- DL manuals

- Waters

- Measuring Instruments

- Xevo TQ-XS Mass

- Overview And Maintenance Manual

Waters Xevo TQ-XS Mass Overview And Maintenance Manual

Summary of Xevo TQ-XS Mass

Page 1

Waters xevo tq-xs mass spectrometry system overview and maintenance guide 715004990 revision a copyright © waters corporation 2016 all rights reserved.

Page 2: General Information

General information copyright notice © 2016 waters corporation. Printed in the united states of america and in ireland. All rights reserved. This document or parts thereof may not be reproduced in any form without the written permission of the publisher. The information in this document is subject t...

Page 3: Customer Comments

Nano lc tm is a trademark of waters corporation. Nanoacquity ® is a registered trademark of waters corporation. Nanoflow tm is a trademark of waters corporation. Nanotile ® is a registered trademark of waters corporation. Oerlikon ® is a registered trademark of oc oerlikon corporation ag. Openlynx t...

Page 4: Contacting Waters

Understand what you expect from our documentation so that we can continuously improve its accuracy and usability. We seriously consider every customer comment we receive. You can reach us at tech_comm@waters.Com . Contacting waters contact waters with enhancement requests or technical questions rega...

Page 5: Safety Considerations

Drinagh, wexford, ireland safety considerations some reagents and samples used with waters instruments and devices can pose chemical, biological, or radiological hazards (or any combination thereof). You must know the potentially hazardous effects of all substances you work with. Always follow good ...

Page 6

Prohibited: do not place vessels containing liquid—such as solvent bottles—atop the workstation or ancillary equipment or otherwise expose those units to dripping or splashing liquids. Spilled solvents hazard prohibited: to avoid equipment damage caused by spilled solvent, do not place reservoir bot...

Page 7

Mass spectrometer high temperature hazard source ion block assembly hazards associated with removing an instrument from service warning: to avoid personal contamination with biohazards, toxic materials, and corrosive materials, wear chemical-resistant gloves when performing this procedure. Warning: ...

Page 8: Operating This Device

Contamination permissible. That authority must also prescribe the method of decontamination to be used and the appropriate protection for personnel undertaking the decontamination process. You must handle items such as syringes, fused silica lines, and borosilicate tips used to carry sample into the...

Page 9

Symbol definition date of manufacture authorized representative of the european community confirms that a manufactured product complies with all applicable european community directives or australia emc compliant confirms that a manufactured product complies with all applicable united states and can...

Page 10: Emc Considerations

When fitted with waters options (apci, apgc, appi, asap, esci, nanoflow esi, trizaic, unispray, uplc, ionkey), or optional third-party sources (dart, desi, or ldtd), the xevo tq- xs does not comply with the european union in vitro diagnostic device directive 98/79/ec. Calibrating to calibrate lc sys...

Page 11: Ec Authorized Representative

Ism classification: ism group 1 class a this classification has been assigned in accordance with iec cispr 11 industrial scientific and medical (ism) instruments requirements. Group 1 products apply to intentionally generated and/or used conductively coupled radio- frequency energy that is necessary...

Page 12: Table of Contents

Table of contents general information .......................................................................................................Ii copyright notice ..................................................................................................................................... Ii tr...

Page 13

1.2.5 software and data system ...................................................................................................23 1.3 ionization techniques and source probes......................................................................................23 1.3.1 electrospray ionization ........

Page 14

2.4.1 power led...........................................................................................................................39 2.4.2 operate led........................................................................................................................40 2.5 tuning and cali...

Page 15

3.5.1 installing the nanoflow source............................................................................................77 3.5.2 fitting a borosilicate glass capillary (nanovial) .................................................................... 80 3.5.3 positioning the borosilicate glass ...

Page 16

4.13.5 fitting the sampling cone assembly to the source........................................................... 110 4.14 cleaning the ion block assembly...............................................................................................111 4.14.1 removing the ion block assembly from th...

Page 17

4.26.2 fitting the new appi lamp drive assembly o-rings.......................................................... 163 4.27 replacing the unispray probe assembly ..................................................................................165 4.27.1 removing the unispray probe assembly ............

Page 18

B.6 connecting the nitrogen exhaust line ........................................................................................199 b.7 connecting liquid waste lines .....................................................................................................201 b.8 connecting the workstati...

Page 19: Waters Xevo Tq-Xs Overview

1 waters xevo tq-xs overview the xevo tq-xs is a tandem quadrupole, atmospheric pressure ionization (api) mass spectrometer. It is designed for routine hplc/ms/ms and uplc/ms/ms analyses in quantitative and qualitative applications, and can operate at fast acquisition speeds compatible with ultraper...

Page 20: 1.1 Intellistart Technology

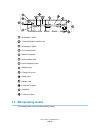

Figure 1–1: waters xevo tq-xs source enclosure 1.1 intellistart technology intellistart technology monitors instrument performance and indicates when the instrument is ready for use. The software automatically tunes and mass calibrates the instrument, displays performance readbacks, and enables simp...

Page 21

1.2 acquity uplc/ms xevo tq-xs systems the waters xevo tq-xs is compatible with the acquity uplc systems. If you are not using an acquity uplc system, refer to the documentation relevant to your lc system. 1.2.1 acquity uplc system the acquity uplc system includes a binary or quaternary solvent mana...

Page 22

Probe adaptor source enclosure source enclosure release xevo tq-xs access door to the fluidics sample manager binary solvent manager or quaternary solvent manager sample organizer (optional on the acquity uplc system) column heater solvent tray access door to the fluidics valve removable panel for a...

Page 23

• waters 2998 pda detector • waters 2487 uv detector • waters 1525µ binary gradient pump + 2777 autosampler 1.2.5 software and data system you can use masslynx software v4.2 to control the mass spectrometer. The software enables these major operations: • configuring the system • creating lc and ms/m...

Page 24

1.3.1 electrospray ionization in electrospray ionization (esi), a strong electrical charge is applied to the eluent as it emerges from a nebulizer. The droplets that compose the resultant aerosol undergo a reduction in size (solvent evaporation). As solvent continues to evaporate, the charge density...

Page 25

1.3.5 unispray the unispray source enables the detection of a wide range of compounds in a single analysis. In contrast to electrospray ionization, unispray uses a grounded capillary, and the resulting spray is directed at an impactor pin held at a voltage, creating smaller charged droplets, amenabl...

Page 26

Replaces the esi or apci probe in the instrument’s source housing and has no external gas or electrical connections. See the atmospheric solids analysis probe operator's guide supplement for further details. 1.3.9 apgc the waters apgc couples an agilent gc with the xevo tq-xs. Doing so enables you t...

Page 27

• from the lc column. • from three integral reservoirs. (the reservoirs can also deliver sample, by direct or combined infusion, to enable optimization at analytical flow rates.) • from a wash reservoir that contains solvent for automated flushing of the instrument’s solvent delivery system. For fur...

Page 28: 1.5 Ion Optics

1.4.2 system components the onboard system incorporates a 7-port selector valve, a multi-position diverter valve, a pump, and three sample reservoirs. The sample reservoirs are mounted on the instrument’s front panel. When you select a solvent from the instrument console, an led illuminates the appr...

Page 29: 1.6 Ms Operating Modes

Quadrupole 1 (ms1) t-wave/scanwave collision cell quadrupole 2 (ms2) conversion dynode detector assembly photomultiplier tube source sampling orifice isolation valve z-spray ion source sample inlet sample cone conjoined ion guide stepwave t-wave ion guide 1.6 ms operating modes the following table s...

