- DL manuals

- Watlow

- Control Unit

- F4T

- User Manual

Watlow F4T User Manual

0600-0092-0000 Rev. B

Made in the U.S.A.

March 2015

User’s Guide

Registered Company

Winona, Minnesota USA

ISO 9001

TOTAL

3 Year Warranty

CUSTOMER

SATISFACTION

F4T Controller

Installation and Troubleshooting

1241 Bundy Boulevard., Winona, Minnesota USA 55987

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507

http://www.watlow.com/F4T.cfm

Summary of F4T

Page 1

0600-0092-0000 rev. B made in the u.S.A. March 2015 user’s guide registered company winona, minnesota usa iso 9001 total 3 year warranty customer satisfaction f4t controller installation and troubleshooting 1241 bundy boulevard., winona, minnesota usa 55987 phone: +1 (507) 454-5300, fax: +1 (507) 45...

Page 2

Safety information we use note, caution and warning symbols throughout this document to draw your attention to important operational and safety information. A “note” marks a short message to alert you to an important detail. A “caution” safety alert appears with information that is important for pro...

Page 3

Symbol explanation unit has been reviewed and approved by csa international for use as temperature indicating-regulating equipment per csa c22.2 no. 24. See: www.Csa-international.Org this f4t user’s guide is copyrighted by watlow electric manufacturing company, © march 2015 with all rights reserved...

Page 4: Table of Contents

Watlow f4t install & troubleshooting • 1 • table of contents tc table of contents chapter 1: overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 available f4t literature and resources . . . . . . . . . . . . . . . . . . . . . . . . . 2 chapter 2: install and wire . . ...

Page 5: Chapter 1: Overview

Watlow f4t install & troubleshooting • 2 • chapter 1 overview chapter 1: overview 1 available f4t literature and resources document title and part number description f4t setup and operation user guide, part number: 0600-0093-0000 this document looks deeper at the system con- figuration using compose...

Page 6: Warranty

Watlow f4t install & troubleshooting • 3 • chapter 1 overview warranty the f4t controller is manufactured by iso 9001-registered processes and is backed by a three-year warranty to the first purchaser for use, providing that the units have not been misapplied. Since watlow has no control over their ...

Page 7

Watlow f4t install & troubleshooting • 4 • chapter 1 overview document overview and purpose the purpose of this document is to assist the installer in providing necessary information to mount, wire and power up the f4t controller. This document also provides information to as- sist in the process of...

Page 8: Chapter 2: Install and Wire

Watlow f4t install & troubleshooting • 5 • chapter 2 install and wire chapter 2: install and wire 2 getting started quickly . . .The logical approach the steps below outline installation and wiring for the base alone. More detail for each is provided in the following sections. 1. Using this document...

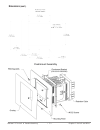

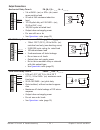

Page 9: Installing The F4T

Watlow f4t install & troubleshooting • 6 • chapter 2 install and wire dimensions (cont .) installing the f4t panel mounting the base 1. Make the panel cutout using the mounting template dimensions above and insert the case assembly into the panel cutout. 2. While pressing the case assembly firmly ag...

Page 10

Watlow f4t install & troubleshooting • 7 • chapter 2 install and wire dimensions (cont .) flush mounting the base 1. Fabricate the mounting panel per the flush mount vertical or horizontal panel template (shown below). 2. Press pem standoffs (based on panel material) into mounting panel per supplier...

Page 11

Watlow f4t install & troubleshooting • 8 • chapter 2 install and wire dimensions (cont .).

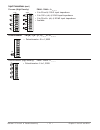

Page 12: Wiring The F4T Base

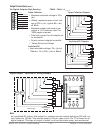

Watlow f4t install & troubleshooting • 9 • chapter 2 install and wire electrical isolation wiring the f4t base identify connector pinout power and communications terminal function warning: Óç use national electric (nec) or other country- specific standard wiring and safety practices when wiring and ...

