- DL manuals

- Waterstage

- Air Conditioner

- WGHA050DG

- Technical manual

Waterstage WGHA050DG Technical manual

Summary of WGHA050DG

Page 1

Air to water split dhw integrated type design & technical manual innovative solution of domestic heating dtw_sdi003e_01.

Page 2: 2. Hydraulic Unit

2. Hydraulic unit dtw_sdi003e_01--chapter02 2015.02.18 comfort series_single phase type: wga050dg wga100dg high power series: wgg140dg wgyk160dg9.

Page 3: C O N T E N T S

H y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g c o n t e n t s hydraulic 22 unit 12 features 22222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222hu01 - 01 22 specifications 222222222222222222222222222...

Page 4: Features

- (hu01 - 01) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g features 12 model : wg a050dg wg a100dg wgg140dg wgyk160dg9 compact hydraulic unit design with dhw tank intelligent control 2-zone individual control * z h...

Page 5

- (hu01 - 02) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g high reliability high durability z corrosion protected • no flow switch and no filter necessary • easy installation and maintenance z all hydraulic safety and c...

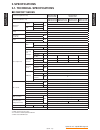

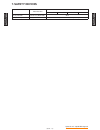

Page 6: Specifications

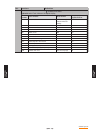

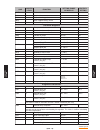

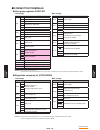

- (hu01 - 03) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g specifications 22 technical specifications 2-12 comfort series model name (hydraulic unit) wgya050dg6 wgha050dg wgya100dg6 wgha100dg model name (outdoor unit) w...

Page 7

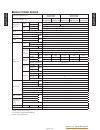

- (hu01 - 04) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g high power series model name (hydraulic unit) wgyg140dg6 wghg140dg wgyk160dg9 wghg140dg model name (outdoor unit) woyg112lcta wohg112lcta woyg140lcta wohg140lct...

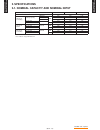

Page 8: Electrical Specifications

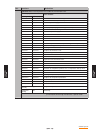

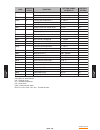

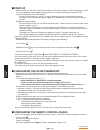

- (hu01 - 05) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g electrical specifications 2-22 comfort series model name (hydraulic unit) wgya050dg6 wgha050dg wgya100dg6 wgha100dg model name (outdoor unit) woya060lfca woha06...

Page 9

- (hu01 - 06) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g high power series model name (hydraulic unit) wgyg140dg6 wghg140dg wgyk160dg9 wghg140dg model name (outdoor unit) woyg112lcta wohg112lcta woyg140lcta wohg140lct...

Page 10

- (hu01 - 07) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g energy efficiency value model name hydraulic unit wgya050dg6 wgha050dg wgya100dg6 wgha100dg outdoor unit woya060lfca woha060lfca woya060lfca woha060lfca woya080...

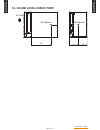

Page 11: Dimensions

- (hu01 - 08) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g dimensions 32 dimensional drawing 3-12 model : wg a050dg, wga100dg, wg g140dg, wgyk160dg9 175 210 47 1296 648 55 1135 1189 244 43 630 599 576 644 1850 184...

Page 12: Installation Place

- (hu01 - 09) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g installation place 3-22 installation precautions the room in which the appliance operates must comply with the prevailing regulations. • to facilitate maintenan...

Page 13: Piping Diagram

- (hu01 - 10) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g piping diagram 42 model : wg a050dg, wga100dg, wg g140dg, wgyk160dg9 outdoor unit refrigerant heating terminal (floor heating, radiator, etc.) hot water w...

Page 14: Wiring Diagram

- (hu01 - 11) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g wiring diagram 52 wiring diagram 5-12 model : wgya050dg6, wgya100dg6, wgyg140dg6 ou/ or ou/ or 3 2 1 3 2 1 c.C 2a 1a 1b 2b ex1 ex2 ex3 l n 1 2 3 4 5 l n com l l...

Page 15

- (hu01 - 12) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g model : wgha050dg, wgha100dg, wghg140dg ou/ or ou/ or 3 2 1 3 2 1 c.C 2a 1a 1b 2b ex1 ex2 ex3 l n 1 2 3 4 5 l n com l l n x10 x11 x12 x13 x14 x15 x30 x50 x70 x7...

Page 16

- (hu01 - 13) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g model : wgyk160dg9 ou/ or ou/ or 3 2 1 3 2 1 c.C 2a 1a 1b 2b ex1 ex2 ex3 l n 1 2 3 4 5 l n com l l n x10 x11 x12 x13 x14 x15 x30 x50 x70 x75 x80 x82 x83 x84 x86...

Page 17: External Connection Diagram

- (hu01 - 14) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g external connection diagram 5-22 model : wg a050dg, wga100dg, wgg140dg ex1 ex2 ex3 x60 x86 l x84 x11 2 1 3 m b9 b2 m b1 3 2 1 1 2 1 3 2 b2 m b1 outdoor se...

Page 18

- (hu01 - 15) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g model : wgyk160dg9 ex1 ex2 ex3 x60 x86 l x84 x11 2 1 3 m b9 b2 m b1 3 2 1 1 2 1 3 2 b2 m b1 outdoor sensor room thermostat** room thermostat** wireless remote c...

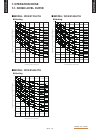

Page 19: Hydraulic Performance

- (hu01 - 16) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g hydraulic performance 62 static pressure drop unit 6-12 variable pressure 1mbar = 10 mmce = 100 pa 0 100 200 300 400 500 600 mbar m /h 3 1 1.5 2 2.5 0.5 0 2 4 6...

