- DL manuals

- Waters

- Measuring Instruments

- Xevo TQ-S micro

- Overview And Maintenance Manual

Waters Xevo TQ-S micro Overview And Maintenance Manual

Summary of Xevo TQ-S micro

Page 1

Waters xevo tq-s micro overview and maintenance guide 715004599/ revision b copyright © waters corporation 2014 – 2016 all rights reserved.

Page 2

Ii january 11, 2016, 715004599 rev. B.

Page 3: Copyright Notice

January 11, 2016, 715004599 rev. B iii general information copyright notice © 2014 – 2016 waters corporation. Printed in the united states of america and in ireland. All rights reserved. This document or parts thereof may not be reproduced in any form without the written permission of the publisher....

Page 4: Customer Comments

Iv january 11, 2016, 715004599 rev. B customer comments waters’ technical communications organization invites you to report any errors that you encounter in this document or to suggest ideas for otherwise improving it. Help us better understand what you expect from our documentation so that we can c...

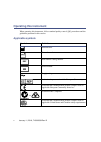

Page 5: Safety Hazard Symbol Notice

January 11, 2016, 715004599 rev. B v safety hazard symbol notice documentation needs to be consulted in all cases where the symbol is used to find out the nature of the potential hazard and any actions which have to be taken. Considerations specific to the xevo tq-s micro power cord replacement haza...

Page 6

Vi january 11, 2016, 715004599 rev. B spilled solvents hazard flammable solvents hazard when using flammable solvents, ensure that a stream of nitrogen continuously flushes the instrument’s source, and the nitrogen supply pressure remains above 400 kpa (4 bar, 58 psi). You must also install a gas-fa...

Page 7

January 11, 2016, 715004599 rev. B vii glass-breakage hazard high temperature hazard xevo tq-s micro high temperature hazard: warning: to avoid injuries from broken glass, falling objects, or exposure to toxic or biohazardous substances, never place containers on top of the instrument or on its fron...

Page 8

Viii january 11, 2016, 715004599 rev. B hazards associated with removing an instrument from service when you remove the instrument from use to repair or dispose of it, you must decontaminate all of its vacuum areas. These are the areas in which you can expect to encounter the highest levels of conta...

Page 9: Equipment Misuse Notice

January 11, 2016, 715004599 rev. B ix fcc radiation emissions notice changes or modifications not expressly approved by the party responsible for compliance, could void the users authority to operate the equipment. This device complies with part 15 of the fcc rules. Operation is subject to the follo...

Page 10: Operating This Instrument

X january 11, 2016, 715004599 rev. B operating this instrument when operating this instrument, follow standard quality-control (qc) procedures and the guidelines presented in this section. Applicable symbols symbol definition manufacturer date of manufacture part number catalog number serial number ...

Page 11

January 11, 2016, 715004599 rev. B xi consult instructions for use electrical and electronic equipment with this symbol may contain hazardous substances and should not be disposed of as general waste. For compliance with the waste electrical and electronic equipment directive (weee) 2012/19/eu, cont...

Page 12: Audience and Purpose

Xii january 11, 2016, 715004599 rev. B audience and purpose this guide is for operators of varying levels of experience. It gives an overview of the instrument and explains how to prepare it for operation, switch between modes of operation, and maintain it. Intended use of the xevo tq-s micro waters...

Page 13: Emc Considerations

January 11, 2016, 715004599 rev. B xiii • use one or more internal standard compounds, preferably isotopically labeled analytes. Emc considerations canada spectrum management emissions notice this class a digital product apparatus complies with canadian ices-001. Cet appareil numérique de la classe ...

Page 14: Ec Authorized Representative

Xiv january 11, 2016, 715004599 rev. B ec authorized representative waters corporation stamford avenue altrincham road wilmslow sk9 4ax united kingdom telephone: +44-161-946-2400 fax: +44-161-946-2480 contact: quality manager.

Page 15: Table of Contents

January 11, 2016, 715004599 rev. B xv copyright notice ..................................................................................................................... Iii trademarks ...................................................................................................................

Page 16

Xvi january 11, 2016, 715004599 rev. B combined esi and apci (esci)...................................................................................... 31 atmospheric pressure chemical ionization (apci) .......................................................... 31 dual-mode appi/apci source .........

Page 17

January 11, 2016, 715004599 rev. B xvii rebooting the instrument .................................................................................................... 53 leaving the mass spectrometer ready for operation ........................................................ 54 emergency shutdown of...

Page 18

Xviii january 11, 2016, 715004599 rev. B 4 maintenance procedures .......................................................................................... 89 maintenance schedule .......................................................................................................... 91 spare par...

Page 19

January 11, 2016, 715004599 rev. B xix disassembling the source ion block assembly................................................................ 127 cleaning the ion block components................................................................................ 132 assembling the source ion block...

Page 20

Xx january 11, 2016, 715004599 rev. B replacing the air filter ....................................................................................................... 184 replacing the roughing pump oil ..................................................................................... 187 replaci...

Page 21

January 11, 2016, 715004599 rev. B xxi connecting the edwards oil-free roughing pump ........................................................... 238 connecting electric cables to the edwards oil-free roughing pump............................... 241 connecting to the nitrogen gas supply ................

Page 22

Xxii january 11, 2016, 715004599 rev. B.

Page 23: Specifications and Operating

January 11, 2016, 715004599 rev. B 23 1 specifications and operating modes this chapter describes the instrument, including its controls and connections for gas and plumbing. Contents: topic page uses and compatibility ....................................................................................

Page 24: Uses and Compatibility

1 specifications and operating modes 24 january 11, 2016, 715004599 rev. B uses and compatibility the waters ® xevo ® tq-s micro is a triple quadrupole, atmospheric pressure ionization (api) mass spectrometer. Designed for routine hplc/ms/ms and uplc ® /ms/ms analyses in quantitative and qualitative...

Page 25

Uses and compatibility january 11, 2016, 715004599 rev. B 25 xevo tq-s micro shown with visor down, and visor up: intellistart technology intellistart™ technology monitors lc/ms/ms performance and reports when the instrument is ready for use. The software automatically tunes and mass calibrates the ...

Page 26

1 specifications and operating modes 26 january 11, 2016, 715004599 rev. B the intellistart fluidics 1 system is built into the instrument. It delivers sample directly to the ms probe from the lc column or from two integral reservoirs. The integral reservoirs can also deliver sample through direct o...

Page 27

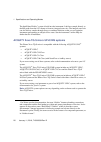

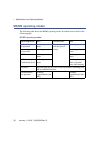

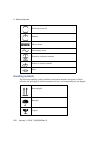

Uses and compatibility january 11, 2016, 715004599 rev. B 27 acquity system core components core system components for each acquity system are listed below: system core components acquity uplc • binary solvent manager • sample manager • column heater • uplc detectors • solvent tray • acquity uplc co...

Page 28

1 specifications and operating modes 28 january 11, 2016, 715004599 rev. B for further instruction, see the acquity uplc system operator’s guide , acquity uplc h-class system guide, acquity uplc i-class system guide, and controlling contamination in uplc/ms and hplc/ms systems (part number 715001307...

Page 29: Software and Data System

Uses and compatibility january 11, 2016, 715004599 rev. B 29 xevo tq-s micro with acquity uplc system: software and data system masslynx v4.1 software can control the mass spectrometer. See page 30 for more information about those applications. Masslynx software enables these major operations: • con...

Page 30

1 specifications and operating modes 30 january 11, 2016, 715004599 rev. B masslynx v4.1 masslynx software acquires, analyzes, manages, and distributes mass spectrometry, ultraviolet (uv), evaporative light scattering, and analog data. Openlynx tm and targetlynx tm application managers are included ...

Page 31: Combined Esi and Apci (Esci)

Ionization techniques and source probes january 11, 2016, 715004599 rev. B 31 ionization techniques and source probes note: available source options can vary depending on the software used to operate the xevo tq-s micro. Refer to the masslynx online help for more information about supported sources....

Page 32: Nanoflow Source

1 specifications and operating modes 32 january 11, 2016, 715004599 rev. B lamp drive assembly. The appi lamp drive assembly comprises a uv lamp and a repeller electrode. In addition, a specially shaped, dual, appi/apci corona pin can be used. You can operate the source in appi, apci, or dual mode, ...

Page 33: Ionkey Source

Ionization techniques and source probes january 11, 2016, 715004599 rev. B 33 atmospheric solids analysis probe (asap) the asap facilitates rapid analysis of volatile and semivolatile compounds in solids, liquids, and polymers. It is particularly suited to analyzing low-polarity compounds.The asap d...

Page 34: Intellistart Fluidics System

1 specifications and operating modes 34 january 11, 2016, 715004599 rev. B intellistart fluidics system functionality the intellistart fluidics system is a solvent delivery system built into the mass spectrometer. It delivers sample or solvent directly to the ms probe in one of three ways: • from th...