Page 13: Flex Module Installation

Watlow f4t install & troubleshooting • 10 • chapter 2 install and wire wire size and torque for screw terminations • 0.0507 to 3.30 mm 2 (30 to 12 awg) single-wire termination or two 1.31 mm 2 (16 awg) • 0.57 nm (5.0 lb.-in.) torque power requirements • 85 to 264v Å (ac), (models f4t _ _ [ 1, 2, 3, ...

Page 14: Wiring The Modules

Watlow f4t install & troubleshooting • 11 • chapter 2 install and wire 5. With the component side of the module facing right (viewing the controller from the rear) insert the module in to the slot until it latches. 6. Remove the screw terminal block from the module. 7. Wire field devices to the appr...

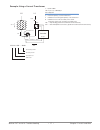

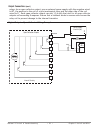

Page 15

Watlow f4t install & troubleshooting • 12 • chapter 2 install and wire place the quencharc directly across the external coil as shown below. For a dc load, place the cathode of the diode, to the positive voltage of the load and the anode to the ground of the load. Note: it is possible that the termi...

Page 16

Watlow f4t install & troubleshooting • 13 • chapter 2 install and wire rtd fm [m, l] a - [l, u, y * ] _ _ a - a _ _ _ 2-wire rtd t1 s1 r1 s3 s1 3-wire rtd t1 s1 r1 s2 s3 s1 • 2 or 3-wire platinum, 100 and 1,000 Ω @ 32°f (0°c) calibration to din curve (0.00385 Ω/Ω/°c) • rtd excitation current of 0.09...

Page 17

Watlow f4t install & troubleshooting • 14 • chapter 2 install and wire input connections (cont .) process (high density) fmha - raaa - a _ _ _ volts - + - + - + - + s1 r1 s2 r2 s3 r3 s4 r4 amps - + - + - + - + s1 r1 s2 r2 s3 r3 s4 r4 • 0 to 20 ma @ 100 Ω input impedance • 0 to 10vÎ (dc) @ 20 kΩ inpu...

Page 18

Watlow f4t install & troubleshooting • 15 • chapter 2 install and wire input connections (cont .) thermistor fm [m, l] a - [m, t] aaa - a _ _ _ s1 r1 • >20 mΩ input impedance • 0 to 40kΩ, 0 to 20kΩ, 0 to 10kΩ, 0 to 5kΩ • 2.252kΩ and 10kΩ base at 77°f (25°c) • drive current is 109 μa as a constant cu...

Page 19

Watlow f4t install & troubleshooting • 16 • chapter 2 install and wire input connections (cont .) digital input fmla - yeba - a _ _ _ b2 d2 • update rate 10hz • voltage - max. Input 36v at 3ma - input inactive when = 2v - input active when => 3v at 0.25ma • dry contact - input inactive when => 500Ω ...

Page 20

Watlow f4t install & troubleshooting • 17 • chapter 2 install and wire example: using a current transformer controller output n ct input l2 l1 fuse ssr 3a x 4 12a 48ma 48ma 12a x 4 = 48a turns around ct turns around ct ct primary current ct secondary current total current ct ratio r = 1000:1 : i s =...

Page 21

Watlow f4t install & troubleshooting • 18 • chapter 2 install and wire output connections mechanical relay form a fm [m, l]a - _ _ ja - a _ _ _ normally open common l2 k2 • 5 a at 240vÅ (ac) or 30vÎ (dc) maxi- mum resistive load • 20 ma at 24v minimum inductive load • 125 va pilot duty at 120/240v Å...

Page 22

Watlow f4t install & troubleshooting • 19 • chapter 2 install and wire output connections (cont .) four mechanical relays form a (high density) fmha - jaaa - a _ _ _ normally open common l1 k1 normally open common normally open common normally open common l2 k2 l3 k3 l4 k4 • 5 a at 240vÅ (ac) or 30v...

Page 23

Watlow f4t install & troubleshooting • 20 • chapter 2 install and wire output connections (cont .) four 2a solid-state relays, form a (high density) fmha - laaa - a _ _ _ normally open common l1 k1 l2 l3 k3 l4 normally open normally open common normally open • 2a at 20 to 264vÅ (ac) maximum resistiv...