Page 20: Safety Devices

- (hu01 - 17) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g safety devices 72 protection form model wga050dg wga100dg wgg140dg wgyk160dg9 circuit protection current fuse (main pcb) 20 a high pressure protection saf...

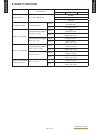

Page 21: Standard Accessories

- (hu01 - 18) - hydraulic unit / split dhw integrated h y d r a u l ic u n it wg 0 5 0 -16 0 d g h y d r a u l ic u n it wg 0 5 0 -16 0 d g standard accessories 82 name and shape q'ty application installation and operating manual 1 operation manual 5 outdoor sensor 1 to monitor the outdoor temperatu...

Page 22: 1. Outdoor Unit

1. Outdoor unit dtw_3sp003e_01--chapter01 2016.02.18 3 phase type : wok112lcta wok140lcta wok160lcta.

Page 23: C O N T E N T S

C o n t e n t s outdoor 11 unit 11 features 11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111ou01 - 01 21 specifications 1111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111ou01 - 04 2-11 nom...

Page 24: Features

- (ou01 - 01) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a features 11 models : wo k112lcta, wok140lcta, wok160lcta high performance powerful heating z high power models realize high leaving water temperature and high heating...

Page 25

- (ou01 - 02) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a high efficiency z energy efficiency is improved by the linear control injection technology and the optimization of refrigerant cycle control. High power model realizes h...

Page 26

- (ou01 - 03) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a wide comfort wide comfort by the clean energy produced by reliably delivers “comfort” to diverse spaces in the home up to the living room, bedrooms, bath and swimming po...

Page 27: Specifications

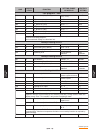

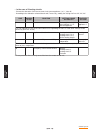

- (ou01 - 04) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a specifications 21 nominal capacity and nominal input 2-11 * test conditions comply with en14511-2 model name (outdoor unit) wo Ûk112lcta wo Ûk140lcta wo Ûk160lcta power ...

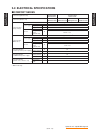

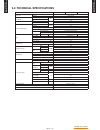

Page 28: Technical Specifications

- (ou01 - 05) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a technical specifications 2-21 model name (outdoor unit) wo Ûk112lcta wo Ûk140lcta wo Ûk160lcta enclosure colour beige (10yr 7.5/1.0) material steel sheet dimensions (h x...

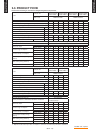

Page 29: Product Fiche

- (ou01 - 06) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a product fiche 2-31 product fiche according to commission delegated regulation (eu) 811/2013 model hydraulic unit wsyk160dg9 wshg140dg *1 wgyk160dg9 wghg140dg *1 wsyk160d...

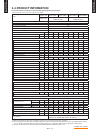

Page 30: Product Information

- (ou01 - 07) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a product information 2-41 product information according to commission delegated regulation (eu) 813/2013 product information is based on the average climate condition. Mo...

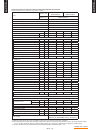

Page 31

- (ou01 - 08) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a product information according to commission delegated regulation (eu) 813/2013 product information is based on the average climate condition. Model hydraulic unit wsyk16...

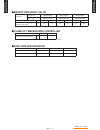

Page 32

- (ou01 - 09) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a energy efficiency value model name hydraulic unit wsyk160dg9 wshg140dg wsyk160dg9 wshg140dg wsyk160dg9 wshg140dg outdoor unit woyk112lcta wohk112lcta woyk140lcta wohk140...

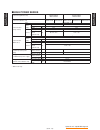

Page 33: Electrical Specifications

- (ou01 - 10) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a electrical specifications 2-51 model name (outdoor unit) wo Ûk112lcta wo Ûk140lcta woÛk160lcta available voltage range v 342 - 457 power supply voltage v 3n ~ 400v frequ...

Page 34: Dimensions

- (ou01 - 11) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a dimensions 31 dimensional drawing 3-11 models : wo k112lcta, wok140lcta, wok160lcta (unit : mm) 330 31 650 119 132 (370 ) 38 (liquid) 45 66 46 ( gas ) 1290 900 21 9 8...

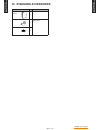

Page 35: Installation Place

- (ou01 - 12) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a installation place 3-21 single outdoor unit installation 3-2-11 (unit : mm) when the upward area is open 150 200 200 300 1000 or more 1000 or more 150 obstacles at rear ...

Page 36: 3-2-21

- (ou01 - 13) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a multiple outdoor unit installation 3-2-21 (unit : mm) when the upward area is open 300 1500 or more 500 1500 or more obstacles at rear only obstacles at front only obsta...

Page 37: Piping Diagram

- (ou01 - 14) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a piping diagram 41 models : wo k112lcta, wok140lcta, wok160lcta heating terminal (floor heating, radiator) dedicated compressor for injection port mounting sub accumul...

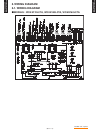

Page 38: Wiring Diagram

- (ou01 - 15) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a wiring diagram 51 wiring diagram 5-11 models : wo k112lcta, wok140lcta, wok160lcta.

Page 39: External Input & Output

- (ou01 - 16) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a external input & output 5-21 models : wo k112lcta, wok140lcta, wok160lcta input output connector remarks low noise mode ― cn19 see external input/output settings for ...

Page 40

- (ou01 - 17) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a peak cut mode z operation that suppressed the current value can be performed by means of the following on- • site work. The air conditioner is set to the peak cut mode b...

Page 41

- (ou01 - 18) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a external output compressor status output z compressor operation status signal can be output by means of the following on-site work. • circuit diagram example signal outd...

Page 42: Capacity Tables

- (ou01 - 19) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a capacity tables 61 heating capacity 6-11 model : wok112lcta ft 30°c 35°c 40°c 45°c 50°c 55°c 60°c ot hc ip cop hc ip cop hc ip cop hc ip cop hc ip cop hc ip cop hc ip c...

