- DL manuals

- Watlow Electric

- Controller

- F4D Series

- User manual

Watlow Electric F4D Series User manual

0600-0032-0000 Rev G

*0600-0032-0000*

April 2004

$15.00

User’s Manual

Series F4S/D

96mm x 96mm Ramping Controller (1/4 DIN)

with Guided Setup and Programming

1241 Bundy Boulevard, Winona, Minnesota USA

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507 http://www.watlow.com

Registered Company

Winona, Minnesota USA

Summary of F4D Series

Page 1

0600-0032-0000 rev g *0600-0032-0000* april 2004 $15.00 user’s manual series f4s/d 96mm x 96mm ramping controller (1/4 din) with guided setup and programming 1241 bundy boulevard, winona, minnesota usa phone: +1 (507) 454-5300, fax: +1 (507) 452-4507 http://www.Watlow.Com registered company winona, ...

Page 2: About Watlow Winona

Watlow winona is a division of watlow electric mfg. Co., st. Louis, missouri, a manufacturer of industrial electric heating products since 1922. Watlow begins with a full set of specifications and completes an indus- trial product that is manufactured in-house, in the u.S.A. Watlow products include ...

Page 3

Wa t l o w s e r i e s f 4 s / d ta b l e o f c o n t e n t s ■ i introduction chapter 1: introduction . . . . . . . . . . . . . . . . . 1.1 chapter 2: keys, displays and navigation . . .2.1 operations chapter 3: operations . . . . . . . . . . . . . . . . . .3.1 profiles chapter 4: profile programmi...

Page 4: Technical Assistance

I i ■ ta b l e o f c o n t e n t s wa t l o w s e r i e s f 4 s / d safety information in this manual note, caution and warning symbols appear throughout this book to draw your attention to important operational and safety information. A “note” marks a short message to alert you to an important deta...

Page 5: Chapter One: Introduction

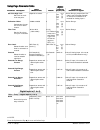

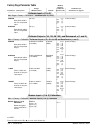

Wa t l o w s e r i e s f 4 s / d i n t r o d u c t i o n ■ 1 . 1 1 chapter one: introduction overview inputs and outputs figure 1.1a — single-channel series f4 (f4s_ - _ _ _ _ - _ _ _ _ ) inputs and outputs. Figure 1.1b — dual-channel series f4 (f4d_ - _ _ _ _ - _ _ _ _ ) inputs and outputs. 4 digit...

Page 6

Sample application: environmental testing with a dual channel f4 using multiple inputs and outputs figure 1.2 — sample application 1: series f4 dual channel using multiple inputs and outputs. F 4 1 2 i 1b 1b 2a 2a 2b 2b 1a 1a main page___________ go to profiles go to setup go to factory overview and...

Page 7

Wa t l o w s e r i e s f 4 s / d i n t r o d u c t i o n ■ 1 . 3 this sample application is continued in the operations, profile programming and setup chapters. Main page___________ go to profiles go to setup go to factory 3. Customize and name andy customized the main page so he could tell the stat...

Page 8: Setup Steps

1 . 4 ■ i n t r o d u c t i o n wa t l o w s e r i e s f 4 s / d setup steps the ˆ key during all these steps, the information key will summon helpful definitions and setup tips. Just position the cursor next to the item you want to know more about, then press the key. Press it again to return to yo...

Page 9: Navigation

Wa t l o w s e r i e s f 4 s / d k e y s , d i s p l a y s a n d n a v i g a t i o n ■ 2 . 1 chapter two: keys, displays & navigation displays and indicator lights . . . . . . . . . . . . . . . . .2.2 custom main page . . . . . . . . . . . . . . . . . . . . . . . . .2.3 keys and navigation . . . . ....

Page 10

Displays and indicator lights figure 2.2 — series f4s/d displays and indicator lights. (f4d shown) f 4 1 2 i 1b 1b 2a 2a 2b 2b 1a 1a main page___________ go to profiles go to setup go to factory upper display displays channel 1 actual process values during operation. Displays error information if er...

Page 11: Custom Main Page

Wa t l o w s e r i e s f 4 s / d k e y s , d i s p l a y s a n d n a v i g a t i o n ■ 2 . 3 custom main page figure 2.3 — default main page parameters. 2 dual channel f4d main page_____ input 1 error input 2 error input 3 error alarm 1 condition alarm 2 condition autotuning ch 1 autotuning ch 2 cur...

Page 12: Keys and Navigation

2 . 4 ■ k e y s , d i s p l a y s a n d n a v i g a t i o n wa t l o w s e r i e s f 4 s / d keys and navigation figure 2.4 — series f4 keys and navigation. Setup page main>setup choose to setup system analog input 1 f 4 1 2 i 1b 1b 2a 2a 2b 2b 1a 1a main page___________ go to profiles go to setup g...

Page 13: Guided Setup

Wa t l o w s e r i e s f 4 s / d k e y s , d i s p l a y s a n d n a v i g a t i o n ■ 2 . 5 guided setup in most f4 menus, setup and programming tasks are guided. For example, once you select analog input 1 on the setup page, all parameters neces- sary to configure that input are linked: 1. Use > t...

Page 14: Numbers

2 . 6 ■ k e y s , d i s p l a y s a n d n a v i g a t i o n wa t l o w s e r i e s f 4 s / d how to enter numbers and names figure 2.6 — how to enter numbers and names. (f4d shown) f 4 1 2 i 1b 1b 2a 2a 2b 2b 1a 1a f 4 1 2 i 1b 1b 2a 2a 2b 2b 1a 1a 1 . Navigate to the parameter you want to name. You...

Page 15

Wa t l o w s e r i e s f 4 s / d k e y s , d i s p l a y s a n d n a v i g a t i o n ■ 2 . 7 ˆ ˆ information key answers your questions figure 2.7 — the information key. (f4d shown) i f 4 1 2 i 1b 1b 2a 2a 2b 2b 1a 1a toggle the information key ˆ between the parameter you need to know about and its ...

Page 16

Main page parameter table modbus register range read/write conditions for parameter description (modbus value) default [i/o, set, ch] parameters to appear go to factory set security settings, and calibrate and re- store factory settings. Go to setup set up inputs and outputs, configure the system an...