Page 35: System Operation

Intellistart fluidics system january 11, 2016, 715004599 rev. B 35 system operation the software automatically controls solvent and sample delivery during auto-tuning, auto-calibration, and method development. The selector valve systematically makes connections between the fluidics components to car...

Page 36: Ion Optics

1 specifications and operating modes 36 january 11, 2016, 715004599 rev. B ion optics the mass spectrometer’s ion optics operate as follows: 1. Samples from the lc or intellistart fluidics system are introduced at atmospheric pressure into the ionization source. 2. The ions pass through the sample c...

Page 37

Ms operating modes january 11, 2016, 715004599 rev. B 37 in ms mode, the instrument can acquire data at scan speeds as high as 20,000 da/s. Use this mode for instrument tuning and calibration before ms/ms analysis. See the mass spectrometer’s online help for further information. Use the selected ion...

Page 38: Ms/ms Operating Modes

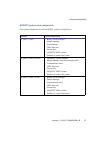

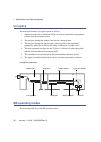

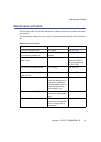

1 specifications and operating modes 38 january 11, 2016, 715004599 rev. B ms/ms operating modes the following table shows the ms/ms operating modes, described in more detail in the following pages. Ms/ms operating modes: operating mode ms1 collision cell ms2 product (daughter) ion spectrum static (...

Page 39: Product (Daughter) Ion Mode

Ms/ms operating modes january 11, 2016, 715004599 rev. B 39 product (daughter) ion mode product ion mode is the most commonly used ms/ms operating mode. You can specify an ion of interest for fragmentation in the collision cell, thus yielding structural information. Product ion mode: typical applica...

Page 40

1 specifications and operating modes 40 january 11, 2016, 715004599 rev. B typical application you typically use the precursor ion mode for structural elucidation—that is, to complement or confirm product scan data—by scanning for all the precursors of a common product ion. Multiple reaction monitor...

Page 41

Ms/ms operating modes january 11, 2016, 715004599 rev. B 41 typical application you typically use radar mode during method development prior to performing mrm or pics to quantify known analytes in complex samples: • drug metabolite and pharmacokinetic studies • environmental, for example, pesticide ...

Page 42: Constant Neutral Loss Mode

1 specifications and operating modes 42 january 11, 2016, 715004599 rev. B constant neutral loss mode constant neutral loss mode detects the loss of a specific neutral fragment or functional group from an unspecified precursor(s). The scans of ms1 and ms2 are synchronized. When ms1 transmits a speci...

Page 43: Sample Inlet

Sample inlet january 11, 2016, 715004599 rev. B 43 sample inlet either of two methods delivers solvent and sample to the installed probe: • an lc system, which delivers the eluent from an lc analysis. • intellistart fluidics system, which uses onboard solutions to automate instrument optimization. Y...

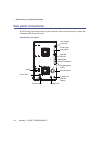

Page 44: Rear Panel Connections

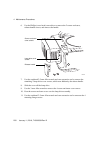

1 specifications and operating modes 44 january 11, 2016, 715004599 rev. B rear panel connections the following figure shows the rear panel locations of the connectors used to operate the instrument with external devices. Instrument rear panel: power turbo vacuum source vent nitrogen inlet collision...

Page 45: Preparing For Operation

January 11, 2016, 715004599 rev. B 45 2 preparing for operation this chapter describes how to start and shut down the instrument. Contents: topic page starting the mass spectrometer ..................................................................... 46 preparing the intellistart fluidics system......

Page 46

2 preparing for operation 46 january 11, 2016, 715004599 rev. B starting the mass spectrometer starting the mass spectrometer entails powering-on the workstation, logging in, powering-on the mass spectrometer and all other instruments, and then starting the masslynx software. Requirement: you must p...

Page 47

Starting the mass spectrometer january 11, 2016, 715004599 rev. B 47 5. Allow 3 minutes for the embedded pc (located inside the mass spectrometer) to initialize and to sound an alert indicating that the pc is ready. Tip: the power and status leds change as follows: • each system instrument’s power l...

Page 48

2 preparing for operation 48 january 11, 2016, 715004599 rev. B 7. To evacuate (pump down) the mass spectrometer, follow the procedure below for masslynx software. Masslynx software: a. Click intellistart in the masslynx main window’s lower left-hand corner. Result: the mass spectrometer’s console a...

Page 49

Starting the mass spectrometer january 11, 2016, 715004599 rev. B 49 verifying the instrument’s state of readiness when the instrument is in good operating condition, the power and operate leds show constant green. You can view any error messages in intellistart software. Monitoring the instrument l...

Page 50

2 preparing for operation 50 january 11, 2016, 715004599 rev. B running the instrument at different flow rates the acquity uplc system runs at high flow rates. To optimize desolvation, and thus sensitivity, run the acquity xevo tq-s micro system at appropriate gas flows and desolvation temperatures....

Page 51

Preparing the intellistart fluidics system january 11, 2016, 715004599 rev. B 51 preparing the intellistart fluidics system for additional information, see page 246 and appendix d . Installing the reservoir bottles use standard reservoir bottles (15-ml) for instrument setup and calibration. Use the ...

Page 52

2 preparing for operation 52 january 11, 2016, 715004599 rev. B to install the reservoir bottles: 1. Remove the reservoir bottle caps. 2. Screw the reservoir bottles onto the instrument, as shown below. 3. For each reservoir bottle, ensure that the end of the solvent delivery tube is positioned so t...

Page 53: Purging The Infusion Pump

Rebooting the instrument january 11, 2016, 715004599 rev. B 53 purging the infusion pump whenever you replace a solution bottle, purge the infusion pump with the solution that you are going to use next. See the mass spectrometer’s online help for details. Requirement: ensure that the end of the tubi...

Page 54

2 preparing for operation 54 january 11, 2016, 715004599 rev. B tip: an audible alert sounds when the reboot sequence is complete. Leaving the mass spectrometer ready for operation leave the mass spectrometer in operate mode except in the following cases: • when performing routine maintenance • when...

Page 55

January 11, 2016, 715004599 rev. B 55 3 changing the mode of operation this chapter describes how to prepare the mass spectrometer for the following modes of operation: • esi (electrospray ionization) • esci (combined electrospray and atmospheric pressure chemical ionization) • apci (atmospheric pre...

Page 56: Esi Mode

3 changing the mode of operation 56 january 11, 2016, 715004599 rev. B esi mode the following sections explain how to install and remove an esi probe. For further details on running esi applications, see page 31 . Installing the esi probe required material chemical-resistant, powder-free gloves to i...

Page 57

Esi mode january 11, 2016, 715004599 rev. B 57 3. With the probe label facing you, carefully slide the esi probe into the hole in the probe adjuster assembly, ensuring that the probe location dowel aligns with the location hole of the probe adjuster assembly. 4. Tighten the probe locking ring to sec...

Page 58

3 changing the mode of operation 58 january 11, 2016, 715004599 rev. B 6. Using peek tubing equal to 0.004-inch id, connect port s of the selector valve to the esi probe. Recommendation: to reduce peak broadening, use 0.004-inch id tubing for sample flow rates ≤ 1.2 ml/min; use 0.005-inch id tubing ...

Page 59: Removing The Esi Probe

Esi mode january 11, 2016, 715004599 rev. B 59 removing the esi probe required material chemical-resistant, powder-free gloves to remove the esi probe: 1. Prepare the instrument for removing the probe according to the procedure on page 97 , “preparing the instrument for operations on or inside its s...

Page 60: Esci Mode

3 changing the mode of operation 60 january 11, 2016, 715004599 rev. B esci mode to run esci applications, you must fit an esi probe and corona pin to the esi/apci/esci source enclosure. See “installing the esi probe” on page 56 , “installing the corona pin in the source” on page 101 , and “intellis...

Page 61

Apci mode january 11, 2016, 715004599 rev. B 61 apci mode: hot gas from the ionsabre ii probe passes between the sample cone and the corona pin, which is typically operated with a discharge current of 5 µa. Mobile phase molecules rapidly react with ions generated by the corona discharge to produce s...

Page 62

3 changing the mode of operation 62 january 11, 2016, 715004599 rev. B to install the ionsabre ii probe: 1. Prepare the instrument for working on the source (see page 97 ). 2. With the probe label facing toward you, carefully slide the ionsabre ii probe into the hole in the probe adjuster assembly, ...

Page 63

Apci mode january 11, 2016, 715004599 rev. B 63 • if you are replacing the tubing between the selector valve and the probe, minimize the length to reduce peak broadening. • when cutting the tubing to length, cut it squarely (that is, perpendicular to its horizontal axis). 5. Install the corona pin (...

Page 64

3 changing the mode of operation 64 january 11, 2016, 715004599 rev. B removing the ionsabre ii probe required material chemical-resistant, powder-free gloves to remove the ionsabre ii probe: 1. Prepare the instrument for working on the source (see page 97 ). 2. Remove the corona pin (see page 101 )...