Page 43

- (ou01 - 20) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a model : wok140lcta ft 30°c 35°c 40°c 45°c 50°c 55°c 60°c ot hc ip cop hc ip cop hc ip cop hc ip cop hc ip cop hc ip cop hc ip cop -25°c 5.99 3.54 1.69 5.90 3.92 1.51 5....

Page 44

- (ou01 - 21) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a model : wok160lcta ft 30°c 35°c 40°c 45°c 50°c 55°c 60°c ot hc ip cop hc ip cop hc ip cop hc ip cop hc ip cop hc ip cop hc ip cop -25°c 6.06 3.59 1.69 5.97 3.98 1.50 5....

Page 45: Cooling Capacity

- (ou01 - 22) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a cooling capacity 6-21 * model : wo k112lcta * : optional parts “cooling kit" is necessary for cooling operation. Ft : flow temperature ot : outdoor temperature cc : coo...

Page 46

- (ou01 - 23) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a model : wo k140lcta * : optional parts “cooling kit" is necessary for cooling operation. Ft : flow temperature ot : outdoor temperature cc : cooling capacity (kw) ip : ...

Page 47

- (ou01 - 24) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a model : wo k160lcta * : optional parts “cooling kit" is necessary for cooling operation. Ft : flow temperature ot : outdoor temperature cc : cooling capacity (kw) ip : ...

Page 48: Operation Noise

- (ou01 - 25) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a operation noise 71 noise level curve 7-11 model : wo k160lcta o c ta v e b a n d s o u n d p re s s u re l e v e l, d b: (0 d b = 0 .0 0 0 2 µ b a r) octave band center...

Page 49: Sound Level Check Point

- (ou01 - 26) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a sound level check point 7-21 microphone 1m microphone air flow.

Page 50: Operation Range

- (ou01 - 27) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a operation range 81 coolin g mode flow temperature (°c) flow temperature (°c) heating mode sanitary mode outdoor temperature (°cdb) 43 8 6 35 35 0 -20 -25 8 60 outdoor te...

Page 51: Safety Devices

- (ou01 - 28) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a safety devices 91 protection from model wo Ûk112lcta woÛk140lcta woÛk160lcta circuit protection current fuse (main pcb) 5a 250v 3.15a 250v 10a 250v fan motor protection ...

Page 52: Standard Accessories

- (ou01 - 29) - outdoor unit / 3 phase o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a o u t d o o r u n it wo k1 1 2 -1 6 0 l c t a standard accessories 101 name and shape q'ty application installation manual 1 drain pipe 1 for outdoor unit drain piping work. Drain cap 2.

Page 53: 3. Control System

3. Control system dtw_sdi003e_01--chapter03 2016.02.18 wga050dg (hydraulic unit) wga100dg (hydraulic unit) wgg140dg (hydraulic unit) wgyk160dg9 (hydraulic unit).

Page 54: C O N T E N T S

C o n t r o l sy s t e m c o n t r o l sy s t e m c o n t e n t s control system 33 13 features ………………………………………………………………………………… cs01 - 01 23 functions ……………………………………………………………………………… cs01 - 03 2-13 user interface and remote control (optional parts) …………… cs01 - 03 2-23 room thermostat (optional parts...

Page 55: Features

- (cs01 - 01) - control system c o n t r o l sy s t e m c o n t r o l sy s t e m features 13 smart & comfort control the outdoor temperature is detected by sensor and the heating water temperature is controlled automatically. The setting of room temperature and operation mode can be easily set. A wi...

Page 56

- (cs01 - 02) - control system - (cs01 - 02) - c o n t r o l sy s t e m c o n t r o l sy s t e m extendibility z diverse operation control meets diverse needs by combining with optional parts. Options 2-temperature simultaneous heating floor heating + radiator heating (split type only) operation tog...

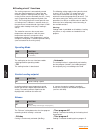

Page 57: Functions

- (cs01 - 03) - control system c o n t r o l sy s t e m c o n t r o l sy s t e m functions 23 user interface 2-13 and remote control (optional parts) auto esc ok 0 4 8 1 2 1 6 2 0 2 4 1 2 3 4 5 1 2 3 4 6 5 7 12 8 6 7 8 9 ref 3 functions - definitions 1 selecting dhw operating mode (domestic hot wate...

Page 58

- (cs01 - 04) - control system - (cs01 - 04) - c o n t r o l sy s t e m c o n t r o l sy s t e m ref 3 functions - definitions 6 information display various data. - designation line floor drying current setpoint - current drying day - terminated drying days - state heat pump 8006 state supplementary...

Page 59

- (cs01 - 05) - control system - (cs01 - 05) - c o n t r o l sy s t e m c o n t r o l sy s t e m ref 3 functions - definitions - reading error codes hydraulic unit : fault visible on the digital display. Error number error contents error location heat pump operation despite the error - no connection...

Page 60

- (cs01 - 06) - control system - (cs01 - 06) - c o n t r o l sy s t e m c o n t r o l sy s t e m ref 3 functions - definitions hydraulic unit : flashing of the led visible on the interface card. Led display error contents led 2 (green) led 1 (red) 1 flash 1 flash communication error between hydrauli...

Page 61

- (cs01 - 07) - control system - (cs01 - 07) - c o n t r o l sy s t e m c o n t r o l sy s t e m ref 3 functions - definitions outdoor unit : to access the electronic board, you must remove the front (right-hand) facing from the outdoor unit. Faults are coded by led flashes. Sw1 sw2 sw3 sw4 sw5 (1) ...

Page 62

- (cs01 - 08) - control system - (cs01 - 08) - c o n t r o l sy s t e m c o n t r o l sy s t e m ref 3 functions - definitions 7 confirm "ok" input into the selected menu. - confirmation of the parameter settings. - confirmation of the adjustment to the comfort temp. Setting. - 8 selecting cooling m...

