gradient table 103 this section describes: • documenting the gradient table • programming the gradient table note: when creating gradient, event, and detector tables, be sure that you design the time-related parameters specified in each table to work effectively with the time-related para...

Page 132

104 creating powerline methods this line in the gradient table should: • be executed by the controller after the separation is complete (run time has elapsed) and allow enough time for the column to equilibrate • change the flow rate to that used in the initial line of the gradient table • have the ...

Page 133

Creating a gradient table 105 figure 6-3 illustrates the flow, %c, and %d profiles for this gradient table. Figure 6-3 auto•blend gradient profile 6.1.2 programming the gradient table this section provides instructions for: • entering parameter values in the gradient table • editing the gradient tab...

Page 134

106 creating powerline methods . Figure 6-4 program gradient flowchart.

Page 135

Creating a gradient table 107 accessing the program gradient screen press the program table function key to display the powerline controller program gradient screen ( figure 6-5 ). Figure 6-5 powerline controller program gradient screen in addition to the gradient table parameters, there are five ac...

Page 136

108 creating powerline methods exiting the program gradient screen to exit the program gradient screen, press either: • the next table screen key to access the program event screen • any function key, except the program table key, to enter another mode 6.1.3 entering parameter values in the gradient...

Page 137

Creating a gradient table 109 7. At the curve field, type the gradient curve profile number for the gradient segment. Figure 6-6 shows the gradient curve profiles. Figure 6-6 gradient curve profiles 8. Repeat steps 3 through 7 for each line in the gradient table. 9. If you wish, enter the line to re...

Page 138

110 creating powerline methods deleting lines to delete individual lines from a table: 1. Move the cursor to any field on the line you want to delete. 2. Press the clear line screen key. This immediately clears the line the cursor is on and moves succeeding lines in the table up one line. The cursor...

Page 139

Creating an event table 111 to save the new table, repeat steps 1 and 2, and assign a different table number to the table. Continue this process until you locate a table that can be replaced with the new table. Replacing existing tables a maximum of 15 tables of one type can be stored in permanent m...

Page 140

112 creating powerline methods note: when creating gradient, event, and detector tables, be sure that you design the time-related parameters specified in each table to work effectively with the time-related parameters in the other two tables of the same set. 6.2.1 documenting the event table define ...

Page 141

Creating an event table 113 once set, events remain in that state until you set them to new conditions. Hint for event 5 to program a beeping alarm, specify pulse instead of on. If you turn on the alarm, include another step to turn off the alarm. Otherwise, manually turn off the alarm using the can...

Page 142

114 creating powerline methods event actions the action selections for events 1 through 5 are: • 0 = off • 1 = on • 2 = pulse (generates 600 millisecond pulse) event 6 (sparge) requires specification of a sparge rate between 0 and 100 ml/min. Event 7 requires that you specify a column heater tempera...

Page 143

Creating an event table 115 6.2.2 programming the event table figure 6-8 illustrates the steps involved in using the program event screen to create an event table. Use this flowchart for quick reference once you become familiar with the waters 600e system..

Page 144

116 creating powerline methods figure 6-8 program event flowchart.

Page 145

Creating an event table 117 the remainder of this section describes how to access the program event screen and enter an event table. Accessing the program event screen 1. Press the program table function key to display the program gradient screen (see figure 6-5 ). 2. Press the next table screen key...

Page 146

118 creating powerline methods 6.2.3 entering parameter values in the event table to enter the parameter values into the program event table (see figure 6-9 ): 1. Move the cursor to the table # field. 2. Type a table number between 1 and 15. Press enter. If an event table is already stored under thi...

Page 147

Creating a detector table 119 6.2.4 editing the event table for details on editing the event table, see the procedure for editing the gradient table in section 6.1.4, editing the gradient table . 6.3 creating a detector table skip this section if you are not using powerline detectors in your waters ...

