- DL manuals

- Waters

- Control Unit

- Alliance e2695

- Operator's Manual

Waters Alliance e2695 Operator's Manual

Summary of Alliance e2695

Page 1

Waters alliance e2695 separations module operator’s guide 715003794/revisionb copyright © waters corporation 2013 all rights reserved view more resources at www.Chromatography.Co.

Page 2

Ii july 29, 2013, 715003794 rev. B.

Page 3: General Information

July 29, 2013, 715003794 rev. B iii general information copyright notice © 2013 waters corporation. Printed in the united states of america and in ireland. All rights reserved. This document or parts thereof may not be reproduced in any form without the written permission of the publisher. The infor...

Page 4: Contacting Waters

Iv july 29, 2013, 715003794 rev. B we seriously consider every customer comment we receive. You can reach us at tech_comm@waters.Com. Contacting waters contact waters ® with enhancement requests or technical questions regarding the use, transportation, removal, or disposal of any waters product. You...

Page 5: Module

July 29, 2013, 715003794 rev. B v considerations specific to the waters alliance e2695 separations module solvent leakage hazard the source exhaust system is designed to be robust and leak-tight. Waters recommends you perform a hazard analysis, assuming a maximum leak into the laboratory atmosphere ...

Page 6: Safety Hazard Symbol Notice

Vi july 29, 2013, 715003794 rev. B hand crush hazard high temperature hazard fcc radiation emissions notice changes or modifications not expressly approved by the party responsible for compliance, could void the users authority to operate the equipment. This device complies with part 15 of the fcc r...

Page 7: Equipment Misuse Notice

July 29, 2013, 715003794 rev. B vii equipment misuse notice if the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired. Safety advisories consult appendix a for a comprehensive list of warning and caution advisories. Operating thi...

Page 8: Applicable Symbols

Viii july 29, 2013, 715003794 rev. B applicable symbols audience and purpose this guide is intended for use by individuals who need to install, operate, maintain, or troubleshoot the waters alliance e2695 separations module. This guide sets forth procedures for unpacking, installing, using, maintain...

Page 9: Calibrating

July 29, 2013, 715003794 rev. B ix intended use of the waters alliance e2695 separations module waters designed the alliance e2695 separations module, an integrated solvent and sample management platform, to facilitate all critical separations functions. The waters alliance e2695 separations module ...

Page 10: Ec Authorized Representative

X july 29, 2013, 715003794 rev. B nonresidential) locations and can be directly connected to a low voltage, power-supply network. Ec authorized representative waters corporation (micromass uk ltd.) floats road wythenshawe manchester m23 9lz united kingdom telephone: +44-161-946-2400 fax: +44-161-946...

Page 11: Table of Contents

July 29, 2013, 715003794 rev. B xi general information .................................................................................... Iii copyright notice .................................................................................................. Iii trademarks ............................

Page 12

Xii july 29, 2013, 715003794 rev. B spill protection................................................................................................... 26 record-keeping functions .................................................................................. 26 power supply ........................

Page 13

July 29, 2013, 715003794 rev. B xiii 2 install the e2695 separations module ................................................ 45 installation overview ........................................................................................ 45 site requirements ...........................................

Page 14

Xiv july 29, 2013, 715003794 rev. B enter values in parameter fields ...................................................................... 88 configure the separations module ................................................................ 91 set configuration parameters...............................

Page 15

July 29, 2013, 715003794 rev. B xv monitor your hplc system ........................................................................... 119 perform direct functions ................................................................................ 123 dry prime the system ................................

Page 16

Xvi july 29, 2013, 715003794 rev. B set separation method parameters ............................................................. 150 set mobile phase screen parameter values.................................................... 151 set sample parameter values............................................

Page 17

July 29, 2013, 715003794 rev. B xvii safety and handling ........................................................................................ 219 use the error log ............................................................................................. 220 perform main diagnostic tests .......

Page 18

Xviii july 29, 2013, 715003794 rev. B caution advisory .............................................................................................. 265 warnings that apply to all waters instruments and devices ................. 266 warnings that address the replacing of fuses ........................

Page 19

July 29, 2013, 715003794 rev. B xix gpc solvents and seal choices ........................................................................ 293 solvent compatibility ...................................................................................... 294 solvents to avoid .............................

Page 20

Xx july 29, 2013, 715003794 rev. B.

Page 21: E2695 Separations Module

July 29, 2013, 715003794 rev. B 21 1 getting started with the alliance e2695 separations module separations module overview the alliance e2695 separations module is an integrated solvent and sample management platform. Integrating the two, traditional high performance liquid chromatography (hplc) co...

Page 22: Hplc System Configurations

1 getting started with the alliance e2695 separations module 22 july 29, 2013, 715003794 rev. B alliance e2695 separations module (front view): hplc system configurations the separations module supports rs-232, ieee-488, ethernet, and i/o connections for compatibility with a variety of hplc system c...

Page 23: Solvent Bottle Tray Kits

Separations module overview july 29, 2013, 715003794 rev. B 23 – the waters 2414, 2410, or 410 refractive index detector and the waters 2487 dual wavelength or waters 486 tunable absorbance detector – the waters 2487 dual wavelength or waters 486 tunable absorbance detector • as a component of an hp...

Page 24

1 getting started with the alliance e2695 separations module 24 july 29, 2013, 715003794 rev. B a-series solvent bottle organizer configuration: solvent bottle organizer detector e2695 separations module drip tray.

Page 25

Separations module overview july 29, 2013, 715003794 rev. B 25 b-series solvent bottle tray configuration (only single detector shown): c-series solvent bottle bucket configuration: control of chromatographic functions once you program a method, the separations module controls these functions: solve...

Page 26: Spill Protection

1 getting started with the alliance e2695 separations module 26 july 29, 2013, 715003794 rev. B • solvent composition • flow rate • plunger seal wash flow • needle-wash flow • sample injection • in-line vacuum degassing • external events • operation of detectors over the ieee-488 interface bus • col...

Page 27: Power Supply

Solvent management system overview july 29, 2013, 715003794 rev. B 27 power supply the separations module is factory equipped with a 600 watt (w) power supply. This power supply provides immediate compatibility for an optional sample heater/cooler. The power supply is protected against short circuit...

Page 28: Solvent Blending

1 getting started with the alliance e2695 separations module 28 july 29, 2013, 715003794 rev. B 4. Just before the accumulator chamber empties, the solvent in the primary piston chamber is precompressed to a pressure slightly less than that indicated by the system pressure transducer. 5. When the ac...

Page 29: Loss of Prime Protection

Solvent management system overview july 29, 2013, 715003794 rev. B 29 • plunger seal wash solvent flows from a reservoir to the solenoid wash pump and then to a cavity behind the main plunger seal in the primary head. • the solvent flows from the head and into the cavity behind the plunger seal, in ...

Page 30

1 getting started with the alliance e2695 separations module 30 july 29, 2013, 715003794 rev. B low-internal-volume degasser chambers. The result is shortened instrument priming and equilibration times, and minimum delay when resuming operation from an idle state or following a solvent change. The d...

Page 31: Flow Path

Sample management system overview july 29, 2013, 715003794 rev. B 31 sample management system overview the sample management system holds and positions the sample vials and injects the samples into the solvent flow. The system’s five carousels hold as many as 24 sample vials for a total of 120 vials...

Page 32: Normal Flow

1 getting started with the alliance e2695 separations module 32 july 29, 2013, 715003794 rev. B normal flow during normal flow, v1 is open, allowing solvent to flow along two paths: • 95 percent of the solvent flows through the body of v2, the sample loop pressure transducer, the sample loop, and ne...

Page 33: Vial Presence

Sample management system overview july 29, 2013, 715003794 rev. B 33 spills and condensation in the sample compartment are routed to a waste connection below the front panel. You can load a carousel into the carrier while an injection is underway. An open-door sensor prevents the carrier from automa...

Page 34: Operating Configurations

1 getting started with the alliance e2695 separations module 34 july 29, 2013, 715003794 rev. B syringe assembly: operating configurations the separations module can operate in three general control modes: • system controller • no interaction • remote control both system controller and no interactio...

Page 35: System Controller Mode

Operating configurations july 29, 2013, 715003794 rev. B 35 system controller mode in this standalone mode, the separations module functions as the hplc system controller. You can perform runs manually or automatically in the system controller mode. For a manual run, you input parameter values and s...