Page 17: Chapter Three: Operations

Wa t l o w s e r i e s f 4 s / d o p e r a t i o n s ■ 3 . 1 3 chapter three: operations static set point control . . . . . . . . . . . . . . . . . . . . . .3.1 profile control . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.2 alarm set points . . . . . . . . . . . . . . . . . . . . . . ....

Page 18: Profile Control

3 . 2 ■ o p e r a t i o n s wa t l o w s e r i e s f 4 s / d ç warning check the configuration of the controller on the setup page before starting and running a profile (if the setup page is not locked). Make sure the settings are appropri- ate to the profile: input sensor ranges and limits, digital...

Page 19

Wa t l o w s e r i e s f 4 s / d o p e r a t i o n s ■ 3 . 3 π the profile key: • initiates the ramping profile mode; • initiates the hold-profile state; • initiates the resume-profile command; • initiates the terminate-profile command. The profile key functions only from the main page. It will not ...

Page 20: Alarm Set Points

3 . 4 ■ o p e r a t i o n s wa t l o w s e r i e s f 4 s / d alarm set points the series f4 includes two alarm outputs, which can be programmed as process or deviation alarms. Process alarms notify the operator when process values exceed or fall below alarm low and alarm high set points. Deviation a...

Page 21: Multiple Pid Sets

Wa t l o w s e r i e s f 4 s / d o p e r a t i o n s ■ 3 . 5 integral (reset): define the integral time in min- utes per repeat; define reset in repeats per minute. Set repeats per minute if units are u.S.; minutes per repeat if units are si. Derivative (rate): define the derivative (rate) time in m...

Page 22: Cascade

3 . 6 ■ o p e r a t i o n s wa t l o w s e r i e s f 4 s / d cascade cascade control is available on the series f4 con- trollers. For background information about cascade control, see the features chapter. Select cascade control through the analog input 3 menu (setup page) and choose process cascade...

Page 23: Sample Application:

Andy, an engineer with the ajax testing company, is running temperature and humidity tests on navigational equipment. He runs the test profile, military standard test 810d, having already set up the controller and programmed the profile. In step 4, the temperature in the chamber exceed- ed the alarm...

Page 24

3 . 8 ■ o p e r a t i o n s wa t l o w s e r i e s f 4 s / d troubleshooting alarms and errors • configure output as an alarm. • check alarm set points. • check the alarm sides setting. • check the alarm type setting. • check the alarm logic for compatibility with system peripherals and annunciators...

Page 25

Wa t l o w s e r i e s f 4 s / d o p e r a t i o n s ■ 3 . 9 • turn the controller off, then on again. • turn the controller off, then on again. • turn the controller off, then on again. • call your watlow distributor or represen- tative. • call your watlow distributor or represen- tative. • loss of...

Page 26: Operations Page Map

Operations page map ✔ note: some parameters may not appear, depending on the mod- el and configuration of the controller. 3 . 1 0 ■ o p e r a t i o n s wa t l o w s e r i e s f 4 s / d autotune pid channel 1 autotune tune off pid set 1 pid set 2 pid set 3 pid set 4 pid set 5 channel 2 autotune tune ...

Page 27

Wa t l o w s e r i e s f 4 s / d o p e r a t i o n s ■ 3 . 1 1 operations page parameter table modbus register range read/write conditions for parameter description (modbus value) default [i/o, set, ch] parameters to appear *this section is also applicable for cascade inner loop. ✔ note: for more in...

Page 28

3 . 1 2 ■ o p e r a t i o n s wa t l o w s e r i e s f 4 s / d operations page parameter table modbus register range read/write conditions for parameter description (modbus value) default [i/o, set, ch] parameters to appear ✔ note: press the information key ˆ for more task-related tips. Active if pi...

Page 29

Wa t l o w s e r i e s f 4 s / d o p e r a t i o n s ■ 3 . 1 3 operations page parameter table modbus register range read/write conditions for parameter description (modbus value) default [i/o, set, ch] parameters to appear ✔ note: for more information about how parameter settings affect the control...

Page 30

Active if alarm 2 type (setup page) is set to deviation. 322 r/w 999 (999) 0 to 30000 (0 to 30000) alarm 2 high deviation set the deviation above set point 2 that will trigger an alarm. Active if alarm 2 type (setup page) is set to deviation. Active if decimal is set to 0.0 321 r/w -999 (-999) -99.9...

Page 31

Wa t l o w s e r i e s f 4 s / d o p e r a t i o n s ■ 3 . 1 5 operations page parameter record make a photocopy of this page and enter your settings on that copy. Name _________________________________________________ date __________________________________________________ operations page pid set c...

Page 32: Notes

Notes 3 . 1 6 ■ o p e r a t i o n s wa t l o w s e r i e s f 4 s / d.

Page 33: Overview

Wa t l o w s e r i e s f 4 s / d p r o f i l e p r o g r a m m i n g ■ 4 . 1 chapter four: profile programming what is a ramping profile? . . . . . . . . . . . . . . . . . .4.2 step types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.2 profile plan checklist . . . . . . . . . . . . ...

Page 34: What Is A Ramping Profile?

Six types of steps are available in the series f4. They are the building blocks of ramping profiles. Use the six step types to create simple or complex profiles involving all inputs and outputs. The se- ries f4 prompts you to define each step’s proper- ties, listed below. • autostart • ramp time • r...

Page 35: Profile Plan Checklist

Wa t l o w s e r i e s f 4 s / d p r o f i l e p r o g r a m m i n g ■ 4 . 3 soak soak maintains the set point from the previous step for a chosen time in hours, minutes and sec- onds. Define the soak step by choosing: 1. Wait for an event or process value; (wait for events are set up in the setup p...

Page 36: How to Program A New Profile

How to program a new profile the series f4 uses a question-and-answer format to prompt you to define the steps and step types of a new profile. Here’s how: 1. Go to the profiles page. Move the cursor to go to profiles (at the bottom of the main page), then press the right key . . 2. Create a new pro...

Page 37: Get Information From The

• how much time it will take to reach set point; • what the set point is; • which pid set to activate; and • whether you want a guaranteed soak. Continue defining step types until your pro- file is complete. The last step must be an end step. 6. Choose the end-state. All profiles end with an end ste...

Page 38: How to Edit A Profile

How to edit a profile to change one or more parameters in any step of a profile, choose edit profile on the profiles page. 1. Go to the profiles page. Move the cursor to go to profile (at the bottom of the main page), then press . . 2. Choose to edit a profile. Press . . 3. Choose the profile you wa...