Page 148

120 creating powerline methods 3. When the table entries are complete, keep the analysis plan and file sheet as a permanent record of your table. Detector table entries affect the two uv/vis detectors (waters 486 and 490e). There is a separate sensitivity parameter for the waters 410 ri detector and...

Page 149

Creating a detector table 121 figure 6-11 detector table flowchart.

Page 150

122 creating powerline methods accessing the detector tables screen 1. Press the program table function key to display the program gradient screen (see figure 6-5 ). 2. Press the next table screen key to display the program event screen (see figure 6-9 ). 3. Press the next table screen key. The dete...

Page 151

Creating a detector table 123 6.3.3 entering parameter values in the detector table to enter the parameter values into the detector table (see figure 6-12 ): 1. Move the cursor to the table # field. 2. Type a table number between 1 and 15. Press enter. If a detector table is already stored under thi...

Page 152

124 creating powerline methods c. At the det/chan field, type a value to specify which uv/vis detector (1 = det #1 or 2 = det #2) or channel to change. Press enter. D. At the l field, type a wavelength value between 190 and 600 nm. Press enter. Note: by default, wavelength changes are accompanied by...

Page 153

Creating a method table 125 a method table can contain up to 48 lines. These lines specify a combination of tables (gradient, event, and detector), and include such information as vial numbers, number of injections, injection volumes, and run times. Each line in the method table executes in order an...

Page 154

126 creating powerline methods figure 6-13 program methods flowchart.

Page 155

Creating a method table 127 accessing the program methods screen to access the program methods screen, press the program method function key. The program methods screen appears with the cursor at the step field ( figure 6-14 ). Figure 6-14 program methods screen in addition to the methods table para...

Page 156

128 creating powerline methods 6.4.3 entering parameter values in the method table note: when the program methods table (see figure 6-14 ) first appears, the step 1 line contains default values. You can modify these values if you wish. For subsequent lines, the system automatically provides step num...

Page 157

Creating a method table 129 entering a special vial code affects which parameters appear on that line. Some parameters are not available when you use certain special vial codes. 3. At the last vial field, type the number of the vial from which you wish to make the last injection. Press enter. Note: ...

Page 158

130 creating powerline methods 5. At the inj vol field, type the sample volume for all injections. Press enter. • when using a waters autosampler (717plus), the maximum volume is determined by the loop size (200 µ l or 2000 µl) installed in the autosampler. • when using the manual injector, a non-po...

Page 159

Creating a method table 131 2. Press the insert line screen key. This copies the line the cursor is presently on to the new line and reorders the step numbers. 3. Edit the information on the new line as necessary. Saving tables whenever you change a table, you must save the changes before powering d...

Page 160

132 creating powerline methods.

Page 161

Using an injector 133 chapter 7 running powerline methods this chapter describes how to run a powerline method using the operate method mode. The operate method mode executes the time-based tables that you created in chapter 6, creating powerline methods . Before you begin this chapter assumes that ...

Page 162

134 running powerline methods to load the sample into the rheodyne 7725i: 1. Turn the handle on the manual injector to the load position ( figure 7-1 ). Figure 7-1 rheodyne 7725i injector in the load position 2. Load a syringe with sample. The loop may be partially filled or overfilled. The injector...

Page 163

Using an injector 135 6. Allow sufficient time for the sample to clear the injector before repositioning the load/inject handle. Reposition the load/inject handle as follows: • if you are operating in the gradient mode, or if the next sample is not ready to be loaded, leave the handle in the inject ...

Page 164

136 running powerline methods overview the waters 600e system treats a non-powerline autoinjector as an external device. Programming considerations when you make injections using a non-powerline autoinjector through either the direct control mode or operate method mode: • specify the special vial co...

Page 165

Setting initial operating parameters 137 figure 7-2 operate method flowchart.

Page 166

138 running powerline methods accessing initial operate method screen press the operate method function key. The initial operate method screen appears with the cursor at the step # field ( figure 7-3 ). Figure 7-3 initial operate method screen this screen displays the following: • step number, vial ...

