- DL manuals

- Waters

- Security Sensors

- TQ Detector

- Quick Start Manual

Waters TQ Detector Quick Start Manual

Summary of TQ Detector

Page 1

Waters tq detector quick start guide 71500126803/revision a copyright © waters corporation 2007. All rights reserved..

Page 2: Copyright Notice

Copyright notice © 2007 waters corporation. Printed in the united states of america and ireland. All rights reserved. This document or parts thereof may not be reproduced in any form without the written permission of the publisher. The information in this document is subject to change without notice...

Page 3

Iii customer comments waters’ technical communications department invites you to tell us of any errors you encounter in this document or to suggest ideas for otherwise improving it. Please help us better understand what you expect from our documentation so that we can continuously improve its accura...

Page 4: Safety Considerations

Iv safety considerations some reagents and samples used with waters ® instruments can pose chemical, biological, and radiological hazards. Be sure you are aware of the potentially hazardous effects of all substances you work with. Always observe good laboratory practice (glp) guidelines, published b...

Page 5

V flammable solvents hazard never let the nitrogen supply pressure fall below 400 kpa (4 bar, 58 psi) during analyses that require flammable solvents. Connect to the lc output with a gas-fail connector to stop the lc solvent if the nitrogen supply fails. High temperature hazard waters tq detector hi...

Page 6

Vi high voltage hazard safety advisories consult appendix a for a comprehensive list of warning and caution advisories. Warning: • to avoid electric shock, do not remove the tq detector’s protective panels. The components they cover are not user-serviceable. • to avoid non-lethal electric shock, any...

Page 7: Operating This Device

Vii operating this device when operating this device, follow standard quality control procedures and the guidelines presented in this section. Symbols intended use the waters tandem quadrupole (tq) detector is intended to be used as a research tool to deliver authenticated mass measurement in both m...

Page 8

Viii calibration to calibrate lc systems, follow acceptable calibration methods using at least five standards to generate a standard curve. The concentration range for standards should cover the entire range of quality-control samples, typical specimens, and atypical specimens. To calibrate mass spe...

Page 9

Ix ivd authorized representative information ivd authorized representative waters corporation (micromass uk limited) is registered in the united kingdom with the medicines and healthcare products regulatory agency (mhra) at market towers, 1 nine elms lane, london, sw8 5nq. The reference number is iv...

Page 10

X.

Page 11: Table of Contents

Table of contents xi safety considerations .......................................................................................... Iv instrument-specific safety considerations ......................................................... Iv flammable solvents hazard .....................................

Page 12

Xii table of contents ion optics ............................................................................................................. 1-9 ms operating modes ....................................................................................... 1-10 ms/ms operating modes ......................

Page 13

Table of contents xiii shutting down the tq detector .................................................................. 2-15 putting the tq detector in standby mode for overnight shutdown ........... 2-15 complete tq detector shutdown ....................................................................

Page 14

Xiv table of contents caution symbol .................................................................................................. A-5 warnings that apply to all waters instruments ......................................... A-5 electrical and handling symbols .......................................

Page 15: Waters Tq Detector Overview

1-1 1 waters tq detector overview this chapter describes the instrument, including its controls and gas and plumbing connections. Contents: topic page overview 1-2 ionization techniques and source probes 1-7 ion optics 1-9 ms operating modes 1-10 ms/ms operating modes 1-11 sample inlet 1-14 vacuum s...

Page 16: Overview

1-2 waters tq detector overview overview waters tq detector the waters ® tq detector is a tandem quadrupole, atmospheric pressure ionization (api) mass spectrometer. Designed for routine uplc™/ms/ms analyses in quantitative and qualitative applications, it can operate at fast acquisition speeds comp...

Page 17

Overview 1-3 waters tq detector with doors open: intellistart technology intellistart™ technology monitors lc/ms/ms performance and reports when the tq detector is ready for use. The intellistart software automatically tunes and mass calibrates the tq detector and displays performance readbacks. Int...

