- DL manuals

- Watt Drive

- Inverter

- L2500 Series

- Manual

Watt Drive L2500 Series Manual - Watt Drive Worldwide

WATT DRIVE worldwide

WATT DRIVE ANTRIEBSTECHNIK GMBH

A-2753 Markt Piesting

Wöllersdorferstraße 68

Austria, EUROPE

Tel.: +43 / 2633 / 404-0

Fax: +43 / 2633 / 404-220

e-mail: watt@wattdrive.com

Web: www.wattdrive.com

BA.FBE.UR.023.001.07.03

L2500 Kurzanleitung dt/engl.

Watt Drive operates a policy of continuous development. Therefore, we reserve the right to make

changes and improvements to any of our products described in this manual without prior notice. Any

changes, improvements and typing errors justify no claims for compensation.

WATT DRIVE NORD GmbH

Eickelstraße 4

D-59759 Arnsberg

Germany, EUROPE

Tel.: +49 / 2932 / 96 81-0

Fax: +49 / 2932 / 96 81-81

e-mail: info@wattdrive.de

Web: www.wattdrive.de

WATT DRIVE SÜD GmbH

Walkenmühleweg 49

D-72379 Hechingen

Germany, EUROPE

Tel.: +49 / 7471 / 9865-0

Fax: +49 / 7471 / 9865-29

e-mail: info@wattdrive-sued.de

Web: www.wattdrive-sued.de

WATT EURO-DRIVE (Far East) Pte Ltd

67B, Joo Koon Circle

Singapore 629082

Tel.: +65 / 686 22 220

Fax: +65 / 686 23 330

e-mail: watteuro@pacific.net.sg

Web: www.wattdrive.com

WATT EURO-DRIVE (Malaysia) Sdn Bhd

No. 17 Jalan Bulan U5/8

Bandar Pinggiran Subang 2

40150 Shah Alam

Selangor Darul Ehsan

Malaysia

Tel.: +603 / 785 91626, 785 91613

Fax: +603 / 785 91623

e-mail: watt_kl@tm.net.my

Web: www.wattdrive.com

Summary of L2500 Series

Page 1

Frequency inverter series l2500 manual.

Page 2: Watt Drive Worldwide

Watt drive worldwide watt drive antriebstechnik gmbh a-2753 markt piesting wöllersdorferstraße 68 austria, europe tel.: +43 / 2633 / 404-0 fax: +43 / 2633 / 404-220 e-mail: watt@wattdrive.Com web: www.Wattdrive.Com ba.Fbe.Ur.023.001.07.03 l2500 kurzanleitung dt/engl. Watt drive operates a policy of ...

Page 3

0-1 please read this manual carefully before you install and operate an l2500 series inverter and observe all of the instructions given in there. This manual may also serve as a reference guide and therefore should always be kept at hand. ! Danger! This message indicates a situation which may lead t...

Page 4

Warnings 0-2 ! Caution! Rotating shafts and electrical potentials above ground level can be hazardous. Therefore it is strongly recommended that all electrical work conform to the national electrical codes and local regulations. Installation, maintenance and alignment should be performed by qualifie...

Page 5

0-3 table of contents • chapter 1 – receiving and inspection • chapter 2 – storage and installation • chapter 3 – wiring • chapter 4 – digital keypad operation • chapter 5 – parameters • chapter 6 – maintenance and inspections • chapter 7 – troubleshooting and fault information • chapter 8 – summary...

Page 6

Chapter 1: receiving and inspection 1-1 if there is any nameplate information not corresponding to your purchase order or any problem, please contact your supplier. Chapter 1 receiving and inspection this l2500 ac drive has gone through rigorous quality control tests at the factory before shipment. ...

Page 7

2 2-1 chapter 2 storage and installation 2.1 storage the ac drive should be kept in the shipping carton before installation. In order to retain the warranty coverage, the ac drive should be stored properly when it is not to be used over for an extended period of time. Some storage suggestions are: s...