Page 167

Starting a run 139 if autostart is active at this time, the keyboard will be locked. To abort the autostart, unlock the keyboard on the pump setup screen (see section 4.3.2, setting pump setup parameters ). After the keyboard is unlocked, make your changes to the initial operate method screen as fol...

Page 168

140 running powerline methods 2. Press the operate method function key again. The operate methods screen appears ( figure 7-4 ). Figure 7-4 operate methods screen operate methods screen keys in addition to the current system conditions, the operate methods screen displays the screen keys described i...

Page 169

Starting a run 141 system status flag values the lower-left corner of the operate methods screen displays a system status flag. This flag is similar to the screen keys except that it appears in reverse video. The flag assumes one of the statuses listed in table 7-2 . 7.3.2 downloading operating para...

Page 170

142 running powerline methods 7.3.3 running a method note: the 600 controller examines the status of the 490e detector before initiating a run. If the detector is in the standby state, the controller automatically turns on the lamp. Using the rheodyne 7725i manual injector to begin a run with the rh...

Page 171

Modifying conditions while running 143 2. Program and start the autoinjector. 3. Press the start run key as soon as possible after the injection occurs. Note: an autostart method can override a method that you started with the start run screen key. Starting the run-time clock when the controller rec...

Page 172

144 running powerline methods 7.4.1 changing parameters you can change the following parameters during a run: • sparge rate • column heater temperature • event switch status (on/off) • operating parameters for any of the detectors note: you can change parameters only if the keyboard is unlocked. To ...

Page 173

Modifying conditions while running 145 flow causes switch s4 to default to the off position. This action provides an additional level of control for non-ieee devices. Note: the receipt of the stop flow signal (at the 600 controller’s stop flow rear panel terminal) suspends the controller’s run, grad...

Page 174

146 running powerline methods to modify a table that is currently running: 1. Stop the run by pressing the abort screen key from the operate methods screen. The caution i screen appears. 2. Press the abort screen key from the caution i screen ( figure 7-5 ). 3. Modify the table. 4. Save the table by...

Page 175

Modifying conditions while running 147 figure 7-5 caution i screen 2. Take one of the following actions: • to cancel the abort and resume monitoring the method, press the operate method function key. The operate methods screen appears. • to immediately abort the run, press the abort function key. Th...

Page 176

148 running powerline methods figure 7-6 caution ii screen 2. Take one of the following actions: • to cancel the abort and continue monitoring the method, press the operate method function key. The operate methods screen appears. • to abort the method immediately and enter the direct control mode, p...

Page 177

149 chapter 8 setting gradient controller operating parameters this chapter contains the information you need to set the operating parameters when you want to use the waters 600 controller as a gradient controller. The operating parameters apply to all controller operations, whether you are running ...

Page 178

150 setting gradient controller operating parameters gradient controller screens figure 8-1 illustrates the relationships of the screens associated with the waters 600 controller in its gradient controller configuration. Use figure 8-1 to navigate through gradient controller operation. Note: in grad...

Page 179

Setting up the 600 as a gradient controller 151 figure 8-2 illustrates the steps involved in using the pump configuration screen. Use this flowchart as a quick reference for setting the parameters on the pump configuration screen. Figure 8-2 pump configuration flowchart.

Page 180

152 setting gradient controller operating parameters exiting the pump configuration screen • if you want to save the parameter values displayed on the screen, press the configure screen key. The system reboots and displays the powerup screen. Pressing the configure screen key also aborts a run in pr...

Page 181

Setting up the 600 as a gradient controller 153 2. Check the controller type field. If the type field contains: • w600e gradient controller - skip the rest of this section and proceed to section 8.1.2, communicating with a data system . • w600e powerline controller - continue with step 3. 3. Press t...

Page 182

154 setting gradient controller operating parameters figure 8-5 powerline controller pump configuration screen 5. Move the cursor to the unit type field. 6. Type 0 to select the gradient controller. Press enter. 7. Press the configure screen key. The controller reboots and returns to the gradient co...