Page 18

1-4 waters tq detector overview acquity tqd uplc/ms system note: the waters tq detector is designed for compatibility with the acquity uplc system; if you are not using an acquity uplc system, refer to the documentation relevant to the lc system being used. The acquity tqd uplc/ms system includes an...

Page 19

Overview 1-5 waters acquity tqd: masslynx mass spectrometry software and data system masslynx is a high-performance mass spectrometry application that acquires, analyzes, manages, and distributes ultra-violet (uv), evaporative light scattering, analog, and mass spectrometry data. Masslynx software p...

Page 20

1-6 waters tq detector overview • reviewing data. • printing data. See also: masslynx 4.1 user documentation and online help for more information on installing and using masslynx software. Acquity uplc console the acquity uplc console is a software application with which you configure settings, moni...

Page 21

Ionization techniques and source probes 1-7 ionization techniques and source probes electrospray ionization (esi) in electrospray ionization (esi), a strong electrical charge is given the eluent as it emerges from a nebulizer. The droplets that compose the resultant aerosol undergo a reduction in si...

Page 22

1-8 waters tq detector overview esci mode: see also: “electrospray ionization (esi)” on page 1-7 . Atmospheric pressure chemical ionization a dedicated high performance atmospheric pressure chemical ionization (apci) probe is offered as an option. See also: the waters tq detector operator’s guide fo...

Page 23: Ion Optics

Ion optics 1-9 ion optics the tq detector’s ion optics operate as follows: • samples from the lc or intellistart fluidics system are introduced at atmospheric pressure into the ionization source. • the ions pass through the sample cone into the vacuum system. • the ions pass through the transfer opt...

Page 24: Ms Operating Modes

1-10 waters tq detector overview ms operating modes the following table shows the ms operating modes. The ms1 mode, in which ms1 is used as the mass filter, is the most common and most sensitive method of performing ms analysis. It is directly analogous to using a single-quadrupole mass spectrometer...

Page 25: Ms/ms Operating Modes

Ms/ms operating modes 1-11 ms/ms operating modes the following table shows the ms/ms operating modes. Product (daughter) ion mode product ion mode is the most commonly used ms/ms operating mode. An ion of interest is selected for fragmentation in the collision cell, thus yielding structural informat...

Page 26

1-12 waters tq detector overview • method development for mrm screening studies: – identifying product ions for use in mrm transitions. – optimizing cid tuning conditions to maximize the yield of a specific product ion to be used in mrm analysis. Precursor (parent) ion mode precursor ion mode: typic...

Page 27

Ms/ms operating modes 1-13 multiple reaction monitoring mode: typical application you typically use mrm to quantify known analytes in complex samples: • drug metabolite and pharmacokinetic studies. • environmental, for example, pesticide and herbicide analysis. • forensic or toxicology, for example,...

Page 28: Sample Inlet

1-14 waters tq detector overview constant neutral loss mode: typical application you typically use constant neutral loss mode to screen mixtures for a specific class of compound that is characterized by a common fragmentation pathway, indicating the presence of compounds containing a common function...

Page 29: Rear Panel

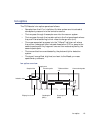

Rear panel 1-15 rear panel the following figure shows the rear panel locations of the connectors used to operate the tq detector with external devices. Tq detector rear panel: vacuum waters corporation 34 maple street milford, ma 01757 u.S.A. Serial number acn 065444751 vacuum source vent api gas 6....

Page 30

1-16 waters tq detector overview intellistart fluidics system overview the intellistart fluidics system is built into the tq detector. The system delivers sample directly to the ms probe in one of two ways: • from the lc column • from two integral reservoirs. Tip: the integral reservoirs can also de...

Page 31

Intellistart fluidics system operation 1-17 intellistart fluidics system operation control of solvent and sample delivery during auto-tuning, auto-calibration, and method development is automatically performed by the software. Intellistart configuration requirements can be set in the system console....