Page 63: 2-23

- (cs01 - 09) - control system - (cs01 - 09) - c o n t r o l sy s t e m c o n t r o l sy s t e m room thermostat (optional parts) 2-23 °c auto 5 10 11 12 ref 3 functions - definitions 5 selecting heating mode auto - heating operating according to the heating program (summer/winter mode switchover is...

Page 64: Control Setting

- (cs01 - 10) - control system - (cs01 - 10) - c o n t r o l sy s t e m c o n t r o l sy s t e m control setting 2-33 general the settings described below are those which can be modified by the user. We wish to remind you that changing the settings below may cause the heat pump to behave in an undes...

Page 65

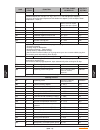

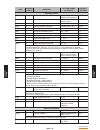

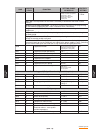

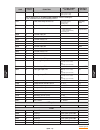

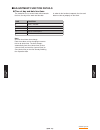

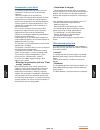

- (cs01 - 11) - control system - (cs01 - 11) - c o n t r o l sy s t e m c o n t r o l sy s t e m function table line access level function setting range or display factory setting time of day and date 1 u hours/minutes 00:00…23:59 2 u day/month 01.01…31.12 3 u year 1900…2099 5 s start of summer time...

Page 66

- (cs01 - 12) - control system - (cs01 - 12) - c o n t r o l sy s t e m c o n t r o l sy s t e m line access level function setting range or display factory setting time program 4 / dhw 560 u pre-selection (day / week) mon-sun, mon-fri, sat-sun, monday, tuesday, … mon-sun 561 u 1 st phase on (start)...

Page 67

- (cs01 - 13) - control system - (cs01 - 13) - c o n t r o l sy s t e m c o n t r o l sy s t e m line access level function setting range or display factory setting 760 s room temp limitation 0.5…4°c 0.5°c as soon as the room temperature = [setpoint line 710 (ex. 20°c) + room temperature limitation ...

Page 68

- (cs01 - 14) - control system - (cs01 - 14) - c o n t r o l sy s t e m c o n t r o l sy s t e m line access level function setting range or display factory setting heating circuit 2 1010 u comfort setpoint reduced setpoint… comfort setpoint maximum 20°c 1012 u reduced setpoint frost protection setp...

Page 69

- (cs01 - 15) - control system - (cs01 - 15) - c o n t r o l sy s t e m c o n t r o l sy s t e m line access level function setting range or display factory setting 1620 i release of dhw load 24h / day heating circuit time programme programme 4 / dhw off-peak tariff (off-peak) programme 4 / dhw and ...

Page 70

- (cs01 - 16) - control system - (cs01 - 16) - c o n t r o l sy s t e m c o n t r o l sy s t e m line access level function setting range or display factory setting 2920 s with electrical utility lock (ex1) locked (blocked on standby), released released released : hp = on _ back-up dhw = off _ 1st b...

Page 71

- (cs01 - 17) - control system - (cs01 - 17) - c o n t r o l sy s t e m c o n t r o l sy s t e m line access level function setting range or display factory setting 5716 s cooling circuit 2 off 4-pipe system cooling 2-pipe system cooling off set the parameter to " 2-pipe system cooling " with the co...

Page 72

- (cs01 - 18) - control system - (cs01 - 18) - c o n t r o l sy s t e m c o n t r o l sy s t e m line access level function setting range or display factory setting 6810 s history 6 time, date, error code 6812 s history 7 time, date, error code 6814 s history 8 time, date, error code 6816 s history ...

Page 73

- (cs01 - 19) - control system - (cs01 - 19) - c o n t r o l sy s t e m c o n t r o l sy s t e m line access level function setting range or display factory setting 8007 i state solar --- 8010 i state buffer --- 8011 i state swimming pool --- 8022 i state supplementary source --- 8025 i state coolin...

Page 74

- (cs01 - 20) - control system - (cs01 - 20) - c o n t r o l sy s t e m c o n t r o l sy s t e m line access level function setting range or display factory setting 8743 u flow temperature 1 0... 140 °c --- flow temperature setpoint 1 --- 8749 i room thermostat 1 no demand, demand no demand 8756 u c...

Page 75

- (cs01 - 21) - control system - (cs01 - 21) - c o n t r o l sy s t e m c o n t r o l sy s t e m adjustment function details time of day and date functions z the controller has an annual clock which contains the time, the day of the week and the date. In order for the function to operate, the time a...

Page 76

- (cs01 - 22) - control system - (cs01 - 22) - c o n t r o l sy s t e m c o n t r o l sy s t e m operator section functions z line function 20 language 22 info 26 operation lock 27 programming lock 28 direct adjustment 29 temperature unit pressure unit info temporary • after pressing the info key, t...

Page 77

- (cs01 - 23) - control system - (cs01 - 23) - c o n t r o l sy s t e m c o n t r o l sy s t e m time program functions (heating circuit 1 & 2, dhw, cooling) z several control programs are available for the heating circuits and the production of dhw. They are initiated in "automatic" mode and contro...

Page 78

- (cs01 - 24) - control system - (cs01 - 24) - c o n t r o l sy s t e m c o n t r o l sy s t e m heating circuit 1 & 2 functions z operating mode for heating circuits there are several functions available which can be individually adjusted for each heating circuit. The programming lines for the 2nd ...

Page 79

- (cs01 - 25) - control system - (cs01 - 25) - c o n t r o l sy s t e m c o n t r o l sy s t e m heating curve slope based on the heating characteristic, the controller computes the flow temperature setpoint which will be used for controlling the flow temperature in consideration of atmospheric cond...

