- DL manuals

- Watsco

- Furnace

- GLT series

- Installation Instructions Manual

Watsco GLT series Installation Instructions Manual

Summary of GLT series

Page 1

92-24161-96-01 supersedes 92-24161-96-00 installation instructions for upflow/horizontal & downflow induced draft gas furnaces with ecm x-13 motors (-)gpt upflow/horizontal series (-)glt downflow series.

Page 2

2 before beginning any troubleshooting procedure, complete the following installation checklist. A furnace malfunction is sometimes caused by an improper installation. By completing this checklist, the problem may be found and corrected. Make copies of the checklist and complete one for every low pr...

Page 3

33 important: to insure proper installation and operation of this product, completely read all instructions prior to attempting to assemble, install, operate, maintain or repair this product. Upon unpacking of the furnace, inspect all parts for damage prior to installation and start-up. Contents ins...

Page 4: Safety Information

4 use only with type of gas approved for this furnace. Refer to the furnace rating plate. Install this furnace only in a location and position as specified in the location requirements and considerations section of these instructions. Provide adequate combustion and ventilation air to the furnace sp...

Page 5

5 duct leaks can create an unbalanced system and draw pollutants such as dirt, dust, fumes and odors into the home causing property damage. Fumes and odors from toxic, volatile or flammable chemicals, as well as automobile exhaust and carbon monoxide (co), can be drawn into the living space through ...

Page 6: General Information

6 the (-)gpt/(-)glt series furnaces are design certified by csa for use with natural and propane gases as follows: as a category i furnace, it may be vented vertically with type b-1 vent pipe and also may be common vented as described in these instructions. This furnace should be installed in accord...

Page 7

7 general information 1. Note: this furnace is shipped with heat exchanger support brackets installed under the back of the heat exchanger. These may be removed before installation, but it is not required. Location this furnace is not approved for installation in a mobile home. Do not install this f...

Page 8

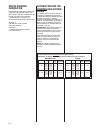

8 c l e a r a n c e t o c o m b u s t ib l e m a t e r ia l (i n c h e s ) u p f l o w /h o r iz o n t a l m o d e l s t o p l e f t s id e f r o n t r ig h t s id e a l t e r n a t e g a s c o n n e c t io n b o t t o m r e t u r n a ir a ir f l o w s u p p l y a ir 26 13 / 16 26 5 / 8 24 11 / 32 2...

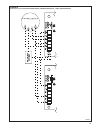

Page 9

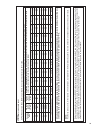

9 figure 4 downflow dimensions r e d u c e d c l e a r a n c e (i n .) m o d e l a b c d e l e ft r ig h t b a c k t o p f ro n t v e n t s h ip . S id e s id e w g ts . 0 5 1 4 1 2 2 7 / 3 2 1 0 3 / 8 ➀ 1 3 1 / 8 0 4 ➁ 0 1 3 6 ➂ 8 5 lb s . 0 7 1 7 1 / 2 1 6 1 1 / 3 2 1 2 1 / 8 ➀ 1 6 5 / 8 0 3 ➁ 0 1...

Page 10

10 clearance – accessibility the design of forced air furnaces with input ratings as listed in the tables on the following pages are certified by csa for the clearances to combustible materials shown in inches. See name/rating plate and clearance label for specific model number and clearance informa...

Page 11

11 failure to prevent products of combustion from being circulated into the living space can create potentially hazardous conditions, including carbon monoxide poisoning that could result in personal injury or death. Do not, under any circumstances, connect return or supply ductwork to or from any o...

Page 12

12 this furnace and any other fuel-burning appliance must be provided with enough fresh air for proper combustion and ventilation of the flue gases. Most homes will require that outside air be supplied into the furnace area. Failure to do so can cause death from carbon monoxide poisoning. Adequate f...

Page 13

13 combustion air must be free of acid forming chemicals; such as sulphur, fluorine and chlorine. These elements are found in aerosol sprays, detergents, bleaches, cleaning solvents, air fresheners, paint and varnish removers, refrigerants and many other commercial and household products. Vapors fro...

Page 14

14 a. One square inch for each 3000 btuh of the total input rating of all equipment located in the enclosure, and b. Not less than the sum of the areas of all vent connectors in the confined space. Important: if the furnace is in a location with an exhaust fan, there must be sufficient ventilation t...

Page 15

15 figure 10 outside air using a horizontal inlet & outlet figure 11 combustion air fitting – optional attic combustion air pull, gpt only b: method 3, gpt only for the optimum in quiet operation, attic air may be brought directly to the furnace. Important: in applications using method 3 for combust...

Page 16: Venting

16 general information the furnace must be vented in accordance with these instructions, national fuel gas code, ansi z223.1 and/or the natural gas installation code, csa-b149.1 & .2 and requirements or codes of the local utility or other authority having jurisdiction. Devices attached to the flue o...

Page 17

17 “b-1” vertical venting type “b-1” vents must be installed in accordance with the terms of their listings and the vent manufacturer’s instructions. “b-1” vents must be supported and spaced in accordance with their listings and the manufacturer’s instructions. All vents must be supported to maintai...

Page 18

18 existing vent systems important retrofit venting instructions if this furnace is a replacement installation, always inspect the existing vent system to be sure there are no obstructions, blockages, or signs of corrosion. When the existing furnace is removed from a venting system serving other app...

Page 19: Gas Supply And Piping

19 figure 15 gas piping installation gas pipe installation gas supply and piping gas supply this furnace is equipped at the factory for use on natural gas only. Conversion to lp gas requires a special kit available from the distributor. Failure to use the proper conversion kit can cause fire, carbon...