Page 39: User Profile Record

Wa t l o w s e r i e s f 4 s / d p r o f i l e p r o g r a m m i n g ■ 4 . 7 user profile record copy this record and use it to plan profiles. Keep it with a setup page parameter record to document the controller’s programmed settings. Profile name:__________________________________ date programmed:...

Page 40: Programming A Profile

To test its customers’ navigational equipment, ajax testing co. Selected a version of military standard test 810d, which is often used to test navigational or other military equipment under hot, humid conditions. The full test requires a two-channel controller to manipu- late both temperature and hu...

Page 41

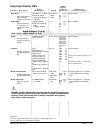

Wa t l o w s e r i e s f 4 s / d p r o f i l e p r o g r a m m i n g ■ 4 . 9 88 90 92 94 98 100 102 104 106 96 3 steps 6 7 8 9 10 11 13 12 14 15 16 17 18 19 17 18 19 20 21 22 23 6 7 8 9 10 11 12 13 14 15 0 1 2 3 4 5 16 test period in hours 58 60 62 64 68 70 74 76 78 80 82 86 66 72 84 88 1 2 % relati...

Page 42

1. Why should i check the setup page before programming a profile? Complex, sophisticated profile control is possible with the series f4’s two or three analog inputs, four digital inputs, four control outputs (two for a single-channel controller), two alarm outputs, two retransmit outputs and eight ...

Page 43: Profiles Page Map

Wa t l o w s e r i e s f 4 s / d p r o f i l e p r o g r a m m i n g ■ 4 . 1 1 profiles page map create profile name profile step x (1 to 256) type autostart date day time ramp time wait for event output (1 to 8) time ch1 sp ch2 sp ch1 pid set x (1 to 5) ch2 pid set x (6 to 10) guar. Soak1 guar. Soa...

Page 44

Profiles page parameter table modbus register range read/write conditions for parameter description (modbus value) default [i/o, set, ch] parameters to appear ✔ note: to edit profiles through serial communications, see p. 7.17, ✔ note: two sets of modbus registers contain profile information: in edi...

Page 45

Profiles page parameter table modbus register range read/write conditions for parameter description (modbus value) default [i/o, set, ch] parameters to appear ✔ note: two sets of modbus registers contain profile informa- tion: in edit mode, the number of the profile being edited is at 4000, and the ...

Page 46

4 . 1 4 ■ p r o f i l e p r o g r a m m i n g wa t l o w s e r i e s f 4 s / d profiles page parameter table modbus register range read/write conditions for parameter description (modbus value) default [i/o, set, ch] parameters to appear ✔ note: two sets of modbus registers contain profile informa- ...

Page 47

Profiles page parameter table modbus register range read/write conditions for parameter description (modbus value) default [i/o, set, ch] parameters to appear wa t l o w s e r i e s f 4 s / d p r o f i l e p r o g r a m m i n g ■ 4 . 1 5 ✔ note: for more information about how parameter settings affe...

Page 48

Active if controller is set to dual channel ramping (channel 2). 4062 r/w 75 (75) set point 2 low limit to set point 2 high limit enter channel 2 idle set point select the channel 2 set point to be main- tained after the pro- file ends. Active: always (channel 1). 4061 r/w 75 (75) set point 1 low li...

Page 49: Chapter Five: Setup

Wa t l o w s e r i e s f 4 s / d s e t u p ■ 5 . 1 chapter five: setup setup guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . .5.1 parameter setup order . . . . . . . . . . . . . . . . . . . . . .5.1 customizing the main page . . . . . . . . . . . . . . . . . .5.2 custom main page para...

Page 50: Customizing The Main Page

5 . 2 ■ s e t u p wa t l o w s e r i e s f 4 s / d • the guaranteed soak band for each channel; • open-loop detection warnings on or off; and • profile-power outage actions. 2. Go the setup page and define all inputs, out- puts and alarms: • analog input x (1 to 3); • digital input x (1 to 4); • con...

Page 51

Wa t l o w s e r i e s f 4 s / d s e t u p ■ 5 . 3 custom main page parameter record make a photocopy of this page and enter your settings on that copy. Name ___________________________________________ date ______________________________ main page will always appear if active: input 1 error input 2 ...

Page 52: Retransmit Output 1

5 . 4 ■ s e t u p wa t l o w s e r i e s f 4 s / d retransmit output 1 to track the temperature of the equipment inside the chamber, andy configured a retransmit out- put to match input 3. He scrolled down the list of inputs and outputs on the setup page and found re- transmit output. He chose 50ºf ...

Page 53: Analog Input 2

Wa t l o w s e r i e s f 4 s / d s e t u p ■ 5 . 5 andy set the compressor control parameter to have the compressor run only when cooling is needed. % on power: 0% % off power: 9% off delay: 30 seconds on delay: 60 seconds there was no computer connection, so andy skipped communications. Then he lef...

Page 54: Setup Page Map

5 . 6 ■ s e t u p wa t l o w s e r i e s f 4 s / d setup page map system guar. Soak band1 guar. Soak band2 current time current date pid units °f or °c show °f or °c ch1 autotune sp ch2 autotune sp input 1 fail input 2 fail open loop ch1 open loop ch2 power-out time power-out action analog input x (...

Page 55

Wa t l o w s e r i e s f 4 s / d s e t u p ■ 5 . 7 setup page parameter table modbus register range read/write conditions for parameter description (modbus value) default (i/o, set, ch) parameters to appear ✔ note: for more information about how parameter settings affect the con- troller’s operation...

Page 56

5 . 8 ■ s e t u p wa t l o w s e r i e s f 4 s / d setup page parameter table modbus register range read/write conditions for parameter description (modbus value) default (i/o, set, ch) parameters to appear active: always. ç caution: changes to sensor, type, units, decimals, scales and set point lim...

Page 57

Wa t l o w s e r i e s f 4 s / d s e t u p ■ 5 . 9 setup page parameter table modbus register range read/write conditions for parameter description (modbus value) default (i/o, set, ch) parameters to appear ✔ note: for more information about how parameter settings affect the con- troller’s operation...

Page 58

5 . 1 0 ■ s e t u p wa t l o w s e r i e s f 4 s / d setup page parameter table modbus register range read/write conditions for parameter description (modbus value) default (i/o, set, ch) parameters to appear ✔ note: press the information key ˆ for more task-related tips. Active: always. 3000-3009 3...