Page 8

Chapter 2: storage and installation 2-2 2.3 installation improper installation of the ac drive will greatly reduce its life. Be sure to observe the following precautions when selecting a mounting location. Failure to observe these precautions may void the warranty! ! Do not mount the ac drive near h...

Page 9

2 2-3 2.4 connections danger hazardous voltage before accessing the ac drive: ! Disconnect all power to the ac drive. ! Wait ten minutes for dc bus capacitors discharge. Any electrical or mechanical modification to this equipment without prior written consent of watt drive gmbh. Will void all warran...

Page 11: Chapter 3 Wiring

3 3-1 chapter 3 wiring n otes on emc ( electro magnetical compatibility ) warning this equipment should be installed, adjusted and serviced by qualified personnel familiar with construction and operation of the equipment and the hazards involved. Failure to observe this precaution could result in bo...

Page 12

Chapter 3 wiring 3-2 observe the following provisions for an electromagnetically compatible setup of your drive system: 1. As user you must ensure that the hf impedance between frequency inverter, filter and ground is as small as possible. • take care it that the connections are metallic and have th...

Page 13

3 3-3 6. Safety measures • ensure that the protective conductor terminal (pe) of the filter is properly connected with the protective conductor terminal of the frequency inverter. An hf ground connection via metal contact between the housings of the filter and the frequency inverter, or solely via c...

Page 14

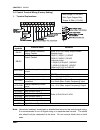

Chapter 3 wiring 3-4 3.1 basic wiring diagram users must connect wiring according to the following circuit diagram shown below. 4.7k 47k 4.7k 4.7k 4.7k 4.7k 4.7k please refer to 3.4 for detail. Npn j2 pnp di1 di2 di3 di4 di5 di6 do1 doc afo gnd.

Page 15

3 3-5 pnp (in source mode) b2 u/t1 v/t2 w/t3 im 3~ note: do not plug in a modem or telephone line to the rs-485 communication port, permanent damage may result. Terminal 1 & 2 are the power sources for the optional copy keypad and should not be used while using rs-485 communication. +2/b1 e gnd +10v...

Page 16

Chapter 3 wiring 3-6 3.2 external wiring items explanations power supply please follow the specific power supply requirement shown in appendix-a. Fuse/nfb (optional) there may be inrush current during power up. Please check the chart of appendix b and select the correct fuse with rated current. Nfb ...

Page 17

3 3-7 3.3 main circuit wiring 1. Main circuit terminals b 2 +2 b1 +1 ac input line terminal braking resitor ground power terminal (3x460v series) dc reactor r l1 s l2 t l3 u t1 v t2 w t3 b 2 l l1 n l2 u t1 v t2 w t3 power terminal (1 230v series) ~ motor connection ac input line terminal motor conne...

Page 18

Chapter 3 wiring 3-8 3.4 control terminal wiring (factory setting) 1. Terminal explanations: do1 doc terminal symbols terminal name remarks ra-rc multi-function indication output contact rb-rc multi-function indication output contact refer to pr.3-06 relay output contact resistor load 5a(n.O.)/3a(n....

Page 19

3 3-9 3.5 wiring notes 1. ! Caution: do not connect the ac input to any of the u/t1, v/t2, w/t3 terminals, as it will damage the ac drive. 2. ! Warning: ensure all screws are tightened to the proper torque rating. 3. During installation, follow all local electrical, construction, and safety codes fo...

Page 20

Chapter 3 wiring 3-10 12. For the single-phase applications, the ac input line can be connected to any two of the three input terminals r/l1, s/l2, t/l3. Note: this drive is not intended for the use with single-phase motors. 13. Route the power and control wires separately, or at 90°angle to each ot...

Page 21

4 4-1 chapter 4 digital keypad operation 4.1 description of digital keypad this digital keypad includes two parts: display panel and keypad. Display panel provides the parameter display and shows operation status of the ac drive. Keypad provides programming interface between users and ac drives. Run...

Page 22

Chapter 4: digital keypad operation 4-2 4.2 explanations of display messages display message descriptions the ac drive master frequency the actual operation frequency present at terminals u/t1, v/t2, and w/t3. The output current present at terminals u/t1, v/t2, and w/t3 the custom unit (u), where u ...

