- DL manuals

- Watlow Electric

- Microwave Oven

- MINICHEF 2000

- Fast Start Manual

Watlow Electric MINICHEF 2000 Fast Start Manual

M

INI

C

HEF

TM

2000

Fast Start Guide

Watlow Controls

1241 Bundy Blvd.

P.O. Box 5580

Winona, Minnesota U.S.A. 55987-5580

(507) 454-5300, Fax (507) 452-4507

WMC2-XFSN-0008

June 1997

(1116)

Made in the U.S.A.

TOTAL

CUSTOMER

SATISFACTION

Registered Company

Winona, Minnesota USA

ISO 9001

97

For All Applications

Summary of MINICHEF 2000

Page 1

M ini c hef tm 2000 fast start guide watlow controls 1241 bundy blvd. P.O. Box 5580 winona, minnesota u.S.A. 55987-5580 (507) 454-5300, fax (507) 452-4507 wmc2-xfsn-0008 june 1997 (1116) made in the u.S.A. Total customer satisfaction registered company winona, minnesota usa iso 9001 97 for all appli...

Page 2: Introduction

Introduction welcome to the m ini c hef 2000™ the m ini c hef 2000 is a configurable, time/temperature and machine function controller that is preprogrammed for dozens of cooking applications. Its compact size and optional horizontal/vertical orientation facilitates streamlined equipment design. It ...

Page 3

M ini c hef ™ 2000 application software selection table to select the application software that best suits your equipment and purpose, first locate the type of equipment in the left column, then check the other columns for fea- tures and options you need. The application number is on the right (appl...

Page 4

Overview of key steps, from installation through operation: 1 install the controller • use the panel knock-out pattern guidelines in this guide. 2 wire the controller • use the connector/wiring information in this guide. 3 configure the controller • after applying power, use the configuration mode t...

Page 5: General Description

General description getting to know your m ini c hef™ 2000 front view back view shown with mating connector terminals installed. Mating connectors and terminals are purchased separately. Figure 5a — front and back view. Figure 5b — mounting collar. Dimensions: overall width x height x depth (include...

Page 6

Step 1 install the controller • select sheet metal (16-, 18-, 20- or 22- gauge panel). • for panel knock-out patterns, see subsequent pages of this guide. • use #6-32 mounting studs x 0.50” length minimum, either pressed or welded. • install the unit with either a horizontal or vertical mounting col...

Page 7

Panel knock-out pattern for a mounting collar in a horizontal position figure 7a — pattern for horizontal panel 16- or 18-gauge thick. Figure 7b — pattern for horizontal panel 20- or 22-gauge thick. .800 in. Ref #6-32 stud (4) minimum recommended length 0.50 in. 2.462 in. 2.125 in. 1.662 in. 1.530 i...

Page 8

Panel knock-out pattern for a mounting collar in a vertical position figure 8 — pattern for vertical panel 16- or 18-gauge thick. Figure 8 — pattern for vertical panel 20- or 22-gauge thick. .800 in. Ref #6-32 stud (4) minimum recommended length 0.50 in. 2.462 in. 3.000 in. 1.662 in. 1.530 in. 1.250...

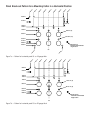

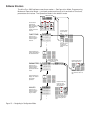

Page 9: Step 2 Wire The Controller

Step 2 wire the controller position the connector with the beveled edges at the top. Not all software applications use or require wiring to all inputs and outputs. For specific information consult the guide for the application you are using. Note: the following illustration is a view of the back of ...

Page 10

Dual rtd option (platinum) f 2 _ _ – 2 _ _ _ – _ _ _ _ (100 Ω rtd, curve selectable) f 2 _ _ – 3 _ _ _ - _ _ _ _ (500 Ω rtd, curve selectable) f 2 _ _ – 4 _ _ _ - _ _ _ _ (1000 Ω rtd, curve selectable) figure 10a — 2-wire rtd. Figure 10b — 3-wire rtd: (will function as a 2-wire rtd). Note: if your c...