Page 30: 1.7 Ms/ms Operating Modes

Table 1–1: ms operating modes: operating mode ms1 collision cell ms2 ms pass all masses resolving (scanning) sir pass all masses resolving (static) ms1 resolving (scanning) pass all masses in ms mode, the instrument can acquire data at scan speeds as high as 20,000 da/s. Use this mode for instrument...

Page 31

Radar is an additional mode with which you simultaneously collect data from the mrm and full scan ms modes. Radar mode can also acquire all detectable ions in both positive and negative full scan ms. 1.7.1 product (daughter) ion mode product ion mode is the most commonly used ms/ms operating mode. Y...

Page 32

Ms1 - scanning collision cell - fragment precursor ions and pass all masses ms2 - static (at product mass) 1.7.2.1 typical application you typically use the precursor ion mode for structural elucidation—that is, to complement or confirm product scan data—by scanning for all the precursors of a commo...

Page 33

1.7.4 constant neutral loss mode constant neutral loss mode detects the loss of a specific neutral fragment or functional group from an unspecified precursor or precursors. The scans of ms1 and ms2 are synchronized. When ms1 transmits a specific precursor ion, ms2 determines whether that precursor l...

Page 34: 1.8 Leak Sensors

Mass, in synchrony with the second quadrupole mass analyzer. This mode results in a significant increase in the signal intensity of full scan spectra. Figure 1–8: scanwave daughter scan mode: ms1 - scanning collision cell - scanwave enabled, fragments precursor ions, accumulates fragment ions and pa...

Page 35: 1.10 Rear Panel

The system monitors the turbomolecular pump speeds and continuously measures vacuum pressure with built-in pirani and penning gauges. The gauges also serve as switches, stopping operation when vacuum loss is detected. A vacuum isolation valve isolates the source sample cone from the mass analyzer, a...

Page 36

Source vent nitrogen inlet pilot valve port turbo vacuum source vacuum collision cell gas inlet june 9, 2016, 715004990 rev. A page 36.

Page 37: Operation

2 preparing the mass spectrometer for operation this chapter describes how to start and shut down the mass spectrometer. 2.1 preparing to start the mass spectrometer this instrument is compatible with the acquity uplc system; if you are not using an acquity uplc system, refer to the documentation re...

Page 38

Requirement: the collision gas is argon; it must be dry and of high purity (99.997%). Regulate the supply at 50 kpa (0.5 bar, 7 psi). 2.2 starting the mass spectrometer starting the mass spectrometer comprises powering-on the workstation, logging in, powering-on the mass spectrometer and all other i...

Page 39

Tips: • in the instrument console, the system ready indicator shows green when the instrument is fully pumped-down (evacuated). • expect the analyzer penning gauge readback to show less than 1e-5 mbar vacuum. Warning: to prevent the ignition of flammable solvent vapors in the enclosed space of a mas...

Page 40

2.4.2 operate led the operate led, located on the right-hand side of the power led, indicates the operating condition. See the mass spectrometer’s online help topic “monitoring the mass spectrometer leds” for details on the operate led indications. 2.5 tuning and calibration information you must tun...

Page 41

2.7 preparing the intellistart fluidics system for additional information, see connecting liquid waste lines . Prohibited: to avoid equipment damage caused by spilled solvent, do not place reservoir bottles directly atop an instrument or device or on its front ledge. Instead, place the bottles in th...

Page 42

2.7.2 installing the low-volume vials warning: to avoid personal contamination with biohazards, toxic materials, and corrosive materials, wear chemical-resistant gloves when performing this procedure. To install low-volume vials: 1. If a standard reservoir bottle is fitted, remove it. 2. Screw the l...

Page 43: 2.8 Purging The Fluidics

To adjust the position of a solvent delivery tube: 1. Open the access door to the fluidics pump (see waters acquity xevo tq-xs uplc/ms system ). 2. Loosen the finger-tight fitting for the solvent delivery tube you are adjusting. Finger-tight fitting solvent delivery tube 3. Move the solvent delivery...

Page 44

• the software fails to establish communication or loses communication with the mass spectrometer. • you perform a software upgrade. To reboot the mass spectrometer: 1. Ensure that the mass spectrometer software is closed. 2. Open the mass spectrometer’s front, left-hand door. 3. Insert a short leng...

Page 45

Notice: for ionkey operation, to protect the ikey when you leave the mass spectrometer in operate mode with no flow, set the capillary voltage to zero. 2.11 emergency shutdown of the mass spectrometer warning: to avoid electric shock, observe the following procedure to isolate the instrument from th...

Page 46

3 changing the mode of operation 3.1 changing the mode of operation this chapter describes how to prepare the mass spectrometer for the following modes of operation: • esi (electrospray ionization) • esci (combined electrospray and atmospheric pressure chemical ionization) • apci (atmospheric pressu...

Page 47

3.2.2 esci mode to operate in esci mode, you must fit an esi probe adaptor and corona pin to the source enclosure. The system, with the esi probe adaptor installed and corona discharge pin fitted, can alternate between esi and apci ionization modes, facilitating data acquisition in esi and apci mode...

Page 48

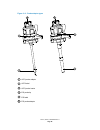

Figure 3–2: probe adaptor types apci probe adaptor apci label apci probe heater esi probe tip esi label esi probe adaptor june 9, 2016, 715004990 rev. A page 48.

Page 49

Figure 3–3: probe assembly probe inlet peek fitting identification label for part number capillary probe adaptor peek fitting for esci and apci modes, you must also install a corona pin. Table 3–1: configuration for esi/esci/apci modes mode probe adaptor install corona pin esi esi no esci esi yes ap...

Page 50

3.2.5 installing the probe adaptor figure 3–4: probe adaptor parts probe adaptor cap removed from probe adaptor probe adaptor cap tether locking ring probe adaptor identification label probe adaptor cap release buttons required materials • chemical-resistant, powder-free gloves to install the probe ...

Page 51

1. To prepare for installing a probe assembly, press together the probe-adaptor-cap release buttons, in the direction shown by the arrows in the following figure, and lift the probe adaptor cap off the probe adaptor. Figure 3–5: probe adaptor cap release 2. For esi probe adaptors, remove the protect...

Page 52

Probe location dowel figure 3–8: locating the esi probe adaptor location hole for probe location dowel probe adjuster assembly figure 3–9: locating the apci probe adaptor location hole for probe location dowel probe adjuster assembly 4. Rotate the probe adaptor locking ring clockwise to secure the p...

Page 53

Figure 3–10: probe adaptor, mounted on the source enclosure: probe adaptor cap tether probe adaptor cap source enclosure probe adjuster assembly high voltage connector esi probe adaptor cable (esi probe adaptor only) probe adaptor locking ring 5. For esi probe adaptors, connect the esi probe adaptor...

Page 54

• ensure that you use a probe assembly appropriate for your application. For example, using an esi probe assembly with an apci probe adaptor compromises instrument performance. You can use the part number on the identification label to verify the probe assembly type. • ensure that the probe adaptor ...

Page 55

Warning: to avoid electric shock, do not insert any item into the probe cap aperture when the probe cap is fitted to the instrument. Notice: to avoid damaging the probe assembly, take care when inserting the capillary into the probe adaptor. Do not use force. Warning: to avoid harmless, static-like ...

Page 56

Figure 3–13: probe assembly fitted to the probe adaptor probe adaptor fitting tip: the probe adaptor fitting on the unispray probe assembly is not compatible with the probe adaptor. If you cannot fit the probe adaptor cap, ensure that you are installing the correct probe assembly. 3. Tilt the probe ...

