- DL manuals

- Watt Drive

- Inverter

- V3000-015HF

- Manual

Watt Drive V3000-015HF Manual

Summary of V3000-015HF

Page 1

Inverter series v3000 m a n u a l.

Page 2: Manual

General descriptions seite 2 / 180 manual these two manuals provide you with a general information how to use v3000 frequency inverter and how to apply, if needed, special applications. V3000 installation manual provides you with the information necessary to install, start-up and operate the v3000 f...

Page 3: Watt Drive Worldwide

General descriptions seite 3 / 180 watt drive worldwide watt drive antriebstechnik gmbh a-2753 markt piesting tel.: +43/2633/404-0 fax: +43/2633/404-220 wöllersdorferstraße 68 internet: http:\\www.Wattdrive.Com e-mail: watt@wattdrive.Com watt drive nord gmbh d-59759 arnsberg tel.: +49/2932/9681-0 fa...

Page 4: Safety

General descriptions seite 4 / 180 safety for the best results with v3000 series inverter, read this manual and all of the warning sign attached to the inverter carefully before installing and operating it, and follow the instructions exactly. Keep this manual handy for your quick reference. Definit...

Page 5

General descriptions seite 5 / 180 precaution : this is equipment should be installed, adjusted and serviced by qualified electrical maintenance personal familiar with the construction and operation of the equipment and the hazards involved. Failure to observe this precaution could results in bodily...

Page 6

General descriptions seite 6 / 180 precautions for emc (electromagnetic compatibility) you are required to safety the emc directive (89/336/eec) when using an v3000 inverter in a european country. To safety the emc directive and to comply with standard, follows the checklist below. : this equipment ...

Page 7

General descriptions seite 7 / 180 revision history table no . Revision contents the date of issue operation manual no. 1 initial release of manual nb611x sep. 1999 nb611x.

Page 8: Warning

General descriptions seite 8 / 180 1. Installation and wiring do not remove the rubber bush. Due to the possibility that a wire may be damaged, shorted or may have a ground fault with the edge of the wiring cover. …… p.2-1 be sure to ground the unit. Otherwise, there is a danger of electric shock an...

Page 9: Caution

General descriptions seite 9 / 180 install using non-combustible materials (metal etc.) it is a fire risk. ……… . P.2- 1 do not install combustible materials nearby. It is a fire risk. ……… . P.2- 1 do not carry unit by top cover, always carry by supporting base of unit. There is a risk of falling and...

Page 10: Caution

General descriptions seite 10 / 180 be sure to install the earth leakage circuit breaker on the inputting side. Otherwise, there is in the danger of fire. ……… . P.2- 5 be sure to use power cables, earth leakage breakers and electromagnetic contactors that are rated correctly. Otherwise, there is the...

Page 11

General descriptions seite 11 / 180 c o n t e n t s safety ...............................................................................................4 definitions and symbols ................................................................................... 4 precaution...........................

Page 12

General descriptions seite 12 / 180 setting of the output frequency...........................................................56 selection with limits of operation direction ..........................................56 selection on stop...................................................................

Page 13

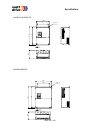

General descriptions seite 13 / 180 6.2 dimension ................................................................................. 178.

Page 14

General descriptions seite 14 / 180 1.1 inspection upon unpacking 1.1.1 inspection of the unit open the package and pick out the inverter, please check the following item. If you discover any unknown parts or the unit is in bad condition, please contact your supplier or the local watt distributor. (...

Page 15

General descriptions seite 15 / 180 1.2 question and warranty of the unit 1.2.1 request upon asking if you have any questions regarding damage to the unit, unknown parts or for general enquiries please contact your supplier or the local watt distributor with the following information. (1) inverter m...

Page 16

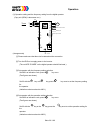

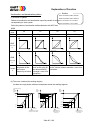

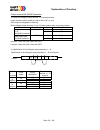

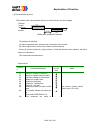

General descriptions seite 16 / 180 1.3 appearance 1.3.1 appearance and names of parts appearance from the front connector installation point of self-contained option control circuit main circuit terminals wiring blind cover front cover removed power alarm lamp digital spacer cover terminals specifi...