Page 80

- (cs01 - 26) - control system - (cs01 - 26) - c o n t r o l sy s t e m c o n t r o l sy s t e m eco functions line function hc1 hc2 730 1030 summer/winter heating limit summer/winter heating limit the summer/winter heating limit switches the heating on or off through the year according to the tempe...

Page 81

- (cs01 - 27) - control system - (cs01 - 27) - c o n t r o l sy s t e m c o n t r o l sy s t e m room influence line function hc1 hc2 750 1050 room influence control types: when using a room temperature sensor there are 3 different types of control to choose from. Setting control type - - - % simple...

Page 82

- (cs01 - 28) - control system - (cs01 - 28) - c o n t r o l sy s t e m c o n t r o l sy s t e m quick setback line function 760 1060 room temp limitation 780 1080 quick setback room temp limitaion the "room temperature limitation" function enables the heating circuit pump to be deactivated should t...

Page 83

- (cs01 - 29) - control system - (cs01 - 29) - c o n t r o l sy s t e m c o n t r o l sy s t e m reduced setpoint increase line function hc1 hc2 800 1100 reduced setpoint increase start 801 1101 reduced setpoint increase end this function is used mainly in heating installations that do not have high...

Page 84

- (cs01 - 30) - control system - (cs01 - 30) - c o n t r o l sy s t e m c o n t r o l sy s t e m floor curing function off • the function is deactivated. Heating operational (fh) • the first part of the temperature profile is automatically completed. Heating "ready for occupancy" (bh) • the second p...

Page 85

- (cs01 - 31) - control system - (cs01 - 31) - c o n t r o l sy s t e m c o n t r o l sy s t e m heating circuit frost protection informations: the heating circuit frost protection is continuously activated (protection mode ) and is not adjustable. Heating circuit frost protection in heating mode: -...

Page 86

- (cs01 - 32) - control system - (cs01 - 32) - c o n t r o l sy s t e m c o n t r o l sy s t e m cooling circuit 1 functions z the cooling sequence is automatically started when the room temperature is higher than the comfort setpoint in cooling mode (line 902). The cooling function must be activate...

Page 87

- (cs01 - 33) - control system - (cs01 - 33) - c o n t r o l sy s t e m c o n t r o l sy s t e m cooling characteristic line function 908 flow temp setpoint at ot 25°c 909 flow temp setpoint at ot 35°c the controller computes the flow temperature required for a given composite outdoor temperature ba...

Page 88

- (cs01 - 34) - control system - (cs01 - 34) - c o n t r o l sy s t e m c o n t r o l sy s t e m cooling limit at ot if the composite outdoor temperature is higher than the cooling limit, cooling is released. If the composite outdoor temperature falls at least 0.5°c below the cooling limit, cooling ...

Page 89

- (cs01 - 35) - control system - (cs01 - 35) - c o n t r o l sy s t e m c o n t r o l sy s t e m flow setpoint limitation line function 923 flow temp setpoint min at ot 25°c 924 flow temp setpoint min at ot 35°c it is possible to assign a lower limit to the cooling flow temperature. The limitation l...

Page 90

- (cs01 - 36) - control system - (cs01 - 36) - c o n t r o l sy s t e m c o n t r o l sy s t e m control according to outdoor conditions with room influence the difference between the room temperature and the setpoint value is measured and taken into account for temperature control. This enables tak...

Page 91

- (cs01 - 37) - control system - (cs01 - 37) - c o n t r o l sy s t e m c o n t r o l sy s t e m mixing valve control line function 938 mixing valve decrease 941 actuator running time 945 mixing valve in heating mode mixing valve decrease the cooling demand issued by cooling circuit 1 to production ...

Page 92

- (cs01 - 38) - control system - (cs01 - 38) - c o n t r o l sy s t e m c o n t r o l sy s t e m domestic hot water functions (with dhw kit or with integrated dhw models) z the control sets the dhw temperature, according to the time program or continuously, to the desired setpoint. The priority of d...

Page 93

- (cs01 - 39) - control system - (cs01 - 39) - c o n t r o l sy s t e m c o n t r o l sy s t e m release line function 1620 release of dhw load (24h/day / heating circ time pgm / time program 4/dhw / low-tariff/ time pgm 4/dhw or low-tariff) 24h/day (not recommended) regardless of the time programs,...

Page 94

- (cs01 - 40) - control system - (cs01 - 40) - c o n t r o l sy s t e m c o n t r o l sy s t e m dhw mode holiday status release (line 1620) time program status (program 4) low- tariff status (ex2) dhw mode level off x x x x frost protection on yes x x x frost protection on no … … x … on no low-tari...

Page 95

- (cs01 - 41) - control system - (cs01 - 41) - c o n t r o l sy s t e m c o n t r o l sy s t e m swimming pool functions z line function 2056 setpoint source heating the controller enables a swimming pool to be heated by the heat pump. An individual setpoint can be set by means of line 2056, which a...

Page 96

- (cs01 - 42) - control system - (cs01 - 42) - c o n t r o l sy s t e m c o n t r o l sy s t e m heat pump functions z line function 2803 overrun time cond pump 2843 compressor off time min 2844 switch-off temp max 2862 locking time stage 2 2873 compressor mod run time 2882 release integral electric...

Page 97

- (cs01 - 43) - control system - (cs01 - 43) - c o n t r o l sy s t e m c o n t r o l sy s t e m compensation heat deficit this function compensates for excess heat and heatdeficits. These can occur in the following situations: minimum compressor on and off times in the case of low temperature req...

Page 98

- (cs01 - 44) - control system - (cs01 - 44) - c o n t r o l sy s t e m c o n t r o l sy s t e m supplementary source z a supplementary producer can be operated in addition to the main producer (heat pump). Release of the supplementary producer depends on a number of parameters a detailed descriptio...