Page 59

Wa t l o w s e r i e s f 4 s / d s e t u p ■ 5 . 1 1 setup page parameter table modbus register range read/write conditions for parameter description (modbus value) default (i/o, set, ch) parameters to appear ✔ note: for more information about how parameter settings affect the con- troller’s operati...

Page 60

5 . 1 2 ■ s e t u p wa t l o w s e r i e s f 4 s / d setup page parameter table modbus register range read/write conditions for parameter description (modbus value) default (i/o, set, ch) parameters to appear ✔ note: press the information key ˆ for more task-related tips. Setup page parameter table ...

Page 61

Wa t l o w s e r i e s f 4 s / d s e t u p ■ 5 . 1 3 setup page parameter table modbus register range read/write conditions for parameter description (modbus value) default (i/o, set, ch) parameters to appear ✔ note: for more information about how parameter settings affect the con- troller’s operati...

Page 62

5 . 1 4 ■ s e t u p wa t l o w s e r i e s f 4 s / d setup page parameter table modbus register range read/write conditions for parameter description (modbus value) default (i/o, set, ch) parameters to appear setup page parameter table modbus register range read/write conditions for parameter descri...

Page 63

Wa t l o w s e r i e s f 4 s / d s e t u p ■ 5 . 1 5 setup page parameter table modbus register range read/write conditions for parameter description (modbus value) default (i/o, set, ch) parameters to appear ✔ note: for more information about how parameter settings affect the con- troller’s operati...

Page 64: Setup Page Parameter Record

5 . 1 6 ■ s e t u p wa t l o w s e r i e s f 4 s / d setup page parameter record make a photocopy of this page and enter your settings on that copy. Name ___________________________________________ date ______________________________ setup page system menu system menu setting setting guar. Soak band...

Page 65: Chapter Six: Features

Chapter six: features inputs calibration offset . . . . . . . . . . . . . . . . . . . . . . .6.2 filter time constant . . . . . . . . . . . . . . . . . . . . .6.2 set point low limit and high limit . . . . . . . . . .6.3 high scale and low scale . . . . . . . . . . . . . . . .6.3 event . . . . . . ....

Page 66: Inputs/outputs

Inputs/outputs calibration offset calibration offset allows a device to compensate for an inaccurate sensor, lead resistance or other fac- tors that affect the input value. A positive offset in- creases the input value, and a negative offset de- creases the input value. You can view or change the of...

Page 67

Wa t l o w s e r i e s f 4 s / d f e a t u r e s ■ 6 . 3 set point low limit and high limit the controller constrains the set point to a value between a low limit and a high limit. The high lim- it cannot be set higher than the sensor high limit or lower than the low limit. The low limit cannot be s...

Page 68: Control Methods

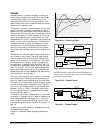

6 . 4 ■ f e a t u r e s wa t l o w s e r i e s f 4 s / d control methods on-off control on-off control switches the output either full on or full off, depending on the input, set point and hys- teresis values. The hysteresis value indicates the amount the process value must deviate from the set poin...

Page 69

Wa t l o w s e r i e s f 4 s / d f e a t u r e s ■ 6 . 5 proportional plus integral (pi) control the droop caused by proportional control (reset) can be corrected by adding integral control. When the system settles down the integral value is tuned to bring the temperature or process value closer to ...

Page 70

6 . 6 ■ f e a t u r e s wa t l o w s e r i e s f 4 s / d multiple pid sets the series f4 has five pid sets available for each channel, sets 1 to 5 for channel 1 and sets 6 to 10 for channel 2, allowing optimal performance under different conditions, loads and temperatures. In the static set point mo...

Page 71: Other Features

Wa t l o w s e r i e s f 4 s / d f e a t u r e s ■ 6 . 7 other features autotuning the autotuning feature allows the controller to measure the system response to determine effective settings for pid control. When autotuning is initi- ated the controller reverts to on-off control. The temperature mus...

Page 72: Alarms

6 . 8 ■ f e a t u r e s wa t l o w s e r i e s f 4 s / d alarms alarms are activated when the process value or temperature leaves a defined range. A user can configure how and when an alarm is triggered, what action it takes and whether it turns off auto- matically when the alarm condition is over. ...

Page 73

Wa t l o w s e r i e s f 4 s / d f e a t u r e s ■ 6 . 9 alarm latching a latched alarm will remain active after the alarm condition has passed. It can only be deactivated by the user. An alarm that is not latched (self-clear- ing) will deactivate automatically when the alarm condition has passed. L...

Page 74: Advanced Features

6 . 1 0 ■ f e a t u r e s wa t l o w s e r i e s f 4 s / d advanced features boost heat and boost cool the boost heat feature uses a digital output to turn on an additional heater to speed up the heating. As the process temperature approaches the set point, the boost heat output switches off so that...

Page 75

Wa t l o w s e r i e s f 4 s / d f e a t u r e s ■ 6 . 1 1 cascade cascade control is a control strategy in which one control loop provides the set point for another loop. It allows the process or part temperature to be reached quickly while minimizing overshoot. Cas- cade is used to optimize the pe...

Page 76: Notes

Notes 6 . 1 2 ■ f e a t u r e s wa t l o w s e r i e s f 4 s / d.

Page 77: Overview

Chapter seven: communications exception responses . . . . . . . . . . . . . . . . . . . . . . .7.2 modbus registers (alphabetical order) . . . . . . . . .7.2 profiling registers . . . . . . . . . . . . . . . . . . . . . . . . . .7.10 modbus registers (numerical order) . . . . . . . . . . .7.13 commu...

Page 78: Series F4 Modbus Registers

103 % power output 1a, status r 0 to 100 (expressed in %) 107 % power output 1b, status r 0 to 100 (expressed in %) 111 % power output 2a, status r 0 to 100 (expressed in %) 115 % power output 2b, status r 0 to 100 (expressed in %) 102 alarm 1, status r 106 alarm 2, status r 303 alarm high deviation...

Page 79

1306 autotune pid, lockout r/w 0 full access 1 read only 2 password 3 hidden 304 autotune set point, channel 1, value r/w 50 to 150 (expressed in %) 323 autotune set point, channel 2, value r/w 50 to 150 (expressed in %) 2062 boost cool % power, digital output 7 r/w -100 to 0 for cool (expressed in ...