Page 36

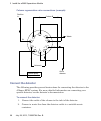

1 getting started with the alliance e2695 separations module 36 july 29, 2013, 715003794 rev. B digital signal control of an hplc system: in the system controller mode, the separations module can control as many as three detector channels on the ieee-488 bus (two uv detector channels and one ri dete...

Page 37: No Interaction Mode

Operating configurations july 29, 2013, 715003794 rev. B 37 no interaction mode in this standalone mode, the separations module controls non-ieee-488 devices in the hplc system using the input/output (i/o) connections on its rear panel. This mode disconnects the separations module from the ieee-488 ...

Page 38

1 getting started with the alliance e2695 separations module 38 july 29, 2013, 715003794 rev. B • rs-232 communications by non-waters data systems • an external autosampler (the waters 2700 sample manager, for example) with the separations module in the operate gradient by event in mode use the proc...

Page 39: Options and Accessories

Options and accessories july 29, 2013, 715003794 rev. B 39 the separations module can communicate with empower software via ethernet or via the ieee-488 interface bus (but not both simultaneously). Use empower software to create instrument methods and method sets to control the separations module an...

Page 40: Column Heater

1 getting started with the alliance e2695 separations module 40 july 29, 2013, 715003794 rev. B column heater the column heater maintains the column at temperatures from 5 °c above ambient (minimum of 20 °c) to 60 °c. An alarm warns you when the temperature varies outside the range that you specify....

Page 41: Column Selection Valve

Options and accessories july 29, 2013, 715003794 rev. B 41 column selection valve the motorized column selection valve enables the system to switch solvent flow to one of several columns. Such valves are only recognized by alliance if they are installed in the column heater. The column selection val...

Page 42

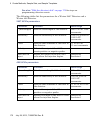

1 getting started with the alliance e2695 separations module 42 july 29, 2013, 715003794 rev. B the e2695 has four column selection valve options, as described in the following table. The software automatically detects the presence and type of column selection valve when you power-on the separations...

Page 43

Options and accessories july 29, 2013, 715003794 rev. B 43 e2695 column heater: two-column selection valve the firmware does not recognize the 2-column selection valve (6 port, 2 position) option. Instead, the option is controlled via one of the four i/o event switches on the separations module’s re...

Page 44

1 getting started with the alliance e2695 separations module 44 july 29, 2013, 715003794 rev. B six-column selection valve the 6-column selection valve selects any one of six column positions. You can specify any position as bypass or waste. For more information, see “connect the column selection va...

Page 45: Module

July 29, 2013, 715003794 rev. B 45 2 install the e2695 separations module installation overview this chapter explains how to connect electrical cables, signal cables, tubing and fittings, and hardware options to the separations module. Contents: topic page installation overview ........................

Page 46: Site Requirements

2 install the e2695 separations module 46 july 29, 2013, 715003794 rev. B major steps to installing the separations module: required materials: • screwdriver, #2 phillips ® • screwdriver, flat-blade • open-end wrench, 5/16-inch • tubing cutter • e2695 separations module startup kit once you install ...

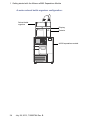

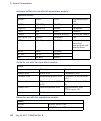

Page 47

Firmware and software requirements july 29, 2013, 715003794 rev. B 47 typical system dimensions for the e2695 separations module: the top panel of the separations module can support the weight of two detectors, the detector drip tray, and the solvent bottle tray with four filled solvent bottles. Be ...

Page 48: Unpack

2 install the e2695 separations module 48 july 29, 2013, 715003794 rev. B software installed in the separations module. Similarly, the external remote management system that controls the separations module must also meet minimum software requirements. See the alliance e2695 separations module releas...

Page 49

Connect to the electrical power supply july 29, 2013, 715003794 rev. B 49 to connect to the electrical supply: 1. Ensure that the separations module is powered-off. 2. Connect the power cord to the connector on the rear panel. 3. Connect the other end of the power cord to a properly grounded ac powe...

Page 50

2 install the e2695 separations module 50 july 29, 2013, 715003794 rev. B connect tubing and attachments install b-series detector base and drip tray in the alliance hplc b-series configuration, the solvent bottle tray and detector base kit (176003104) consists of a solvent bottle tray and adjacent ...

Page 51

Connect tubing and attachments july 29, 2013, 715003794 rev. B 51 • replace the feet on the detector and then install the bottle tray and detector base. Important: you should replace the feet on the bottom of the detector so that they correctly fit into the detector base. Failure to do so may result...

Page 52

2 install the e2695 separations module 52 july 29, 2013, 715003794 rev. B detector, on the front left-hand side. You must install the drain fitting for the 2998; the rest are pre-installed. 2. Seat the detector on the detector base. 3. Make sure the end of the detector drip tray tubing protrudes fro...

Page 53

Connect tubing and attachments july 29, 2013, 715003794 rev. B 53 b series detector to drip tray tubing (2424 shown): install a and c series drip tray and support bracket in the alliance hplc a and c-series configurations, the detector drip tray is not included with the solvent bottle tray kit, but ...

Page 54

2 install the e2695 separations module 54 july 29, 2013, 715003794 rev. B • screwdriver, t-20 torx • wrench, 7 mm to install the drip tray on the detector (applies to 2424, 2489, and 2998 only): 1. Disconnect all cabling and other connections from the detector. 2. Open the front door of the detector...

Page 55

Connect tubing and attachments july 29, 2013, 715003794 rev. B 55 a and c series drip tray installed: 9. Install the elbow fitting on the right end of the drip tray. To install the detector support bracket and detector: 1. Power-off the separations module and disconnect the column module cable from ...

Page 56

2 install the e2695 separations module 56 july 29, 2013, 715003794 rev. B 3. Using the hardware provided with the support bracket, secure the bracket to the top of the rear panel on the separations module: • on the left side of the separations module, fasten the two m4 star screws. • on the right si...

Page 57

Connect tubing and attachments july 29, 2013, 715003794 rev. B 57 a and c series detector drain routing - no drip tray: drain fitting location tube routing end of tube syringe drip tray.

Page 58

2 install the e2695 separations module 58 july 29, 2013, 715003794 rev. B a and c series detector drain routing - with drip tray: install solvent supply tubing the tubing from the separations module to the solvent reservoirs is coiled and stored in front of the separations module, near the syringe c...

Page 59

Connect tubing and attachments july 29, 2013, 715003794 rev. B 59 to install the solvent lines: 1. Uncoil the solvent lines stored in front of the separations module, near the syringe compartment. 2. Remove the filter from each solvent line and insert the free end of each solvent line through a rese...

Page 60: Make Waste Line Connections

2 install the e2695 separations module 60 july 29, 2013, 715003794 rev. B solvents with no or very low flow for long periods, you can tee a solvent trap into the vent line to collect the small amount of condensation formed near the unit. Make waste line connections you must make waste line connectio...

Page 61

Connect tubing and attachments july 29, 2013, 715003794 rev. B 61 5. Connect the tubing you cut in step 4 between the elbow and the waste reservoir. Condensation waste line the condensation waste outlet from the sample compartment is also located under the front panel of the separations module, to t...

Page 62: Connect The Column

2 install the e2695 separations module 62 july 29, 2013, 715003794 rev. B to install the needle-wash and plunger seal-wash reservoirs: 1. Place the needle-wash reservoir and plunger seal-wash reservoir in the drip tray atop the separations module. 2. Place the needle-wash inlet line (green) in the n...

Page 63

Connect tubing and attachments july 29, 2013, 715003794 rev. B 63 to connect the column: 1. Pass the red outlet tubing through the opening in the middle of the right-hand side panel. 2. Connect the red outlet tubing to the column inlet, and tighten the fitting. Two sets of column clips and m4 × 10 s...

Page 64

2 install the e2695 separations module 64 july 29, 2013, 715003794 rev. B connect the column selection valve these optional column selection valves switch the flow path among multiple columns: • 3-column selection valve • 6-column selection valve • 2-column regeneration valve two-column selection va...

Page 65

Connect tubing and attachments july 29, 2013, 715003794 rev. B 65 three-column selection valve configuration (as shipped): install the 3-column selection valve after installing the column heater or column heater/cooler (see “install the column heater and column heater/cooler” on page 81 ). Required ...