Page 32

1-18 waters tq detector overview 6. Click ok. 7. Click reservoir a or b. 8. In the select reservoir dialog box, click a or b. 9. Click ok. Tip: if the selected reservoir is different from the current reservoir, the system purges as the reservoir changes. 10. Click the current diverter valve position...

Page 33

Intellistart fluidics system operation 1-19 to program the ms method: 1. In the masslynx window, click ms method. 2. In the ms methods window, click options > method events. 3. In the method events dialog box, select the appropriate flow state, as shown in the following table. Tip: at instrument pow...

Page 34

1-20 waters tq detector overview.

Page 35: Preparing The Waters Tq

2-1 2 preparing the waters tq detector for operation this chapter describes how to start and shut-down the tq detector. Contents: topic page starting the tq detector 2-2 preparing the intellistart fluidics system 2-9 rebooting the tq detector 2-14 shutting down the tq detector 2-15.

Page 36: Starting The Tq Detector

2-2 preparing the waters tq detector for operation starting the tq detector note: the waters tq detector is designed for compatibility with the acquity uplc system; if you are not using an acquity uplc system, refer to the documentation relevant to the system being used. Starting the tq detector ent...

Page 37

Starting the tq detector 2-3 4. Press the power switch on the top, left-hand side of the tq detector and acquity instruments. Each system instrument “beeps” and runs a series of startup tests. 5. Allow 3 minutes for the embedded pc to initialize. An audible alert sounds when the pc is ready. The pow...

Page 38

2-4 preparing the waters tq detector for operation 8. Click control > pump to start the roughing pump. The operate led remains off. Tip: there is a 20-second delay, during which the turbopump is starting, before the roughing pump starts. Intellistart displays “instrument in standby”..

Page 39

Starting the tq detector 2-5 9. Click resolve or operate to put the tq detector into operate mode. When the tq detector is in good operating condition, intellistart displays “ready”. Tip: clicking resolve should prepare the system for operation, putting the tq detector into operate mode. If clicking...

Page 40

2-6 preparing the waters tq detector for operation configuring intellistart to configure intellistart: 1. In the acquity uplc console system tree, click tq detector. 2. Click configure > intellistart configuration. 3. In the intellistart configuration dialog box, in the checks list, select the check...

Page 41

Starting the tq detector 2-7 running the tq detector at high flow rates acquity uplc is run at high flow rates. To optimize desolvation, and thus sensitivity, the acquity tqd system should be run at appropriate gas flows and desolvation temperatures. Intellistart automatically sets these when you en...

Page 42

2-8 preparing the waters tq detector for operation monitoring the tq detector leds light-emitting diodes on the tq detector indicate its operational status. Power led the power led, to the top, left-hand side of the tq detector’s front panel, indicates when the tq detector is powered-on or powered-o...

Page 43

Preparing the intellistart fluidics system 2-9 preparing the intellistart fluidics system see also: appendix b of the waters tq detector operator’s guide. Installing the solvent manifold drip tray required materials chemical-resistant, powder-free gloves to install the solvent manifold drip tray: in...

Page 44

2-10 preparing the waters tq detector for operation installing the reservoir bottles required materials chemical-resistant, powder-free gloves to install the reservoir bottles: 1. Remove the reservoir bottle caps. 2. Screw the reservoir bottles onto the tq detector as shown below. Warning: the reser...

Page 45

Preparing the intellistart fluidics system 2-11 diverter valve positions column and syringe in home position after power-up after power-up, the flow path between the column and waste is open. The syringe is empty, and the flow path between it and waste is open. Lc position in the lc position, the fl...

Page 46

2-12 preparing the waters tq detector for operation infusion position in infusion mode combined position with lc flow and syringe in idle mode column infusion lc waste probe syringe reservoir a reservoir b off on b a infusion column combined lc waste probe syringe reservoir a reservoir b off off b a...

Page 47

Preparing the intellistart fluidics system 2-13 waste position in the waste position, both the lc flow and the infusion syringe flow are directed to waste. The syringe mode can be only static or dispensing (that is, never drawing). Purging the infusion syringe whenever you replace a solution bottle,...