Page 57

Figure 3–15: probe adaptor cap probe adaptor cap tether probe adaptor probe assembly tubing 4. Slide the probe adaptor cap along the probe assembly, over the probe adaptor peek fitting. 5. Push the probe adaptor cap on to the probe adaptor until it clicks. Tips: • do not squeeze the probe adaptor ca...

Page 58

Figure 3–16: seating the probe adaptor cap probe adaptor cap seated incorrectly; edge does not align with the edge of the probe adaptor probe adaptor cap seated correctly; edge aligns with the edge of the probe adaptor 6. If you are not immediately connecting the probe assembly to the fluidics, inse...

Page 59

Figure 3–17: peek fitting holder probe inlet peek fitting peek fitting holder probe assembly tubing warning: to avoid electric shock or solvent ignition, when connecting esi or upc 2 source probes directly to non-waters equipment, ensure that the liquid outlet connection is grounded. 7. To connect t...

Page 60

Figure 3–18: tubing connection between the diverter valve and the esi probe tip: the other plumbing connections are omitted for clarity. Probe adaptor cap peek fitting holder leak tray probe adaptor probe inlet peek fitting connected to diverter valve tubing c. Close the access door to the intellist...

Page 61

You can remove the probe adaptor with or without the probe assembly installed. To remove the probe assembly, see removing the existing probe assembly . Required materials chemical-resistant, powder-free gloves to remove the esi probe adaptor: warning: to avoid personal contamination with biohazards ...

Page 62

3.2.8.1 installing the corona pin in the source required materials chemical-resistant, powder-free gloves to install the corona pin in the source: warning: to avoid personal contamination with biohazards, toxic materials, and corrosive materials, wear chemical-resistant gloves when performing this p...

Page 63

Warning: to avoid puncture wounds, handle sharp parts and materials with care. 4. Fit the corona pin to the corona pin mounting contact, ensuring that the corona pin is securely mounted and that its tip aligns with the sample cone orifice. Figure 3–20: corona pin: corona pin 5. Close the source encl...

Page 64

Figure 3–21: source enclosure source window vernier probe adjuster 3.2.8.2 removing the corona pin from the source required materials chemical-resistant, powder-free gloves to remove the corona pin from the source: warning: to avoid personal contamination with biohazards, toxic materials, and corros...

Page 65

1. Prepare the instrument for working on the source (see prepare the instrument for working on the source ). Warning: to avoid burn injuries, take great care while performing this procedure. Warning: to avoid puncture wounds, take great care while working with the source enclosure open if an esi pro...

Page 66

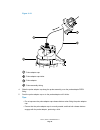

Sample molecules appi lamp drive assembly repeller electrode uv lamp photons from the uv lamp sample cone sample ions apci probe the apci probe introduces vaporized sample into the source where photons generated by an ultra-violet (uv) lamp (mounted in the appi lamp drive assembly) produce sample io...

Page 67

Sample cone apci probe the apci probe introduces vaporized sample into the source. The sample passes between the sample cone and the corona pin, which typically operates with a discharge current of 5 µa. The corona discharge generates ions that react with the mobile phase molecules to produce stable...

Page 68

Figure 3–25: dual operation in appi mode: repeller electrode with voltage applied corona pin inactive photons from the uv lamp sample cone apci probe 3.3.4 the combined appi/apci source components the combined appi/apci source comprises the apci probe adaptor and a source enclosure with an appi lamp...

Page 69

Appi lamp drive assembly notice: to prevent damage to the corona pin and lamp assembly, ensure that the lamp assembly does not touch the corona pin when the source enclosure door is closed. The uv lamp, which you ignite via a control in the masslynx software tune window, provides a constant photon o...

Page 70

Warning: to avoid electric shock, ensure that the instrument is suitably prepared before commencing this procedure. To install the combined appi/apci source: 1. Prepare the instrument for working on the source (see preparing the instrument for working on the source ). Warning: to avoid burn injuries...

Page 71: 3.4 Unispray Source

Warning: to avoid personal contamination with biohazards, toxic materials, and corrosive materials, wear chemical-resistant gloves when performing this procedure. Warning: to avoid electric shock, ensure that the instrument is prepared for working on the source before commencing this procedure. Warn...

Page 72

Figure 3–28: unispray source - front and rear view june 9, 2016, 715004990 rev. A page 72.

Page 73

Probe inlet shaft vertical probe adjuster horizontal probe adjuster impactor pin capillary adjuster source enclosure front panel see also: for information about maintaining the source components: • replacing the unispray probe assembly • maintaining the unispray impactor pin 3.4.1 installing the uni...

Page 74

Tip: if you must fit the probe assembly, do so by inserting the probe assembly into the probe inlet shaft atop the source, and screwing the probe fitting into the probe inlet. See fitting the unispray probe assembly . 4. Using two hands, fit the unispray source enclosure to the two supporting studs ...

Page 75

Figure 3–30: unispray source connections probe adjuster cable (yellow) high-voltage connector 6. Slide open the instrument's source interface door. Figure 3–31: unispray source connections to mass spectrometer june 9, 2016, 715004990 rev. A page 75.

Page 76

Instrument source interface door high-voltage cable socket probe adjuster cable socket (yellow) 7. Connect the high-voltage cable to the high-voltage cable socket on the mass spectrometer. 8. Connect the probe adjuster cable to the probe adjuster cable socket on the mass spectrometer. 9. Close the i...

Page 77: 3.5 Nanoflow Esi Source

3.5 nanoflow esi source the nanoflow source enclosure comprises the nanoflow stage (for x- , y- , z- axis adjustment), the sprayer-enclosure, and a microscope camera. Figure 3–32: nanoflow source, stage and microscope camera: microscope camera sprayer enclosure x, y, z stage a sprayer is mounted on ...

Page 78

Warning: to avoid personal contamination with biohazards, toxic materials, and corrosive materials, wear chemical-resistant gloves when performing this procedure. Warning: to avoid electric shock, ensure that the instrument is prepared for working on the source before commencing this procedure. Warn...

Page 79

4. Using both hands, fit the nanoflow source enclosure to the two supporting studs on the source adaptor housing. 5. Close the source enclosure door. 6. Connect a 1/16-inch ptfe tube between the mass-flow controller output (mounted beneath the stage on the front of the nanoflow source) and your spra...

Page 80

3.5.2 fitting a borosilicate glass capillary (nanovial) required materials: • chemical-resistant, powder-free gloves • needle-nose pliers • borosilicate glass capillary • fused silica syringe needle or geloader tip • fused silica tubing cutter to fit a borosilicate glass capillary (nanovial): warnin...

Page 81

Figure 3–35: capillary union 6. Remove the existing capillary from the sprayer. 7. Carefully remove the new borosilicate glass capillary from its case by lifting it vertically while pressing on the foam with two fingers. Figure 3–36: capillary foam 8. Load sample into the capillary using a fused sil...

Page 82

11. Finger-tighten the nut so that five mm of glass capillary protrudes from its end. Tip: measure the protrusion from the end of the nut to the shoulder of the glass capillary. Figure 3–37: sprayer assembly: ptfe tubing ferrule union knurled nut blue conductive elastomer glass capillary 5-mm protru...

Page 83: 3.6 Ionkey Source

3.5.3 positioning the borosilicate glass capillary tip having obtained a signal, you must adjust the tip position to maximize it. Using the three-axis manipulator, you can adjust the tip position up and down, left and right, forward and backward. As a starting point, set the tip so that it is on the...