Page 80

2556 cycle time value, control output 2b r/w number 2605 dead band 1a, cascade pid set 1, channel 1 r/w 0 to 30000 2615 dead band 1a, cascade pid set 2, channel 1 r/w 0 to 30000 2625 dead band 1a, cascade pid set 3, channel 1 r/w 0 to 30000 2635 dead band 1a, cascade pid set 4, channel 1 r/w 0 to 30...

Page 81

Wa t l o w s e r i e s f 4 s / d c o m m u n i c a t i o n s ■ 7 . 5 1077 digital input 2, start profile r/w 1 to 40 1078 digital input 2, start step r/w 1 to 256 225 digital input 3, status 0 low 1 high 1065 digital input 3 condition r/w 0 low 1 high 1064 digital input 3 function r/w 0 off 1 panel ...

Page 82

748 high power limit, control output 2a r/w low limit+1 to 100 (expressed in %) 765 high power limit, control output 2b r/w low limit+1 to 100 (expressed in %) 711 high scale, retransmit output 1 r/w low scale +1 to 30000 (maximum sensor range) 728 high scale, retransmit output 2 r/w low scale +1 to...

Page 83

Wa t l o w s e r i e s f 4 s / d c o m m u n i c a t i o n s ■ 7 . 7 2651 integral 1b , cascade pid set 1, channel 1 r/w 000 to 9999 (expressed in hundredths of minutes) 2661 integral 1b , cascade pid set 2, channel 1 r/w 000 to 9999 (expressed in hundredths of minutes) 2671 integral 1b , cascade pi...

Page 84

1609 process output 1b, 4.000ma, calibrate w 0000 to 6000 (expressed in microamps) 1616 process output 2a, 1.000v, calibrate w 0000 to 3000 (expressed in thousandths volts) 1617 process output 2a, 10.000v, calibrate w 0000 to 12000 (expressed in thousandths volts) 1615 process output 2a, 20.000ma, c...

Page 85

Wa t l o w s e r i e s f 4 s / d c o m m u n i c a t i o n s ■ 7 . 9 574 rate 1b, pid set 3, channel 1 r/w 000 to 999 (expressed in hundredths of minutes) 584 rate 1b, pid set 4, channel 1 r/w 000 to 999 (expressed in hundredths of minutes) s 594 rate 1b, pid set 5, channel 1 r/w 000 to 999 (express...

Page 86

11 100 Ω din rtd 12 100 Ω jis rtd 13 4 to 20 ma 14 0 to 20 ma 15 0 to 5v 16 1 to 5v 17 0 to 10v 18 0 to 50mv 23 500 Ω din rtd 24 500 Ω jis rtd 25 1k Ω din rtd 26 1k Ω jis rtd 611 sensor type, analog input 2 r/w 0 j 1 k 2 t 3 e 4 n 5 c 6 d 7 pt2 8 r 9 s 10 b 11 100 Ω din rtd 12 100 Ω jis rtd 13 4 to ...

Page 87

Wa t l o w s e r i e s f 4 s / d c o m m u n i c a t i o n s ■ 7 . 1 1 4006 autostart, date (day) r/w 1 to 31 4005 autostart, date (month) r/w 0 to 12 4007 autostart, date (year) r/w 1998 to 2035 4008 autostart, day (of week) r/w 0 every day 1 sunday 2 monday 3 tuesday 4 wednesday 5 thursday 6 frida...

Page 88

3700-09 name, profile 21 (10 characters) 3710-19 name, profile 22 (10 characters) 3720-29 name, profile 23 (10 characters) 3730-39 name, profile 24 (10 characters) 3740-49 name, profile 25 (10 characters) 3750-59 name, profile 26 (10 characters) 3760-69 name, profile 27 (10 characters) 3770-79 name,...

Page 89

Wa t l o w s e r i e s f 4 s / d c o m m u n i c a t i o n s ■ 7 . 1 3 0 model, diagnostics 1 serial number, first part, diagnostics 2 serial number, second part, diagnostics 3 software number, diagnostics 4 software revision, diagnostics 5 mfg. Date, diagnostics 8 input 1 type, diagnostics 9 input ...

Page 90

7 . 1 4 ■ c o m m u n i c a t i o n s wa t l o w s e r i e s f 4 s / d 1075 digital input 1, start profile 1076 digital input 1, start step 1077 digital input 2, start profile 1078 digital input 2, start step 1079 digital input 3, start profile 1080 digital input 3, start step 1081 digital input 4, ...

Page 91

Wa t l o w s e r i e s f 4 s / d c o m m u n i c a t i o n s ■ 7 . 1 5 2665 dead band 1b, cascade pid set 2, channel 1 2667 hysteresis 1b, cascade pid set 2, channel 1 2670 proportional band 1b, cascade pid set 3, channel 1 2671 integral 1b , cascade pid set 3, channel 1 2672 reset 1b, cascade pid s...

Page 92

Active: always. No modbus address. 1 1 to 247 address set the controller’s ad- dress between 1 and 247. Active: always. No modbus address. 19200 19200 9600 baud rate set the transmission speed in bits/seconds. Main > setup > communications communications 7 . 1 6 ■ c o m m u n i c a t i o n s wa t l ...

Page 93: F4 Modbus Applications:

Wa t l o w s e r i e s f 4 s / d c o m m u n i c a t i o n s ■ 7 . 1 7 f4 modbus applications: profile overview a maximum of 40 files may be created, with a total of 256 steps. Each time a new file is creat- ed, the file is placed after the previously created file. As files are deleted, newly create...

Page 94

7 . 1 8 ■ c o m m u n i c a t i o n s wa t l o w s e r i e s f 4 s / d *profiles without custom-written names are referred to by their numbers (profile 1, profile 2, etc.), create profile write modbus register 4002=1 set file number write modbus register 4000=1 to 40 -optional- rename profile* regis...

Page 95

Wa t l o w s e r i e s f 4 s / d c o m m u n i c a t i o n s ■ 7 . 1 9 f4 modbus applications: autostart step set step type to "autostart" write modbus register 4003=0 enter month to start profile write modbus register 4005=1 to 12 enter day to start profile write modbus register 4006=1 to 31 start ...

Page 96

7 . 2 0 ■ c o m m u n i c a t i o n s wa t l o w s e r i e s f 4 s / d f4 modbus applications: ramp time, ramp rate, soak steps (page 1 of 3) digital inputs must be configured as events before profiling: “digital input 1 to 4 function = wait for event” and “digital input 1 to 4 condition = low or hi...