Page 99

- (cs01 - 45) - control system - (cs01 - 45) - c o n t r o l sy s t e m c o n t r o l sy s t e m flow control line function 3720 switching integral 3723 locking time switching integral the temperature-time integral is a continuous summation of the temperature differential over time. In this case, th...

Page 100

- (cs01 - 46) - control system - (cs01 - 46) - c o n t r o l sy s t e m c o n t r o l sy s t e m locking time the locking time enables the heat pump to reach a stable operating state before the supplementary source is allowed to switch on. The supplementary source is released only when the locking t...

Page 101

- (cs01 - 47) - control system - (cs01 - 47) - c o n t r o l sy s t e m c o n t r o l sy s t e m dhw storage tank functions z dhw charging at the nominal setpoint temperature (line 1610) always takes place in two stages. In the first stage, only the heating pump heats the dhw tank. The power supplie...

Page 102

- (cs01 - 48) - control system - (cs01 - 48) - c o n t r o l sy s t e m c o n t r o l sy s t e m heater line function 5061 electric immersion heater release electric immersion heater release 24h/day • the heater is continuously active regardless of time programs. 0 6 12 18 24 h dhw release • the hea...

Page 103

- (cs01 - 49) - control system - (cs01 - 49) - c o n t r o l sy s t e m c o n t r o l sy s t e m configuration functions z when an installation is started up, the hydraulic unit diagram presetting for that installation must be entered. Pre-settings line function 5700 pre-setting only pre-setting 1 t...

Page 104

- (cs01 - 50) - control system - (cs01 - 50) - c o n t r o l sy s t e m c o n t r o l sy s t e m basic unit ex/e line function 5981 5983 5985 contact type input ex1, ex2, ex3 the type of contact can be selected: nc the input’s function is active when voltage is not present. No the input’s function i...

Page 105

- (cs01 - 51) - control system - (cs01 - 51) - c o n t r o l sy s t e m c o n t r o l sy s t e m reset to default parameters all parameters can be reset to factory settings, except followings: time and date, user interface, and all time programs, as well as the operating hours and the various counte...

Page 106

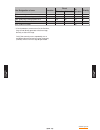

- (cs01 - 52) - control system - (cs01 - 52) - c o n t r o l sy s t e m c o n t r o l sy s t e m table of error messages which can be displayed: no3 designation of error location reset hp operation priority manual automatic 0: no fault 10: outdoor sensor bx4 (x84) no no yes 6 30: flow sensor 1 bx1 (...

Page 107

- (cs01 - 53) - control system - (cs01 - 53) - c o n t r o l sy s t e m c o n t r o l sy s t e m no3 designation of error location reset hp operation priority manual automatic 359: no cooling valve y21 no no yes 3 360: no process reversing valve y22 no no yes 3 364: heat pump cooling system error no...

Page 108

- (cs01 - 54) - control system - (cs01 - 54) - c o n t r o l sy s t e m c o n t r o l sy s t e m service / special operation functions z maintenance maintenance functions can be used as a preventive step for periodically monitoring the installation. All maintenance functions can be individually acti...

Page 109

- (cs01 - 55) - control system - (cs01 - 55) - c o n t r o l sy s t e m c o n t r o l sy s t e m simulation line function 7150 simulation outside temp simulation outside temp to make the starting-up and troubleshooting processes easier, it is possible to simulate an outdoor temperature in the range ...

Page 110

- (cs01 - 56) - control system - (cs01 - 56) - c o n t r o l sy s t e m c o n t r o l sy s t e m input / output test functions z input/output testing is used to ensure that the connected components are in working order. Relay output testing selection of a setting from relay testing closes the corres...

Page 111

- (cs01 - 57) - control system - (cs01 - 57) - c o n t r o l sy s t e m c o n t r o l sy s t e m input test ex1-3 line function 7911 input ex1 7912 input ex2 7913 input ex3 by selecting a setting from input test ex1-3, the relevant input will be displayed, enabling it to be checked. Display of 0 v m...

Page 112

- (cs01 - 58) - control system - (cs01 - 58) - c o n t r o l sy s t e m c o n t r o l sy s t e m state functions z the current operating status of the installation can be viewed by means of status displays. Messages line function 8000 state heating circuit 1 8001 state heating circuit 2 8003 state d...

Page 113

- (cs01 - 59) - control system - (cs01 - 59) - c o n t r o l sy s t e m c o n t r o l sy s t e m state dhw (8003) end user (info level) commissioning, engineer thermostat response thermostat response manual action active manual action active draw-off mode draw-off mode adiabatic cooling active adiab...

Page 114

- (cs01 - 60) - control system - (cs01 - 60) - c o n t r o l sy s t e m c o n t r o l sy s t e m state cooling circuit 1 (8004) end user (info level) commissioning, engineer dewpoint sensor activated dewpoint sensor activated manual action active manual action active fault fault frost protection act...

Page 115

- (cs01 - 61) - control system - (cs01 - 61) - c o n t r o l sy s t e m c o n t r o l sy s t e m state heat pump (8006) end user (info level) commissioning, engineer emergency mode emergency mode fault fault locked locked, outdoor temperature locked, external locked, economy mode lim. Time active co...

Page 116

- (cs01 - 62) - control system - (cs01 - 62) - c o n t r o l sy s t e m c o n t r o l sy s t e m state supplementary source (8022) end user (info level) commissioning, engineer locked locked, solid fuel boiler locked, outside temperature locked, economy mode in operation for hc, dhw in operation for...

Page 117

- (cs01 - 63) - control system - (cs01 - 63) - c o n t r o l sy s t e m c o n t r o l sy s t e m diagnostics heat generation functions z various setpoints and actual values, relay switch status data can be displayed for purposes of diagnosis. Heat pump line function 8402 electric immersion heater 1 ...