Page 65: Combined Appi/apci Source

Combined appi/apci source january 11, 2016, 715004599 rev. B 65 combined appi/apci source operate this optional, replacement source enclosure in appi, apci, or dual appi/apci mode. Dual-mode appi/apci performs rapid switching between ionization modes. Appi operation in atmospheric pressure photoioni...

Page 66: Apci Operation

3 changing the mode of operation 66 january 11, 2016, 715004599 rev. B apci operation the atmospheric pressure chemical ionization (apci) mode produces singly charged protonated or deprotonated molecules for a large range of nonvolatile analytes. In apci mode, the source is fitted with an apci coron...

Page 67: Dual-Mode Operation

Combined appi/apci source january 11, 2016, 715004599 rev. B 67 dual-mode operation dual-mode operation enables rapid switching between appi and apci ionization modes and allows high-throughput operations (for example, for sample screening). You replace the standard corona pin with a specially shape...

Page 68

3 changing the mode of operation 68 january 11, 2016, 715004599 rev. B the combined appi/apci source components the combined appi/apci source comprises the standard ionsabre ii probe and a source enclosure with an appi lamp drive incorporated. The combined appi/apci source enclosure: notice: to prev...

Page 69

Combined appi/apci source january 11, 2016, 715004599 rev. B 69 the uv lamp, which you ignite via a control in the masslynx tune window, provides a constant photon output. You vary the intensity of incident radiation upon the sample molecules by adjusting the distance between the uv lamp and probe t...

Page 70

3 changing the mode of operation 70 january 11, 2016, 715004599 rev. B installing the combined appi/apci source required material chemical-resistant, powder-free gloves to install the combined appi/apci source: 1. Prepare the instrument for working on the source (see page 97). 2. Remove the probe fr...

Page 71: Enclosure

Combined appi/apci source january 11, 2016, 715004599 rev. B 71 7. Connect the ht cable to the instrument’s front panel connector. 8. Install the ionsabre ii probe to the source, and ensure that it is working correctly (see page 61 ). Tip: an automatic pressure test runs each time you close the sour...

Page 72: Nanoflow Source

3 changing the mode of operation 72 january 11, 2016, 715004599 rev. B 7. Fit the blanking plug to the pin’s mounting contact. Nanoflow source the nanoflow source enclosure comprises the nanoflow stage (for x- axis, y- axis, and z- axis adjustment), the sprayer-enclosure, and a microscope camera. Na...

Page 73

Nanoflow source january 11, 2016, 715004599 rev. B 73 the low flow rates involved with operating the nanoflow source prohibit its use with the instrument’s solvent delivery system. Installing the nanoflow source required material chemical-resistant, powder-free gloves to install the nanoflow source:...

Page 74

3 changing the mode of operation 74 january 11, 2016, 715004599 rev. B 4. On the nanoflow source, loosen the stage retaining screw, pull the stop screw, and slide the stage fully out of the enclosure. 5. Using both hands, fit the nanoflow source enclosure to the two supporting studs on the source ad...

Page 75

Nanoflow source january 11, 2016, 715004599 rev. B 75 9. Connect the high-voltage cable to the instrument’s hv connection. Tip: the nanoflow stage contains a high-voltage interlock, so the capillary voltage (the voltage applied to the sprayer assembly) and the sampling cone voltage remain disabled u...

Page 76

3 changing the mode of operation 76 january 11, 2016, 715004599 rev. B fitting a borosilicate glass capillary (nanovial) required materials • chemical-resistant, powder-free gloves • needle-nose pliers • borosilicate glass capillary • fused silica syringe needle or geloader ® tip • fused silica cutt...

Page 77

Nanoflow source january 11, 2016, 715004599 rev. B 77 5. Unscrew the union from the end of the sprayer assembly. 6. Remove the existing capillary from the sprayer. 7. Carefully remove the new borosilicate glass capillary from its case by lifting vertically while pressing on the foam with two fingers...

Page 78

3 changing the mode of operation 78 january 11, 2016, 715004599 rev. B recommendation: when using a geloader tip, break the glass capillary in half, scoring it with a fused silica cutter so that the geloader can reach the capillary’s tip. 9. Thread the knurled nut and approximately 5 mm of conductiv...

Page 79

Nanoflow source january 11, 2016, 715004599 rev. B 79 15. Carefully push the stage back into the nanoflow source enclosure, using the stop and handle. Positioning the borosilicate glass capillary tip having obtained a signal, you must adjust the tip position to maximize it. Using the three-axis mani...

Page 80: Ionkey Source

3 changing the mode of operation 80 january 11, 2016, 715004599 rev. B ionkey source the ionkey source integrates uplc separation into the source of the mass spectrometer. For a complete description, see “ionkey source” on page 33 . The following sections explain how to install or remove an ionkey s...

Page 81

Ionkey source january 11, 2016, 715004599 rev. B 81 to install the ionkey source: 1. Prepare the instrument for working on its source (see page 97 ). 2. Remove the probe from the currently installed source: • if you are removing an esi probe, see page 59 . • if you are removing an ionsabre ii probe,...

Page 82

3 changing the mode of operation 82 january 11, 2016, 715004599 rev. B ionkey source connections: 6. Connect the data/power cable to the pspi connector on the rear of the µsample manager, and use a screwdriver to firmly tighten the connector screws. Data/power cable to pspi connector on µsample mana...

Page 83

Ionkey source january 11, 2016, 715004599 rev. B 83 source connections to mass spectrometer: 7. Connect the high voltage cable (white) to the high voltage supply outlet on the mass spectrometer. 8. Connect the options cable (blue) to the options port on the mass spectrometer. Data/power cable to psp...

Page 84

3 changing the mode of operation 84 january 11, 2016, 715004599 rev. B 9. Identify each fluid line by the part numbers printed on their shrink-wrap tubing. Fluid line aperture: ionkey tubing assemblies: part number order number description 430004188 700010399 inlet tube 430004190 700010400 infusion ...

Page 85

Ionkey source january 11, 2016, 715004599 rev. B 85 µsample manager injection valve: 10. Connect the fluid inlet line to port 6 on the injection valve of the µsample manager. 11. Connect the fluid infusion line to port 2 on the fluidics divert valve. 12. Connect the optional post-column addition lin...

Page 86: Removing The Ionkey Source

3 changing the mode of operation 86 january 11, 2016, 715004599 rev. B installing the camera in the ionkey source to install the camera software for the ionkey source: 1. Connect the camera cable from the video output connector on the mass spectrometer’s rear panel to the video-to-usb converter box....

Page 87

Ionkey source january 11, 2016, 715004599 rev. B 87 see the acquity uplc m-class documentation for further information about installing the source holder on the m-class cart, and securing the source enclosure to the holder. See m-class cart universal source holder (part number 715004884) for further...

Page 88

3 changing the mode of operation 88 january 11, 2016, 715004599 rev. B 9. Swing open the ionkey source enclosure unit from the source mounting on the mass spectrometer. 10. Disconnect the high voltage cable (white) from the high voltage supply outlet on the mass spectrometer. 11. Disconnect the opti...

Page 89: Maintenance Procedures

January 11, 2016, 715004599 rev. B 89 4 maintenance procedures this chapter provides the maintenance guidelines and procedures necessary to maintain the instrument’s performance. Keep to a maintenance schedule, and perform maintenance as required and described in this chapter. Contents: topic page m...

Page 90

4 maintenance procedures 90 january 11, 2016, 715004599 rev. B cleaning the ionsabre ii probe tip............................................................ 166 replacing the ionsabre ii probe sample capillary.................................... 167 cleaning or replacing the corona pin................

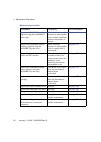

Page 91: Maintenance Schedule

Maintenance schedule january 11, 2016, 715004599 rev. B 91 maintenance schedule the following table lists periodic maintenance schedules that ensure optimum instrument performance. The maintenance frequencies shown apply to instruments that normally receive moderate use. Maintenance schedule: proced...

Page 92

4 maintenance procedures 92 january 11, 2016, 715004599 rev. B clean the ionsabre ii probe tip. (options using the ionsabre ii probe only.) when sensitivity decreases to unacceptable levels or when significant chemical interference is present. See page 166 . Replace the ionsabre ii probe capillary. ...

Page 93: Spare Parts

Spare parts january 11, 2016, 715004599 rev. B 93 spare parts replace only spare parts, which are the parts mentioned in this document. For details about spare parts, use the waters quality parts ® locator on the waters web site’s services & support page. Replace the roughing pump’s demister element...

Page 94

4 maintenance procedures 94 january 11, 2016, 715004599 rev. B troubleshooting with connections insight connections insight ® is an “intelligent” device management (idm) web service that enables waters to provide proactive service and support for the acquity uplc system. To use connections insight, ...

Page 95: Safety and Handling

Safety and handling january 11, 2016, 715004599 rev. B 95 safety and handling bear in mind the following safety considerations when performing maintenance procedures: warning: to avoid personal contamination, always wear chemical-resistant, powder-free gloves while handling instrument components. Th...