Page 23

4 4-3 4.3 explanation of led indicators run fwd rev stop stop ac drive when stop button has been pressed. Run led lights during run operation. Fwd led lights during forward operation. Rev led lights during reverse operation. 1. Description of led functions of run and stop output frequency of the ac ...

Page 24

Chapter 4: digital keypad operation 4-4 4.4 keypad operation change display mode set frequency set frequency set frequency set freq. Change display item change display mode change display mode change operation direction display freq. Command display parameter number rev state can't attain if reverse...

Page 25

5 5-1 chapter 5’ – quick start guide the parameters of the inverter drives v2500 are pre-set by factory to application based values that usually occur in standard environment. When following the warnings in the introduction of this manual and the storage and installation guidelines in chapter 2 as w...

Page 26

Chapter 5’: quick start guide 5-2 groupe 2: operation method parameters para- meter explanation settings factory setting actual setting 2-00 source of frequency command d0: master frequency input determined by digital keypad. (record the frequency of power loss and it can do analog overlap plus) d1:...

Page 27

5 5-3 para- meter explanation settings factory setting actual setting 4-03 potentiometer reverse motion enable d0: forward motion only d1: reverse motion enabled d0 4-04 multi-function digital input terminal 1 (di1, di2) d0: parameter disable d1: di1=fwd/stop, di2=rev/stop d2: di1=fwd/rev, di2=run/s...

Page 28

Maintenance and inspections 6-1 chapter 6 maintenance and inspections modern ac drives are based on solid state electronics technology, preventive maintenance is required to operate this ac drive in its optimal condition, and to ensure a long life. It is recommended to perform a monthly check up of ...

Page 29

7 7-1 chapter 7 troubleshooting and fault information the l2500 ac drive has a comprehensive fault diagnostic system that includes several different alarms and fault messages. Once a fault is detected, the corresponding protective functions will be activated. The following faults are displayed as sh...

Page 30

Chapter 7: troubleshooting and fault information 7-2 fault name fault descriptions corrective actions the ac drive detects excessive drive output current. Note: the ac drive can withstand up to 150% of the rated current for a maximum of 60 seconds. 1. Check whether the motor is overloaded. 2. Reduce...

Page 31

7 7-3 fault name fault descriptions corrective actions internal memory ic can not be programmed. 1. Switch off power supply. 2. Check whether the input voltage falls within the rated ac drive input voltage. 3. Switch the ac drive back on. Internal memory ic can not be read. 1. Check the connections ...

Page 33

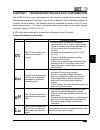

8 8-1 chapter 8 summary of parameter settings ! : the parameter can be set during operation, *: twice and/or adapted value for 400/460v class. Group 0: user parameters para- meter explanation settings factory setting actual setting 0-00 identity code of ac drive read-only d # 0-01 rated current disp...

Page 34

Chapter 8: summary of parameter settings 8-2 group 1 basic parameters para - met er explanation settings factory setting actual setting 1-00 maximum output freq. D50.0 to d400 hz d50.0 1-01 maximum voltage frequency (base freq) d10.0 to d400 hz d50.0 1-02 maximum output voltage d2.0v to d255v* d230 ...

Page 35

8 8-3 group 2 operation method parameters para- meter explanation settings factory setting actual setting 2-00 source of frequency command d0: master frequency input determined by digital keypad. (record the frequency of power loss and it can do analog overlap plus) d1: master frequency determined b...

Page 36

Chapter 8: summary of parameter settings 8-4 group 3 output function parameters para- meter explanation settings factory setting actual setting 3-00 analog output signal d0: analog frequency (0 to max. Output frequ.: pr-1-00) d1: analog current (0 to 250% of rated drive output current d0 3-01 analog...

Page 37

8 8-5 group 4: input function parameters para- meter explanation settings factory setting actual setting 4-00 potentiometer bias frequ. ! D 0.0 to d 100.0% d0.0 4-01 potentiometer bias polarity ! D0: positive bias d1: negative bias d0 4-02 potentiometer frequency gain ! D1 to d200 % d100 4-03 potent...