Page 66

2 install the e2695 separations module 66 july 29, 2013, 715003794 rev. B 3. Replace the stainless steel union shipped inside the column heater or column heater/cooler with the column. Tip: the column can be the one supplied with the valve, or it can be a different one. 4. Route the waste line (inst...

Page 67

Connect tubing and attachments july 29, 2013, 715003794 rev. B 67 six-column selection valve connections (example): two-column regeneration valve the 2-column regeneration valve is shipped separately with a coil of 0.010-inch peek tubing, a 0.0025-inch id restrictor tube, and upchurch sealtight™ fit...

Page 68: Connect The Detector

2 install the e2695 separations module 68 july 29, 2013, 715003794 rev. B column regeneration valve connections (example): connect the detector the following provides general instructions for connecting the detector to the alliance hplc system. For more detailed information on connecting your specif...

Page 69: Signal Connections

Signal connections july 29, 2013, 715003794 rev. B 69 tip: to avoid spill damage, install a drip tray below the detector’s tubing connections. See page 50 through page 53 for drip tray installation instructions. Signal connections the rear panel of the separations module provides connection terminal...

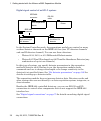

Page 70

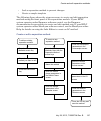

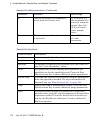

2 install the e2695 separations module 70 july 29, 2013, 715003794 rev. B connect signal cables: no yes start signal connections complete no yes connect to non-waters data system? Install rs-232 cable no yes connect to non-ieee, non-ethernet detector or an external auto- sampler? Install event and i...

Page 71: I/o Signal Connections

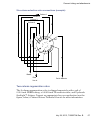

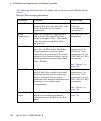

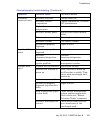

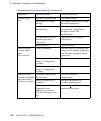

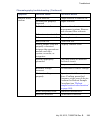

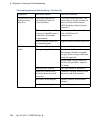

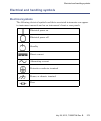

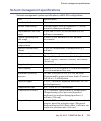

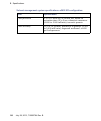

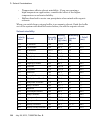

Signal connections july 29, 2013, 715003794 rev. B 71 i/o signal connections the rear panel includes two removable connectors that hold the screw terminals for i/o signals. These connectors are keyed so that they can be inserted only one way. I/o signal connectors: i/o signals the following table de...

Page 72

2 install the e2695 separations module 72 july 29, 2013, 715003794 rev. B i/o signals: signal description inject start an output (contact closure) to indicate that an injection began. Connect a wire pair to the two inject start terminals. Stop flow an input that enables other lc components to stop t...

Page 73

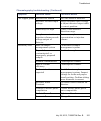

Signal connections july 29, 2013, 715003794 rev. B 73 the following table describes the parameter voltages for the chart out signals. Chart out outputs the analog signal (specified in the current separation method, or default separation method) to a device such as an integrator or strip chart record...

Page 74

2 install the e2695 separations module 74 july 29, 2013, 715003794 rev. B event switches switches 1 through 4 on connector a can serve as contact-closure switches to control column selection valves, fraction collectors, or similar external devices. Each pair of switch terminals (the two switch 1 ter...

Page 75: Digital Signal Connections

Signal connections july 29, 2013, 715003794 rev. B 75 digital signal connections the rear panel includes one rs-232 interface connector, one ieee-488 interface connector, and one ethernet connector for digital signal communications (see the figure “rear panel of the separations module:” on page 49 )...

Page 76

2 install the e2695 separations module 76 july 29, 2013, 715003794 rev. B ieee-488 connections use the ieee-488 interface connector (see the figure “rear panel of the separations module:” on page 49 ) to connect the separations module to these ieee-488 devices: • waters 2487, 486, 2414, 2410, and 41...

Page 77

Signal connections july 29, 2013, 715003794 rev. B 77 see the figure on page 36 for the signal connections (ieee-488 and rs-232) in a typical hplc system where the separations module functions as the system controller. See “empower control” on page 38 for a description of the signal connections used...

Page 78: Add Hardware Options

2 install the e2695 separations module 78 july 29, 2013, 715003794 rev. B as with ieee-488 control, triggering of waters ethernet-controlled devices, such as 2489, 2998, 2414, and 2424 detectors, occurs over the ethernet cable, and so requires no external i/o cables. Exception: waters 2475 fluoresce...

Page 79

Add hardware options july 29, 2013, 715003794 rev. B 79 • union (part number wat097334) to remove the side panel: note: this procedure applies only to a separations module with no column heater or column heater/cooler option installed. If the column heater or column heater/cooler option is installed...

Page 80

2 install the e2695 separations module 80 july 29, 2013, 715003794 rev. B to install a sample loop: 1. Use the 5/16-inch wrench to disconnect the sample loop from the pressure transducer, and the needle tee on the injector assembly (see the figure, below). 2. Connect one end of the sample loop to th...

Page 81: Install A Syringe

Add hardware options july 29, 2013, 715003794 rev. B 81 reinstall the right-hand side panel this procedure applies only to a separations module with no column heater or column heater/cooler option. If the column heater or column heater/cooler option is installed, see page 202 for instructions on how...

Page 82

2 install the e2695 separations module 82 july 29, 2013, 715003794 rev. B.

Page 83: Module For Operation

July 29, 2013, 715003794 rev. B 83 3 prepare the e2695 separations module for operation power-on the separations module power-on the separations module by moving the power switch (located at the top of the left-hand side panel) to i. The start-up diagnostic tests begins. Startup diagnostic tests on ...

Page 84: The Main Screen

3 prepare the e2695 separations module for operation 84 july 29, 2013, 715003794 rev. B once the electronic part of the diagnostics test is complete, the display shows the test results. The main screen when the initial part of the test routine is successful, the main screen appears in the display. T...

Page 85: Screen Display Overview

Operating overview july 29, 2013, 715003794 rev. B 85 screen display overview the main screen (and all others) contain these three areas: • banner • data • screen keys banner area the always displayed banner area of the screen indicates the current status of the separations module and reports this i...

Page 86: Use The Keypad

3 prepare the e2695 separations module for operation 86 july 29, 2013, 715003794 rev. B more screen key the more screen key appears on various screens. Pressing it displays an additional set of screen keys. Use the keypad the following table describes the functions of the keypad keys. Screen keys in...

Page 87

Operating overview july 29, 2013, 715003794 rev. B 87 keypad functions: key function moves the cursor one field to the left. Moves the cursor one field to the right. Moves the cursor to the field above a current field. Moves the cursor to the field below a current field. Moves the cursor to the left...

Page 88

3 prepare the e2695 separations module for operation 88 july 29, 2013, 715003794 rev. B enter values in parameter fields to enter parameter values: 1. Use the screen keys or the menu/status key to display the appropriate screen. 2. Use the arrow keys to select the parameter field you want to change....

Page 89

Operating overview july 29, 2013, 715003794 rev. B 89 a. Use the arrow keys to select the check box. B. Press a numeric that corresponds to an option to activate the option. 6. To clear a check box, press any numeric keyto clear the box and deactivate the option. Enter an alphanumeric string when yo...

Page 90

3 prepare the e2695 separations module for operation 90 july 29, 2013, 715003794 rev. B steps for entering alphabetic data: example: to enter the name “dave” in the user name field: 1. Press the abcdef screen key. 2. Press the d screen key. 3. Press the more screen key, then press the lowercase scre...

Page 91: Set Configuration Parameters

Configure the separations module july 29, 2013, 715003794 rev. B 91 6. Press the stuvwx screen key. 7. Press the v screen key. 8. Press the abcdef screen key. 9. Press the e screen key. 10. Press enter to store the entry. Configure the separations module before you can operate the separations module...

Page 92

3 prepare the e2695 separations module for operation 92 july 29, 2013, 715003794 rev. B tip: the baud rate is automatically set to 1200 when you set the waters 746 integrator as the printer type. • date format – selects between mdy (for example, aug 28 07) or dmy (28 aug 07). • pressure units – sele...

Page 93

Configure the separations module july 29, 2013, 715003794 rev. B 93 auto shutdown you can set up the separations module to shut down automatically after a specified period of inactivity, which is defined as follows: • no keyboard use • no injections performed • no changes sent to the separations mod...

Page 94

3 prepare the e2695 separations module for operation 94 july 29, 2013, 715003794 rev. B result: the separations module shuts down in the absence of activity for the specified period. 6. Press exit. If you want to use auto shutdown to turn off the lamp of a 2487 or 486 detector, program a lamp off ev...