Page 48: Rebooting The Tq Detector

2-14 preparing the waters tq detector for operation rebooting the tq detector sometimes you might need to reboot the tq detector: • when the tune window fails to respond. • when masslynx fails to initialize. • immediately following software download. Rebooting the tq detector by pressing the reset b...

Page 49

Shutting down the tq detector 2-15 shutting down the tq detector recommendation: you should always leave the tq detector in operate mode except when performing routine maintenance. It is not necessary to switch to standby mode. However, shutting down the tq detector is acceptable provided that you c...

Page 50

2-16 preparing the waters tq detector for operation complete tq detector shutdown to completely shut down the tq detector: 1. Put the tq detector in standby mode. See also: “putting the tq detector in standby mode for overnight shutdown” on page 2-15 . 2. In the acquity uplc console, click api gas ....

Page 51

Shutting down the tq detector 2-17 emergency tq detector shutdown to shut down the tq detector in an emergency: 1. Operate the power button on the front of the tq detector. 2. Disconnect the power cable from the back of the tq detector. Warning: the tq detector’s power switch does not isolate the in...

Page 52

2-18 preparing the waters tq detector for operation.

Page 53: Esi and Esci Modes of

3-1 3 esi and esci modes of operation this chapter describes how to prepare the tq detector for the following modes of operation: • esi (electrospray ionization) • esci (combined electrospay and atmospheric pressure chemical ionization) if your system uses apci mode, refer to chapter 6 of the waters...

Page 54: Introduction

3-2 esi and esci modes of operation introduction the esi and esci ionization mode options use the standard esi probe that is fitted to the instrument when it is shipped from the factory. For esci operation, the corona pin is used in conjunction with the esi probe. The following sections explain how ...

Page 55

Installing the esi probe 3-3 3. Remove the protective sleeve, if fitted, from the esi probe tip. 4. Ensure that the contacts on the esi probe align with the probe adjuster assembly contacts, and carefully slide the esi probe into the hole in the probe adjuster assembly. 5. Secure the esi probe by ti...

Page 56

3-4 esi and esci modes of operation esi probe mounted on the source enclosure, showing the connections to the front panel: 6. Connect the esi probe’s ptfe tube to the nebulizer gas connection. 7. Ensure that the probe adjuster assembly’s electrical lead is connected to the instrument’s probe connect...

Page 57: Installing The Corona Pin

Installing the corona pin 3-5 installing the corona pin required materials • chemical-resistant, powder-free gloves • needle-nose pliers • 80:20 acetonitrile/water to install the corona pin: 1. In the acquity uplc console, click standby , and confirm that the operate indicator is not illuminated. 2....

Page 58

3-6 esi and esci modes of operation 4. Use the needle-nose pliers to remove the blanking plug from the corona pin mounting contact. Tip: store the blanking plug in a safe location. Corona pin mounting contact: 5. Use the needle-nose pliers to fit the corona pin to the mounting contact. Requirement: ...

Page 59

Optimizing the esi probe for esci operation 3-7 corona pin: 6. Use the vernier probe adjuster to position the esi probe tip so that it is pointing approximately mid-way between the tips of the sample cone and corona pin. See also: figure titled “esi probe mounted on the source enclosure, showing the...

Page 60

3-8 esi and esci modes of operation 4. Click ok. 5. In the masslynx tune window, click ion mode > esci+. 6. Select box numbers 1 and 2, clear box numbers 3 and 4 (above the peak display). 7. In row 1, set ion mode to es. 8. In row 2, set ion mode to apci. 9. In each row, set mass to 42 and span to 5...

Page 61: Removing The Corona Pin

Removing the corona pin 3-9 removing the corona pin required materials • chemical-resistant, powder-free gloves • needle-nose pliers to remove the corona pin: 1. In the acquity uplc console, click standby , and confirm that the operate indicator is not illuminated. 2. Open the instrument’s access do...