Page 118

- (cs01 - 64) - control system - (cs01 - 64) - c o n t r o l sy s t e m c o n t r o l sy s t e m diagnostics consumers functions z various setpoints and actual values, relay switch status and timing status data can be displayed for purposes of diagnosis. Outside temperatures line function 8700 outsi...

Page 119

- (cs01 - 65) - control system - (cs01 - 65) - c o n t r o l sy s t e m c o n t r o l sy s t e m domestic hot water line function 8820 dhw pump 8821 electric immersion heater dhw 8830 dhw temperature 8840 hours run dhw pump 8841 start counter dhw pump 8842 hours run electric dhw 8843 start counter e...

Page 120

- (cs01 - 66) - control system - (cs01 - 66) - c o n t r o l sy s t e m c o n t r o l sy s t e m status of relays for extension modules 1 and 2 line function 9050 relay output qx21 module 1 9051 relay output qx22 module 1 9052 relay output qx23 module 1 9053 relay output qx21 module 2 9054 relay out...

Page 121: Electrical Connections

- (cs01 - 67) - control system c o n t r o l sy s t e m c o n t r o l sy s t e m electrical connections 33 overview of all the electrical connections 3-13 the wiring diagram for the hydraulic unit is shown in detail on electrical wiring diagrams. (chapter 1 for outdoor unit and chapter 2 for hydraul...

Page 122: 3-23

- (cs01 - 68) - control system - (cs01 - 68) - c o n t r o l sy s t e m c o n t r o l sy s t e m electrical connections on the hydraulic unit 3-23 open the front cover • 1 2 open the power control box • note: ensure that the general electrical power supply has been cut off before starting any repair...

Page 123

- (cs01 - 69) - control system - (cs01 - 69) - c o n t r o l sy s t e m c o n t r o l sy s t e m make the connections in accordance with the diagram(s)3 • do not place the sensor lines and the sector supply lines in parallel in order to avoid causing inadvertent interference due to voltage points in...

Page 124

- (cs01 - 70) - control system - (cs01 - 70) - c o n t r o l sy s t e m c o n t r o l sy s t e m do not place the sensor lines and the sector supply lines in parallel in order to avoid interferences due to voltage points in the sector supply. Ensure that all the electrical cables are housed in the s...

Page 125: 3-33

- (cs01 - 71) - control system - (cs01 - 71) - c o n t r o l sy s t e m c o n t r o l sy s t e m connections to the heat pump regulator 3-33 (accessories and options) models: wgya050dg6, wgya100dg6, and wgyg140dg6 single phase model aci dhw storage tank electrode heat pump regulator (x100) l earth n...

Page 126

- (cs01 - 72) - control system - (cs01 - 72) - c o n t r o l sy s t e m c o n t r o l sy s t e m models: wgha050dg, wgha100dg, and wghg140dg single phase / 3-phase model aci dhw storage tank electrode heat pump regulator (x100) l earth n qx31 qx32 n qx33 qx34 n n n qx35 qx35 1 2 3 b1 m b2 h33 m bx31...

Page 127

- (cs01 - 73) - control system - (cs01 - 73) - c o n t r o l sy s t e m c o n t r o l sy s t e m model : wgyk160dg9 3-phase model ou/ or ou/ or 3 2 1 3 2 1 c.C 2a 1a 1b 2b ex1 ex2 ex3 l n 1 2 3 4 5 l n com l l n x10 x11 x12 x13 x14 x15 x30 x50 x70 x75 x80 x82 x83 x84 x86 x100 x60 3 2 1 m bk bn bu rp...

Page 128

- (cs01 - 74) - control system - (cs01 - 74) - c o n t r o l sy s t e m c o n t r o l sy s t e m single phase / 3 phase model x10 x11 x12 x13 x14 x15 x30 x50 x70 x75 x80 x82 x83 x84 x86 x100 x60 connections to the heat pump regulator (a cc e ss o ri e s a n d o p tio n s) d3 d2 d1 ux3 m di6 di7 m b ...

Page 129

- (cs01 - 75) - control system - (cs01 - 75) - c o n t r o l sy s t e m c o n t r o l sy s t e m connection terminals heat pump regulator rvs213827 z low voltage main voltage terminal use terminal use x75 m gnd (common with interface pcb) x10 l power supply di7 hp error earth di6 defrost n uref comp...

Page 130

- (cs01 - 76) - control system - (cs01 - 76) - c o n t r o l sy s t e m c o n t r o l sy s t e m outdoor sensor the outdoor sensor is required for the heat pump to operate correctly. Consult the fitting instructions on the sensor’s packaging. Place the sensor on the coldest part, generally the north...

Page 131

- (cs01 - 77) - control system - (cs01 - 77) - c o n t r o l sy s t e m c o n t r o l sy s t e m start-up make sure that all dip sw on the interface card are off before starting up. Dip sw shuold be set off - for normal operation. Power supply to the hydraulic unit must be turned off while toching d...

Page 132

- (cs01 - 78) - control system - (cs01 - 78) - c o n t r o l sy s t e m c o n t r o l sy s t e m in the case of 2 heating circuits choose the allocation of the remote control unit (room appliance 1 or 2…) line 40*. - according to the allocation selected check and, if necessary, modify the settings...

Page 133: Installation

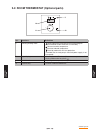

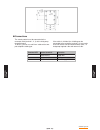

- (cs01 - 79) - control system c o n t r o l sy s t e m c o n t r o l sy s t e m installation 43 outdoor sensor 4-13 model : qac34 24.5 25 8.6 5.5 6 9.6 installation z h (1/2 h ) m in imu m 2 .5 m field supply.

Page 134: 4-23

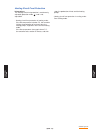

- (cs01 - 80) - control system c o n t r o l sy s t e m c o n t r o l sy s t e m remote control (optional parts) 4-23 model : utw-c75xa the remote control includes the functions of the room unit together with those of the user interface mounted in series on the hydraulic unit. It can be used, theref...