Page 183

Setting up the 600 as a gradient controller 155 this section assumes that your system was installed as described in the waters 600e multisolvent delivery system installation and maintenance guide and you have made the appropriate ieee-488 cable connections to the data system. Setting the ieee-488 ad...

Page 184

156 setting gradient controller operating parameters 2. Press the pump config screen key. The gradient controller pump configuration screen appears ( figure 8-7 ). Figure 8-7 gradient controller pump configuration screen 3. Move the cursor to the ieee-488 field. 4. Type a number from 2 to 29 that is...

Page 185

Setting up the 600e pump 157 8.2 setting up the 600e pump this section describes how to access and use the pump setup screen in gradient control mode. It includes the following information: • accessing the gradient controller pump setup screen • setting gradient controller pump setup parameters • ex...

Page 186

158 setting gradient controller operating parameters figure 8-8 illustrates the steps for using the pump setup screen. Use figure 8-8 as a quick reference for setting the parameters on the pump setup screen. Figure 8-8 pump setup flowchart 8.2.1 accessing the pump setup screen to access the gradient...

Page 187

Setting up the 600e pump 159 2. If you are at the gradient controller pump configuration screen (see figure 8-7 ) and do not need to save changes, press the cancel screen key to return to the gradient controller pump setup screen ( figure 8-9 ). 3. If you are at the gradient controller pump configur...

Page 188

160 setting gradient controller operating parameters 8.2.2 setting pump setup parameters this section describes the pump parameters and provides procedures for setting each parameter on the pump setup screen. The pump parameters are: • reservoirs to sparge • pump col. Temp. Heater limit • press limi...

Page 189

Setting up the 600e pump 161 to set the pump column-temperature heater limit: 1. Move the cursor to the pump col. Temp. Heater limit field. 2. Type the appropriate temperature value (0 to 99) in °c. 3. Press enter. Press limits defines the high and low operating-pressure limits of the waters 600e pu...

Page 190

162 setting gradient controller operating parameters chart out determines which signal is available at the chart terminal on the rear panel of the controller. This 0- to 10-mv signal can be the eluent flow rate (flow) or the composition percentage of any one of the four eluents (%a, %b, %c, or %d). ...

Page 191

Setting up the 600e pump 163 3. If the actual flow rate is less than or greater than 1.0 ml/min, type a flow factor value to compensate for the difference. The valid range is 0.950 to 1.050. For example, if your actual flow rate is 0.98 ml/min, use a flow factor of 1.02. 4. Press enter. Autostart sp...

Page 192

164 setting gradient controller operating parameters if you want to run your system 12 hours from now and start on table 1, type the following in the autostart field: in 12 hrs 0 min start run of table 1 6. Activate autostart by pressing the lock keyboard screen key. The countdown time displays on t...

Page 193

165 chapter 9 running gradient controller in isocratic mode once you have familiarized yourself with the waters 600e multisolvent delivery system and prepared it according to the procedures in chapters 1 through 3 and 8, you may make a run in the isocratic mode. Isocratic control isocratic operation...

Page 194

166 running gradient controller in isocratic mode • prepared your system as outlined in chapter 3, preparing your 600e system for operation • set operating parameters as described in chapter 8, setting gradient controller operating parameters 9.1 setting run conditions before you make a run with the...

Page 195

Setting run conditions 167 figure 9-1 illustrates the steps involved in using the isocratic screen. Use figure 9-1 for quick reference once you become familiar with your 600e system. Figure 9-1 isocratic control flowchart.

Page 196

168 running gradient controller in isocratic mode accessing the isocratic screen to access the isocratic screen ( figure 9-2 ), press the direct function key on the controller front panel. Figure 9-2 isocratic screen in addition to the parameters shown on the screen, the isocratic screen displays th...

Page 197

Setting run conditions 169 • sparge • temperature flow rate specifies the eluent flow rate. Note: some columns require a flow ramp up. See the column care and use manual for guidelines. Be sure that the values for the maximum and minimum operating pressures programmed on the pump setup screen are ap...