Page 62

3-10 esi and esci modes of operation 4. Use the needle-nose pliers to remove the corona pin from its mounting contact. Tip: store the corona pin in a safe location. See also: figure titled “corona pin:” on page 3-7 . 5. Use the needle-nose pliers to fit the blanking plug to the corona pin mounting c...

Page 63: Removing The Esi Probe

Removing the esi probe 3-11 removing the esi probe required materials chemical-resistant, powder-free gloves to remove the esi probe: 1. Prepare the instrument for working on the source. See also: chapter 5 of the waters tq detector operator’s guide. 2. Open the instrument’s access door. 3. Disconne...

Page 64

3-12 esi and esci modes of operation 8. If available, fit the protective sleeve to the esi probe tip. 9. Close the instrument’s access door..

Page 65: Operating The Waters Tq

4-1 4 operating the waters tq detector this chapter is an introduction to operating your tq detector; it explains these tasks: • setting-up your tq detector. • performing a sample tune. • developing instrument methods. • verifying the system. Contents: topic page setting-up the instrument 4-2 perfor...

Page 66: Setting-Up The Instrument

4-2 operating the waters tq detector setting-up the instrument the intellistart instrument setup calibrates the instrument and then, by default, performs a sample tune. If calibration is unnecessary, you can perform only a sample tune. See also: “performing a sample tune” on page 4-7 . Tip: instrume...

Page 67

Setting-up the instrument 4-3 8. Click ok. 9. Click to purge the system. Tip: system purge takes approximately 2 minutes. 10. Repeat step 9 . Rationale: purging the intellistart fluidics system twice ensures that any traces of previously used solutions are removed from the system. 11. Click on the c...

Page 68

4-4 operating the waters tq detector 8. Click fill from reference file. Result: the default mass values appear in the instrument tune masses text boxes. Rule: you must click fill from reference file every time you select a new calibration reference file. Instrument setup parameters dialog box instru...

Page 69

Setting-up the instrument 4-5 to specify the sample tune parameters: 1. In the intellistart setup parameters dialog box, click the sample tune tab. 2. Click copy instrument setup masses. Rationale: the tune masses from the instrument setup tab are copied into the sample tune masses boxes. Instrument...

Page 70

4-6 operating the waters tq detector instrument setup parameters dialog box sample tune tab with example sample tune parameters: to start instrument set-up: 1. Click start . Result: a message appears reminding you to ensure that the calibrant solutions, calibration parameters and lc flow are set cor...

Page 71: Performing A Sample Tune

Performing a sample tune 4-7 example acquity uplc console display during calibration: intellistart creates tune and calibration files, which are saved as specified on the instrument setup parameters dialog box’s instrument setup tab. Once calibration is complete, the sample tune starts on the four m...

Page 72

4-8 operating the waters tq detector 2. In the acquity uplc console system tree, click tq detector. 3. Ensure that the ion mode is es+. 4. In the acquity uplc console system tree, click intellistart. 5. Clear the instrument setup check box. 6. If you require system pre-checking, click pre-checks. Ra...

Page 73

Developing experiment methods 4-9 developing experiment methods intellistart allows you to automatically develop quantitative mrm or sir methods for compounds of interest. Up to four compounds can be handled in a single process. Up to three transitions can be selected for each compound.In this examp...

Page 74

4-10 operating the waters tq detector instrument setup parameters dialog box method developer tab: in this case, sulfadimethoxine.Exp is the method file created. The validation pane selections save optimization data for validation purposes and creates an autotune report file (sulfadimethoxine.Xml). ...

Page 75

Verifying the system using system qc 4-11 verifying the system using system qc the system qc function uses pre-defined lc/ms methods to test the system by injecting a diagnostic sample on-column. The sample helps identify any problems with the configured system by providing these data: • sensitivity...

Page 76

4-12 operating the waters tq detector an inlet file must be created independently. See also: the masslynx online help. Requirement: intellistart reads the tune, inlet, and method files from the system qc project (systemqc.Pro). You must save the tune, inlet, and method files to the aqudb folder of t...