Page 135

- (cs01 - 81) - control system - (cs01 - 81) - c o n t r o l sy s t e m c o n t r o l sy s t e m connections z the remote control must be connected to the connector x86 (terminal 1, 2, 3) of the heat pump controller board. To do this, you can use a 0.5mm² cable of the two- pair telephone cable type....

Page 136

- (cs01 - 82) - control system c o n t r o l sy s t e m c o n t r o l sy s t e m model : utw-c78xd (wireless) the remote control includes the functions of the room unit together with those of the user interface mounted in series on the hydraulic unit. It can be used, therefore, not only to measure t...

Page 137

- (cs01 - 83) - control system - (cs01 - 83) - c o n t r o l sy s t e m c o n t r o l sy s t e m.

Page 138: 4-33

- (cs01 - 84) - control system - (cs01 - 84) - c o n t r o l sy s t e m c o n t r o l sy s t e m room thermostat (optional parts) 4-33 model : utw-c55xa the room thermostat is optional. Select an appropriate place for the room thermostat by following these rules: central room ● installation height, ...

Page 139

- (cs01 - 85) - control system - (cs01 - 85) - c o n t r o l sy s t e m c o n t r o l sy s t e m model : utw-c58xd (wireless) the room thermostat is optional. Select an appropriate place for the room thermostat by following these rules: central room ● installation height, approx. 1.5 m ● inner wall ...

Page 140: Rf Module (Optional Parts)

- (cs01 - 86) - control system - (cs01 - 86) - c o n t r o l sy s t e m c o n t r o l sy s t e m rf module (optional parts) 4-43 model : utw-m60xd, utw-mrcxd the wireless components should be located such that transmission is as interference-free as possible. ● the following criteria must be observe...

Page 141: Dimensions

- (cs01 - 87) - control system c o n t r o l sy s t e m c o n t r o l sy s t e m dimensions 53 outdoor sensor 5-13 model : qac34 79.8 91.6 49.7 24.5 25 8.6 5.5 6 9.6 front view side view rear view top view bottom view (unit : mm).

Page 142: 5-23

- (cs01 - 88) - control system c o n t r o l sy s t e m c o n t r o l sy s t e m remote control (optional parts) 5-23 model : utw-c75xa / utw-c78xd (wireless) controller z front view side view rear view top view 159 82 37 holder z front view side view rear view bottom view 32.5 80 56 60 100 9 11 39 ...

Page 143: 5-33

- (cs01 - 89) - control system - (cs01 - 89) - c o n t r o l sy s t e m c o n t r o l sy s t e m room thermostat (optional parts) 5-33 model : utw-c55xa / utw-c58xd (wireless) unit z front view side view rear view bottom view top view 96 47 4.2 56 60 56 60 96 (unit : mm).

Page 144: Rf Module (Optional Parts)

- (cs01 - 90) - control system - (cs01 - 90) - c o n t r o l sy s t e m c o n t r o l sy s t e m rf module (optional parts) 5-43 model : utw-m60xd 66.5 55.8 43 71 28.8 front view side view bottom view (unit : mm).

Page 145

- (cs01 - 91) - control system - (cs01 - 91) - c o n t r o l sy s t e m c o n t r o l sy s t e m model : utw-mrcxd front view side view rear view 96 96 40 4.2 56 60 56 91 96 60 (unit : mm).

Page 146: Packing List (Accessories)

- (cs01 - 92) - control system c o n t r o l sy s t e m c o n t r o l sy s t e m packing list (accessories) 63 remote control (optional parts) 6-13 model : utw-c75xa* / utw-c78xd (wireless) name and shape quantity application remote control 1 use for atw operation remote control holder 1 use as remo...

Page 147: Rf Module (Optional Parts)

- (cs01 - 93) - control system c o n t r o l sy s t e m c o n t r o l sy s t e m rf module (optional parts) 6-33 model : utw-m60xd name and shape quantity application rf module 1 operating instructions 1 model : utw-mrcxd name and shape quantity application rf module 1 operating instructions 1.

Page 148: Wiring Specifications

- (cs01 - 94) - control system c o n t r o l sy s t e m c o n t r o l sy s t e m wiring specifications 73 outdoor sensor 7-13 model : qac34 use size wire type remarks outdoor sensor cable 0.75 mm² 2 wires connection max. Cable length: 60 m use shielded (field supplied) in accordance with the regiona...

Page 149: Specifications

- (cs01 - 95) - control system c o n t r o l sy s t e m c o n t r o l sy s t e m specifications 83 outdoor sensor 8-13 model : qac34 size ( h x w x d mm ) 91.6 x 79.8 x 49.7 weight ( g ) 73 cable length ( m ) 60 remote control (optional parts) 8-23 model : utw-c75xa size ( h x w x d mm ) 185 x 82 x ...

Page 150: Rf Module (Optional Parts)

- (cs01 - 96) - control system c o n t r o l sy s t e m c o n t r o l sy s t e m rf module (optional parts) 8-43 model : utw-m60xd size ( h x w x d mm ) 67 x 71 x 56 weight ( g ) 54 cable length ( m ) 1.5 power ( v ) 5.5 frequency band (mhz) 868 model : utw-mrcxd size ( h x w x d mm ) 96 x 96 x 40 w...

Page 151

Distributed by : iso 9001 certified number:09 100 89394 fujitsu general ( thailand ) co., ltd. Iso 14001 certified number:09 104 9245 3-3-17, suenaga, takatsu-ku, kawasaki 213-8502, japan http://www.Fujitsu-general.Com/ " " is a worldwide trademark of fujitsu general limited. Copyright© 2016 fujitsu...