Page 95

Configure the separations module july 29, 2013, 715003794 rev. B 95 9. Press the ok screen key. Set report options use the report options dialog box to define information sent to the printer or integrator. (before you print a report, select the printer in the printer section of the configuration scr...

Page 96

3 prepare the e2695 separations module for operation 96 july 29, 2013, 715003794 rev. B 5. Press exit to return to the main screen. The following figure is an example of a report made with all options selected. Sample report: report: alliance e2695 separations module serial number: f01sm7885m printe...

Page 97

Configure the separations module july 29, 2013, 715003794 rev. B 97 sample report (continued): compression check parameters the separations module provides a compression check to test for leaks in the sample loop, seal pack, and valves (v1, v2, and v3). You enter the parameter values that determine ...

Page 98: Configure The Operating Mode

3 prepare the e2695 separations module for operation 98 july 29, 2013, 715003794 rev. B configure the operating mode use the system field in the configuration screen to select one of nine operating modes: • no interaction – for standalone operation. • system controller – for standalone operation whe...

Page 99

Configure the separations module july 29, 2013, 715003794 rev. B 99 • controlled via rs232 (ascii) – use when a non-waters data system controls the separations module via rs-232 communications and using ascii control, as specified by the data system. • controlled via rs232 (binary) – use when a non-...

Page 100

3 prepare the e2695 separations module for operation 100 july 29, 2013, 715003794 rev. B 3. Press the detectors screen key. Result: a list of active devices and their ieee-488 interface bus addresses appears: a. Press the scan screen key to update the list. B. Press the ok screen key to return to th...

Page 101

Configure the separations module july 29, 2013, 715003794 rev. B 101 with mass spectrometers, using the ieee-488 interface between the masslynx computer and the separations module. To set the separations module to the controlled by masslynx mode: 1. Select the system field in the configuration scree...

Page 102

3 prepare the e2695 separations module for operation 102 july 29, 2013, 715003794 rev. B • choose ignore if the stop flow i/o terminals of the separations module are not used. • choose high if the output connection from the external autosampler to the stop flow i/o terminals of the separations modul...

Page 103

Prepare the solvent management system july 29, 2013, 715003794 rev. B 103 to set the separations module to the controlled via rs-232 (ascii) or (binary) mode: 1. Select the system field in the configuration screen, and then press enter to display a list of operating modes. 2. Select controlled via r...

Page 104: Prepare Solvent Reservoirs

3 prepare the e2695 separations module for operation 104 july 29, 2013, 715003794 rev. B prepare the solvent management system for operation: tip: to maintain the efficiency of the solvent management system, and to obtain accurate, reproducible chromatograms, use only chromatography-grade solvents. ...

Page 105: Degassing Solvents

Prepare the solvent management system july 29, 2013, 715003794 rev. B 105 version of “controlling contamination in uplc/ms and hplc/ms systems” at the waters’ website (www.Waters.Com) in the support library under waters division/services & support. Choose solvent reservoirs that provide a snug fit f...

Page 106

3 prepare the e2695 separations module for operation 106 july 29, 2013, 715003794 rev. B • the pressure field displays the current vacuum level in psia, bar, or kpa. Prime the plunger seal-wash pump the seal-wash solvent lubricates each plunger and flushes away any solvent or dried salts forced past...

Page 107

Prepare the sample management system for operation july 29, 2013, 715003794 rev. B 107 6. Push on the syringe plunger to force seal-wash solvent through the system. 7. When seal-wash solvent flows out the seal-wash waste tube, press the halt screen key. 8. Reinstall the inlet filter, and place the s...

Page 108: Purge The System

3 prepare the e2695 separations module for operation 108 july 29, 2013, 715003794 rev. B preparing the sample management system: purge the system purge the sample management system on these occasions: • you primed the solvent management system. • you changed solvents. • you see bubbles in the syring...

Page 109: Prime The Needle-Wash Pump

Prepare the sample management system for operation july 29, 2013, 715003794 rev. B 109 5. In the purge injector dialog box, adopt the default value of 6.0 volumes, and then press enter. Result: the solvent management system gradually attains a predetermined flow rate, flushing the sample loop with t...

Page 110: Adjust The Seal Pack

3 prepare the e2695 separations module for operation 110 july 29, 2013, 715003794 rev. B the following table lists some needle-wash solvents recommended for use with certain mobile phase conditions. High sample concentrations can require other needle-wash solvents. To prime the needle-wash pump: 1. ...

Page 111: Load Carousels

Prepare the sample management system for operation july 29, 2013, 715003794 rev. B 111 • a “compression check failed” error message appears. • a “missing restrictor” alarm appears during a diagnostic procedure. • you change the seal pack or needle. • you rebuild the seal pack. Before you adjust the ...

Page 112: Operation

3 prepare the e2695 separations module for operation 112 july 29, 2013, 715003794 rev. B 5. Close the carousel door. If you enable the “verify carousel placement” check box (the default setting) in the configuration screen, an error message appears if you attempt to make an injection from a carousel...

Page 113

Procedures for preparing the separations module for operation july 29, 2013, 715003794 rev. B 113 tip: to maximize degasser efficiency (and fill all four degasser chambers with solvent), fill all four solvent reservoirs (even if you use fewer than four solvents). If you choose water as one of the “u...

Page 114

3 prepare the e2695 separations module for operation 114 july 29, 2013, 715003794 rev. B change from a buffered solvent to an organic solvent to change from a buffered solvent to a totally organic solvent in the separations module: 1. Remove the solvent line from the reservoir containing the buffere...

Page 115: Flush The Flow Path

Power-off the separations module july 29, 2013, 715003794 rev. B 115 flush the flow path to flush buffered mobile phase from the flow path: 1. Replace the buffered mobile phase with hplc-quality water, and wet prime the system for 10 minutes at 3 ml/min (see “wet prime the system” on page 129 ). 2. ...

Page 116

3 prepare the e2695 separations module for operation 116 july 29, 2013, 715003794 rev. B.

Page 117: Front Panel Control

July 29, 2013, 715003794 rev. B 117 4 front panel control this chapter explains how to manually control the components of your hplc system through the front panel of the separations module. When the separations module is configured in the no interaction or operate gradient by event in mode, you cont...

Page 118: Reinitialize The System

4 front panel control 118 july 29, 2013, 715003794 rev. B reinitialize the system it is good practice to reinitialize the system instruments at least once a week. When the separations module and detectors are power-cycled (powered-off for a minimum of one minute, and then powered-on), each undergoes...

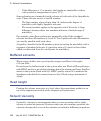

Page 119: Load The Carousel

Monitor your hplc system july 29, 2013, 715003794 rev. B 119 load the carousel to load the carousel: 1. Open the carousel door if it is closed. 2. Press the next screen key (or select the desired carousel screen key) to position the carousel turntable for loading the appropriate carousel. 3. Load th...

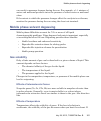

Page 120

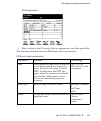

4 front panel control 120 july 29, 2013, 715003794 rev. B first page of the status screen: press the next page screen key to display the second page of the status screen. Second page of the status screen: press the sample queue screen key to display a list of current sample sets. Press the abort sam...

Page 121

Monitor your hplc system july 29, 2013, 715003794 rev. B 121 sample set queue: the following table describes the functions of the parameters in the status screen fields. You can make changes only in the fields outlined with a solid border. Status screen parameters: parameter description method indic...

Page 122

4 front panel control 122 july 29, 2013, 715003794 rev. B degasser • mode • vac pump • pressure indicates the status of the inline vacuum degasser (if installed). Selects the mode of operation: on, or off. Indicates whether the vacuum pump motor is active or idle. Current vacuum level in psia, bar, ...

Page 123: Perform Direct Functions

Perform direct functions july 29, 2013, 715003794 rev. B 123 perform direct functions the following figure outlines the procedure for using the front panel to set up the separations module to perform a direct function. Injector indicates the current position of the needle port. Valid positions are: ...

Page 124

4 front panel control 124 july 29, 2013, 715003794 rev. B steps to setting up a direct control run: to access the direct control functions: 1. Press menu/status to display the status screen (see the figure on page 120 ). 2. Press the direct function screen key. A list of direct functions appears. 3....