Page 24

Watlow f4t install & troubleshooting • 21 • chapter 2 install and wire output connections (cont .) 3 mechanical relays, 2 form c, 1 form a (high density) fmha - baaa - a _ _ _ normally open common l1 k1 j1 l2 l3 k3 j3 normally open normally closed normally closed common normally open • 5a at 24 to 2...

Page 25

Watlow f4t install & troubleshooting • 22 • chapter 2 install and wire output connections (cont .) tri-process/retransmit (high density) fmha - faaa - a _ _ _ volts - / current - volts + / current + f1 h1 f2 h2 f3 h3 volts - / current - volts + / current + volts - / current - volts + / current + • 0...

Page 26

Watlow f4t install & troubleshooting • 23 • chapter 2 install and wire output connections (cont .) six digital outputs (high density) fmha - caaa - a _ _ _ internal common open collector/switched dc b1 d1 d2 d3 d4 d5 d6 z1 supply open collector/switched dc open collector/switched dc open collector/s...

Page 27

Watlow f4t install & troubleshooting • 24 • chapter 2 install and wire output connections (cont .) relays. As an open collector output, use an external power supply with the negative wired to b7, the positive to the coil of a pilot mechanical relay and the other side of the coil wired to d_. Each op...

Page 28

Watlow f4t install & troubleshooting • 25 • chapter 2 install and wire communications connections eia-232/485 modbus rtu communications 485 common 485 t+/r+ cb ca cc cb ca c5 c3 c2 slot b, e 485 t-/r- 485 t+/r+ 485 t-/r- 232 common 232 (tx) to db9 pin 2 (rd) 232 (rd) to db9 pin 3 (tx) • wire t-/r- t...

Page 29: Chapter 3: Connecting A Pc

Watlow f4t system • 26 • chapter 3 connecting to a pc chapter 3: connecting a pc 3 using the user interface (ui) to change or view ethernet settings understanding the front panel navigational buttons when looking at the front panel of the f4t, at the bottom of the display, four push buttons are disp...

Page 30

Watlow f4t system • 27 • chapter 3 connecting to a pc default ethernet parameters and settings the bracketed bold settings below represent the defaults as delivered from the factory: • ip address mode: [ dhcp], fixed - dhcp, dynamic host configuration protocol, allows for dynamic distribution of net...

Page 31

Watlow f4t system • 28 • chapter 3 connecting to a pc connecting the f4t base to a pc dhcp connection there are two ways to connect the f4t over ethernet to a pc (fixed ip or dhcp). Because the f4t is delivered as a dhcp client, we'll take a look at this method first. The picture below shows two f4t...

Page 32: Composer Software

Watlow f4t system • 29 • chapter 3 connecting to a pc composer software composer is the pc-based software used to configure an f4t controller for a specific applica- tion. Use composer to configure which flex modules the controller expects to find in each of its slots and to customize the controller...

Page 33

Watlow f4t system • 30 • chapter 3 connecting to a pc symbols related to pluggable modules as viewed from the menu bar, the symbol that will be displayed to the left of the pluggable modules button will be of the most significance. The red exclamation will always take prece- dence. Symbol descriptio...

Page 34: Chapter 4: Calibration

Watlow f4t install & troubleshooting • 31 • chapter 4 calibration chapter 4: calibration 4 calibrating the f4t all controllers are calibrated and are accurate to the specified specifications (see appendix for specifications) when they ship from the manufacturing facility. If an input is suspect as b...

Page 35

Watlow f4t install & troubleshooting • 32 • chapter 4 calibration calibration of analog inputs to calibrate an analog input, you will need to provide a source of two electrical signals or resistance values near the extremes of the range that the application is likely to utilize. See recommended valu...

Page 36

Watlow f4t install & troubleshooting • 33 • chapter 4 calibration using composer software to calibrate analog inputs to obtain access to the calibration screens: 1. Start composer software if not already running. 2. From the dashboard click on connect to a system and select the appropriate device. 3...