Page 198

170 running gradient controller in isocratic mode sparge determines the rate at which the system sparges the eluent reservoirs. To set the sparge rate value: 1. Move the cursor to the sparge field. 2. Type the appropriate sparge rate value (0 to 100 ml/min). Press enter. Note: the system uses the sa...

Page 199

Performing an isocratic run 171 connecting external devices before setting any of the event switches, connect the external device to the switch terminals on the rear panel of the controller. See the waters 600e multisolvent delivery system installation and maintenance guide for more information on t...

Page 200

172 running gradient controller in isocratic mode 9.2.2 starting a run using the rheodyne 7725i manual injector 1. Load the injector loop with sample. See section 11.1.1, using the rheodyne 7725i manual injector . 2. Turn the injector handle to the inject position to make the injection. Using a non-...

Page 201

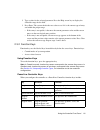

Creating a gradient table 173 chapter 10 creating gradient controller time-based tables this chapter describes how to create time-based tables (gradient tables and event tables) for unattended operation of the waters 600e multisolvent delivery system. Gradient tables control the 600e pump, whereas e...

Page 202

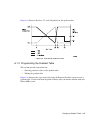

174 creating gradient controller time-based tables 10.1.1 documenting the gradient table define the information you want in a gradient table before you actually program a gradient table. This minimizes the need for you to reprogram the table later. Using the analysis plan and file sheet appendix c, ...

Page 203

Creating a gradient table 175 reducing flow include a final line in the gradient table to reduce the flow rate after the last injection to conserve eluent when the sample set completes. This final line in the gradient table should: • appear as the last line in the table. • be set to a time at least ...

Page 204

176 creating gradient controller time-based tables figure 10-2 illustrates the flow rate and the %c, and %d profiles for the gradient table in figure 10-1 . Figure 10-2 auto•blend gradient profile 10.1.2 programming the gradient table figure 10-3 illustrates the steps involved in using the program g...

Page 205

Creating a gradient table 177 figure 10-3 program gradient flowchart.

Page 206

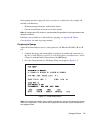

178 creating gradient controller time-based tables accessing the program gradient screen to display the gradient controller program gradient screen ( figure 10-4 ), press the program method function key. Figure 10-4 gradient controller program gradient screen in addition to the gradient table parame...

Page 207

Creating a gradient table 179 exiting the program gradient screen to exit the program gradient screen and enter another mode, press any function key except the program method key. 10.1.3 entering parameter values into the gradient table to enter the parameter values into the table displayed on the p...

Page 208

180 creating gradient controller time-based tables 8. Repeat steps 3 through 7 for each line in the gradient. When entering information for subsequent lines in the table, enter the time value for each line and press enter. This action copies the values from the previous line to the new line. 9. If d...

Page 209

Creating a gradient table 181 if the new line appears at the end of the table, the values from the previous line are copied into the new line when you enter the time for that line. Edit the copied conditions as necessary. Saving tables whenever you change a table, you must save the changes before po...

Page 210

182 creating gradient controller time-based tables 3. If desired, clear the table by pressing the clear table screen key. 4. Enter the new information. 5. When you have entered all information, save the table by pressing the save screen key. This replaces the preexisting table with the new table in ...

Page 211

Creating an event table 183 2. Before you program the event table (see section 10.2.2, programming the event table ), develop the table by writing each change as an individual line on the analysis plan and file sheet. On each line of the analysis plan and file sheet, write: • time of event • event t...

Page 212

184 creating gradient controller time-based tables hint for event 5 to program a beeping alarm, specify pulse instead of on. If you turn on the alarm, include another step to turn off the alarm. Otherwise, manually turn off the alarm by pressing the cancel alarm screen key on the operate gradient sc...

Page 213

Creating an event table 185 events 8 and 9 require specification of a table number between 1 and 15. Event 10 requires 1 to turn on the lamp or 0 to turn off the lamp. See “hints for event 10” on page 184 for background information on using event 10 sample event table figure 10-6 is a simple example...