Page 17: Warning

Installation and wiring seite 17 / 180 2.1 installation do not remove the rubber bush. Due to the possibility that a wire may be damaged, shorted or may have a ground fault with the edge of the wiring cover. Install using non-combustible materials (metal etc.) it is a fire risk. Do not install combu...

Page 18

Installation and wiring seite 18 / 180 2.1.1 installation 1. Transportation this inverter has plastic parts. So handle with care. Do not over tighten the wall mounting fixings as the mountings may crack, causing is a risk of falling. Do not install or operate the inverter if there appears to be dama...

Page 19

Installation and wiring seite 19 / 180 5. Operating environment - air install the inverter avoiding any place that has dust, corrosive gas, explosive gas, combustible gas, mist of coolant and sea damage. 6. Mounting position mount the inverter in a vertical position using screws or bolts. The surfac...

Page 20: Warning

Installation and wiring seite 20 / 180 2.1.2 blind cover of wiring parts (1) cable entry through rubber bushes the wiring should be done after making a cut in the rubber bushes with nippers or cutters. (2) cable entry through conduit after taking out the rubber bushes, connect the conduit. Note; exc...

Page 21

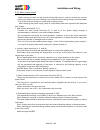

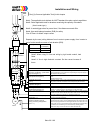

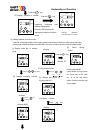

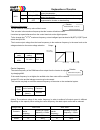

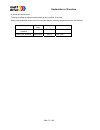

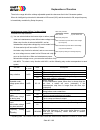

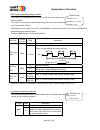

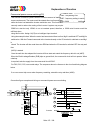

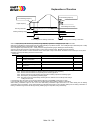

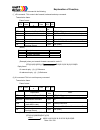

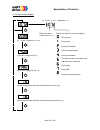

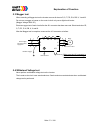

Installation and wiring seite 21 / 180 2.2.1 terminal connection diagram fm output monitor (pwm) am output monitor (analogue output) intelligent input (8 connection) ami output monitor (analogue output) power source 3 intelligent relay output connection (initial alarm) brd circuit is - 15kw d earth ...

Page 22

Installation and wiring seite 22 / 180 a nal og ue po we r s ourc e f re q u ency setti ng moni to r d ig it al (con nec ti on ) s enso r po we r s ourc e inpu t si g nal s e tti n g o per at io n/ func ti o n /s e le cti o n e tc . A nal og ue outp ut sig nal c ondi ti on/a la rm (1) explanation of...

Page 23

Installation and wiring seite 23 / 180 2.2.2 main circuit wiring (1) warning on wiring when carrying out work on the inverter wiring make sure to wait for at least ten minutes before you remove the cover. Making sure to check that the charge lamp is not illuminated. A final check should always be ma...

Page 24

Installation and wiring seite 24 / 180 5. Regenerative breaking unit connection terminals the inverters rated more than 18.5kw don’t contain a brd circuit. If regenerative braking is required an external brd circuit (option) is required along with the resistor (option). Connect external regenerative...

Page 25

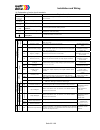

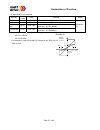

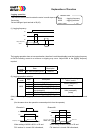

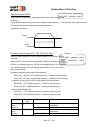

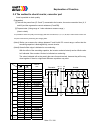

Installation and wiring seite 25 / 180 (2) wiring of main circuit terminals the wiring of main circuit terminals for inverter is the following picture. Wiring of terminals corresponding type v3000-015-037nf/ hf ro-to : m4 other : m4 v3000-055nf/hf ro-to : m4 other : m5 v3000-075nf/hf ro-to : m4 othe...