Page 37: Chapter 5: Troubleshooting

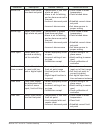

Watlow f4t install & troubleshooting • 34 • chapter 5 troubleshooting chapter 5: troubleshooting 5 indication description possible cause(s) corrective action alarm won’t clear or reset alarm will not clear or reset with key- pad or digital input • alarm latching is active • alarm set to incorrect ou...

Page 38

Watlow f4t install & troubleshooting • 35 • chapter 5 troubleshooting indication description possible cause(s) corrective action alarm low sensor input below low alarm set point • temperature is less than alarm set point • alarm is set to latching and an alarm occurred in the past • incorrect alarm ...

Page 39

Watlow f4t install & troubleshooting • 36 • chapter 5 troubleshooting indication description possible cause(s) corrective action limit high sensor input above high limit set point • temperature is greater than limit set point • limit outputs latch and require reset • incorrect alarm set point • chec...

Page 40

Watlow f4t install & troubleshooting • 37 • chapter 5 troubleshooting indication description possible cause(s) corrective action no heat/cool action output does not activate load • output function is incor- rectly set • control mode is incor- rectly set • algorithim is set off • output is incorrectl...

Page 41

Watlow f4t install & troubleshooting • 38 • chapter 5 troubleshooting indication description possible cause(s) corrective action no serial communica- tion cannot establish se- rial communications with the controller • address parameter incor- rect • incorrect protocol se- lected • baud rate incorrec...

Page 42

Watlow f4t install & troubleshooting • 39 • chapter 5 troubleshooting indication description possible cause(s) corrective action heater error heater error • current through load is above current trip set point • current through load is below current trip set point • check that the load cur- rent is ...

Page 43

Watlow f4t install & troubleshooting • 40 • chapter 5 troubleshooting replacing the battery all f4t controllers are equipped with a field replaceable battery. In a worse case scenario, the battery should be replaced every 7.5 years. If a replacement is required, the part num- ber for the battery is ...

Page 44

Watlow f4t install & troubleshooting • 41 • chapter 5 troubleshooting installing a new battery: 1. Observing polarity (as shown in the previous graphic), insert the new battery from the bottom of the holder (2 open slots - red circles as shown in picture below). 2. Insert the battery perpendicular t...

Page 45: Chapter 6: Appendix

Watlow f4t install & troubleshooting • 42 • chapter 8 appendix chapter 6: appendix f4t base specifications line voltage/power (minimum/maximum ratings) • high voltage option: 85 to 264v~ (ac) 47/63hz • low voltage option: 20.4 to 30.8v (~ ac) (Î dc), 47/63hz • power consumption: 23 w, 54va maximum •...

Page 46

Watlow f4t install & troubleshooting • 43 • chapter 8 appendix user interface • 4.3 inch tft pcap color graphic touch screen • 4 keys: home, main menu, back, help profile ramp/soak • profile engine affects one to four loops in synch • 40 profiles with up to 50 steps per profile real time clock and b...

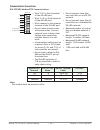

Page 47

Watlow f4t install & troubleshooting • 44 • chapter 8 appendix number of function blocks by ordering option function block basic set 1 set 2 alarm 6 8 14 compare none 4 16 counter none 4 16 linearization 4 4 8 logic none 12 24 math none 12 24 process value 4 4 8 special output function none 2 4 time...

Page 48

Watlow f4t install & troubleshooting • 45 • chapter 8 appendix f4t base ordering information base includes: 4.3 inch color graphical touch panel, 2 usb host, usb configuration port, stan- dard bus, wired ethernet modbus ® tcp. Scpi protocol and backwards compatible modbus for select key series f4d/p...

Page 49

Watlow f4t install & troubleshooting • 46 • chapter 8 appendix flex modules and limit i/o specifications 1 universal input • thermocouple, grounded or ungrounded sensors - >20mΩ input impedance • max. Of 2kΩ source resistance • rtd 2 or 3 wire, platinum, 100Ω and 1000Ω @ 32°f (0°c) calibration to di...