Page 214

186 creating gradient controller time-based tables figure 10-7 program event flowchart.

Page 215

Creating an event table 187 accessing the program event screen press the program table function key to display the program event screen ( figure 10-8 ). Figure 10-8 gradient controller program event screen in addition to the event table parameters, the program event screen displays four active scree...

Page 216

188 creating gradient controller time-based tables exiting the program event screen to exit the program event screen, press any function key except the program table key to enter another mode. 10.2.3 entering parameter values into the event table to enter the parameter values into the program event ...

Page 217

Using an injector 189 chapter 11 running gradients this chapter describes how to run gradient and event tables using the operate gradient mode of the gradient controller. Execution of these time-based tables allows you to: • implement flow and compositional gradients • activate external events this ...

Page 218

190 running gradients to load the sample into the rheodyne 7725i: 1. Turn the handle on the manual injector to the load position ( figure 11-1 ). Figure 11-1 rheodyne 7725i injector in the load position 2. Load a syringe with sample. The loop may be partially filled or overfilled. The injector is eq...

Page 219

Setting initial operating parameters 191 6. Allow sufficient time for the sample to clear the injector before repositioning the load/inject handle. Reposition the load/inject handle as follows: • if you are operating in the gradient mode, or if the next sample is not ready to be loaded, leave the ha...

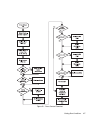

Page 220

192 running gradients figure 11-2 summarizes the steps involved in running gradients. Use this flowchart for quick reference once you become familiar with your waters 600e system. Figure 11-2 operate gradient flowchart.

Page 221

Setting initial operating parameters 193 accessing the initial operate gradient screen to access the initial operate gradient screen, press the operate method function key. The initial operate gradient screen appears ( figure 11-3 ). Figure 11-3 initial operate gradient screen this screen displays: ...

Page 222

194 running gradients canceling the run to cancel the run, press any function key, except the operate method key, to select another mode. 11.3 starting a run this section assumes that you have already set your initial operating parameters. If you have not, review section 11.2, setting initial operat...

Page 223

Starting a run 195 in addition to the current system conditions, the operate gradient screen displays the screen keys described in table 11-1 . 11.3.2 running a gradient setting initial conditions to start the pump at the initial conditions of the gradient table you want to run, press the initial sc...

Page 224

196 running gradients to begin a run with an external non-powerline autoinjector: 1. Load the sample vials into the autoinjector. 2. Program and start the autoinjector. See the autoinjector manual. 3. When the autoinjector makes the injection, it sends a contact closure signal to the inject input te...

Page 225

Modifying conditions while running 197 11.4 modifying conditions while running this section describes how to modify conditions during a run, including: • changing parameters • holding conditions constant • stopping flow • modifying gradient and event tables • switching to another table • aborting th...

Page 226

198 running gradients when you press hold: • gradient clock stops • run-time clock stops 2. To continue system operation from the point at which you suspended it, press the resume run screen key. The gradient and run-time clocks continue from where they stopped. 11.4.3 stopping flow you generally us...

Page 227

Modifying conditions while running 199 to modify a table during a run: 1. Press the program method function key to display the gradient table or the program table function key to display the event table. 2. Move the cursor to the table # field and type the number of the table to modify. Press enter....

Page 228

200 running gradients 11.4.6 aborting the run using the direct function key 1. Press the direct function key. The caution screen appears ( figure 11-5 ). The caution screen prompts you to immediately abort the gradient or cancel the abort. Figure 11-5 caution screen 2. Take one of the following acti...

Page 229

201 appendix a specifications this appendix contains 600e system specifications for the following areas: • operational • electrical • environmental • physical • optional rheodyne 7725i manual injector table a-1 operational specifications item specification number of eluents one to four. Modes of ope...

Page 230

202 specifications program storage storage for 15 sets of tables (gradient, program event, and detector), with a maximum of 15 steps per table. Storage for a time-based multi-method program with up to 48 individual steps. Eeprom stores setup parameters and tables, and preserves memory indefinitely f...