Page 96

4 maintenance procedures 96 january 11, 2016, 715004599 rev. B see appendix a for safety advisory information. Notice: to avoid damaging the ikey: • handle it with care. The component parts are fragile. • for recommendations regarding the maximum pressure to subject the device to, see the ikey separ...

Page 97: Source

Preparing the instrument for operations on or inside its source january 11, 2016, 715004599 rev. B 97 preparing the instrument for operations on or inside its source for safety reasons, you must follow this procedure before working on the source (for example, when changing the probe, operating the s...

Page 98

4 maintenance procedures 98 january 11, 2016, 715004599 rev. B removing and refitting the source enclosure the optional combined appi/apci, nanoflow and ionkey sources are supplied as a complete source enclosure. To fit them, you must first remove the standard source enclosure. Removing the source e...

Page 99

Removing and refitting the source enclosure january 11, 2016, 715004599 rev. B 99 5. Using both hands, grasp the source enclosure and lift it vertically off the two supporting studs on the source adaptor housing. 6. Store the cables neatly by plugging them into the cable-storage positions on the rea...

Page 100

4 maintenance procedures 100 january 11, 2016, 715004599 rev. B fitting the source enclosure to the instrument required material chemical-resistant, powder-free gloves to fit the source enclosure: 1. Using both hands, fit the source enclosure to the two supporting studs on the source adaptor housing...

Page 101

Installing and removing the corona pin january 11, 2016, 715004599 rev. B 101 installing and removing the corona pin for esci, apci, and dual-mode apci/appi operation, you must fit a corona pin. Installing the corona pin in the source required material chemical-resistant, powder-free gloves to insta...

Page 102

4 maintenance procedures 102 january 11, 2016, 715004599 rev. B 3. Remove the blanking plug from the corona pin mounting contact. Tip: store the blanking plug in a safe location. Corona pin mounting contact: 4. Fit the corona pin to the mounting contact, ensuring that the corona pin is securely moun...

Page 103

Installing and removing the corona pin january 11, 2016, 715004599 rev. B 103 5. Close the source enclosure. 6. Look through the source window, and use the vernier probe adjuster to position the probe tip so that it is pointing approximately midway between the tips of the sample cone and corona pin....

Page 104

4 maintenance procedures 104 january 11, 2016, 715004599 rev. B operating the source isolation valve you must close the source isolation valve to isolate the source from the instrument vacuum system for certain maintenance procedures. Required material chemical-resistant, powder-free gloves to close...

Page 105

Operating the source isolation valve january 11, 2016, 715004599 rev. B 105 3. Close the source isolation valve by moving its handle counterclockwise, to the vertical position. To open the source isolation valve after completing a maintenance procedure: 1. Open the source isolation valve by moving i...

Page 106

4 maintenance procedures 106 january 11, 2016, 715004599 rev. B 2. Close the source enclosure. Isolation valve handle in open position.

Page 107: Removing O-Rings and Seals

Removing o-rings and seals january 11, 2016, 715004599 rev. B 107 removing o-rings and seals when performing certain maintenance procedures, you must remove o-rings or seals from instrument components. An o-ring removal kit can be purchased separately. O-ring removal kit: to remove an o-ring: 1. Use...

Page 108: Cleaning The Instrument Case

4 maintenance procedures 108 january 11, 2016, 715004599 rev. B cleaning the instrument case use a soft cloth, dampened with water, to clean the outside surfaces of the instrument. Emptying the exhaust trap bottle inspect the exhaust trap bottle in the instrument’s exhaust line daily, and empty it b...

Page 109

Emptying the exhaust trap bottle january 11, 2016, 715004599 rev. B 109 required material chemical-resistant, powder-free gloves to empty the nitrogen exhaust trap bottle: 1. In the masslynx software’s ms console, click stop flow . 2. Pull the source enclosure release (located at the bottom, right-h...

Page 110

4 maintenance procedures 110 january 11, 2016, 715004599 rev. B gas ballasting the roughing pump the roughing pump draws large quantities of solvent vapors. The vapors tend to condense in the pump oil, diminishing pumping efficiency. Gas ballasting purges condensed contaminants from the oil. Note: t...

Page 111

Gas ballasting the roughing pump january 11, 2016, 715004599 rev. B 111 gas ballast the roughing pump when these conditions apply: • with esi operation, once a week • when the roughing pump oil appears cloudy • when the vacuum pressure is higher than normal • when condensate forms in the roughing pu...

Page 112

4 maintenance procedures 112 january 11, 2016, 715004599 rev. B to gas ballast the roughing pump: 1. Move the gas ballast valve handle on the pump counterclockwise, from the horizontal position to the vertical position. 2. Run the pump for 30 to 60 minutes. Tip: it is normal for the roughing pump te...

Page 113

Adding oil to the roughing pump january 11, 2016, 715004599 rev. B 113 the roughing pump oil level appears in the roughing pump’s oil level sight glass. Check the oil level weekly; you must maintain the oil level at or near the indicated maximum level when the pump is not operating. Requirement: you...

Page 114

4 maintenance procedures 114 january 11, 2016, 715004599 rev. B 3. Using the funnel, add anderol vacuum oil, type gs 495, into the oil filler aperture until the oil reaches the oil level sight glass max level. 4. Ensure that the o-ring on the oil filler plug is clean and properly seated. 5. Use the ...

Page 115

Cleaning the sampling cone assembly january 11, 2016, 715004599 rev. B 115 cleaning the sampling cone assembly you can remove the sampling cone assembly (the sample cone, o-ring, and cone gas nozzle) for cleaning without venting the instrument. Removing the sampling cone assembly from the source req...

Page 116

4 maintenance procedures 116 january 11, 2016, 715004599 rev. B to remove the sampling cone assembly from the source: 1. Close the source isolation valve (see page 104 ). 2. Grasp the cone gas nozzle handle, and use it to rotate the sampling cone assembly 90 degrees, moving the handle from the verti...

Page 117

Cleaning the sampling cone assembly january 11, 2016, 715004599 rev. B 117 disassembling the sampling cone assembly required material • chemical-resistant, powder-free gloves • combined 2.5-mm allen wrench and cone extraction tool to disassemble the sampling cone assembly: 1. Slide the collar to the...

Page 118

4 maintenance procedures 118 january 11, 2016, 715004599 rev. B 2. Insert the collar in the sample cone. 3. Rotate the tool and collar counter-clockwise and then lift them to remove the sample cone from the cone gas nozzle. Notice: to avoid damaging the fragile sample cone, do not place it on its ti...

Page 119

Cleaning the sampling cone assembly january 11, 2016, 715004599 rev. B 119 4. Remove the o-ring from the sample cone. 5. If the o-ring shows signs of deterioration or damage, dispose of it in accordance with local environmental regulations. 6. Unscrew and remove the peek cone gas nozzle handle from ...

Page 120

4 maintenance procedures 120 january 11, 2016, 715004599 rev. B cleaning the sample cone and cone gas nozzle required materials • chemical-resistant, powder-free gloves. • appropriately sized glass vessels in which to completely immerse components when cleaning. Use only glassware not previously cle...

Page 121

Cleaning the sampling cone assembly january 11, 2016, 715004599 rev. B 121 a. Rinse the components by immersing them in separate glass vessels containing water and then place the vessels in the ultrasonic bath for 20 minutes. B. Remove any residual water from the extraction cone by immersing it in a...

Page 122

4 maintenance procedures 122 january 11, 2016, 715004599 rev. B assembling the sampling cone assembly required material clean, chemical-resistant, powder-free gloves to assemble the sampling cone assembly: 1. Fit the cone gas nozzle handle onto the cone gas nozzle and turn the handle clockwise to ti...

Page 123

Cleaning the sampling cone assembly january 11, 2016, 715004599 rev. B 123 fitting the sampling cone assembly to the source required material chemical-resistant, powder-free gloves warning: to avoid personal contamination with biohazards or toxic materials, and to avoid spreading contamination to un...

Page 124

4 maintenance procedures 124 january 11, 2016, 715004599 rev. B to fit the sampling cone assembly to the source: 1. Ensure that the source isolation valve is in the closed position (see page 104 ). 2. Hold the sampling cone assembly so that the cone gas nozzle handle is oriented horizontally and at ...

Page 125

Cleaning the ion block assembly january 11, 2016, 715004599 rev. B 125 cleaning the ion block assembly clean the ion block assembly if cleaning the sample cone and cone gas nozzle fails to increase signal sensitivity. Removing the ion block assembly from the source assembly required materials • chem...

Page 126

4 maintenance procedures 126 january 11, 2016, 715004599 rev. B 5. Use the combined 2.5-mm allen wrench and cone extraction tool to unscrew the 4, captive, ion block assembly securing screws. 6. Remove the ion block assembly from the peek ion block support. Screws securing the ion block assembly ion...

Page 127

Cleaning the ion block assembly january 11, 2016, 715004599 rev. B 127 disassembling the source ion block assembly required materials • chemical-resistant, powder-free gloves • combined 2.5-mm allen wrench and cone extraction tool • o-ring removal kit to disassemble the ion block assembly: 1. Ensure...