Page 77

Verifying the system using system qc 4-13 3. In the intellistart setup parameters dialog box’s system qc tab, enter the number of pre-run and run injections, the vial (that is, the position of your sample in the autosampler) and the injection volume. Tip: at least two injections are required for a r...

Page 78

4-14 operating the waters tq detector tip: the calculations do not include injections where no peak was found. For example, if only eight out of ten injections evidence detected peaks, the acceptance test results would be based on eight values rather than ten. However, the system qc process would al...

Page 79: Safety Advisories

A-1 a safety advisories waters instruments display hazard symbols designed to alert you to the hidden dangers of operating and maintaining the instruments. Their corresponding user guides also include the hazard symbols, with accompanying text statements describing the hazards and telling you how to...

Page 80: Warning Symbols

A-2 safety advisories warning symbols warning symbols alert you to the risk of death, injury, or seriously adverse physiological reactions associated with an instrument’s use or misuse. Heed all warnings when you install, repair, and operate waters instruments. Waters assumes no liability for the fa...

Page 81

Warning symbols a-3 warnings that apply to particular instruments, instrument components, and sample types the following warnings can appear in the user manuals of particular instruments and on labels affixed to them or their component parts. Burst warning this warning applies to waters instruments ...

Page 82

A-4 safety advisories mass spectrometer shock hazard this warning applies to all waters mass spectrometers. This warning applies to certain instruments when they are in operate mode. Biohazard warning this warning applies to waters instruments that can be used to process material that might contain ...

Page 83: Caution Symbol

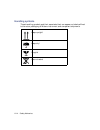

Caution symbol a-5 chemical hazard warning this warning applies to waters instruments that can process corrosive, toxic, flammable, or other types of hazardous material. Caution symbol the caution symbol signifies that an instrument’s use or misuse can damage the instrument or compromise a sample’s ...

Page 84

A-6 safety advisories attention: changes or modifications to this unit not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment. Important: toute modification sur cette unité n’ayant pas été expressément approuvée par l’autorité responsa...

Page 85

Warnings that apply to all waters instruments a-7 warning: use caution when working with any polymer tubing under pressure: • always wear eye protection when near pressurized polymer tubing. • extinguish all nearby flames. • do not use tubing that has been severely stressed or kinked. • do not use n...

Page 86

A-8 safety advisories attenzione: prestare attenzione durante l’utilizzo dei tubi di polimero pressurizzati: • indossare sempre occhiali da lavoro protettivi nei pressi di tubi di polimero pressurizzati. • estinguere ogni fonte di ignizione circostante. • non utilizzare tubi soggetti che hanno subit...

Page 87

Warnings that apply to all waters instruments a-9.

Page 88

A-10 safety advisories warning: the user shall be made aware that if the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired. Attention: l’utilisateur doit être informé que si le matériel est utilisé d’une façon non spécifiée par ...

Page 89

Warnings that apply to all waters instruments a-11 warning: to protect against fire hazard, replace fuses with those of the same type and rating. Attention: remplacez toujours les fusibles par d’autres du même type et de la même puissance afin d’éviter tout risque d’incendie. Vorsicht: zum schutz ge...

Page 90

A-12 safety advisories warning: to avoid possible electrical shock, disconnect the power cord before servicing the instrument. Attention: afin d’éviter toute possibilité de commotion électrique, débranchez le cordon d’alimentation de la prise avant d’effectuer la maintenance de l’instrument. Vorsich...

Page 91

Electrical and handling symbols a-13 electrical and handling symbols electrical symbols these can appear in instrument user manuals and on the instrument’s front or rear panels. Electrical power on electrical power off standby direct current alternating current protective conductor terminal frame, o...

Page 92

A-14 safety advisories handling symbols these handling symbols and their associated text can appear on labels affixed to the outer packaging of waters instrument and component shipments. Keep upright! Keep dry! Fragile! Use no hooks!.