Page 231

203 table a-2 electrical specifications item specification power requirements maximum power: 250 va frequency 47 to 63 hz fuse time- or operator- controllable switch closures four controllable switch closures to ground as follows: • ttl-compatible terminals pulled up with 10-k ohm resistors to 5 v. ...

Page 232

204 specifications hold output one ttl-compatible switch closure to ground. Maximum current sink: 100 ma. Low output indicates pumps stopped due to: • exceeding high-pressure limit • below low-pressure limit • abort input • “powerup” condition used to communicate with hold input on waters 717plus au...

Page 233

205 table a-4 physical specifications item specification wetted surface material 316 stainless steel, ruby, sapphire, fluorocarbon polymer controller height: 7.19 inches (18.26 cm) depth: 21.75 inches (55.25 cm) width: 11.32 inches (28.75 cm) weight: 33 lb (15 kg) pump height: 9.625 inches (24.4 cm)...

Page 234

206 specifications.

Page 235

Eluent compatibility with the 600e system 207 appendix b eluent considerations this appendix describes eluents for use with your waters 600e multisolvent delivery system. It also provides information on eluent properties, including: • eluent compatibility • clean eluent • eluent miscibility • head h...

Page 236

208 eluent considerations eluents to use materials of construction used in the 600e system are nonreactive with most acids, bases, salts, and organic eluents. The following list of eluents has been approved for use with the 600e system. These include salts, acids and bases in concentrations up to 1 ...

Page 237

Eluent compatibility with the 600e system 209 • licl0 4 • na 2 b 4 o 7 • na 2 co 3 • na 2 s • na 2 so 4 • nacl • sodium acetate • nah 2 bo 3 • nahco 3 • nahso 4 • nano 3 • naocl • nh 4 cl • perfluorobutyric acid • phosphate • tartrate • trilithium citrate • tris • 4-(2-pyridylazo)resorcinol monosodi...

Page 238

210 eluent considerations • perchloric acid • nitric acid, up to 30% (6 n) • lactic acid • methanesulphonic acid • octanesulphonic acid • oxalic acid • pyridine-2,6-dicarboxylic acid • trifluoroacetic acid (tfa), up to 10% bases the following is a list of bases that may be used with the 600e system:...

Page 239

Clean eluent 211 • cyclohexanone • dibutyl phthalate • dimethyl formamide • dimethyl sulfoxide • ethanol • ethyl acetate • ethylene dichloride • ethylene glycol • formaldehyde • heptane • hexane • iso-octane • iso-propanol • lysine hydrochloride • methanol • methyl ethyl ketone • methylene chloride ...

Page 240

212 eluent considerations when using a buffer, obtain a high-quality reagent and filter it through a 0.45 micron filter such as the type in the eluent clarification kit available from waters. Using clean water when operating a system with aqueous eluents, use high-purity, filtered water such as that...

Page 241

Eluent miscibility 213 • when using a high-ionic-strength buffer, flush all fluid pathways with distilled water before shutting down the system. Leave distilled water in the system (flush with 10% methanol in water for shutdowns scheduled to be more than one day). See section 2.5, powering down the ...

Page 242

214 eluent considerations adapted from godfrey, norman b., solvent selection via miscibility number, chemtech, 359-363 (1972). B.3.2 using miscibility numbers (m-numbers) miscibility numbers (m-numbers) are used to predict the miscibility of a liquid with one of the standard eluents (see table b-1 )...

Page 243

Head height 215 • a difference of 16 units indicates that the two liquids possess a critical solution temperature between 25 and 75 °c, with 50 °c as the optimal temperature. • if the difference equals 17 or more, the two liquids are immiscible, or their critical solution temperature is above 75 °c....

Page 244

216 eluent considerations for example, a 1:1 mixture of water and methanol produces twice the pressure of either water or methanol alone. If the extent to which the pressure changes affect the analysis is not known, monitor the pressure during the run using the controller chart output terminal provi...