Page 128

4 maintenance procedures 128 january 11, 2016, 715004599 rev. B 4. Use the combined 2.5-mm allen wrench and cone extraction tool to loosen the 2 captive screws securing the ion block cover plate. 5. Remove the ion block cover plate. 6. Grasp the isolation valve, and pull it out of the ion block. Ion...

Page 129

Cleaning the ion block assembly january 11, 2016, 715004599 rev. B 129 7. Use the o-ring removal kit to carefully remove the isolation valve o-ring (see page 107 ). 8. If the isolation valve o-ring shows signs of deterioration or damage, dispose of it in accordance with local environmental regulatio...

Page 130

4 maintenance procedures 130 january 11, 2016, 715004599 rev. B 10. Carefully remove the peek terminal block and ceramic heater mounting block, complete with heater cartridge assembly, from the ion block. Tip: you can invert the ion block assembly to facilitate this process. Notice: to avoid damagin...

Page 131

Cleaning the ion block assembly january 11, 2016, 715004599 rev. B 131 11. Use the o-ring removal kit to carefully remove the cover seal from the ion block (see also page 107 ). 12. Use the o-ring removal kit to carefully remove the cone gas o-ring from the ion block. 13. If the cover seal or cone g...

Page 132

4 maintenance procedures 132 january 11, 2016, 715004599 rev. B cleaning the ion block components required materials • chemical-resistant, powder-free gloves. • appropriately sized glass vessels in which to completely immerse components when cleaning. Use only glassware not previously cleaned with s...

Page 133

Cleaning the ion block assembly january 11, 2016, 715004599 rev. B 133 3. If you used formic acid in the cleaning solution, do as follows: a. Rinse the components by immersing them separately in glass vessels containing water and then placing the vessels in the ultrasonic bath for 20 minutes. B. Dry...

Page 134

4 maintenance procedures 134 january 11, 2016, 715004599 rev. B to assemble the ion block assembly: 1. Carefully fit the peek terminal block and ceramic heater mounting block, complete with heater cartridge assembly, to the ion block. 2. Use the combined 2.5-mm allen wrench and cone extraction tool ...

Page 135

Cleaning the ion guide assembly january 11, 2016, 715004599 rev. B 135 fitting the ion block assembly to the source assembly required materials • chemical-resistant, powder-free gloves • combined 2.5-mm allen wrench and cone extraction tool to fit the ion block assembly to the source assembly : 1. F...

Page 136: From The Instrument

4 maintenance procedures 136 january 11, 2016, 715004599 rev. B removing the pumping block assembly and ion guide assembly from the instrument required materials • chemical-resistant, powder-free gloves • 3-mm allen wrench to remove the pump block assembly and ion guide assembly from the instrument:...

Page 137: The Pumping Block Assembly

Cleaning the ion guide assembly january 11, 2016, 715004599 rev. B 137 removing the ion guide assembly and differential aperture from the pumping block assembly required materials • chemical-resistant, powder-free gloves • 3-mm allen wrench notice: to avoid damaging the ion guide assembly when remov...

Page 138

4 maintenance procedures 138 january 11, 2016, 715004599 rev. B to remove the ion guide assembly and differential aperture support from the pumping block assembly: 1. Use the 3-mm allen wrench to unscrew and remove the two screws securing the differential aperture and the ion guide assembly boards t...

Page 139

Cleaning the ion guide assembly january 11, 2016, 715004599 rev. B 139 • flat-head screwdriver to remove the differential aperture support and the differential aperture from the ion guide assembly: 1. Place the ion guide assembly with differential aperture on to a clean flat surface. 2. Disconnect t...

Page 140

4 maintenance procedures 140 january 11, 2016, 715004599 rev. B 4. Use the flat-blade screwdriver to remove the three screws securing the differential aperture from its support. 5. Make sure the o-ring is in good condition. Cleaning the differential aperture required materials: • chemical resistant,...

Page 141

Cleaning the ion guide assembly january 11, 2016, 715004599 rev. B 141 4. Carefully pour the cleaning solution from the vessel holding the differential aperture into the holding container, retaining the differential aperture in the vessel. Tip: you can reuse waters ms cleaning solution for one subse...

Page 142

4 maintenance procedures 142 january 11, 2016, 715004599 rev. B to clean the ion guide assembly: 1. Bend a peek or ptfe tube into a hook shape. 2. Insert one end of the hook into one of the holes in the ion guide’s rear circuit board carrier. 3. Use the hook to carefully suspend the ion guide assemb...

Page 143

Cleaning the ion guide assembly january 11, 2016, 715004599 rev. B 143 4. Add 1:1 methanol/water to the glass vessel until the ion guide assembly is immersed completely. 5. Place the vessel in the ultrasonic bath for 30 minutes. 6. Carefully remove the ion guide assembly from its vessel, and blow-dr...

Page 144: Pumping Block Assembly

4 maintenance procedures 144 january 11, 2016, 715004599 rev. B to fit the differential aperture and the differential aperture support onto the ion guide assembly: 1. Check the condition of the o-ring between the differential aperture and the differential aperture support. If necessary, use the o-ri...

Page 145: The Instrument

Cleaning the ion guide assembly january 11, 2016, 715004599 rev. B 145 to fit the ion guide assembly and differential aperture onto the pumping block assembly: 1. Check the seals on the pumping block assembly to make sure they are not damaged. 2. Place the ion guide assembly and differential apertur...

Page 146

4 maintenance procedures 146 january 11, 2016, 715004599 rev. B replacing the esi probe tip and gasket maintaining the esi probe involves replacing the following components of the probe when required: if the esi probe tip is damaged or blocked, follow the procedure “replacing the probe tip and gaske...

Page 147

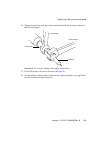

Replacing the esi probe tip and gasket january 11, 2016, 715004599 rev. B 147 to replace the esi probe tip and gasket: 1. Remove the esi probe from the source (see page 59 ). 2. Unscrew and remove the esi probe tip by holding the probe shaft steady, using the 7-mm wrench, and unscrewing the probe ti...

Page 148

4 maintenance procedures 148 january 11, 2016, 715004599 rev. B 3. Remove the nickel gasket from the probe tip. 4. Dispose of the nickel gasket in accordance with local environmental regulations. 5. If the probe tip is damaged, dispose of it in accordance with local environmental regulations, and co...

Page 149

Replacing the esi probe tip and gasket january 11, 2016, 715004599 rev. B 149 7. Carefully slide the probe tip onto the esi probe, ensuring that the capillary feeds through the stainless steel tube inside the probe tip. 8. Screw the probe tip onto the esi probe assembly. 9. Tighten the probe tip usi...

Page 150

4 maintenance procedures 150 january 11, 2016, 715004599 rev. B replacing the esi probe capillary replace the stainless steel esi probe capillary if it becomes irreversibly blocked, or if it becomes contaminated or damaged. Required materials • chemical-resistant, powder-free gloves • combined 2.5-m...

Page 151

Replacing the esi probe tip and gasket january 11, 2016, 715004599 rev. B 151 to remove the existing capillary: 1. Remove the probe from the source enclosure (see page 59 ). 2. Use the 2.5-mm allen wrench to loosen the three captive screws securing the probe’s end cover in place, and then remove the...

Page 152

4 maintenance procedures 152 january 11, 2016, 715004599 rev. B 4. Unscrew and remove the esi probe tip by holding the probe shaft steady using the 7-mm wrench and unscrewing the probe tip using the 10-mm wrench, as shown in the following figure: 5. Remove the nickel gasket from the probe tip. Warni...

Page 153

Replacing the esi probe tip and gasket january 11, 2016, 715004599 rev. B 153 6. Dispose of the nickel gasket in accordance with local environmental regulations. 7. Remove the slide port assembly from the probe assembly by pulling the peek union. Note : the capillary is attached to the slide port, a...

Page 154

4 maintenance procedures 154 january 11, 2016, 715004599 rev. B 10. Loosen the lock nut at the base of the peek union using both the 7-mm and 8-mm wrenches. Note: use the 8-mm wrench to hold the peek union while you loosen the lock nut using the 7-mm wrench. Capillary slide port lock nut 7-mm wrench...

Page 155

Replacing the esi probe tip and gasket january 11, 2016, 715004599 rev. B 155 11. Unscrew and remove the peek union from the slide port using both the 7-mm and 8-mm wrenches. Note: hold the slide port steady by attaching the 7-mm wrench to the flattened grooves on the slide port’s collar, as shown i...

Page 156

4 maintenance procedures 156 january 11, 2016, 715004599 rev. B to install the new capillary : 1. Slide the new ferrule onto the new ptfe liner tube so that approximately 2 mm of liner tubing is exposed beyond the tapered end of the ferrule. Note : ensure that the ferrule is oriented as shown in the...