Page 20

20 lp conversion note: for installation, see specific lp kit installation instructions. The valve can be converted to use liquefied petroleum (lp) gas by replacing the pressure regulator spring with the conversion kit spring. This lp kit spring allows the regulator to maintain the proper adjusted ma...

Page 21

21 table 3 lp gas pipe capacity table (cu. Ft./hr.) setting gas pressure the maximum gas supply pressure to the furnace should be 10.5” w.C. Natural gas, or 13” w.C. Lp gas. The minimum supply gas pressure to the gas valve should be 5" w.C. Natural gas or 11" w.C. Lp gas. A properly calibrated manom...

Page 22

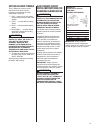

22 table 4 adjusting or checking furnace input elevations above 2000 ft require that the furnace input rate be adjusted and that the size of the burner orifices be re-calculated based on elevation and gas heating value. The burner orifices may (or may not) need to be changed. See the section titled ...

Page 23: Electrical Wiring

23 turn off electric power at the fuse box or service panel before making any electrical connections. Also, the ground connection must be completed before making line voltage connections. Failure to do so can result in electrical shock, severe personal injury or death. Important: the furnace must be...

Page 24

24 field installed option accessories electronic air cleaner electronic air cleaner line voltage power can be supplied from the screw terminal “eac” and a line voltage neutral screw terminal on the control board. Power is on any time the blower is activated. See figure 18. Humidifier humidifier line...

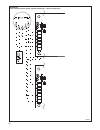

Page 25

25 figure 19 ut electronic controls 1028-930r2 control board, twinning connection -- single stage operation a099201.

Page 26

26 figure 20 utec 1028-930r2 control board, twinning connection -- two-stage operation a099301.

Page 27

27 80+ high altitude instructions (tables 6 & 9) installation of this furnace at altitudes above 2000 ft (610 m) shall be in accordance with local codes, or in the absence of local codes, the national fuel gas code, ansi z223.1/nfpa 54 or national standard of canada, natural gas and propane installa...

Page 28

28 orifice ordering information orifice sizes are selected by adding the 2-digit drill size required in the orifice part number. Drill sizes available are 39 through 64; metric sizes available 1.10mm (-90) and 1.15mm (-91): orifice part number 62-22175-(drill size) example 1: # 60 drill size orifice...

Page 29

29 t a b l e 9 s u p p l e m e n t a l o r if ic e s iz e c h a r t 80 p lu s m od el s on ly wi th 2 5, 00 0 bt u' s pe r b ur ne r. Do n ot u se th is ch ar t f or a ny 9 0+ m od el s. Na tu ra l g as q ui ck r ef er en ce c ha rt f o r o ri fi ce s el ec ti o n, a t 3. 5" w .C . A nd a pp ro xi m...

Page 30: Start-Up Procedure

30 lighting instructions this appliance is equipped with a direct spark ignition device. This device lights the main burners each time the room thermostat (closes) calls for heat. See lighting instructions on the furnace. To start furnace 1. Be sure that the manual gas valve has been in the “off” po...

Page 31

31 setting blower timings the ut electronic controls control boards have four quick connect terminals for connecting the motor speed leads. These are: 1. Fan — motor runs on this speed when the thermostat is in the “fan” position. 2. Cool — connect desired cooling speed. 3. Heat — connect desired he...

Page 32: Air Flow

32 air flow the importance of proper air flow over the heat exchanger cannot be over emphasized. It is important that each duct system be sized and installed for the specific application by properly applying the appropriate industry accepted standard. If less than minimum standards are applied, the ...

Page 33

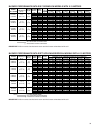

33 low red 1 916 [432] 803 [379] 669 [315] 561 [264] 504 [237] 421 [198] med-lo yellow 2 993 [468] 952 [449] 910 [429] 827 [390] 793 [374] 706 [333] med purple 3 1205 [568] 1158 [546] 1124 [530] 1056 [498] 1024 [483] 950 [448] med-hi* blue* 4* 1367 [645] 1333 [629] 1300 [613] 1236 [583] 1203 [567] 1...

Page 34: Safety Features

34 limit control the high limit cut-off temperature is set at the factory and cannot be adjusted. The temperature setting prevents the air temperature leaving the furnace from exceeding the maximum outlet air temperature, which, if exceeded, will shut the furnace down. There are several reasons for ...

Page 35: Maintenance

35 figure 26 filter retaining rod disconnect main electrical power to the unit before attempting any maintenance. Failure to do so can cause electrical shock resulting in severe personal injury or death. Filters filter application and placement are critical to airflow, which may affect the heating a...

Page 36

36 figure 27 upflow filter retaining rod (side return) filter rod 45-24095-01 filter rod support angle ae-60520-01 filter support angle (see angle detail) ae-61883-01 filter rod support angle ae-60520-01 filter support angle ae-61883-01 cut-out and drill detail filter and rod assembly rod & filter s...

Page 37

37 system operation information advise the customer to: 1. Keep the air filters clean. The heating system will operate better, more efficiently and more economically. 2. Arrange the furniture and drapes so that the supply air registers and the return air grilles are unobstructed. 3. Close doors and ...

Page 38

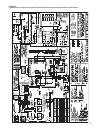

38 figure 30 troubleshooting flowchart go to e warning integrated furnace control (ifc) troubleshooting guide hazardous voltage line voltage connections disconnect power before servicing. Service must be by a trained, qualified service technician. Note: most failures are not due to the ifc. Double c...

Page 39

39 figure 31 for models with ut electronic controls 1028-928 integrated furnace control and direct spark ignition.

Page 40

Cm 0510 40