Page 84

3.6.1 installing the ionkey source the ionkey source enclosure comprises the ikey docking port, the ikey locking handle, the sprayer-enclosure, and a microscope camera. Figure 3–39: ionkey source: microscope camera handle for locking and unlocking the ikey separation device front cover docking port ...

Page 85

Warning: to avoid burn injuries, exercise care when handling the components of the source enclosure heated to high temperatures. Wait until the hot components have sufficiently cooled before you handle them. 2. Remove the existing source enclosure (see removing the source enclosure from the instrume...

Page 86

5. Connect the data/power cable to the pspi connector on the rear of the µsample manager, and use a screwdriver to firmly tighten the connector screws. Figure 3–41: source connections to mass spectrometer: data/power cable to pspi µsample manager high-voltage cable options cable 6. Connect the high-...

Page 87

Figure 3–42: fluid line aperture: aperture closed aperture open (spring-loaded) fluid line aperture figure 3–43: µsample manager injection valve: fluid inlet line connected to injection valve port 6 9. Connect the fluid inlet line to port 6 on the injection valve of the µsample manager. 10. Connect ...

Page 88

3.6.2 installing ionkey source software if you are installing an ionkey source on your xevo tq-xs for the first time, you must install the appropriate masslynx software scn and the acquity uplc m-class driver pack. For further details, see the following documents: • acquity uplc m-class system guide...

Page 89

Alternative: if you are using the ionkey source with an acquity uplc m-class system mounted on an m-class cart fitted with an ionkey or universal source holder, you can secure the source enclosure to the holder. Doing so keeps the enclosure close to the xevo tq-xs, for when it is next needed. Securi...

Page 90

8. Swing open the ionkey source enclosure unit from the source mounting on the mass spectrometer. 9. Disconnect the high-voltage cable (white) from the high-voltage supply outlet on the mass spectrometer. 10. Disconnect the reference probe power cable (green) from the reference probe power inlet on ...

Page 91: Maintenance Procedures

4 maintenance procedures this section provides the maintenance guidelines and procedures necessary to maintain the mass spectrometer's performance. Keep to a maintenance schedule, and perform maintenance as required and described in this section. 4.1 maintenance schedule the following table lists pe...

Page 92

Table 4–1: maintenance schedule: (continued) procedure frequency for information... Clean or replace the corona pin (apci and esci modes). When the corona pin is corroded or black, or the sensitivity decreases to unacceptable levels. See cleaning or replacing the corona pin . Replace the apci probe ...

Page 93: 4.2 Spare Parts

4.2 spare parts waters recommends that you replace only the parts mentioned in this document. For spare parts details, see the waters quality parts locator on the waters web site’s services & support page ( http://www.Waters.Com/waters/en_us/spare-parts/nav.Htm?Cid=511444 ). 4.3 troubleshooting with...

Page 94: 4.4 Safety and Handling

4.4 safety and handling bear in mind the following safety considerations when performing maintenance procedures: warning: to avoid personal contamination with biohazards, toxic materials, and corrosive materials, wear chemical-resistant gloves when performing this procedure. Warning: observe good la...

Page 95

Notice: to avoid damaging the ikey: • handle it with care. The component parts are fragile. • for recommendations regarding the maximum pressure to subject the device to, see the ikey separation device care and use manual (part number 720004897en). • do not apply electrospray potential to the emitte...

Page 96

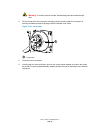

Note: if column flow is required, divert the lc flow to waste: 1. 1. In the instrument console system tree, expand xevo tq-xs detector, interactive fluidics. 2. Click control . 3. Select waste as the flow state. 2. In the instrument console, click standby , and confirm that the operate indicator is ...

Page 97

4. Disconnect the probe adjuster and options cables from the instrument’s connectors. Warning: to avoid puncture wounds, handle sharp parts and materials with care. Notice: to avoid damaging the sample inlet, when removing a nanolockspray source enclosure, you must slide the sprayer platform out of ...

Page 98

4.6.2 fitting the source enclosure to the instrument required materials chemical-resistant, powder-free gloves to fit the source enclosure to the instrument: warning: to avoid personal contamination with biohazards, toxic materials, and corrosive materials, wear chemical-resistant gloves when perfor...

Page 99

4.7.1 closing the source isolation valve to close the source isolation valve before starting a maintenance procedure: warning: to avoid personal contamination with biohazards, toxic materials, and corrosive materials, wear chemical-resistant gloves when performing this procedure. 1. Prepare the inst...

Page 100

4.7.2 opening the source isolation valve to open the source isolation valve after completing a maintenance procedure: warning: to avoid personal contamination with biohazards, toxic materials, and corrosive materials, wear chemical-resistant gloves when performing this procedure. Warning: to avoid p...

Page 101

Figure 4–4: o-ring removal kit: tool 1 tool 2 to remove an o-ring: note: to avoid damaging the component when removing an o-ring or seal from it, ensure that you do not scratch the component with the removal tool. Use the tools as aids to pull the o-ring or seal from its groove. Tip: if the o-ring o...

Page 102

Figure 4–5: nitrogen exhaust trap bottle: to laboratory exhaust port from instrument pilot valve port cap bottle support nitrogen exhaust trap bottle from instrument exhaust connection one-way valve required materials chemical-resistant, powder-free gloves to empty the nitrogen exhaust trap bottle: ...

Page 103

Warning: to avoid personal contamination with biohazards, toxic materials, and corrosive materials, wear chemical-resistant gloves when performing this procedure. 3. Unscrew and remove the nitrogen exhaust trap bottle from the cap and associated fittings. Warning: to avoid contaminating uncontaminat...

Page 104

4.13.1 removing the sampling cone assembly from the source required materials chemical-resistant, powder-free gloves to remove the sampling cone assembly from the source: warning: to avoid personal contamination with biohazards, toxic materials, and corrosive materials, wear chemical-resistant glove...

Page 105

Figure 4–7: ion block assembly notice: to avoid damaging the stepwave assembly, do not switch the instrument into operate mode when the isolation valve is closed. Notice: to avoid damage, do not open the source isolation valve before fitting the sampling cone assembly to the ion block assembly 4.13....

Page 106

Figure 4–8: cone extraction tool location combined 2.5-mm hex wrench and cone extraction 2. Slide the collar to the end of the tool. Figure 4–9: cone extraction tool collar 3. Insert the collar in the sample cone. Figure 4–10: inserting the cone extraction tool insert the collar notice: to avoid dam...

Page 107

4. Rotate and lift the tool and collar to remove the sample cone from the cone gas nozzle. Figure 4–11: removing the sample cone rotate the tool remove the sample cone 5. Remove the o-ring from the sample cone. Figure 4–12: o-ring removed from the sample cone sample cone o-ring cone gas nozzle handl...

Page 108

Warning: to avoid spreading contamination, dispose of all waste materials according to local environmental regulations. 6. If the o-ring shows signs of deterioration or damage, dispose of it in accordance with local environmental regulations. 7. Unscrew and remove the peek cone gas nozzle handle fro...

Page 109

3. Place the vessels in the ultrasonic bath for 30 minutes. 4. If you used formic acid in the cleaning solution, do as follows: a. Rinse the components by immersing them in separate glass vessels containing water and then placing the vessels in the ultrasonic bath for 20 minutes. B. Remove any resid...