Page 157

Replacing the esi probe tip and gasket january 11, 2016, 715004599 rev. B 157 5. Pull the capillary through the slide port so that the end of the capillary aligns with the end of the ptfe liner tube, as shown in the figure. 6. Insert the capillary and liner tube fully into the peek union, ensuring t...

Page 158

4 maintenance procedures 158 january 11, 2016, 715004599 rev. B 7. Feed the capillary through the liner tube and peek union, to expose approximately 50 mm of capillary on the opposite side of the union. 8. Screw the peek union onto the slide port, ensuring that the union is not fully tightened. Requ...

Page 159

Replacing the esi probe tip and gasket january 11, 2016, 715004599 rev. B 159 10. Insert the red peek tubing into the probe inlet connector, to expose approximately 25 mm of tubing beyond the narrow end of the inlet connector. 11. Using the end of the red peek tubing, push the capillary into the pee...

Page 160

4 maintenance procedures 160 january 11, 2016, 715004599 rev. B 13. Finger-tighten the peek union onto the slide port, and then, using the 7-mm and 8-mm wrenches, tighten by an additional quarter-turn. 14. Finger-tighten the lock nut onto the peek union, and then, using the 7-mm and 8-mm wrenches, t...

Page 161

Replacing the esi probe tip and gasket january 11, 2016, 715004599 rev. B 161 15. Slide the new conductive liner tube and knurled nut onto the capillary, and then tighten the knurled nut. . 16. Perform a leak test on the peek union and slide port assembly by attaching the free end of the red peek tu...

Page 162

4 maintenance procedures 162 january 11, 2016, 715004599 rev. B 18. Carefully thread the capillary through the probe assembly until the slide port and peek union assembly reach the top of the probe assembly. 19. Push the slide port and peek union assembly into the probe assembly so that the dowel on...

Page 163

Replacing the esi probe tip and gasket january 11, 2016, 715004599 rev. B 163 20. Fit the nebulizer adjuster knob to the peek union, and fully tighten the knob. 21. Fit the end cover and gasket around the nebulizer adjuster knob. Important: ensure that the end cover’s drip point is orientated so tha...

Page 164

4 maintenance procedures 164 january 11, 2016, 715004599 rev. B 22. Secure the end cover and gasket to the esi probe by tightening the three captive screws using the 2.5-mm allen wrench. 23. Insert the new nickel gasket into the esi probe tip so that the gasket is seated around the narrow, stainless...

Page 165

Replacing the esi probe tip and gasket january 11, 2016, 715004599 rev. B 165 26. Tighten the probe tip using the 7-mm wrench and the 10-mm wrench, as shown in the following figure: important: to avoid gas leakage, fully tighten the probe tip. 27. Fit the esi probe to the source enclosure (see page ...

Page 166

4 maintenance procedures 166 january 11, 2016, 715004599 rev. B cleaning the ionsabre ii probe tip clean the ionsabre ii probe tip when you detect buffer buildup on the probe tip or when the signal intensity weakens. See the mass spectrometer’s online help for further details. To clean the ionsabre ...

Page 167

Replacing the ionsabre ii probe sample capillary january 11, 2016, 715004599 rev. B 167 replacing the ionsabre ii probe sample capillary replace the stainless steel sample capillary in the ionsabre ii probe if it becomes blocked and you cannot clear it, or if it becomes contaminated or damaged. Remo...

Page 168

4 maintenance procedures 168 january 11, 2016, 715004599 rev. B 4. Remove the end cover and gasket. 5. Unscrew and remove the nebulizer adjuster knob. 6. Remove the peek union/unf coupling assembly and capillary from the probe. Tip: the peek union used with the ionsabre ii probe is notched on one of...

Page 169: Installing The New Capillary

Replacing the ionsabre ii probe sample capillary january 11, 2016, 715004599 rev. B 169 8. Unscrew the finger-tight peek union from the unf coupling. 9. Remove the ferrule from the capillary. 10. Remove the capillary from the unf coupling. 11. Dispose of the capillary and ferrule in accordance with ...

Page 170

4 maintenance procedures 170 january 11, 2016, 715004599 rev. B to install the new capillary: 1. Use the sharp knife or peek tubing cutter to cut a piece of red peek tubing approximately 60 cm (24 inches) long. Requirement: cut the tubing squarely (that is, perpendicular to its horizontal axis). 2. ...

Page 171

Replacing the ionsabre ii probe sample capillary january 11, 2016, 715004599 rev. B 171 5. Insert the capillary in the peek union, and ensure that it is fully seated. 6. Screw the unf coupling into the peek union, finger-tight only. 7. Gently tug on the capillary, testing to ensure that it stays in ...

Page 172

4 maintenance procedures 172 january 11, 2016, 715004599 rev. B 16. Fit the nebulizer adjuster knob to the peek union/unf coupling assembly. 17. Finger-tighten the nebulizer adjuster knob onto the probe assembly. 18. Fit the probe gasket and end-cover to the probe assembly. 19. Use the combined 2.5-...

Page 173

Cleaning or replacing the corona pin january 11, 2016, 715004599 rev. B 173 • corona pin to clean or replace the corona pin: 1. Remove the corona pin from the source (see page 103 ) and inspect the pin for damage. 2. Replace the corona pin if it is damaged; otherwise clean its tip with the lapping f...

Page 174

4 maintenance procedures 174 january 11, 2016, 715004599 rev. B replacing the ionsabre ii probe heater replace the ionsabre ii probe heater if it fails to heat the probe. Removing the ionsabre ii probe heater required material chemical-resistant, powder-free gloves to remove the ionsabre ii probe he...

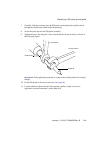

Page 175

Replacing the ionsabre ii probe heater january 11, 2016, 715004599 rev. B 175 2. Gripping the probe heater as shown, carefully pull it off the probe assembly. 3. Dispose of the probe heater in accordance with local environmental regulations. Notice: to avoid damaging the probe heater’s electrical co...

Page 176

4 maintenance procedures 176 january 11, 2016, 715004599 rev. B fitting the new ionsabre ii probe heater required materials • chemical-resistant, powder-free gloves • ionsabre ii probe heater to fit the new ionsabre ii probe heater: 1. Use the probe adjuster knob to adjust the capillary so that it p...

Page 177

Replacing the ion block source heater january 11, 2016, 715004599 rev. B 177 replacing the ion block source heater replace the ion block source heater if it fails to heat when the instrument is pumped down (evacuated). Required materials • chemical-resistant, powder-free gloves • needle-nose pliers ...

Page 178

4 maintenance procedures 178 january 11, 2016, 715004599 rev. B 3. Use the combined 2.5-mm allen wrench and cone extraction tool to loosen the 2 captive screws securing the ion block cover plate. 4. Remove the ion block cover plate. 5. Use the combined 2.5-mm allen wrench and cone extraction tool to...

Page 179

Replacing the ion block source heater january 11, 2016, 715004599 rev. B 179 6. Use the needle-nose pliers to carefully swing the ring terminal tags out of the terminal block. 7. Use the needle-nose pliers to gently grasp the heat-shrink tubing on the heater cartridge assembly and slide the assembly...

Page 180

4 maintenance procedures 180 january 11, 2016, 715004599 rev. B 9. Use the needle-nose pliers to gently grasp the heat-shrink tubing on the new heater cartridge assembly and slide the assembly into the ion block. 10. Use the needle-nose pliers to position the 2 heater wire ring tags fully down on th...

Page 181: Enclosure Seals

Replacing the source assembly seals january 11, 2016, 715004599 rev. B 181 removing the probe adjuster assembly probe and source enclosure seals required materials • chemical-resistant, powder-free gloves • o-ring removal kit.

Page 182

4 maintenance procedures 182 january 11, 2016, 715004599 rev. B to remove the probe adjuster assembly probe and source enclosure seals: 1. Remove the source enclosure from the instrument (see page 98 ). 2. Use the o-ring removal kit to carefully remove the following seals from the probe adjuster ass...

Page 183: Seals

Replacing the source assembly seals january 11, 2016, 715004599 rev. B 183 4. Dispose of all the seals in accordance with local environmental regulations. Fitting the new source enclosure and probe adjuster assembly seals required materials • chemical-resistant, powder-free gloves • wash bottle cont...

Page 184: Replacing The Air Filter

4 maintenance procedures 184 january 11, 2016, 715004599 rev. B to fit the new source enclosure and probe adjuster assembly probe seals: 1. Ensure that all the grooves for seals are free from dirt and debris. Tip: if contamination is present, use 1:1 methanol/water, applied to a lint-free cloth, to ...

Page 185

Replacing the air filter january 11, 2016, 715004599 rev. B 185 to replace the air filter: 1. Lift the instrument’s visor so that the source probe is fully exposed. 2. Fully open the source enclosure. 3. Disconnect the probe cable from the high-voltage connector, and leave the cable in a position th...

Page 186

4 maintenance procedures 186 january 11, 2016, 715004599 rev. B 4. Open the air filter grill by pulling the tab at the top of the grill toward you. 5. Remove and dispose of the old filter. 6. Place the new filter flat on the inside part of the grill, with its edges beneath the metal lip. 7. Close th...