Page 26

Installation and wiring seite 26 / 180 see [(4) common applicable tools] in this chapter note1: the applicable tools indicate for watt standard four-pole squirrel-cage motor. Note2: select applicable tools for breakers examining the capacity of breakers. (use inverter type.) note3: it needs bigger w...

Page 27: Warning

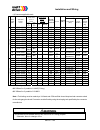

Installation and wiring seite 27 / 180 (4) common applicable tools applicable tools power lines r,s,t,u,v, w,p,pd, external resister between p and rb motor output (kw) applicable inverter model mm 2 or more awg or more mm 2 awg screw size of terminal terminal torque (nm) leak breaker (elb) circuit b...

Page 28

Installation and wiring seite 28 / 180 5) connecting power to the control circuit, separating from main power when the protection circuit of inverter is activated and the electromagnetic contactor on the input supply to the inverter isolates the power supply, the control circuit power supply from th...

Page 29

Installation and wiring seite 29 / 180 2.2.3 terminal connection diagram (1) wiring 1. Both the cm1 and l terminal is insulated to both the common terminal of the input and output signals. Do not short or earth these common terminals. 2. Use twisted screened cable, for the input and output wires of ...

Page 30

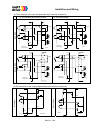

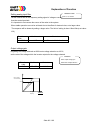

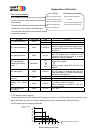

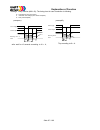

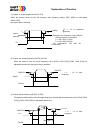

Installation and wiring seite 30 / 180 h o2 am fm th fw 8 cm1 5 3 1 14 13 11 al1 l o oi ami p24 plc cm1 7 6 4 2 15 cm2 12 alo al2 (3)change of input logic type the logic type of intelligent input terminals is sink type (factory default). To change the input logic type into source type, take off the ...

Page 31

Installation and wiring seite 31 / 180 (4) the connection to the input programmable logic controller (sequencer) to use interface power within inverter to use outside power (5) the connection to the output programmable logic controller (sequencer) (take off the short bar of control terminal.) si nk ...

Page 32

Operation seite 32 / 180 3.1 operation this inverter requires two different signals in order for the inverter to operate correctly. The inverter requires both an operation setting and a frequency setting. The following indicates the details of each method of operation and the necessary instructions ...

Page 33

Operation seite 33 / 180 (3) operation setting and frequency setting from both digital operator and terminal operator this is the method of inverter operating from both of the above two operating methods it is possible that the operation setting and the frequency setting can be selected for both the...

Page 34

Operation seite 34 / 180 3.2 test run this is the common connection example. Please refer to 4.1 digital operator, for the detailed use of the digital operator (ope-sr). (1) to input the operation setting and the frequency setting from terminal control. (arrangements) [1] please make sure that the c...

Page 35

Operation seite 35 / 180 impress voltage between [ o ] and [ l ] of terminal to start operation. [7] input ending operation setting. Turn off between [ fw ] and [ cm ] to stop slowly down..

Page 36

Operation seite 36 / 180 (2) operation setting and the frequency setting from the digital operator (copy unit (srw) is also same use.) (arrangements) [1] please make sure that there isn’t matter about the connection. [2] turn the elb on to supply power to the inverter. (the red led “power” on the di...

Page 37

Operation seite 37 / 180 [5] set the output frequency set f001 as indication code, as press the key once. (indication code of four figures is shown.) set to the desired output frequency with the key or the key, press the key once to store it. (indication code turns back to f001.) [6]set the operatio...

Page 38

Operation seite 38 / 180 when overcurrent tripping or overvoltage tripping occurs during the test run, increase the acceleration time or the deceleration time. 4.1 about digital operator (ope-s) explanation of operating the digital operator (ope-s) v3000 series operates by using the digital operator...

Page 39

Explanation of function seite 39 / 180 name contents monitor display of frequency, output current and set value lamp on run (operation) light on when the inverter is running program lamp light on when displaying set value of each function in monitor section light will flash on and off as a warning (...