Page 97

Wa t l o w s e r i e s f 4 s / d c o m m u n i c a t i o n s ■ 7 . 2 1 f4 modbus applications: ramp time, ramp rate, soak steps (page 2 of 3) analog inputs and digital outputs must be configured before programming a profile. See setup page map..

Page 98

7 . 2 2 ■ c o m m u n i c a t i o n s wa t l o w s e r i e s f 4 s / d f4 modbus applications: ramp time, ramp rate, soak steps (page 3 of 3).

Page 99

Wa t l o w s e r i e s f 4 s / d c o m m u n i c a t i o n s ■ 7 . 2 3 f4 modbus applications: f4 modbus applications: jump step end step jump initiates another step or profile. File must exist at location specified..

Page 100

7 . 2 4 ■ c o m m u n i c a t i o n s wa t l o w s e r i e s f 4 s / d f4 modbus applications: editing, deleting, starting a profile.

Page 101

Wa t l o w s e r i e s f 4 s / d c o m m u n i c a t i o n s ■ 7 . 2 5 f4 modbus applications: naming a profile profiles without custom-written names are referred to by their numbers (profile 1, profile 2, etc.). Follow this procedure to customize the profile name, using ascii-equivalent decimal cod...

Page 102

F4 modbus applications: monitor current step assumes controller is configured for functions read - you can’t read a digital output if it doesn’t exist. 7 . 2 6 ■ c o m m u n i c a t i o n s wa t l o w s e r i e s f 4 s / d.

Page 103: Overview

✔ note: for more information about how parameter settings affect the controller’s operation, see the features chapter. Wa t l o w s e r i e s f 4 s / d s e c u r i t y a n d l o c k s ■ 8 . 1 chapter eight: security and locks 8 overview the series f4 allows users to set separate security levels for ...

Page 104: Enter A Password

Enter a password if you try to set password security before any password has been established, a pop-up message will give you the opportunity to enter one. Use the . , > password, which can consist of letters, numbers or both. After entering and confirming the password, re-enter the chosen menu or p...

Page 105

Wa t l o w s e r i e s f 4 s / d s e c u r i t y a n d l o c k s ■ 8 . 3 note: for more information about how parameter settings affect the controller’s operation, see the features chapter. Set lockout menu parameter table modbus register range read/write conditions for parameter description (modbus...

Page 106: Notes

8 . 4 ■ s e c u r i t y a n d l o c k s wa t l o w s e r i e s f 4 s / d notes.

Page 107: Chapter Nine: Calibration

✔ note: for more information about how parameter settings affect the controller’s operation, see the features chapter. Wa t l o w s e r i e s f 4 c a l i b r a t i o n ■ 9 . 1 chapter nine: calibration thermocouple input procedure . . . . . . . . . . . . . . . .9.2 rtd input procedure . . . . . . . ...

Page 108: Thermocouple Input Procedure

9 . 2 ■ c a l i b r a t i o n wa t l o w s e r i e s f 4 s / d thermocouple input procedure equipment • type j reference compensator with reference junction at 32°f (0°c), or type j thermocouple calibrator to 32°f (0°c). • precision millivolt source, 0 to 50mv minimum range, 0.002mv resolution. Inpu...

Page 109

Wa t l o w s e r i e s f 4 s / d c a l i b r a t i o n ■ 9 . 3 voltage process input procedure equipment • precision voltage source, 0 to 10v minimum range, with 0.001v resolution. Input x (1 to 3) setup and calibration 1. Connect the correct power supply to terminals 1, 2 and 3 (see the wiring chap...

Page 110: Process Output Procedure

9 . 4 ■ c a l i b r a t i o n wa t l o w s e r i e s f 4 s / d press . Once at the calibrate input 3 prompt. At the 4.000ma prompt press . Once and to store the 4.000ma input press > once. 10. Enter 20.000ma from the current source to the controller. Allow at least 10 seconds to stabilize. Press . O...

Page 111: Retransmit Output Procedure

Wa t l o w s e r i e s f 4 s / d c a l i b r a t i o n ■ 9 . 5 output 2a setup and calibration 1. Connect the correct power supply to terminals 1, 2 and 3 (see the wiring chapter and the appendix). Milliamperes 2. Connect the volt/ammeter to terminals 36 (+) and 37 (-). 3. Press the right key . At t...

Page 112: Calibration Menu Map

9 . 6 ■ c a l i b r a t i o n wa t l o w s e r i e s f 4 s / d volt/ammeter. The controller should stabilize within one second. Repeat until the volt/amme- ter reads 4.000ma. Press . To store the value. 4. Press the right key . At the calibrate rexmit 1 prompt. At the 20.000ma prompt press . Once. U...

Page 113

Wa t l o w s e r i e s f 4 s / d c a l i b r a t i o n ■ 9 . 7 factory page parameter table modbus register range read/write conditions for parameter description (modbus value) default [i/o, set, ch] parameters to appear *the tenth character of your model number determines what prompts appear and wh...

Page 114

Factory page parameter table modbus register range read/write conditions for parameter description (modbus value) default [i/o, set, ch] parameters to appear ✔ note: press the information key ˆ for more task-related tips. 9 . 8 ■ c a l i b r a t i o n wa t l o w s e r i e s f 4 s / d 1601 w modbus: ...

Page 115: Chapter Ten: Diagnostics

Wa t l o w s e r i e s f 4 s / d d i a g n o s t i c s ■ 1 0 . 1 chapter ten: diagnostics overview ✔ note: to see how all the pages, menus and parameters are grouped, refer to the inside back cover of this manual. ✔ note: for more information about how parameter settings affect the controller’s oper...

Page 116

1 0 . 2 ■ d i a g n o s t i c s wa t l o w s e r i e s f 4 s / d ✔ note: press the information key ˆ for more task-related tips. Active: always. 19 r dc (3) ssr (2) process (4) none (0) out2b displays the output 2b type. Active: always. 18 r dc (3) ssr (2) process (4) none (0) out2a displays the out...

Page 117

Wa t l o w s e r i e s f 4 s / d d i a g n o s t i c s ■ 1 0 . 3 ✔ note: for more information about how parameter settings affect the controller’s operation, see the features chapter. Diagnostic menu parameter table (factory page) modbus register range read/write conditions for parameter description...