Page 187

Replacing the roughing pump oil january 11, 2016, 715004599 rev. B 187 replacing the roughing pump oil change the roughing pump oil annually. Note: this procedure is not required for an edwards oil-free roughing pump. Required materials • chemical-resistant, powder-free gloves • 8-mm allen wrench • ...

Page 188

4 maintenance procedures 188 january 11, 2016, 715004599 rev. B 5. Use the 8-mm allen wrench to remove the oil filler plug. 6. Use the 8-mm allen wrench to remove the oil drain plug. 7. Tip the pump toward the drain plug aperture and allow the oil to drain completely into the container. 8. Dispose o...

Page 189

Replacing the roughing pump oil january 11, 2016, 715004599 rev. B 189 tip: when the oil drain plug is tightened, the plug seals by means of an o-ring. Compression is controlled by the o-ring groove depth in the plug. Increased torque does not improve the plug seal; it only makes the plug difficult ...

Page 190

4 maintenance procedures 190 january 11, 2016, 715004599 rev. B replacing the roughing pump’s oil demister element replace the roughing pump’s oil demister element annually. Note: this procedure is not required for an edwards oil-free roughing pump. Required materials • chemical-resistant, powder-fr...

Page 191

Replacing the roughing pump’s oil demister element january 11, 2016, 715004599 rev. B 191 4. Carefully remove the exhaust flange and oil demister element from the roughing pump. 5. Use the 10-mm wrench to remove the nut that secures the oil demister element to the exhaust flange. Tp02693 oil demiste...

Page 192

4 maintenance procedures 192 january 11, 2016, 715004599 rev. B 6. Holding the oil demister element slightly elevated to prevent the loss of the spring, remove the exhaust flange from the oil demister element. 7. Remove the spring from the oil demister element. 8. Dispose of the oil demister element...

Page 193

Replacing the roughing pump’s oil demister element january 11, 2016, 715004599 rev. B 193 to fit the new oil demister element: 1. Fit the spring onto the new oil demister element. 2. Holding the oil demister element slightly elevated to prevent the loss of the spring, fit the exhaust flange to the o...

Page 194

4 maintenance procedures 194 january 11, 2016, 715004599 rev. B 3. Use the 10-mm wrench to fit and tighten the nut that secures the oil demister element to the exhaust flange. 4. Ensure that the inscription “top” is at the top of the oil demister element, and, using both hands, carefully fit the oil...

Page 195

Appi/apci source—changing the uv lamp bulb january 11, 2016, 715004599 rev. B 195 appi/apci source—changing the uv lamp bulb required materials • chemical-resistant, powder-free gloves • combined 2.5-mm allen wrench and cone extraction tool • small phillips ® (cross-head) screwdriver • 20-cm (8-inch...

Page 196

4 maintenance procedures 196 january 11, 2016, 715004599 rev. B 5. Insert the length of 4-mm nylon tube through the back of the lamp drive assembly, and push the bulb forward. 6. Remove the bulb from the lamp drive assembly. 7. Insert the new bulb into the lamp drive assembly. Tip: the lamp glass is...

Page 197

Appi/apci source—cleaning the lamp window january 11, 2016, 715004599 rev. B 197 2. Pull the source enclosure release (located at the bottom, right-hand side) outward, and swing open the enclosure. 3. Use methanol or isopropyl alcohol, applied to the lint-free cloth, to carefully clean the lamp wind...

Page 198

4 maintenance procedures 198 january 11, 2016, 715004599 rev. B appi/apci source—replacing the appi lamp drive seals the following appi lamp drive assembly o-rings must be renewed at intervals of no greater than 1 year: • uv lamp bulb sealing o-ring • mounting shaft o-rings • uv lamp mounting flange...

Page 199

Appi/apci source—replacing the appi lamp drive seals january 11, 2016, 715004599 rev. B 199 to remove the appi lamp drive assembly seals: 1. Remove the ionsabre ii probe and combined appi/apci source enclosure (see page 71 ). 2. Remove the uv bulb from the lamp drive assembly, and store it in a secu...

Page 200

4 maintenance procedures 200 january 11, 2016, 715004599 rev. B 6. Use the phillips (cross-head) screwdriver to remove the 2 source enclosure, release-handle screws, and remove the handle. 7. Use the combined 2.5-mm allen wrench and cone extraction tool to remove the remaining 2 lamp-drive cover scr...

Page 201

Appi/apci source—replacing the appi lamp drive seals january 11, 2016, 715004599 rev. B 201 tip: take care not to drop the screws inside the lower cover. 12. Slide the lamp assembly, shaft, and flange out of the appi source enclosure. Tip: the cables remain attached to the shaft, which you fully wit...

Page 202

4 maintenance procedures 202 january 11, 2016, 715004599 rev. B 14. Use the combined 2.5-mm allen wrench and cone extraction tool to remove the two insulator screws. 15. Remove the peek insulator from the end of the mounting shaft. 16. Slide the shaft mounting flange off the shaft, and note the corr...

Page 203

Appi/apci source—replacing the appi lamp drive seals january 11, 2016, 715004599 rev. B 203 19. Use the o-ring removal kit to carefully remove the shaft mounting flange o-ring from the appi source enclosure side. 20. Dispose of the o-rings in accordance with local environmental regulations. Warning:...

Page 204

4 maintenance procedures 204 january 11, 2016, 715004599 rev. B fitting the new appi lamp drive assembly o-rings required materials • chemical-resistant, powder-free gloves • 3-mm allen wrench • small phillips (cross-head) screwdriver • small pozidriv screwdriver • 1:1 methanol/water • lint-free clo...

Page 205

Appi/apci source—replacing the appi lamp drive seals january 11, 2016, 715004599 rev. B 205 5. Fit the mounting shaft insertion tool to the mounting shaft. 6. Slide the lamp mounting flange onto the shaft, taking care to align it correctly. 7. Reinsert the shaft through the side of the source enclos...

Page 206

4 maintenance procedures 206 january 11, 2016, 715004599 rev. B 13. Use the small phillips screwdriver to fit and tighten the repeller electrode retaining screw. 14. Insert the uv bulb into the lamp drive assembly and push it fully home. 15. Fully retract the lamp mounting shaft from the source encl...

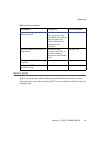

Page 207: Removing A Fluidic Line

Replacing the fluidic lines of the ionkey source january 11, 2016, 715004599 rev. B 207 fluid line connections: to identify the correct tubing assembly for each fluid line, use the following table. Tip: you can use these part numbers to identify each line when it is disconnected from the source. Par...

Page 208

4 maintenance procedures 208 january 11, 2016, 715004599 rev. B • t10 torx screwdriver to remove a fluidic line: 1. Prepare the instrument for working on its source (see page 97 ) . 2. Unlock and remove any ikey installed in the ikey clamp. 3. Open the ionkey source front cover and remove the ikey s...

Page 209

Replacing the fluidic lines of the ionkey source january 11, 2016, 715004599 rev. B 209 4. Remove the gas line using a flat-blade screwdriver. 5. Disconnect the fluidic line being replaced from its source. 6. Remove two t10 torx screws securing the end plate bracket. 7. Slide the end plate, along wi...

Page 210: Installing A Fluidic Line

4 maintenance procedures 210 january 11, 2016, 715004599 rev. B 8. Gently pull off the o-ring from around the tube’s fitting and slide the o-ring to the left. 9. Pull enough of the line being replaced to the right and allow the capillary line to slide through its channel to remove it. 10. Dispose of...

Page 211

Cleaning the ionkey source and connectors january 11, 2016, 715004599 rev. B 211 2. Slide the o-ring away from the end plate fitting. 3. Insert the new fluidic line through the appropriate end plate channel and seat the line’s fitting into the end plate. 4. Secure the fitting with the o-ring. 5. Rei...

Page 212

4 maintenance procedures 212 january 11, 2016, 715004599 rev. B during normal operation, the ionkey source does not require cleaning. After repeated use, however, material can accumulate around the fluid-line connectors or electronic connectors in the ikey docking port. Notice: to avoid damaging the...

Page 213

Cleaning the ionkey source and connectors january 11, 2016, 715004599 rev. B 213 cleaning the fluid-line connectors and electronic connectors: to remove buildup from fluid-line connectors: gently swab the fluid-line connectors and outer edges of the docking port with a lint-free tissue saturated wit...

Page 214

4 maintenance procedures 214 january 11, 2016, 715004599 rev. B replacing the instrument’s fuses if one or both of the mass spectrometer’s fuses blow, the instrument will shut down immediately. If this occurs, disconnect the power cord from the rear panel, and replace the fuses, located at the botto...

Page 215: Safety Advisories

January 11, 2016, 715004599 rev. B 215 a safety advisories waters instruments and devices display hazard symbols that alert you to the hidden dangers associated with a product’s operation and maintenance. The symbols also appear in product manuals where they accompany statements describing the hazar...