Page 110

1. Fit the cone gas nozzle handle to the cone gas nozzle and turn the handle clockwise to tighten. Figure 4–13: cone gas nozzle handle cone gas nozzle sample cone o-ring 2. Carefully fit the sample cone into the cone gas nozzle. 3. Fit the o-ring (a new one, if you disposed of the old o-ring) into t...

Page 111

1. Ensure that the source isolation valve is in the closed position (see closing the source isolation valve ). 2. Hold the sampling cone assembly so that the cone gas nozzle handle is oriented horizontally and at the top, and then slide the sampling cone assembly into the ion block assembly. Figure ...

Page 112

To remove the ion block assembly: warning: to avoid personal contamination with biohazards, toxic materials, and corrosive materials, wear chemical-resistant gloves when performing this procedure. 1. Vent and shut down the mass spectrometer (see the mass spectrometer’s online help for details). Warn...

Page 113

Figure 4–15: ion block assembly securing screws 6. Remove the ion block assembly from the peek ion block support. Figure 4–16: peek ion block support ion block assembly june 9, 2016, 715004990 rev. A page 113.

Page 114

4.14.2 disassembling the source ion block assembly required materials • chemical-resistant, powder-free gloves • combined 2.5-mm hex wrench and cone extraction tool • o-ring removal kit to disassemble the ion block assembly: warning: to avoid personal contamination with biohazards, toxic materials, ...

Page 115

• do not remove the sampling cone assembly retaining blocks. • do not adjust the screws securing the sampling cone assembly retaining blocks. Figure 4–18: source ion block cover plate ion block cover plate securing screw ion block cover plate 5. Remove the ion block cover plate. 6. Grasp the isolati...

Page 116

Warning: to avoid spreading contamination, dispose of all waste materials according to local environmental regulations. 8. If the isolation valve o-ring shows signs of deterioration or damage, dispose of it in accordance with local environmental regulations. 9. Use the combined 2.5-mm allen wrench a...

Page 117

Figure 4–21: removing the peek terminal block and ceramic heater mounting block peek terminal block ceramic heater mounting block 11. Use the o-ring removal kit to carefully remove the cover seal from the ion block (see also removing o-rings and seals ). Figure 4–22: removing the cover seal from the...

Page 118

Warning: to avoid spreading contamination, dispose of all waste materials according to local environmental regulations. 13. If the cover seal or cone gas o-ring shows signs of deterioration or damage, dispose of it in accordance with local environmental regulations. 4.14.3 cleaning the ion block com...

Page 119

A. Rinse the components by immersing them separately in glass vessels containing water and then placing the vessels in the ultrasonic bath for 20 minutes. B. Dry the components by immersing them in separate glass vessels containing methanol and then placing the vessels in the ultrasonic bath for 10 ...

Page 120

1. Carefully fit the peek terminal block and ceramic heater mounting block, complete with heater cartridge assembly, to the ion block. 2. Use the combined 2.5-mm allen wrench and cone extraction tool to tighten the captive peek terminal block securing screw. 3. Ensure that the grooves for the cover ...

Page 121

Warning: to avoid puncture wounds, take great care working with the source enclosure open if one or both of these conditions apply: • an esi probe is fitted (the probe’s tip is sharp). • a corona pin is fitted (the pin’s tip is sharp). Notice: to avoid recontaminating the components, wear clean, che...

Page 122

To remove the ion block support from the source assembly: warning: to avoid personal contamination with biohazards, toxic materials, and corrosive materials, wear chemical-resistant gloves when performing this procedure. 1. Remove the source enclosure from the instrument (see removing the source enc...

Page 123

4. Remove the peek ion block support from the adaptor housing. 5. Use the o-ring removal kit to carefully remove all the o-rings from the peek ion block support (see removing o-rings and seals ). Warning: to avoid spreading contamination, dispose of all waste materials according to local environment...

Page 124

Figure 4–24: seal breaker and locator tool: lip pin handle june 9, 2016, 715004990 rev. A page 124.

Page 125

Figure 4–25: seal breaker and locator tool positioned on the adaptor housing: adaptor housing ion guide cap seal breaker and locator tool 2. Push firmly on the seal breaker and locator tool’s handle, to lever the stepwave assembly slightly out of the adaptor housing. Rationale: moving the assembly i...

Page 126

Figure 4–26: stepwave assembly removal and insertion tool ion block support screw holes (2) brown peek ion guide cap slot cutout pins notice: to avoid damage when removing the stepwave ion guide assembly from the adaptor housing, handle only the brown peek ion guide cap 4. Inserting your thumbs thro...

Page 127

6. Using both hands, fit the source enclosure to the two supporting studs on the source adaptor housing. 7. Close the source enclosure. Rationale: fitting and closing the source enclosure prevents debris entering the instrument while you are working on the stepwave ion guide assembly. 4.15.4 disasse...

Page 128

Second ion guide assembly securing screw first ion guide assembly 2. Separate the first and second ion guide assemblies. Figure 4–28: stepwave ion guide assembly separated second ion guide assembly first ion guide assembly 3. Remove the brown peek gasket from the second ion guide assembly. Figure 4–...

Page 129

Second ion guide assembly brown peek gasket 4. Remove the o-ring from the differential pumping aperture on the second ion guide assembly (see removing o-rings and seals ). Figure 4–30: stepwave second ion guide assembly differential pumping aperture o-ring warning: to avoid spreading contamination, ...

Page 130

4.15.5 cleaning the stepwave ion guide assembly warning: to avoid personal contamination with biohazards, toxic materials, and corrosive materials, wear chemical-resistant gloves when performing this procedure. Notice: to avoid damaging the stepwave ion guide assembly, handle it and its components c...

Page 131

Figure 4–31: cleaning the first ion guide pcb assembly first ion guide pcb assembly hook 3. Add waters ms cleaning solution to the glass vessel until the first ion guide pcb assembly is immersed completely. 4. Repeat step 1 through step 3 for the second ion guide pcb assembly, placing the hook throu...

Page 132

6. Carefully pour the cleaning solution from the vessel holding the first ion guide pcb assembly into the holding container, retaining the ion guide in the vessel. Tip: you can reuse the cleaning solution for one subsequent cleaning. 7. Fill the vessel with deionized water, to rinse the first ion gu...

Page 133

To assemble the stepwave ion guide assembly: notice: to avoid damaging the stepwave ion guide assembly, handle it and its components carefully throughout the cleaning procedure. In particular, to avoid damaging the wiring on assemblies fitted with an externally wired printed circuit board (pcb), do ...

Page 134

Figure 4–34: second ion guide assembly brown peek gasket 3. Align the first ion guide assembly with the second ion guide assembly. 4. Use the combined, 2.5-mm, allen wrench and cone extraction tool to fit and tighten the two screws securing the first ion guide assembly to the second ion guide assemb...

Page 135

1. Pull the source enclosure release (located at the bottom, right-hand side) outwards, and swing open the enclosure. 2. Using both hands, grasp the source enclosure, and lift it vertically off the two supporting studs on the source adaptor housing. 3. Slide the first ion guide assembly end of the s...

Page 136

5. Inserting your thumbs through the slots in the stepwave removal and insertion tool, firmly push the stepwave ion guide assembly into the pumping block assembly. Tip: you will detect some resistance to motion when the stepwave assembly encounters the seal inside the instrument; continue pushing un...

Page 137

4.15.8 fitting the ion block support to the source required materials • chemical-resistant, powder-free gloves • 3-mm hex wrench • new seals and o-rings to fit the peek ion block support to the source: warning: to avoid personal contamination with biohazards, toxic materials, and corrosive materials...