Page 118

1 0 . 4 ■ d i a g n o s t i c s wa t l o w s e r i e s f 4 s / d ✔ note: for more information about how parameter settings affect the controller’s operation, see the features chapter. Diagnostic menu parameter table (factory page) modbus register range read/write conditions for parameter description...

Page 119: Dimensions

Wa t l o w s e r i e s f 4 s / d i n s t a l l a t i o n ■ 1 1 . 1 chapter eleven: installation dimensions figure 11.1a — front view dimensions and gasket gap dimension. Figure 11.1b — side and top view and dimensions. 4.264 in. (108.3 mm) 4.189 in. (106.4 mm) 3.850 in. (97.8 mm) 0.339 in. (8.6 mm) ...

Page 120

Panel dimensions figure 11.2a — multiple panel cutout dimensions. Installing the series f4 controller installing and mounting requires access to the back of the panel. Tools required: one #2 phillips screwdriver. 1. Make the panel cutout using the mounting template dimensions in this chapter. 2. Ins...

Page 121

4. If the installation does not require a nema 4x seal, tighten the four screws with the phillips screwdriver just enough to eliminate the spacing between the rubber gasket and the mounting panel. For a nema 4x seal, tighten the four screws until the gap between the bezel and panel surface is .020 i...

Page 122: Notes

Notes 1 1 . 4 ■ i n s t a l l a t i o n wa t l o w s e r i e s f 4 s / d.

Page 123: Chapter Twelve: Wiring

Wa t l o w s e r i e s f 4 s / d w i r i n g ■ 1 2 . 1 chapter twelve: wiring input-to-output isolation . . . . . . . . . . . . . . . . . . . .12.1 power wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12.2 sensor installation guidelines . . . . . . . . . . . . . . . .12.2 input 1 . ...

Page 124: Power Wiring

1 2 . 2 ■ w i r i n g wa t l o w s e r i e s f 4 s / d ç caution: if high voltage is applied to a low-voltage unit, irreversible damage will occur. ç warning: provide a labeled switch or circuit breaker connected to the series f4 power wiring as the means of disconnection for servicing. Failure to d...

Page 125: Input 1

Input 1 figure 12.3a — thermocouple available on all units impedance: 20m Ω figure 12.3b — rtd (2- or 3-wire) 100 Ω platinum available on all units figure 12.3c — 0-5vÎ, 1-5vÎ or 0-10vÎ (dc) process available on all units. Input impedance: 20k Ω figure 12.3d — 0-20ma or 4-20ma process available on a...

Page 126: Inputs X (2 and 3)

1 2 . 4 ■ w i r i n g wa t l o w s e r i e s f 4 s / d inputs x (2 and 3) figure 12.4a — thermocouple f4s _ - _ _ _ 6 - _ _ _ _ or f4d _ - _ _ _ _ - _ _ _ _ impedance: 20m Ω figure 12.4b — rtd (2-wire) 100 Ω platinum f4s _ - _ _ _ 6 - _ _ _ _ or f4d _ - _ _ _ _ - _ _ _ _ figure 12.4c — rtd (3-wire) ...

Page 127

Wa t l o w s e r i e s f 4 s / d w i r i n g ■ 1 2 . 5 inputs x (2 and 3) (continued) figure 12.5a — 0 to 5vÎ, 1 to 5vÎ or 0 to 10vÎ (dc) process f4s _ - _ _ _ 6 - _ _ _ _ or f4d _ - _ _ _ _ - _ _ _ _ input impedance: 20k Ω figure 12.5b — 0 to 20ma or 4 to 20ma process f4s _ - _ _ _ 6 - _ _ _ _ or f...

Page 128: Digital Inputs X (1 to 4)

1 2 . 6 ■ w i r i n g wa t l o w s e r i e s f 4 s / d digital inputs x (1 to 4) figure 12.6 — digital inputs x (1 to 4) voltage input 0 to 2vÎ (dc) event input low state 3 to 36vÎ (dc) event input high state contact closure 0 to 2k Ω event input low state > 23k Ω event input high state digital inpu...

Page 129

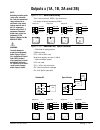

Wa t l o w s e r i e s f 4 s / d w i r i n g ■ 1 2 . 7 outputs x (1a, 1b, 2a and 2b) figure 12.7a — solid-state relay 24vÅ (ac) minimum, 253vÅ (ac) maximum 0.5 amps, off-state impedance 31m Ω figure 12.7b — switched dc, open collector • switched dc configuration com not used dc+ = 22 to 28vÎ (dc) ma...

Page 130: Retransmit and Alarm Output

1 2 . 8 ■ w i r i n g wa t l o w s e r i e s f 4 s / d figure 12.8a — 0 to 20ma, 4 to 20ma, 0 to 5vÎ, 1 to 5vÎ and 0 to 10vÎ (dc) process retransmit and alarm output figure 12.8b — retransmit outputs x (1 and 2) ma maximum load impedance: 800 Ω volts (dc) minimum load impedance: 1k Ω figure 12.8c — ...

Page 131: Digital Outputs X (1 to 8)

Wa t l o w s e r i e s f 4 s / d w i r i n g ■ 1 2 . 9 digital outputs x (1 to 8) figure 12.9a — digital outputs x (1 to 8) digital output supply: +5vÎ (dc) ±5% maximum source current: 80ma (total for all 8 switch dc) open collector: off (open): 42vÎ (dc) maximum @ 10µa on (closed): 0.2vÎ (dc) maxim...

Page 132: Communications Wiring

1 2 . 1 0 ■ w i r i n g wa t l o w s e r i e s f 4 s / d communications wiring figure 12.10a — eia/tia 485 and eia/tia 232 communications figure 12.10b — termination for eia-232 to eia-485 converter if the system does not work properly, it may need termination resistors at each end of the network. A...

Page 133

Communications wiring (continued) figure 12.11a — eia/tia 232 to eia/tia 485 conversion b&b converter (b&b electronics manufacturing company, (815) 433-5100, www.Bb-elec.Com) cmc converter (cmc connecticut micro-computer, inc., 800-426-2872, www.2cmc.Com) figure 12.11b — gpib conversion to eia/tia 2...