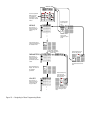

Page 11

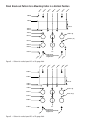

Output 1 note: the following illustrations are views of the back of the controller, not of the mating connector. F 2 _ _ – _ 1 _ _ – _ _ _ _ figure 11a — switched dc option (5v nominal, 30ma, non-isolated). Form a, 0.4a, with or without rc suppression f 2 _ _ – _ 2 _ _ – _ _ _ _ (without rc suppress...

Page 12

Output 2 note: the following illustrations are views of the back of the controller, not of the mating connector. F 2 _ _ - _ _ 1 _ – _ _ _ _ figure 12a — switched dc option (5v nominal, 30ma, non-isolated). Form a, 0.4a, with or without rc suppression f 2 _ _ - _ _ 2 _ - _ _ _ _ (without rc suppress...

Page 13

Event output 1 and event output 2 note: the following illustrations are views of the back of the controller, not of the mating connector. F 2 _ _ - _ _ _ 1 - _ _ _ _ (switched dc, 5v nominal, 30ma, non-isolated outputs) figure 13a — event outputs. ç warning: if event outputs 1 & 2 are used to cause ...

Page 14

Step 3 configure the controller overview of configuration • get to know the keys and how they function in different modes. • review configuration and programming procedures in this guide. • choose applications, functions, parameters and values (see application software selection table in this guide)...

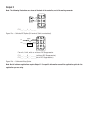

Page 15

Software structure the m ini c hef 2000 software uses three modes — configuration mode, programming mode and operation mode — and each mode contains up to three levels of functions, parameters and values. The operation mode is the default mode. Figure 15 — navigating in configuraton mode. [appl~] [a...

Page 16

Figure 16 — navigating in menu programming mode. [stpt2] [tine2] [fan`2] [``32Ï] [m``1] [m``2] [m``3] • • • • • • b d enter home b e enter escape [``32Ï] [``33Ï] [``34Ï] a b d e g h enter escape home edit d home a edit c f m ini c hef 2000 [`idle] from the operation mode, press the up- and down- arr...

Page 17: Notes

■ 17 notes.

Page 18

Watlow controls watlow controls is a division of watlow electric mfg. Co., st. Louis, missouri, a manu- facturer of industrial electric heating products since 1922. Watlow begins with a full set of specifications and completes an industrial product that is manufactured totally in- house, in the u.S....

Page 19

Specifications (1032) control mode • single and dual heat channels, pid or on/off. 1 • microprocessor-based, programmable, reverse-acting control outputs. • user-selectable embedded application software defines operation of display, keys, inputs, outputs, timing action. • one-step auto-tuning, wathe...

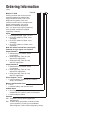

Page 20: Ordering Information

Ordering information (1033) f 2 h a - _ _ _ 1 - _ _ a a m ini c hef ™ 2000 cooking controller with numerous food equipment application software sets, single and dual channel on/off or pid temperature regulation, timer and machine-function control, microprocessor- based, programmable, auto-tuning, wa...

Page 21: Notes

■ 21 notes.

Page 22: Declaration of Conformity

Declaration of conformity watlow controls 1241 bundy boulevard winona, minnesota 55987 usa declares that the following product: english designation: minichef 2000 model number(s): f2(h or u)(a or c)-(1, 2, 3 or 4)(1, 2 or 3)(1, 2 or 3) 1-(0 or 1)(0 or 1)(any two letters or numbers) classification: e...

Page 23: Part Numbers & Accessories

M ini c hef 2000 accessories 0836-0442-0000 sensor input mating connector, (riacon #31007106), 6-position, quick-connect terminal, screw connection for 28-14 awg wires, tighten to 7 in/lb a001-0298-0000 power supply and i / o mating connector kit. Includes: – 1 amp #1-640523-0, 15-position, quick-co...