Page 138

To remove the probe assembly: warning: to avoid personal contamination with biohazards, toxic materials, and corrosive materials, wear chemical-resistant gloves when performing this procedure. Warning: to avoid puncture wounds, handle sharp parts and materials with care. Warning: to avoid electric s...

Page 139

Peek fitting 4. Remove the probe assembly. Warning: to avoid spreading contamination, dispose of all waste materials according to local environmental regulations. 5. Dispose of the probe assembly in accordance with local environmental regulations. 6. To install a new probe assembly, see installing t...

Page 140

To remove the esi probe tip and gasket: warning: to avoid personal contamination with biohazards, wear clean, chemical- resistant, powder-free gloves when performing this procedure. Warning: to avoid burn injuries, take great care while performing this procedure. Warning: to avoid puncture injuries,...

Page 141

Figure 4–39: metal gasket warning: to avoid contaminating uncontaminated surfaces with biologically hazardous, toxic, or corrosive materials, dispose of all waste materials according to local environmental regulations. 4. Dispose of the metal gasket in accordance with local environmental regulations...

Page 142

Figure 4–40: inserting the gasket metal gasket esi probe tip stainless steel tube 2. Fit the probe tip, and screw the tip onto the probe assembly. 3. Use the 7-mm wrench in conjunction with the 10-mm wrench to tighten the probe tip. Important: to avoid gas leakage, fully tighten the probe tip. 4. Fi...

Page 143

4.19 replacing the apci probe heater replace the apci probe heater it fails to heat the probe. 4.19.1 removing the apci probe heater required materials chemical-resistant, powder-free gloves to remove the apci probe heater: warning: to avoid burn injuries, take great care while working with the prob...

Page 144

Notice: to avoid damaging the probe heater's electrical connections, do not twist the heater when removing it from or refitting it to the probe adaptor. Warning: to avoid burn injuries, take great care while performing this procedure. 2. Gripping the probe heater as shown, carefully pull it off the ...

Page 145

Figure 4–43: fitting the probe heater capillary sleeve probe heater connections notice: to avoid damaging the probe heater's electrical connections, do not twist the heater when removing it from or refitting it to the probe adaptor. 2. Fit the probe adaptor to the instrument (see installing the prob...

Page 146

4.20 cleaning or replacing the corona pin required materials • chemical-resistant, powder-free gloves • needle-nose pliers • hplc-grade methanol • lint-free tissue • lapping film • corona pin to clean or replace the corona pin: warning: to avoid personal contamination with biohazards, toxic material...

Page 147

Required materials • chemical-resistant, powder-free gloves • needle-nose pliers • combined 2.5-mm hex wrench and cone extraction tool • new ion block source heater assembly to replace the ion block source heater: warning: to avoid personal contamination with biohazards, toxic materials, and corrosi...

Page 148

Figure 4–45: ion block cover plate securing screw ion block cover plate 4. Remove the ion block cover plate. 5. Use the combined 2.5-mm allen wrench and cone extraction tool to loosen the captive peek terminal block securing screw. Figure 4–46: peek terminal block securing screw heater cartridge ass...

Page 149

6. Carefully remove the peek terminal block and ceramic heater mounting block, complete with heater cartridge assembly, from the ion block. Tip: you can invert the ion block assembly to facilitate this process. Figure 4–47: heater wire securing screws peek terminal block ceramic heater mounting bloc...

Page 150

Heater cartridge assembly ceramic heater mounting block heat-shrink tubing 10. Dispose of the heater cartridge assembly. Notice: to avoid damaging the heater cartridge assembly wires, do not bend or twist them when removing the assembly and ceramic heater mounting block from the ion block. 11. Use t...

Page 151

• source enclosure seal • nebulizer gas seal • desolvation gas seal 4.22.1 removing the probe adjuster assembly probe and source enclosure seals required materials • chemical-resistant, powder-free gloves • o-ring removal kit to remove the probe adjuster assembly probe and source enclosure seals: wa...

Page 152

Probe adjuster nebulizer gas seal probe adjuster assembly probe seal 3. Use the o-ring removal kit to carefully remove the following seals from the source enclosure: • source enclosure seal • nebulizer gas seal • desolvation gas seal figure 4–50: source enclosure seals desolvation gas seal source en...

Page 153

4.22.2 fitting the new source enclosure and probe adjuster assembly probe seals required materials • chemical-resistant, powder-free gloves • wash bottle containing hplc-grade (or better) 1:1 methanol/water • new seals • lint-free cloth to fit the new source enclosure and probe adjuster assembly pro...

Page 154

Groove seal 4. Fit the following new seals to the probe adjuster assembly: • probe seal • nebulizer gas seal 5. Fit the source enclosure to the instrument (see fitting the source enclosure to the instrument ). 4.23 replacing the air filter inside the front door required materials • needle-nose plier...

Page 155

Figure 4–53: filter filter cover 4. Lift the filter, vertically, from its slot in the instrument. Tip: if necessary, use the needle-nose pliers to grasp the filter. Figure 4–54: 5. Dispose of the filter. 6. Fit the new filter into the instrument. 7. Fit the filter cover to the instrument. 8. Tighten...

Page 156

4.24 appi/apci source - changing the uv lamp bulb required materials: • chemical-resistant, powder-free gloves • combined 2.5-mm hex wrench and cone extraction tool • phillips screwdriver • 20-cm (8-inch) length of 4-mm nylon tube warning: to avoid personal contamination with biohazards, toxic mater...

Page 157

Figure 4–55: note: to avoid breaking the bulb, do not use a screwdriver to push the bulb forward in the lamp drive assembly. 5. Insert the length of 4-mm nylon tube through the back of the lamp drive assembly, and push the bulb forward. Figure 4–56: appi lamp bulb nylon tube 6. Remove the bulb from ...

Page 158

4.25 appi/apci source—cleaning the lamp window the transmission of the high-energy photons responsible for appi relies on the cleanliness of the magnesium fluoride lamp window. Clean the window to keep the surface clear of contamination, and avoid reduced sensitivity. Required materials • chemical-r...

Page 159

• uv lamp bulb sealing o-ring • mounting shaft o-rings • uv lamp mounting flange o-ring tip: an automatic pressure test is performed each time the source enclosure is closed and when the instrument starts. 4.26.1 removing the appi lamp drive assembly seals required materials • chemical-resistant, po...

Page 160

4. Use the combined 2.5-mm allen wrench and cone extraction tool to remove the two lamp- drive cover screws (located above the bulb-extraction plug-aperture). Note: to avoid damaging the source enclosure, take care to lay it on a smooth surface. Laying the source enclosure face-first on a hard objec...

Page 161

Figure 4–58: mounting-flange screw lamp mounting flange 12. Slide the lamp assembly, shaft, and flange out of the appi source enclosure. Tip: the cables remain attached to the shaft, which you fully withdraw and lay on the bench beside the source enclosure. Figure 4–59: repeller electrode electrode ...

Page 162

14. Use the combined 2.5-mm allen wrench and cone extraction tool to remove the two insulator screws. 15. Remove the peek insulator from the end of the mounting shaft. 16. Slide the shaft mounting flange off the shaft, and note the correct orientation, for its reassembly. 17. Use the o-ring removal ...

Page 163

Figure 4–62: lamp mounting flange o-ring warning: to avoid contaminating uncontaminated surfaces with biologically hazardous, toxic, or corrosive materials, dispose of all waste materials according to local environmental regulations. 20. Dispose of the o-rings in accordance with local environmental ...