Page 134: Wiring Example

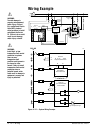

1 2 . 1 2 ■ w i r i n g wa t l o w s e r i e s f 4 s / d wiring example figure 12.12 — system wiring example. 1 l2 2 61 62 4 5 1 2 1 2 (+) (-) 3 12 20 13 14 15 16 2 1cr 17 high-temperature light 1 2 3 4 8 9 10 11 12 r 18 1 8 (+) (-) 1 cr-1 9 2 44 42 6 7 1 2 5 6 7 series f4 f4_h - ca_ _ - 01rg temper...

Page 135: Appendix

Wa t l o w s e r i e s f 4 s / d a p p e n d i x ■ a . 1 appendix glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A.2 declaration of conformity . . . . . . . . . . . . . . . . . . .A.5 specifications (single and dual channel) . . . . . . . A.6 ordering information (single a...

Page 136: Glossary

Glossary ac (Å Å) — see alternating current. Ac/dc (ı ı) — both direct and alternating current. Alternating current — an electric current that reverses at regular intervals, and alternates posi- tive and negative values. American wire gauge (awg) — a standard of the dimensional characteristics of wi...

Page 137

Form a — a single-pole, single-throw relay that us- es only the normally open (no) and common con- tacts. These contacts close when the relay coil is en- ergized. They open when power is removed from the coil. Form b — a single-pole, single-throw relay that us- es only the normally closed (nc) and c...

Page 138

Events, etc. The high process variable is the highest value of the process range, expressed in engineer- ing units. The low process variable is the lowest value of the process range. Proportional — output effort proportional to the error from set point. For example, if the proportion- al band is 20°...

Page 139: Declaration of Conformity

Wa t l o w s e r i e s f 4 s / d a p p e n d i x ■ a . 5 jim boigenzahn winona, minnesota, usa name of authorized representative place of issue general manager september 2001 title of authorized representative date of issue signature of authorized representative declares that the following product: ...

Page 140: Specifications

A . 6 ■ a p p e n d i x wa t l o w s e r i e s f 4 s / d universal analog inputs 1 (2 and 3 optional) • update rates, in1: 20hz; in2 and in3: 10hz thermocouple • type j, k, t, n, c (w5), e, ptii, d (w3), b, r, s rtd • 2- or 3-wire platinum, 100 Ω • jis or din curves, 1.0 or 0.1 indication process • ...

Page 141

Wa t l o w s e r i e s f 4 s / d a p p e n d i x ■ a . 7 ordering information 1/4 din single-channel ramping controller series f4 f4 s - a - 1 ⁄ 4 din, single-channel ramping controller single-channel ramping controller 1 universal analog input, 4 digital inputs, 8 digital outputs, 2 alarms, eia-232...

Page 142

A . 8 ■ a p p e n d i x wa t l o w s e r i e s f 4 s / d index °f or °c 5.7 a a to d 10.3 accuracy a.6 action, end 4.15 active output indicator lights 2.2 add step 4.6 address 5.14, 7.16 agency approvals a.6 alarm 1 high deviation 3.14 alarm 1 high sp 3.14 alarm 1 low deviation 3.14 alarm 1 low sp 3...

Page 143

Wa t l o w s e r i e s f 4 s / d a p p e n d i x ■ a . 9 b&b converter 12.11 cmc converter 12.11 eia-232 to eia-485 conversion 12.11 eia/tia 485 12.10 eia/tia 232 12.10 termination for eia-232 to eia-485 converter 12.10 complementary output, digital out- put 5, function 5.13 compressor control 6.10 ...

Page 144

A . 1 0 ■ a p p e n d i x wa t l o w s e r i e s f 4 s / d action 5.7 indicator lights 2.2 information key 1.4, 2.4, 2.7 input 1 only, process display 5.15 input 1 wiring 12.3 input 2 wiring 12.4–12.5 input 3 wiring 12.4–12.5 input calibration 9.2–9.4 input errors 3.9 input status 2.8 input wiring 1...

Page 145

Wa t l o w s e r i e s f 4 s / d a p p e n d i x ■ a . 1 1 operations page 3.15 profile 4.7 setup page 5.16 parameter setup order 5.1–5.2 parameter tables calibration menu 9.7–9.8 communications menu 5.14, 7.16 diagnostic menu 10.2–10.3 main page 2.8 operations page 3.11–3.14 profiles page 4.12–4.16...

Page 146

A . 1 2 ■ a p p e n d i x wa t l o w s e r i e s f 4 s / d testing 1.2–1.3, 3.7, 4.8–4.9, 5.4–5.5 scale high 5.9, 6.3 scale low 5.9, 6.3 scale offset 5.13 scroll bar 2.2 security and locks, overview 8.1 full access 8.1 hidden 8.1 password 8.1 read-only 8.1 security levels 8.1 segment —see step self-...

Page 147: List of Figures

Wa t l o w s e r i e s f 4 s / f a p p e n d i x ■ a . 1 3 chapter 1 single-channel series f4 inputs/outputs . . . . . . .1.1a dual-channel series f4 inputs/outputs . . . . . . . . .1.1b sample application: environmental testing . . . . . .1.2–1.3 chapter 2 series f4 displays and indicator lights . ...

Page 148

A . 1 4 ■ a p p e n d i x wa t l o w s e r i e s f 4 s / d.

Page 149

Wa t l o w s e r i e s f 4 s / d a p p e n d i x ■ a . 1 5.

Page 150: Series F4 Software Map

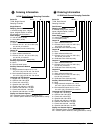

A . 1 6 ■ a p p e n d i x wa t l o w s e r i e s f 4 series f4 software map for ranges, defaults, modbus numbers and other in- formation about the parameters, refer to the parameter tables in the chapters noted below. Main page see chapter 2 input x (1 to 3) error alarm x (1 to 2) condition autotuni...

Page 151: Setup Page

Setup page see chapter 5 system guar. Soak band1 guar. Soak band2 current time current date pid units °f or °c show °f or °c ch1 autotune sp ch2 autotune sp input 1 fail input 2 fail open loop ch1 open loop ch2 power-out time power-out action analog input x (1 to 3) sensor type decimal altitude unit...

Page 152: How to Reach Us

How to reach us your authorized watlow distributor: united states (headquarters): watlow electric manufacturing company 12001 lackland road st. Louis, missouri usa 63146 telephone: +1 (314) 878-4600 fax: +1 (314) 878-6814 europe: watlow gmbh industriegebiet heidig lauchwasenstr. 1, postfach 1165, kr...