Page 125

Perform direct functions july 29, 2013, 715003794 rev. B 125 system prep system prep is a simple-to-use alternative to running the individual functions for wet prime, purge injector, equilibrate, and condition column (described later in this chapter). It performs a series of automated steps to fully...

Page 126: Dry Prime The System

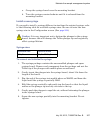

4 front panel control 126 july 29, 2013, 715003794 rev. B tip: to run timed events without injecting a sample, select the inject samples option from the direct functions menu, and enter an injection volume of 0 (see “inject samples” on page 133 ). Dry prime the system use the dry prime option to pri...

Page 127

Perform direct functions july 29, 2013, 715003794 rev. B 127 prime/vent valve with syringe: 6. Press the direct function screen key on the status screen. 7. Select dry prime, and then press enter. 8. In the dry prime dialog box, press the screen key corresponding to the solvent line you want to prim...

Page 128: Run System Prep

4 front panel control 128 july 29, 2013, 715003794 rev. B result: the solvent management system begins to operate. At the end of the priming period, the solvent management system turns off and the separations module enters the idle mode. 13. Perform a wet prime. Run system prep the system prep funct...

Page 129: Wet Prime The System

Perform direct functions july 29, 2013, 715003794 rev. B 129 to run system prep: 1. From either the main screen or the direct functions list, select system prep and press enter. 2. In the system prep dialog box, specify initial settings for the flow rate, composition, sample temperature, and column ...

Page 130

4 front panel control 130 july 29, 2013, 715003794 rev. B to wet prime the system: 1. In the status screen’s composition field, enter 100% for the solvent you want to use for wet priming. Tip: to facilitate purging air from the lines, start the wet prime using the solvent with the lowest viscosity. ...

Page 131

Perform direct functions july 29, 2013, 715003794 rev. B 131 4. Select wet prime, and then press enter. 5. Enter a flow rate of 0.000 ml/min and a time of 5 min. After the solvents in the vacuum degasser are equilibrated and the separations module is prepared to run, perform any of the following fun...

Page 132: Equilibrate The System

4 front panel control 132 july 29, 2013, 715003794 rev. B purge the 2410 and 410 reference cell you can purge the reference and sample sides of the waters 2414, 2410, and 410 differential refractometers using the purge 410 reference direct function. Purge the flow path whenever you change solvents o...

Page 133: Condition The Column

Perform direct functions july 29, 2013, 715003794 rev. B 133 condition the column you condition the column by running a solvent gradient through it without injecting samples or running the events table. You select a separation method (see chapter 6 ) that contains the gradient parameters, and the se...

Page 134

4 front panel control 134 july 29, 2013, 715003794 rev. B 2. Insert the carousel in the sample compartment, as described in “load sample vials” on page 118 . 3. Close the carousel door. Tip: if the door is ajar, the separations module does not perform the injection. 4. In the status screen, enter th...

Page 135: Automatic Runs

July 29, 2013, 715003794 rev. B 135 5 automatic runs you can set up the separations module to make automatic runs when it operates as follows: • in system controller or no interaction mode • controlled by empower software • controlled by masslynx software see “operating configurations” on page 34 fo...

Page 136

5 automatic runs 136 july 29, 2013, 715003794 rev. B main screen: controlled by empower software if your hplc system is controlled by empower software, you perform an automatic run using a project, instrument method, configured system, method set, and sample set stored in software. For details on pe...

Page 137: Run A Sample Set

Perform automatic runs in a standalone mode july 29, 2013, 715003794 rev. B 137 making an automatic run in a standalone mode: run a sample set to run a sample set in a standalone mode: 1. Press the run samples screen key in the main screen. Result: the run samples screen appears, listing all availab...

Page 138

5 automatic runs 138 july 29, 2013, 715003794 rev. B 2. Select the sample set you want to run, and then press one of the following screen keys to perform the indicated tasks: • initial conds – starts the solvent management system at the initial conditions (specified in the first line of the sample s...

Page 139: View Sample Sets

Perform automatic runs in a standalone mode july 29, 2013, 715003794 rev. B 139 view sample sets you can display the sample set table in one of three views described below. Press the next view screen key to scroll from one view to another. • functional view – displays the sample set with one functio...

Page 140

5 automatic runs 140 july 29, 2013, 715003794 rev. B sample set screen - loading view perform a run from a sample template you can perform an automated run in a standalone mode using a sample template stored in the separations module. See “create a sample template” on page 180 for the procedure to c...

Page 141

Perform automatic runs in a standalone mode july 29, 2013, 715003794 rev. B 141 7. Enter the location of the first standard vial, and then press the continue screen key. Requirement: you must use consecutive standard vials. 8. Make sure that the solvents listed in the dialog box are primed and in th...

Page 142: Stop A Run

5 automatic runs 142 july 29, 2013, 715003794 rev. B edit a separation method you can modify a separation method while a sample set is running. If the separation method is being used for the current injection, the current injection is unaffected. You must save the changes to the modified separation ...

Page 143

Perform automatic runs under empower software control july 29, 2013, 715003794 rev. B 143 configure your separations module for empower software control as described in “configure the operating mode” on page 98 . To make an automatic run, perform the following steps at the empower workstation: tip: ...

Page 144

5 automatic runs 144 july 29, 2013, 715003794 rev. B • when the separations module is running under empower software control, and you press abort in the run samples window, the separation module continues running the current gradient and event functions. • you can operate the separations module from...

Page 145: Create Methods, Sample Sets,

July 29, 2013, 715003794 rev. B 145 6 create methods, sample sets, and sample templates chapter 5 explains how to perform an automatic run in a standalone or remote control mode. You can create and store the separation methods, sample sets, and sample templates with which you make automatic runs whe...

Page 146: Sample Sets

6 create methods, sample sets, and sample templates 146 july 29, 2013, 715003794 rev. B • mobile phase composition and flow rate • sample temperature • column temperature • i/o parameters when you run a separation method on another, identically configured separations module in an alliance ® system, ...

Page 147

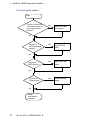

Create and edit separation methods july 29, 2013, 715003794 rev. B 147 • lock a separation method to prevent changes • create a sample template the following figure shows the steps necessary to create and edit separation methods using the front panel of the separations module. If your hplc system op...

Page 148: Create A Separation Method

6 create methods, sample sets, and sample templates 148 july 29, 2013, 715003794 rev. B create a separation method to create a separation method: 1. On the main screen, press the develop methods screen key. Result: the methods screen appears, displaying the following information: • the type of metho...

Page 149: Edit A Separation Method

Create and edit separation methods july 29, 2013, 715003794 rev. B 149 edit a separation method to edit an existing separation method: 1. On the main screen, press the develop methods screen key. 2. In the methods screen, select the separation method you want to edit. Tip: if the separation method i...

Page 150

6 create methods, sample sets, and sample templates 150 july 29, 2013, 715003794 rev. B lock and unlock a separation method to prevent changes to a separation method, you can lock the method. To lock a separation method: 1. On the main screen, press the develop methods screen key. 2. In the methods ...

Page 151

Set separation method parameters july 29, 2013, 715003794 rev. B 151 set mobile phase screen parameter values the mobile phase screen appears when you select a separation method to edit. Press the next or previous screen keys to move among the six method parameter screens. The icon between the next ...

Page 152

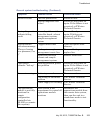

6 create methods, sample sets, and sample templates 152 july 29, 2013, 715003794 rev. B the following table describes the fields and screen keys in the mobile phase screen. Mobile phase screen parameters: parameter function value range initial flow specifies the initial flow rate of the method. For ...

Page 153

Set separation method parameters july 29, 2013, 715003794 rev. B 153 flow ramp specifies the time (in minutes) for the solvent delivery system to reach the maximum system flow rate. This limits the rate of change of the flow rate to protect the column from potentially damaging sudden changes in pres...

Page 154

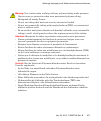

6 create methods, sample sets, and sample templates 154 july 29, 2013, 715003794 rev. B alarms the separations module maintains a log of all enabled errors that occur during operation. Each error can produce a variety of responses, as shown in the following table. Labels (screen key) displays the so...

Page 155

Set separation method parameters july 29, 2013, 715003794 rev. B 155 set gradient table parameter values the gradient table allows you to make time-based changes to the composition of the mobile phase during a run. You can program up to 25 lines in the gradient table. To set the parameters in the gr...