Page 164

Note: to avoid damaging the appi lamp drive assembly o-rings, take care when fitting them. Small nicks, tears, dirt, and dust can compromise their performance, leading to rapid deterioration in the assembly’s operation. 1. Ensure that all the grooves for the o-rings are free from dirt and hairs. Tip...

Page 165

11. Use the combined 2.5-mm allen wrench and cone extraction tool to fit and tighten the two insulator retaining screws. 12. Fit the repeller electrode to the peek insulator. 13. Use the small phillips screwdriver to fit and tighten the repeller electrode retaining screw. 14. Insert the uv bulb into...

Page 166

Figure 4–64: unispray probe assembly peek fitting probe fitting probe capillary 3. Unscrew the probe fitting and pull the probe assembly out of the shaft inlet atop the source enclosure. Warning: to avoid lacerations, puncture injuries, and possible contamination with biohazardous and toxic samples,...

Page 167

To replace the unispray probe assembly: 1. Prepare the instrument for working on the source (see preparing the instrument for working on the source ). Warning: to avoid burn injuries, exercise care when handling the components of the source enclosure heated to high temperatures. Wait until the hot c...

Page 168

4.28 maintaining the unispray impactor pin unispray directs the spray at an impactor pin held at a voltage, creating smaller charged droplets, amenable to easy desolvation. This section provides details about removing, cleaning, and installing the unispray impactor pin. Figure 4–66: unispray impacto...

Page 169

3. Unscrew the pin handle and pull it to withdraw the pin from the mounting block. 4. Dispose of the used pin in accordance with local environmental regulations, or clean the pin, according to the procedure in cleaning the unispray impactor pin. 5. Holding the handle of the pin you are installing, i...

Page 170

Notice: do not rotate the impactor pin when wiping it in the lapping film or when wiping the pin clean, because this can damage the pin. 4. Install the impactor pin in the unispray source (see removing and installing the unispray impactor pin ). 4.29 replacing the fluidic lines of the ionkey source ...

Page 171

Tip: part numbers are embossed on the shrink-wrap below the ferrule assembly. You must disconnect the line from the source to see the part number. 4.29.1 removing a fluidic line required materials • chemical-resistant, powder-free gloves • flat-blade screwdriver • t10 torx driver warning: to avoid p...

Page 172

Figure 4–68: ikey surround 3. Unlock and remove any ikey installed in the ikey clamp. 4. Remove the gas line using a flat-blade screwdriver. June 9, 2016, 715004990 rev. A page 172.

Page 173

Figure 4–69: gas line 5. Disconnect the fluidic line being replaced from its source. 6. Remove two t10 torx screws securing the end plate bracket. June 9, 2016, 715004990 rev. A page 173.

Page 174

Figure 4–70: t10 torx screw end plate bracket t10 torx screw 7. Slide the end plate, along with the capillary tubing, out of the ikey clamp. 8. Gently pull the o-ring from around the tube’s fitting and slide the o-ring to the left. 9. Pull enough of the line being replaced to the right and allow the...

Page 175

10. Remove the o-ring from the tubing. 11. Dispose of the removed tubing in accordance with standard laboratory procedures for contaminated vessels and sharps. 4.29.2 installing a fluidic line required materials • chemical-resistant, powder-free gloves • fluid line assembly warning: to avoid persona...

Page 176

5. Secure the fitting with the o-ring. 6. Reinstall the end plate, end plate bracket, and gas line. 7. Route the open end of the fluidic line through the fluid line aperture on the left of the source. 8. Reinstall the fitting, ferrule, and lock ring onto the end of the new fluidic line, then connect...

Page 177

During normal operation, the ionkey source does not require cleaning. After repeated use, however, material can accumulate around the fluid-line connectors or electronic connectors in the ikey docking port. Figure 4–73: electronic connectors fluid line connectors to remove buildup from fluid-line co...

Page 178

4.30.2 to clean the outside surfaces of the ionkey source to clean the outside surfaces of the ionkey source: 1. Use a lint-free tissue, dampened with water. 2. Clean the other system components according to the supplied documentation. June 9, 2016, 715004990 rev. A page 178.

Page 179: Safety Advisories

A safety advisories waters instruments and devices display hazard symbols that alert you to the hidden dangers associated with a product’s operation and maintenance. The symbols also appear in product manuals where they accompany statements describing the hazards and advising how to avoid them. This...

Page 180

Warning: (risk of injury caused by moving machinery.) warning: (risk of exposure to ultraviolet radiation.) warning: (risk of contacting corrosive substances.) warning: (risk of exposure to a toxic substance.) warning: (risk of personal exposure to laser radiation.) warning: (risk of exposure to bio...

Page 181

Warning: to avoid electric shock, do not remove protective panels from system modules. The components within are not user-serviceable. The following warning applies to certain mass spectrometers when they are in operate mode. Warning: to avoid harmless, static-like electric shock, ensure the mass sp...

Page 182: A.2 Notices

Warning: to avoid personal contamination with biohazards, toxic materials, or corrosive materials, you must understand the hazards associated with their handling. Guidelines prescribing the proper use and handling of such materials appear in the latest edition of the national research council's publ...

Page 183: Devices

A.5 warnings that apply to all waters instruments and devices when operating this device, follow standard quality-control procedures and the equipment guidelines in this section. Warning: changes or modifications to this unit not expressly approved by the party responsible for compliance could void ...

Page 184

Warning: use caution when working with any polymer tubing under pressure: • always wear eye protection when near pressurized polymer tubing. • extinguish all nearby flames. • do not use tubing that has been severely stressed or kinked. • do not use nonmetallic tubing with tetrahydrofuran (thf) or co...

Page 185

Avvertenza: fare attenzione quando si utilizzano tubi in materiale polimerico sotto pressione: • indossare sempre occhiali da lavoro protettivi nei pressi di tubi di polimero pressurizzati. • spegnere tutte le fiamme vive nell'ambiente circostante. • non utilizzare tubi eccessivamente logorati o pie...

Page 186

경고: 가압 폴리머 튜브로 작업할 경우에는 주의하십시오. • 가압 폴리머 튜브 근처에서는 항상 보호 안경을 착용하십시오. • 근처의 화기를 모두 끄십시오. • 심하게 변형되거나 꼬인 튜브는 사용하지 마십시오. • 비금속(nonmetallic) 튜브를 테트라히드로푸란(tetrahydrofuran: thf) 또는 농축 질 산 또는 황산과 함께 사용하지 마십시오. • 염화 메틸렌(methylene chloride) 및 디메틸술폭시드(dimethyl sulfoxide)는 비금속 튜브를 부풀려 튜브의 파열 압력을 크게 감소시킬 수 있으므로 ...

Page 187

警告: 使用者必须非常清楚如果设备不是按照制造厂商指定的方式使用,那么该设备所 提供的保护将被削弱。 경고: 제조업체가 명시하지 않은 방식으로 장비를 사용할 경우 장비가 제공하는 보호 수단이 제대로 작동하지 않을 수 있다는 점을 사용자에게 반드시 인식시켜야 합니다. 警告: ユーザーは、製造元により指定されていない方法で機器を使用すると、機器が提供している 保証が無効になる可能性があることに注意して下さい。 a.6 warnings that address the replacing of fuses the following warnings pertain to in...