Page 245

Eluent degassing 217 temperature temperature affects the solubility of gases in two ways: • the higher the boiling point of a gas, the more soluble the gas is in a given eluent. • increasing the temperature of the gas-liquid solution affects the percentage of gas in solution. If the heat of solution...

Page 246

218 eluent considerations reported a 95-percent reduction in sensitivity of the fluorescence of borate-benzoin complex in air-equilibrated ethanol. 1 the amount of quenching by oxygen varies with different types of compounds. Aromatic hydrocarbons, aliphatic aldehydes, and ketones are especially sus...

Page 247

Eluent degassing 219 heat heating to remove dissolved gas is usually not effective unless you boil the eluent, and this is not practical for mixed eluents. However, low levels of heat will raise the partial pressure of the eluent and thereby reduce the rate of resolubilization of a gas. This may aff...

Page 248

220 eluent considerations.

Page 249

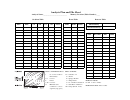

221 appendix c analysis plan use the analysis plan and file sheet that follows to help you define and document: • the gradient, event, and detector tables that compose a method table in powerline control mode (see chapter 6, creating powerline methods ) • the gradient and event tables in gradient co...

Page 250

Analysis plan and file sheet analysis name:___________________________ memory location (table number):____ gradient table time flow %a %b %c %d curve event table time event action detector table events 1-5 actions: 0 = off 1 = on 2 = pulse events 6-10 actions: select a value 410 sensitivity 431/432 ...

Page 251: Numerics

Index 223 numerics 600e system, features 1 – 2 600s controller, see controller a aborting a run 146 – 148 accessing the pump setup screen 65 acids 209 adding fresh eluents 41 – 42 analysis plan and file sheet 103 , 112 , 119 , 174 , 182 , 221 attenuation 93 auto standards 74 , 138 auto•blend 1 , 104...

Page 252

224 index d daily operation 34 data channel 81 data system communicating with 154 – 156 degassing 28 – 30 , 216 – 219 deleting lines in a table 110 detector table creating 119 – 124 description 23 editing 124 entering parameter values 123 – 124 programming 120 – 124 detector table screen accessing 1...

Page 253

Index 225 i compatibility 207 – 211 immiscible 41 incompatible 42 miscibility 28 , 212 – 215 organic 210 properties 213 – 214 sparging 28 – 30 unacceptable 41 using clean 211 viscosity 215 equilibrating the system 38 – 40 , 97 , 171 error messages, clearing 19 event actions 114 , 184 event hints 113...

Page 254

226 index gradient table creating 102 – 111 , 173 – 182 curve profile 109 , 179 description 23 documenting 103 – 105 , 174 – 176 editing 109 – 111 , 180 – 182 entering parameter values 108 – 109 , 179 – 180 example 104 , 163 , 175 initial conditions line 103 , 174 programming 105 – 111 , 176 – 182 r...

Page 255

Index 227 i starting with a non-powerline autoinjector 142 starting with an autosampler 142 stopping flow 144 , 198 method table 70 clearing tables 131 creating 124 – 131 deleting lines 130 description 24 editing 130 – 131 entering parameter values 128 – 130 inserting lines 130 overview 124 programm...

Page 256

228 index pump auto•blend 1 description 3 , 6 – 8 flow factor 68 , 70 , 162 , 163 flow rate 1 , 89 , 108 , 169 , 179 head volume 1 pressure 1 , 40 , 67 , 161 priming 28 , 31 – 34 resuming flow 98 setup 63 – 71 , 157 – 164 stopping the 98 r related documentation xxvi replacing tables 111 report choos...

Page 257

Index 229 i powerline controller pump setup 52 , 65 , 153 powerline program event 117 powerline screen layout 46 program methods 127 pump setup 29 system configure 61 screw terminals aux +12 v 6 chart 5 hold 5 pressure 5 sensitivity 94 sparging eluents 28 – 30 , 218 flow rate 28 , 30 in direct contr...

Page 258

230 index.