Page 216: Warning Symbols

A safety advisories 216 january 11, 2016, 715004599 rev. B warning symbols warning symbols alert you to the risk of death, injury or seriously adverse physiological reactions associated with an instrument’s use or misuse. Heed all warnings when you install, repair, or operate any waters instrument o...

Page 217: Specific Warnings

Warning symbols january 11, 2016, 715004599 rev. B 217 specific warnings the following warnings (both symbols and text) can appear in the user manuals of particular instruments and devices and on labels affixed to them or their component parts. Burst warning this warning applies to waters instrument...

Page 218

A safety advisories 218 january 11, 2016, 715004599 rev. B mass spectrometer shock hazard the following warning applies to all waters mass spectrometers. The following warning applies to certain mass spectrometers when they are in operate mode. Mass spectrometer flammable solvents warning this warni...

Page 219

Warning symbols january 11, 2016, 715004599 rev. B 219 biohazard warning the following warning applies to waters instruments and devices that can process material containing biohazards, which are substances that contain biological agents capable of producing harmful effects in humans. Biohazard and ...

Page 220: Notices

A safety advisories 220 january 11, 2016, 715004599 rev. B notices notices appear where an instrument or device can be subject to use or misuse that can damage it or compromise a sample’s integrity. The exclamation point symbol and its associated statement alert you to such risk. Prohibition symbol ...

Page 221: Devices

Warnings that apply to all waters instruments and devices january 11, 2016, 715004599 rev. B 221 warnings that apply to all waters instruments and devices when operating this device, follow standard quality-control procedures and the equipment guidelines in this section. Attention: changes or modifi...

Page 222

A safety advisories 222 january 11, 2016, 715004599 rev. B warning: use caution when working with any polymer tubing under pressure: • always wear eye protection when near pressurized polymer tubing. • extinguish all nearby flames. • do not use tubing that has been severely stressed or kinked. • do ...

Page 223

Warnings that apply to all waters instruments and devices january 11, 2016, 715004599 rev. B 223 attenzione: fare attenzione quando si utilizzano tubi in materiale polimerico sotto pressione: • indossare sempre occhiali da lavoro protettivi nei pressi di tubi di polimero pressurizzati. • spegnere tu...

Page 224

A safety advisories 224 january 11, 2016, 715004599 rev. B 警告: 当有压力的情况下使用管线时,小心注意以下几点: • 当接近有压力的聚合物管线时一定要戴防护眼镜。 • 熄灭附近所有的火焰。 • 不要使用已经被压瘪或严重弯曲的管线。 • 不要在非金属管线中使用四氢呋喃或浓硝酸或浓硫酸。 • 要了解使用二氯甲烷及二甲基亚枫会导致非金属管线膨胀,大大降低管线的耐压能力。 경고 : 가압 폴리머 튜브로 작업할 경우에는 주의하십시오 . • 가압 폴리머 튜브 근처에서는 항상 보호 안경을 착용하십시오 . • 근처의 화기를 모두 끄십...

Page 225

Warnings that apply to all waters instruments and devices january 11, 2016, 715004599 rev. B 225 warning: the user shall be made aware that if the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired. Attention: l’utilisateur doit ...

Page 226

A safety advisories 226 january 11, 2016, 715004599 rev. B warnings that address the replacing of fuses the following warnings pertain to instruments equipped with user-replaceable fuses. If the fuse types and ratings appear on the instrument: warning: to protect against fire, replace fuses with tho...

Page 227: Electrical Symbols

Electrical and handling symbols january 11, 2016, 715004599 rev. B 227 if the fuse types and ratings do not appear on the instrument: electrical and handling symbols electrical symbols the following electrical symbols and their associated statements can appear in instrument manuals and on an instrum...

Page 228: Handling Symbols

A safety advisories 228 january 11, 2016, 715004599 rev. B handling symbols the following handling symbols and their associated statements can appear on labels affixed to the packaging in which instruments, devices, and component parts are shipped. Electrical power off standby direct current alterna...

Page 229

Electrical and handling symbols january 11, 2016, 715004599 rev. B 229 use no hooks!.

Page 230

A safety advisories 230 january 11, 2016, 715004599 rev. B.

Page 231: External Connections

January 11, 2016, 715004599 rev. B 231 b external connections warning: to avoid skeletal or muscle injury associated with lifting heavy objects, use suitable machinery and the supplied harness to lift the mass spectrometer. Notice: to avoid damaging the mass spectrometer, observe the following preca...

Page 232

B external connections 232 january 11, 2016, 715004599 rev. B external wiring and vacuum connections rear panel connections appear in the figure below. Note that the connectors and controls not identified are for use by waters engineers only. Rear panel: power turbo vacuum source vent nitrogen inlet...

Page 233

Connecting the oil-filled roughing pump january 11, 2016, 715004599 rev. B 233 connecting the oil-filled roughing pump note: to connect the alternative dry roughing pump, see page 238 . Required materials: • chemical-resistant, powder-free gloves • 7-mm nut driver • 8-mm allen wrench • sharp knife •...

Page 234

B external connections 234 january 11, 2016, 715004599 rev. B bear in mind these requirements when connecting the roughing pump: • the pump must be horizontal, or within one degree of horizontal. • the ambient temperature of the area in which you place the pump must range between 15 and 40 ºc. • the...

Page 235

Connecting the oil-filled roughing pump january 11, 2016, 715004599 rev. B 235 3. Attach the nw25 tee to the source vacuum port of the instrument using the nw25 center ring, and then secure the connection with a clamp. 4. Using the nw25 center rings and clamp, and the 7-mm nut driver, attach the fla...

Page 236

B external connections 236 january 11, 2016, 715004599 rev. B 9. Check the oil level in the pump (see “checking the roughing pump oil level” on page 112 , and, if needed, “adding oil to the roughing pump” on page 113 ). Requirement: to ensure correct operation of the roughing pump, do not operate it...

Page 237

Connecting the oil-filled roughing pump january 11, 2016, 715004599 rev. B 237 connecting electric cables to the oil-filled roughing pump roughing pump electrical connections: to make the electrical connections to the roughing pump: 1. Connect the relay cable from the roughing pump d.C. Connector to...

Page 238

B external connections 238 january 11, 2016, 715004599 rev. B connecting the edwards oil-free roughing pump the oil-free roughing pump is an alternative to the oil-filled roughing pump. To connect the oil-filled roughing pump, see page 233 . Required materials • chemical-resistant, powder-free glove...

Page 239

Connecting the edwards oil-free roughing pump january 11, 2016, 715004599 rev. B 239 • nw25/nw40 adaptor (included in the installation kit) • 10-mm reducer fitting (included in the installation kit) • 10-mm id nylon tube (included in installation kit) • 12.7-mm clear pvc exhaust tubing (included in ...

Page 240

B external connections 240 january 11, 2016, 715004599 rev. B to connect the oil-free roughing pump: 1. Place the pump on the floor, within 1.5 m (5 feet) of the instrument. 2. Attach the nw25/nw40 adaptor to the roughing pump inlet flange using an nw40 center ring, and then secure the connection wi...

Page 241

Connecting the edwards oil-free roughing pump january 11, 2016, 715004599 rev. B 241 8. Route the open end of the exhaust tubing to a suitable exhaust vent. 9. Connect electric cables to the roughing pump (see page 241 ). Connecting electric cables to the edwards oil-free roughing pump roughing pump...

Page 242

B external connections 242 january 11, 2016, 715004599 rev. B connecting to the nitrogen gas supply required materials • chemical-resistant, powder-free gloves • sharp knife • wrench • 6-mm ptfe tubing (included in the waters rough pump connect kit) • nitrogen regulator to connect the nitrogen gas s...

Page 243

Connecting to the collision cell gas supply january 11, 2016, 715004599 rev. B 243 gas and exhaust connections: 5. Attach the nitrogen regulator to the nitrogen supply. 6. Install the 6-mm stud into the regulator outlet. 7. Connect the free end of the long piece of 6-mm ptfe tubing to the 6-mm stud....

Page 244

B external connections 244 january 11, 2016, 715004599 rev. B • wrench • 1/8-inch swagelok ® nut and ferrule • 1/8-inch stainless steel tube (supplied with the instrument) to connect the collision cell gas supply: 1. Use the 1/8-inch swagelok nut and ferrule to connect the 1/8-inch stainless steel t...

Page 245

Connecting the nitrogen exhaust line january 11, 2016, 715004599 rev. B 245 to connect the nitrogen exhaust line: 1. Locate the exhaust trap bottle in an accessible area below the instrument (see the figure on page 246 ). 2. Cut a length of 12-mm tubing long enough to connect the instrument to the e...

Page 246

B external connections 246 january 11, 2016, 715004599 rev. B 6. Use snoop (or equivalent) leak detector liquid to ensure that there are no leaks at the instrument exhaust and laboratory exhaust system line connections. Exhaust trap bottle: connecting the liquid waste line required material chemical...

Page 247