Page 40

Explanation of function seite 40 / 180 2. Operating method (1) method to display monitor mode, basic setting mode, extension function mode power on [1] display of monitor contents set (display 0 00 in initial state) when power is turned off while the basic setting mode or the extension setting mode ...

Page 41

Explanation of function seite 41 / 180 monitor mode is displayed by pushing fun (function) key once when display of (display d002) push the key. 1 2 push the key. *1(3) refer to setting method of function code. 1 push the key. Push the key. 2 (19 (19 times) [3] display code no. Of basic setting mode...

Page 42

Explanation of function seite 42 / 180 (2) setting method of function change operation command part. (operatorcontrol terminal) make monitor display “a - - -“ by referring to (1) displaying method. Now operating command part is by the operator, so operating command display push the key. [2] display ...

Page 43

Explanation of function seite 43 / 180 (3) setting method of function code code no. Of monitor modes, basic setting modes and extension function codes can be set easily. Indicate the method to change code no.D001 of monitor mode to function code no. A029 simply. Operation command part displays 02(op...

Page 44

Explanation of function seite 44 / 180 ”a” blinks. The figure lighting is decided by pushing str key [3] change third figure of function code no. First figure “0” blinks. Don’t change third figure and push the str key and confirm [4] change second figure of function code no. Second figure, “0” push ...

Page 45

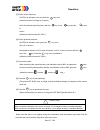

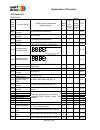

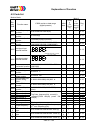

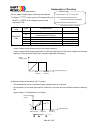

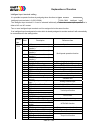

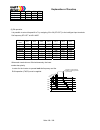

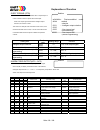

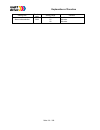

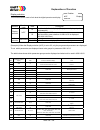

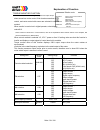

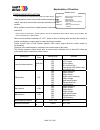

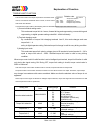

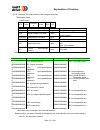

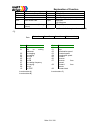

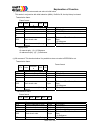

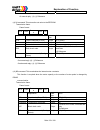

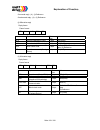

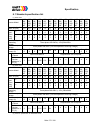

Explanation of function seite 45 / 180 4.2 code list monitor mode dis- play code function name v3000 monitor or data range (digital operator) initial data settin g on runni ng chang e mode during runnin g pag e d001 output frequency monitor 0.00-99.99/100.0-400.0(hz) - - - 4-13 d002 output current m...

Page 46

Explanation of function seite 46 / 180 f00 3 1 st deceleration time 0.01-99.99/100.0-999.9/1000. -3600. (s) 30.0 0 ü ü 4-19 f20 3 2 nd deceleration time 0.01-99.99/100.0-999.9/1000. -3600. (s) 30.0 0 ü ü 4-19 f30 3 3 rd deceleration time 0.01-99.99/100.0-999.9/1000. -3600. (s) 30.0 0 ü ü 4-19 f00 4 ...

Page 47

Explanation of function seite 47 / 180 4.2 code list monitor mode dis- play code function name v3000 monitor or data range (digital operator) initial data settin g on runni ng chang e mode during runnin g pag e d001 output frequency monitor 0.00-99.99/100.0-400.0(hz) - - - 4-13 d002 output current m...

Page 48

Explanation of function seite 48 / 180 f00 3 1 st deceleration time 0.01-99.99/100.0-999.9/1000. -3600. (s) 30.0 0 ü ü 4-19 f20 3 2 nd deceleration time 0.01-99.99/100.0-999.9/1000. -3600. (s) 30.0 0 ü ü 4-19 f30 3 3 rd deceleration time 0.01-99.99/100.0-999.9/1000. -3600. (s) 30.0 0 ü ü 4-19 f00 4 ...