Page 38

Chapter 8: summary of parameter settings 8-6 para- meter explanation settings factory setting actual setting 4-11 acceleration /deceleration speed of constant up/down frequency d0 to d1000 hz/sec d1 group 5: multi-step speed and plc parameters para- meter explanation settings factory setting actual ...

Page 39

8 8-7 group 6: protection parameters para- meter explanation settings factory setting actual setting d0: disable 6-00 over-voltage stall prevention d1: enable d1 230v series: d350 to d410v d390 6-01 over-voltage prevention level 460v series: d700 to d820v d780 6-02 over-current stall prevention leve...

Page 40

Chapter 8: summary of parameter settings 8-8 group 7 motor parameters para- meter explanation settings factory setting actual setting 7-00 motor rated current ! D30 to d120% (% of drive ’ s rated current) d85 7-01 motor no-load current ! D0 to d90% (% of drive ’ s rated current) d50 7-02 torque comp...

Page 41

8 8-9 group 9: communication parameters para- meter explanation settings factory setting actual setting 9-00 communication address ! D1 to d254 d1 d0: baud rate 4800 bps d1: baud rate 9600 bps d2: baud rate 19200 bps 9-01 transmission speed ! D3: baud rate 38400 bps d1 d0: warn and keep operating d1...

Page 42

Appendix a: technical specifications a-1 appendix a: technical specifications 02s 04s 07s 15s 22s 04t 07t 15t 22t 0.2 0.4 0.75 01.Mai 02.Feb 0.4 0.75 01.Mai 02.Feb 1/4 1/2 1 2 3 1/2 1 2 3 0.6 1.0 1.6 2.9 4.2 1.2 2.0 3.3 4.4 1.6 2.5 4.2 7.5 11.0 1.5 2.5 4.2 5.5 recommended 50 hz 72k4 72n4 81n4 91l4 1...

Page 43: Appendix B - Accessories

B b-1 appendix b - accessories b.1 non-fuse circuit breaker chart recommended by watt drive antriebstechnik gmbh (ul 508c, paragraph 45.8.4, part a) 1. For 1-phase drives, the current rating of the breaker shall be four times maximum of input current rating. 2. For 3-phase drives, the current rating...

Page 44

Appendix b - accessories b-2 b.2 braking resistors watt drive recommends the following braking resistors for use with the according inverters of the l2500 series: inverter resistor dimensions w/h/d (mm³) udgl2500-0002saw1 udzbw-200/00080 140/20/60 udgl2500-0004sbw1 udzbw-200/00080 140/20/60 udgl2500...

Page 45

B b-3 dimensions mm (inch) 60 (2.36) 200 (7.87) 85 (3.35) 200 (7.87) 50 (1.97) 27 (1.06) 24 (0.94) 15 (0.52) 4.5 (0.18) 213 (8.39) udznfl-007t.

Page 46

Appendix b - accessories b-4 27 (1.06) 50 (1.97) 228 (8.98) 15 (0.59) 24 (0.94) 100 (3.94) 228 (8.98) 74 (2.91) 5.5 (0.22) 241 (9.49) udznfl-022t.

Page 47: Appendix C - Dimensions

C c-1 appendix c - dimensions a a1 c d a d e c b b1 b achtung hochspannung: vor dem Öffnen des umrichters mindestens 5 minuten warten. Betriebsanleitung beachten warning - high voltage: wait at least 5 minutes before opening. Follow user manual eco-line eco-line.

Page 48

Appendix c - dimensions c-2 a mm (inch) a1 mm (inch) b mm (inch) b1 mm (inch) c mm (inch) d mm (inch) a mm (inch) b mm (inch) c mm (inch) d mm (inch) e mm (inch) udgl2500-0002saw1 85 (3.35) 74 (2.92) 148 (5.83) 133.7 (5.27) 127 (5.0) 5.8 (0.23) - - - 5 (0.32) 8.3 (0.33) udgl2500-0004sbw1 85 (3.35) 7...