Page 50

Watlow f4t install & troubleshooting • 47 • chapter 8 appendix operating range input type range low range high j -210 °c 1200 °c k -270 °c 1371 °c t -270 °c 400 °c n -270 °c 1300 °c e -270 °c 1000 °c r -50 °c 1767 °c s -50 °c 1767 °c b -50 °c 1816 °c c 0 °c 2315 °c d 0 °c 2315 °c f (ptii) 0 °c 1343 ...

Page 51

Watlow f4t install & troubleshooting • 48 • chapter 8 appendix 1 temperature input • thermocouple, grounded or ungrounded sensors - >20mΩ input impedance • max. Of 2kΩ source resistance • rtd 2 wire, platinum, 100Ω and 1000Ω @ 32°f (0°c) calibration to din curve (0.00385Ω/Ω/°c) - maximum lead resist...

Page 52

Watlow f4t install & troubleshooting • 49 • chapter 8 appendix 1 universal process/retransmit output • universal process/retransmit, output range selectable: - 0 to 10v Î(dc) into a min. 1,000Ω load - 0 to 20ma into max. 800Ω load resolution - dc ranges: 2.5mv nominal resolution - ma ranges: 5 µa no...

Page 53

Watlow f4t install & troubleshooting • 50 • chapter 8 appendix flex module - limit ordering information part number ① ② ③ module id type ④ future option - ⑤ ⑥ ⑦ input and output hardware ⑧ future option - ⑨ future options ⑩ custom options and connectors ⑪ d custom options - firmware, overlay, preset...

Page 54

Watlow f4t install & troubleshooting • 51 • chapter 8 appendix input type max error @ 25 deg c accuracy range low accuracy range high units j ±1.75 0 750 deg c k ±2.45 -200 1250 deg c t (-200 to 350) ±1.55 -200 350 deg c n ±2.25 0 1250 deg c e ±2.10 -200 900 deg c r ±3.9 0 1450 deg c s ±3.9 0 1450 d...

Page 55

Watlow f4t install & troubleshooting • 52 • chapter 8 appendix operating range (cont.) input type range low range high madc 0 20 maac -50 50 potentiometer, 1k range 0 1200 resistance, 5k range 0 5000 resistance, 10k range 0 10000 resistance, 20k range 0 20000 resistance, 40k range 0 40000 4 thermist...

Page 56

Watlow f4t install & troubleshooting • 53 • chapter 8 appendix 4 mechanical relay outputs • form a, 5a each, 24 to 240vÅ (ac) or 30vÎ (dc)max., resistive load, 100,000 cycles at rated load. Requires a min. Load of 20ma at 24v, 125 va pilot duty at 120/240 vÅ (ac) or 25 va at 24 vÅ (ac) 2 solid-state...

Page 57

Watlow f4t install & troubleshooting • 54 • chapter 8 appendix flex module - high density ordering information part number ① ② ③ module id type ④ future option - ⑤ input and output hardware ⑥ ⑦ ⑧ future option - ⑨ future options ⑩ custom options and connectors ⑪ d custom options - firmware, overlay,...

Page 58

Watlow f4t install & troubleshooting • 55 • chapter 8 appendix declaration of conformity series f4t watlow electric manufacturing company iso 9001 since 1996. 1241 bundy blvd. Winona, mn 55987 usa declares that the following products: designation: series f4t ¼ din control model numbers: f4t x x (1 t...

Page 59

Watlow f4t install & troubleshooting • 56 • chapter 8 appendix declaration of conformity series ez-zone ® flex modules watlow electric manufacturing company iso 9001 since 1996. 1241 bundy blvd. Winona, mn 55987 usa declares that the following products: designation: series ez-zone ® flex modules mod...

Page 60

Watlow f4t install & troubleshooting • 57 • chapter 8 appendix how to reach us corporate headquarters watlow electric manufacturing company 12001 lackland road st . Louis, mo 63146 sales: 1-800-watlow2 manufacturing support: 1-800-4watlow email: info@watlow .Com website: www .Watlow .Com from outsid...