Page 156

6 create methods, sample sets, and sample templates 156 july 29, 2013, 715003794 rev. B 2. In the gradient screen, specify values in the gradient table as appropriate. 3. Press exit to save the gradient table. The following table describes the parameters in the gradient table. Gradient table paramet...

Page 157: Set Sample Parameter Values

Set separation method parameters july 29, 2013, 715003794 rev. B 157 gradient curves the figure, below presents a visual model of the gradient curve for each of the gradient curve values you can specify in the gradient table. Curve shapes for gradient profiles: set sample parameter values to enter p...

Page 158

6 create methods, sample sets, and sample templates 158 july 29, 2013, 715003794 rev. B sample screen: 2. In the sample screen, enter or select values in the sample screen parameter fields. The following table describes the parameters in the sample screen. Sample parameters: parameter function value...

Page 159

Set separation method parameters july 29, 2013, 715003794 rev. B 159 set autosampler parameter values to enter parameters in the autosampler screen: 1. Press the next or prev screen key to display the autosampler screen. Autosampler screen: syringe draw rate custom selects one of three pre-set syrin...

Page 160

6 create methods, sample sets, and sample templates 160 july 29, 2013, 715003794 rev. B 2. Enter values in the autosampler screen as appropriate. The following table describes the parameters in the autosampler screen. Autosampler parameters: parameter function value range pre-column volume the sampl...

Page 161: Set Column Parameter Values

Set separation method parameters july 29, 2013, 715003794 rev. B 161 set column parameter values to enter parameters in the column screen: 1. Press the next or prev screen keys to display the column screen. Column screen: 2. Enter values in the column screen, as appropriate. The following table desc...

Page 162: Set I/o Parameter Values

6 create methods, sample sets, and sample templates 162 july 29, 2013, 715003794 rev. B set i/o parameter values you set the i/o parameter values when you want to use analog signals to notify other instruments of the status of the separations module. You can do any of these things: • notify a detect...

Page 163

Set separation method parameters july 29, 2013, 715003794 rev. B 163 • select the system parameter signal sent through the chart out terminals. To enter parameters in the i/o screen: 1. Press the next or prev screen key to display the i/o screen. I/o screen: 2. Enter values in the i/o screen, as app...

Page 164

6 create methods, sample sets, and sample templates 164 july 29, 2013, 715003794 rev. B edit the i/o events table in the i/o events table, you set the timing for the following events to occur during a run: • changing the state of event switches • setting the column temperature • setting the sample c...

Page 165

Set separation method parameters july 29, 2013, 715003794 rev. B 165 i/o events table: 2. Enter values in the i/o events table as appropriate, and then press exit. The following table describes the i/o events table’s parameters. I/o events table parameters: parameter function value range time determ...

Page 166: Set Detector Parameters

6 create methods, sample sets, and sample templates 166 july 29, 2013, 715003794 rev. B set detector parameters in a standalone mode, system controller or no interaction, the separations module can control one waters 2414, 2410, or 410 differential refractometer parameter selects the value for the a...

Page 167

Set separation method parameters july 29, 2013, 715003794 rev. B 167 and as many as two uv/vis detector channels (waters 2487 or waters 486 detectors). Use the ieee-488 interface bus to connect the separations module to the detector(s). To make i/o connections to these and other detectors, see “i/o ...

Page 168

6 create methods, sample sets, and sample templates 168 july 29, 2013, 715003794 rev. B 4. To enter control parameters for waters detectors, refer to the “setting absorbance parameters” and “setting ri parameters” procedures that follow. Detector selections: parameter function selections absorbance ...

Page 169

Set separation method parameters july 29, 2013, 715003794 rev. B 169 set absorbance parameters to enter control parameters for a 2487 or 486 uv/vis detector: 1. Press the abs (1) or abs (2)screen key to display the appropriate absorbance detector screen. 2487(1) uv/vis detector screen: 486(1) uv/vis...

Page 170

6 create methods, sample sets, and sample templates 170 july 29, 2013, 715003794 rev. B see also: “edit the detector table” on page 172 for steps on programming detector events. The following tables list the parameters for a waters 2487 detector and a waters 486 detector. 2487 uv/vis parameters: par...

Page 171

Set separation method parameters july 29, 2013, 715003794 rev. B 171 set ri parameters to enter control parameters for a 2414, 2410, or 410 ri detector: 1. In the detectors screen, press the ri screen key to display the 410 detector screen. 410 detector screen: 2. Enter detector parameters as requir...

Page 172

6 create methods, sample sets, and sample templates 172 july 29, 2013, 715003794 rev. B edit the detector table in the detector table, you program 2487 and 486 detector events to occur during a run. To enter events in the detector table: 1. Press the table screen key in the detectors screen. The fol...

Page 173

Set separation method parameters july 29, 2013, 715003794 rev. B 173 detector events screen: 2. Enter parameters in the detector events screen and click exit. The following table describes the parameters in the detector events screen. The following table describes the actions that you can specify wi...

Page 174: Create and Edit A Sample Set

6 create methods, sample sets, and sample templates 174 july 29, 2013, 715003794 rev. B create and edit a sample set a sample set is a table of instructions that the separations module uses to perform an automated run in a standalone mode. During a run, the separations module performs the function i...

Page 175

Create and edit a sample set july 29, 2013, 715003794 rev. B 175 3. Click the sample set screen key. 4. Name the sample set, and then click enter. Tip: the separations module automatically adds the appropriate extension. 5. Enter information in the sample set table as appropriate. 6. Press exit to d...

Page 176

6 create methods, sample sets, and sample templates 176 july 29, 2013, 715003794 rev. B µl amount of sample (or standard) to inject from the current vial. 0.1 to 2000 in 0.1 µl increments (you can enter amounts greater than 100 µl if you install larger sample loops.) min time in minutes before the n...

Page 177

Create and edit a sample set july 29, 2013, 715003794 rev. B 177 auto standards use the autostds function to repetitively run standards after a specified number of vials or injections. You can specify multiple standards vials to support large runs. To use the auto standards function: 1. In the sampl...

Page 178

6 create methods, sample sets, and sample templates 178 july 29, 2013, 715003794 rev. B time delay to allow the sample to passively mix once sample from all vials is in the sample loop. To use the auto add function: 1. In the sample set screen, select autoadd from the drop-down list of functions, an...

Page 179: Link Rows In A Sample Set

Create and edit a sample set july 29, 2013, 715003794 rev. B 179 link rows in a sample set you can link together one or more rows in a sample set so that you can perform multiple functions for the same set of vials. For example, you can link an inject sample function with a purge function, as shown ...

Page 180: Create A Sample Template

6 create methods, sample sets, and sample templates 180 july 29, 2013, 715003794 rev. B create a sample template using a sample template, you define the major parameters of a run and then enter variable parameters, such as number of vials, vial position, and so forth just before you begin the run. T...

Page 181: Maintenance

July 29, 2013, 715003794 rev. B 181 7 maintenance maintenance considerations this chapter describes routine maintenance procedures you can perform to ensure the separations module consistently provides accurate and precise results. Safety and handling when you perform maintenance procedures on your ...

Page 182: Proper Operating Procedures

7 maintenance 182 july 29, 2013, 715003794 rev. B proper operating procedures to ensure your separations module runs as designed, follow the operating procedures and guidelines described in chapter 3 . Reinitialize the system it is good practice to reinitialize the system instruments at least once a...

Page 183: Overview

Maintain the solvent management system july 29, 2013, 715003794 rev. B 183 maintain the solvent management system perform the procedures in this section when you discover a problem with a specific component in the solvent management system. For information about isolating problems in the solvent man...

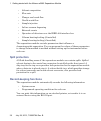

Page 184

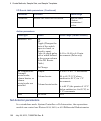

7 maintenance 184 july 29, 2013, 715003794 rev. B solvent management system components: tp01366a accumulator piston chamber system transducer in-line filter primary piston chamber inlet check valve prime/vent valve seal-wash pump primary transducer inlet check valve.

Page 185

Maintain the solvent management system july 29, 2013, 715003794 rev. B 185 remove the head, seal-wash assembly, and plunger for information about isolating problems in the solvent management system, see chapter 8 . See the figure “solvent management system piston chamber components (exploded view):”...