Page 188: A.7 Electrical Symbols

警告: 火災予防のために、ヒューズ交換では機器ヒューズカバー脇のパネルに記載されているタイプお よび定格のヒューズをご使用ください。 finding fuse types and ratings when that information does not appear on the instrument or device: warning: to protect against fire, replace fuses with those of the type and rating indicated in the “replacing fuses” section of the mai...

Page 189: A.8 Handling Symbols

Symbol description electrical power off standby direct current alternating current alternating current (3 phase) safety ground frame, or chassis, terminal fuse functional ground input output a.8 handling symbols the following handling symbols and their associated statements can appear on labels affi...

Page 190

Symbol description use no hooks! Upper limit of temperature lower limit of temperature temperature limitation june 9, 2016, 715004990 rev. A page 190

Page 191: External Connections

B external connections warning: to avoid skeletal or muscle injury associated with lifting heavy objects, use appropriate machinery and the supplied harness to lift the mass spectrometer. Notice: to avoid damaging the mass spectrometer, observe the following precautions: • contact waters technical s...

Page 192

Shielded ethernet video camera connection (for use with the optional nanoflow esi or ionkey source) event inputs and outputs power roughing pump connectors roughing pump grounding connnection nitrogen exhaust nitrogen inlet pilot valve port turbo vacuum source vacuum collision cell gas inlet b.2 con...

Page 193

Figure b–2: ebara oil-free roughing pump exhaust tubing exhaust silencer control signal connector power connector vacuum hose required materials • chemical-resistant, powder-free gloves • 7-mm nut driver • sharp knife the following items are included in the installation kit: june 9, 2016, 715004990 ...

Page 194

• nw25 center rings • nw25 clamps • nw40 center rings • nw40 clamps • nw40 elbow • nw40 tee piece • nw40 to nw16 reducer • nw40 to nw25 reducer • 12.7-mm clear pvc exhaust tubing • pvc hose clamps • vacuum hose to connect the oil-free roughing pump: warning: to avoid personal contamination with bioh...

Page 195

Figure b–3: roughing pump tubing connections to rear of the xevo tq-xs mass spectrometer roughing pump electrical cable attached to vacuum hose vacuum hose to roughing pump nw40 clamps nw25 clamps flexible vacuum tubing nw40/nw25 reducer nw40 tee piece nw40 elbow june 9, 2016, 715004990 rev. A page ...

Page 196

Figure b–4: roughing pump tubing connections to the ebara pump exhaust tubing nw40/nw16 reducer exhaust silencer nw40 clamps vacuum hose from rear of the xevo tq-xs 2. Make the electrical connections to the roughing pump (see making connections to the ebara oil-free roughing pump ). June 9, 2016, 71...

Page 197: Roughing Pump

B.3 making the electrical connections to the ebara oil-free roughing pump figure b–5: roughing pump electrical connections: tape attaching electrical cables to the vacuum hose grounding connector backing pump control connector electronics on/off switch (for use by waters engineers only) pump overrid...

Page 198

Tip: use only the upper backing pump control connector. Leave the lower connector marked delayed backing pump control, disconnected. 3. Connect the grounding cable to the grounding connection. B.4 connecting to the nitrogen gas supply required materials • chemical-resistant, powder-free gloves • 6-m...

Page 199

Source vacuum collision cell gas inlet 2. Attach a nitrogen regulator to the nitrogen supply. Requirement: the nitrogen must be dry and oil-free, with a purity of at least 95%. 3. Connect the free end of the 6-mm ptfe tubing to the nitrogen regulator. 4. Set the nitrogen regulator to 690 kpa (6.9bar...

Page 200

• nitrogen exhaust trap bottle • 4-mm ptfe tubing and 12-mm ptfe tubing (included in the xevo tq-xs installation kit) to connect the nitrogen exhaust line: warning: to prevent the nitrogen exhaust from carrying biologically hazardous, toxic, or corrosive lc solvents, you must use a nitrogen exhaust ...

Page 201

To laboratory exhaust port from instrument pilot valve port cap bottle support nitrogen exhaust trap bottle from instrument exhaust connection one-way valve notice: to avoid gas leaks, use the sharp knife to cut the pvc exhaust tubing squarely (that is, perpendicular to its horizontal axis). 2. Cut ...

Page 202

Required materials • chemical-resistant, powder-free gloves • waste container to connect the liquid waste line: warning: to avoid personal contamination with biohazards, toxic materials, and corrosive materials, wear chemical-resistant gloves when performing this procedure. 1. Place a suitable waste...

Page 203

Warning: to prevent leakage of biologically hazardous, toxic, or corrosive materials, • do not crimp or bend drain lines. A crimp or bend can impede flow to the waste container. • empty the waste container before the lower end of the drain tubes are covered by waste solvent. 3. Route the waste lines...

Page 204: Lc)

B.8 connecting the workstation (systems with no acquity lc) before connecting the workstation to the instrument, set up the workstation according to its accompanying instructions. Locate the workstation within three meters (ten feet) of the mass spectrometer. Requirement: use shielded network cables...

Page 205

B.10 input/output signal connectors warning: to avoid electric shock, all electrical connections to the rear panel must be separated from hazardous voltages by double or reinforced insulation. Circuits of this type are classified as safety extra low voltage (selv). Examples of circuits that are typi...

Page 206

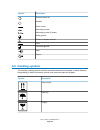

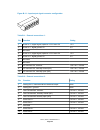

Figure b–11: input/output signal connector configuration: 1 2 3 4 5 6 7 8 9 10 table b–1: external connections 1: pin function rating 1 event in 1+, digital signal, optimum +3.3v max +5v +5 v 2 event in 1-, digital ground, 0v 0 v 3 not used 4 event in 2+, digital signal, optimum +3.3v max +5v +5 v 5...

Page 207

B.11 connecting to the electricity source the mass spectrometer requires a separate, grounded electricity source. The ground connection in the electrical outlet must be common and connected near the system. To connect to the electricity source: recommendation: use a line conditioner or an uninterrup...

Page 208: Compatible Solvents

C materials of construction and compatible solvents to confirm the integrity of the source exhaust system, you must address any safety issues raised in this appendix. C.1 preventing contamination for information on preventing contamination, refer to controlling contamination in ultraperformance lc/m...

Page 209

Table c–1: items exposed to solvent: (continued) item material solvent waste/leak management tygon tubing 2375, polyurethane source enclosure aluminium source enclosure view port silica float glass trap bottle polypropylene trap bottle push-in fittings nitrile butadiene rubber, stainless steel, poly...

Page 210

Solvents are used as additives to the mobile phases at reduced concentration, or as sample diluents. June 9, 2016, 715004990 rev. A page 210

Page 211: D.2 Plumbing Schematic

D intellistart fluidics system plumbing d.1 preventing contamination for information on preventing contamination, refer to controlling contamination in ultraperformance lc/ms and hplc/ms systems (part number 715001307). You can find this document on www.Waters.Com ; click services and support > supp...

Page 212

Acquity system source waste wash vial c vial b vial a analyte pump selector valve diverter valve d.3 ionkey and trizaic source plumbing figure d–2: ionkey and trizaic source plumbing 2 1 6 3 4 5 2 1 3 4 2 1 6 3 4 5 june 9, 2016, 715004990 rev. A page 212.

Page 213: D.4 Tubing Specifications

Trizaic tile or ikey syringe emitter htm trap valve (trizaic only) waste nanoacquity uplc sm, aquity uplc m-class µsm, or trap device ionkey or trizaic source d.4 tubing specifications the following table gives the internal diameter (id), external diameter (ed), color, length, and quantity for the i...