Page 186

7 maintenance 186 july 29, 2013, 715003794 rev. B • replace the plunger seals • clean or replace a plunger • service the seal-wash seals solvent management system piston chamber components (exploded view): to remove the head, seal-wash assembly, and plunger: 1. On the main screen, press the diag scr...

Page 187

Maintain the solvent management system july 29, 2013, 715003794 rev. B 187 page 230 ) and place the seal-wash reservoir on the same level as the separations module. 5. Remove the head, seal-wash assembly, and plunger as one unit (see the figure “plunger, seal-wash, and head:” on page 193 ). For more...

Page 188

7 maintenance 188 july 29, 2013, 715003794 rev. B • plastic tweezers or can of compressed air plunger seal replacement to replace the plunger seal: 1. Remove the head (see “remove the head, seal-wash assembly, and plunger” on page 185 ). 2. Use the plastic end of the seal removal tool to remove the ...

Page 189

Maintain the solvent management system july 29, 2013, 715003794 rev. B 189 face seal replacement to replace the face seals: 1. Remove the head (see “remove the head, seal-wash assembly, and plunger” on page 185 ). 2. Direct compressed air into the center of the face seal, or use plastic tweezers to ...

Page 190

7 maintenance 190 july 29, 2013, 715003794 rev. B 8. If the separations module does not have solvent in the lines, perform a dry prime to draw solvent into the plunger cavity before you perform a wet prime or start delivery of solvents (see “prime the solvent management system” on page 107 ). Replac...

Page 191

Maintain the solvent management system july 29, 2013, 715003794 rev. B 191 seal-wash assembly seals: 4. Wet the seal insertion tool, each new seal, and seal opening with 100% alcohol. 5. Place the new plunger wash seal on the seal insertion tool with the spring side facing away from the seal inserti...

Page 192

7 maintenance 192 july 29, 2013, 715003794 rev. B c. Reinsert the seal-wash tubes into the manifold, and then fully tighten the head nut. D. Return the release ring to the run position. If the separations module’s solvent lines are empty, dry prime the solvent management system before you wet prime ...

Page 193

Maintain the solvent management system july 29, 2013, 715003794 rev. B 193 plunger, seal-wash, and head: 3. Reinspect the plunger. If the plunger shows excessive wear, replace it. If necessary, replace the plunger seal and face seals (see “notes on replacing the plunger seals” on page 187 . To repla...

Page 194

7 maintenance 194 july 29, 2013, 715003794 rev. B if the separations module’s solvent lines are empty, dry prime the solvent management system before you wet prime it or start delivering solvents (see “dry prime the system” on page 126 ). Replace an inlet check valve cartridge tip: for information a...

Page 195

Maintain the solvent management system july 29, 2013, 715003794 rev. B 195 inlet check valve: 5. Tip the inlet check valve housing upside down to dislodge the old check valve cartridge. 6. Inspect the inlet check valve housing, clean it, if necessary, and wet it with 100% alcohol. 7. Wet the new che...

Page 196: Replace The In-Line Filter

7 maintenance 196 july 29, 2013, 715003794 rev. B requirement: set the gpv valve to the solvent a position (see “perform the motors and valves diagnostic test” on page 230 ). 13. If the separations module’s solvent lines are empty, dry prime the solvent management system before you wet prime or star...

Page 197

Maintain the sample management system july 29, 2013, 715003794 rev. B 197 5. Insert the replacement in-line filter element into the in-line filter housing (see the figure “replacing the in-line filter:” on page 197 ). Replacing the in-line filter: 6. Reconnect the in-line filter inlet and outlet hou...

Page 198

7 maintenance 198 july 29, 2013, 715003794 rev. B tip: for information about isolating problems in the sample management system, see chapter 8 . Maintaining the sample management system involves these tasks: • replacing the lower needle wash frit • replacing the syringe • replacing the needle and se...

Page 199

Maintain the sample management system july 29, 2013, 715003794 rev. B 199 sample management system components (front view): tp03541 syringe motor syringe sample carousel.

Page 200

7 maintenance 200 july 29, 2013, 715003794 rev. B sample management system components (right-side view): injector assembly sample loop transducer sample loop.

Page 201

Maintain the sample management system july 29, 2013, 715003794 rev. B 201 remove side panel of separations module some maintenance procedures, such as sample loop and needle and seal-pack replacement, require that you remove the side panel of the separations module to access internal components. Not...

Page 202

7 maintenance 202 july 29, 2013, 715003794 rev. B 2. Disconnect these cables: • ethernet and power cord from rear of detector • external control cable and power cord from rear of column heater or column heater/cooler • power cord from rear of separations module 3. Remove the detector from its base a...

Page 203

Maintain the sample management system july 29, 2013, 715003794 rev. B 203 3. Open the column heater or column heater/cooler door and route the column tubing through the clip on the front of the unit. 4. Slide the drip tray back into the bottom of the column heater or column heater/cooler compartment...

Page 204

7 maintenance 204 july 29, 2013, 715003794 rev. B • vial of needle-wash solvent being used or alternatively 100% alcohol (methanol or isopropanol) • replacement one-piece needle-wash frit tip: immerse the replacement frit for several minutes in the vial of the needle-wash solvent being used, or alte...

Page 205

Maintain the sample management system july 29, 2013, 715003794 rev. B 205 5. Unscrew the lower frit retainer by hand. 6. Remove the frit from the retainer by inserting a small-diameter pick (or paper clip) through the hole in the retainer cap, and discard it. 7. Install the new frit, which has been ...

Page 206

7 maintenance 206 july 29, 2013, 715003794 rev. B syringe assembly components: 4. On the main screen, press the diag screen key. 5. On the diagnostics screen, press the other tests screen key. 6. In the other tests screen, select motors and valves. 7. In the motors and valves screen, verify valve v3...

Page 207

Maintain the sample management system july 29, 2013, 715003794 rev. B 207 a. Grasp the syringe barrel near the mounting bracket. B. Turn the syringe counterclockwise until it is released from the mounting bracket. Install a new syringe if you need to install a syringe different in size from the orig...

Page 208

7 maintenance 208 july 29, 2013, 715003794 rev. B syringe and mounting bracket: 7. Push the syringe plunger down so that the threaded end slides through the syringe guide mounting bracket. 8. Hand tighten the syringe. 9. On the diagnostics screen, press other tests. 10. In the other tests screen, se...

Page 209

Maintain the sample management system july 29, 2013, 715003794 rev. B 209 to configure the separations module for a new syringe size: 1. On the main screen, press the configure screen key. 2. In the configuration screen, select the syringe size field. 3. In the drop-down menu, select the appropriate...

Page 210

7 maintenance 210 july 29, 2013, 715003794 rev. B • contaminant peaks appearing in the chromatogram cannot be corrected by changing the wash solvent in the needle wash system. Tip: for information about isolating problems in the sample management system, see chapter 8 . The procedure for replacing t...

Page 211

Maintain the sample management system july 29, 2013, 715003794 rev. B 211 injector assembly components: to access the injector assembly: note: this procedure applies only to a separations module with no column heater or column heater/cooler option installed. If the column heater or column heater/coo...

Page 212

7 maintenance 212 july 29, 2013, 715003794 rev. B remove the injector assembly: to remove the injector: 1. Cut and remove the tie wraps securing the needle wash lines and restrictor loop. 2. Disconnect the column fluid line between the injector assembly and the column. 3. Insert a 5/16-inch open-end...

Page 213

Maintain the sample management system july 29, 2013, 715003794 rev. B 213 4. Use a 5/16-inch open-end wrench to remove the restrictor loop fitting that is attached to the shorter of the two stainless steel tubes, exiting the bottom of the injector. 5. Disconnect the injector motor cable from the int...

Page 214

7 maintenance 214 july 29, 2013, 715003794 rev. B to replace the needle in the seal pack: 1. With the seal pack removed from the injector, lubricate the tip of the injector needle with 100% alcohol. 2. Align the needle port with the scallop located on the underside of the seal pack, before sliding t...

Page 215

Maintain the sample management system july 29, 2013, 715003794 rev. B 215 to install the seal pack with needle: 1. With the seal pack with needle removed from the injector, rotate the injector’s motor shaft until the needle tee is furthest from the injector base (see the figure “injector assembly co...

Page 216

7 maintenance 216 july 29, 2013, 715003794 rev. B tip: the two needle-wash lines are color-coded. The needle-wash in tubing is green. The needle-wash out tubing is yellow or clear. 3. Reconnect the optical switch cable to the driver circuit board. 4. Reconnect the injector motor cable to the interco...

Page 217

Maintain the sample management system july 29, 2013, 715003794 rev. B 217 • the sample carousels do not turn properly. • the carousel carrier does not engage. Required materials • wrench, allen, 3-mm • nonabrasive cleaner to access the sample compartment: 1. Open the sample compartment and syringe c...

Page 218

7 maintenance 218 july 29, 2013, 715003794 rev. B to clean the sample compartment: 1. Push down about 1/4-inch on the spring-retaining pin in the center of the carousel carrier to loosen the carousel carrier (see the figure “sample compartment components:” on page 218 ). Sample compartment component...

Page 219: Diagnostic Testing and

July 29, 2013, 715003794 rev. B 219 8 diagnostic testing and troubleshooting you troubleshoot the separations module using diagnostic tests and functions, and the troubleshooting procedures described in this chapter. Tip: for information about startup diagnostic tests, see “startup diagnostic tests”...

Page 220: Use The Error Log

8 diagnostic testing and troubleshooting 220 july 29, 2013, 715003794 rev. B use the error log in the error log, view the status messages and warnings that the separations module generated. You can view or print the information to help track possible problems that occurred during system operation. R...

Page 221: Exit The Diagnostics Screens

Perform main diagnostic tests july 29, 2013, 715003794 rev. B 221 perform main diagnostic tests you can perform many diagnostic operations from two diagnostics screens: • diagnostics screen – accesses certain system status information and diagnostic and performance tests for the solvent management s...

Page 222

8 diagnostic testing and troubleshooting 222 july 29, 2013, 715003794 rev. B diagnostics screen fields the fields in the diagnostics screen include: • transducers fields – display the current pressure readings for the separations module’s three transducers. • lifetime counters fields – display total...

Page 223

Perform main diagnostic tests july 29, 2013, 715003794 rev. B 223 prime the plunger seal-wash pump the prime plunger seal-wash test automatically primes the solvent management system plunger seal-wash pump. Perform this test if you discern a lack of flow in the plunger seal-wash system or if you are...

Page 224

8 diagnostic testing and troubleshooting 224 july 29, 2013, 715003794 rev. B perform the compression check the compression check serves these functions: • automatically compresses the solvent in the sample loop and syringe • checks for leaks • determines the compressibility of the solvent in the sys...

Page 225: Prime The Needle-Wash Pump

Perform main diagnostic tests july 29, 2013, 715003794 rev. B 225 failing result if the compression check indicates a failing result, perform these actions: • verify that the parameters you entered for the test are correct (see page 97 ). • confirm that the appropriate solvent is used and that the s...

Page 226: Adjust The Seals

8 diagnostic testing and troubleshooting 226 july 29, 2013, 715003794 rev. B • confirm that fluid is properly drawn from the needle wash reservoir. Adjust the seals the adjust seals test procedure automatically adjusts and optimizes the vertical needle port position in the seal of the autoinjector. ...

Page 227

Perform main diagnostic tests july 29, 2013, 715003794 rev. B 227 confirm the seal data values—top, bottom, and width—fall within the acceptable ranges shown in the table, below. A seal geometry error can appear if these conditions apply: • the adjust seals parameter values are not in the acceptable...

Page 228

8 diagnostic testing and troubleshooting 228 july 29, 2013, 715003794 rev. B c. Contact waters technical service. Service utilities diagnostic tests service utilities diagnostic tests are for use by waters technical service representatives only. These utilities are password-protected. Perform other ...

Page 229

Perform other diagnostic tests and functions july 29, 2013, 715003794 rev. B 229 head removal and replacement moves the plunger into its most forward position so that you can remove the head and replace the plunger and seal wash assembly. “head removal and replacement function” on page 237 inputs an...

Page 230

8 diagnostic testing and troubleshooting 230 july 29, 2013, 715003794 rev. B perform the motors and valves diagnostic test the motors and valves test results inform you whether the parameter values you assign to motors and valves fall within limits acceptable for protecting the system and column. Th...

Page 231

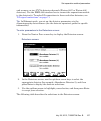

Perform other diagnostic tests and functions july 29, 2013, 715003794 rev. B 231 to perform the motors and valves test, select motors and valves in the other diagnostics screen, and then press the ok screen key. The motors and valves diagnostic screen appears. Motors and valves diagnostic screen: to...

Page 232

8 diagnostic testing and troubleshooting 232 july 29, 2013, 715003794 rev. B control the gpv valve the following table describes the valve positions available in the gpv drop-down list. Control valves v1–v4 to control a valve: 1. In the motors and valves screen, select the valve whose position you w...

Page 233: Sensors Diagnostic Function

Perform other diagnostic tests and functions july 29, 2013, 715003794 rev. B 233 sensors diagnostic function the sensors diagnostic function monitors and displays the current position of all the digital sensors in the separations module. To perform the sensors diagnostic function, select sensors in ...

Page 234: Static Leak Test

8 diagnostic testing and troubleshooting 234 july 29, 2013, 715003794 rev. B static leak test the static leak test performs a solvent pressure ramp up, and monitors the pressure decay in the solvent delivery system to determine whether the inlet check valves, tubing, fittings, or plunger seals are f...

Page 235

Perform other diagnostic tests and functions july 29, 2013, 715003794 rev. B 235 to perform the static leak test: 1. In the other diagnostic screen, select static leak test in the other diagnostics screen, and then press the ok screen key. 2. Follow the instructions in the static leak test screen. 3...

Page 236: Valve Leak Test

8 diagnostic testing and troubleshooting 236 july 29, 2013, 715003794 rev. B • after 7 to 8 minutes of wet priming, inspect the plumbing and fittings for leaks. Use thermal paper, which turns dark on contact with methanol, to detect leaks. Repair any leaks. • remove the resistor, replacing it with a...

Page 237: Inputs And Outputs Test

Perform other diagnostic tests and functions july 29, 2013, 715003794 rev. B 237 4. In the valve leak dialog box, press enter to display the test location selections, and then select the valve to be tested (v1 or v2) or the needle seal pack position (above seal or below seal). 5. Select the test pre...

Page 238

8 diagnostic testing and troubleshooting 238 july 29, 2013, 715003794 rev. B i/o diagnostics screen: 2. Connect two jumper wires between any one of the paired switch outputs that you want to test and any of the inputs. 3. In the i/o diagnostics screen, select the paired switch to which the jumper wi...

Page 239: Keypad Test

Perform other diagnostic tests and functions july 29, 2013, 715003794 rev. B 239 keypad test the keypad test tests the keypad keys. You press the key on the keypad and observe the key as it changes appearance in the keypad diagnostic screen. Run this test if you experience problems with the keypad. ...

Page 240

8 diagnostic testing and troubleshooting 240 july 29, 2013, 715003794 rev. B you can monitor the sample heater/cooler temperature by connecting a chart recorder to the chart out terminals on the rear panel of the separations module. Complete these tasks before you perform the test: • remove all caro...

Page 241

Perform other diagnostic tests and functions july 29, 2013, 715003794 rev. B 241 complete these tasks before you perform the test: • remove all carousels and vials from the sample compartment. • confirm that the column heater or column heater/cooler (if installed) is not in use. To run the defrost s...

Page 242: Create A Gpv Test Method

8 diagnostic testing and troubleshooting 242 july 29, 2013, 715003794 rev. B result: these events occur during the test: • the software prompts you to close the column heater module door. • the column heater test begins at ambient temperature. • the column heater temperature ramps up (for about 8 mi...

Page 243: Verify The Firmware Checksum

Troubleshoot july 29, 2013, 715003794 rev. B 243 turn off the gradient proportioning valve turning off the gradient proportioning valve (gpv) is useful when you replace an inlet check valve cartridge (see “replace an inlet check valve cartridge” on page 194 ). To turn off the gradient proportioning ...

Page 244

8 diagnostic testing and troubleshooting 244 july 29, 2013, 715003794 rev. B 2. Compare the current system operation with the way the system operated before the problem arose. To identify normal operating conditions, maintain a daily log noting overall system performance. Specifically, measure the p...

Page 245

Troubleshoot july 29, 2013, 715003794 rev. B 245 when to call waters technical service you can correct many problems with a alliance e2695 separations module relatively easy. However, if you cannot correct a condition, contact waters technical service. When you do, have the following information ava...

Page 246