Page 49

Explanation of function seite 49 / 180 4.3 explanation of function 4.3.1 monitor mode output frequency monitor indication code d001 displays the frequency the inveter outputs. The data is displayed as follows. When d001 is displayed, the monitor lamp “hz” is illuminated. (display) 0.00 - 99.99 : dis...

Page 50

Explanation of function seite 50 / 180 pid feedback monitor when you select pid function (01) in a071, the inverter displays the feedback value changed by a075 (pid scale). “ display of monitor part ” = “ feedback quantity “ x“ pid scale “ (frequency command value) (a075) (setting) a071 : 0.1(pid is...

Page 51

Explanation of function seite 51 / 180 intelligent input monitor the led display will monitor the state of the intelligent inputs. (example) fw; input intelligent terminal 7,2,1:on input intelligent terminal 8,6,5, 4, 3:off intelligent output monitor the led display will monitor the state of the int...

Page 52

Explanation of function seite 52 / 180 frequency conversion monitor this inverter displays the value changed by the inverter output frequency and the value set in b086 on the monitor part. “monitor part of display” = “ output frequency(d001)” x“ output frequency factor(b086)” (display) display of d0...

Page 53

Explanation of function seite 53 / 180 input electric power monitor display input electric power from inverter. The monitor lamp “kw” (“v” and “a”) should illuminate while the contents of d014 is displayed. (display) 0.0 – 999.9 :display is in 0.1kw unit. D014: input electric power monitor relation.

Page 54

Explanation of function seite 54 / 180 accumulated time monitor on run the operation time of inverter is accumulated and the value is displayed. (display) 0. - 9999. : display is in 1 hour units. 1000 - 9999 : display is in 10 hour units. {100 - {999 : display is in 100 hour units. Power on time mon...

Page 55

Explanation of function seite 55 / 180 the methods of trip monitor (1) trip factor (note2) (2) trip frequency (3) trip current (4) trip voltage (p-n) (5) accumulated time on run (6) power on time 1 2 (note2) in case of no tripping, is displayed..

Page 56

Explanation of function seite 56 / 180 4.3.2 function mode setting of the output frequency setting the output frequency of the motor. The output frequency is set by f001, when the frequency command select (a001) is set to 02. Please refer to the frequency command select (a001) about other methods of...

Page 57

Explanation of function seite 57 / 180 functio n code data contents (00) (setting frequency with the potentiometer the digital operator has.) (note 1) 01 setting frequency with control terminals (terminals: o-l, oi-l, o2-l) 02 setting frequency with digital operator(f001), remote operator. 03 settin...

Page 58

Explanation of function seite 58 / 180 operation command selection select the control of run/stop commands. Operation command from the control terminals (terminal) start/stop by on/off of control terminals. Forward : fw-cm1 terminal reverse : rv-cm1 terminal put 01(rv) to an intelligent input termin...

Page 59

Explanation of function seite 59 / 180 selection of stop key even though the control terminals are selected for the operation command, you can still set whether the stop key of operator (digital operator etc) is effective or not. Function code data contents 00 the stop key is effective. B087 01 the ...

Page 60

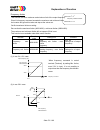

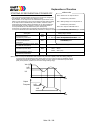

Explanation of function seite 60 / 180 adjustable time the acceleration and deceleration time can be set. Set a long time to accelerate or decelerate slowly or set a short time to accelerate or decelerate quickly. The time setting is the time it takes to accelerate from zero to the maximum frequency...

Page 61

Explanation of function seite 61 / 180 acceleration time t s t s = deceleration time t b t b = (j l + j m ) x n m 9.55 x (t s - t l ) (j l + j m ) x n m 9 55 x (t b +t l ) j l : j of the load converted into motor shaft (kg em 2 ) j m : j of the motor (kg em 2 ) n m : motor revolving (r/min) t s : th...

Page 62

Explanation of function seite 62 / 180 base frequency base frequency and motor voltage avr function (1) base frequency and motor voltage on selection of base frequency and motor voltage, set the output of the inverter (frequency voltage) to the motor rating. The base frequency is the nominal frequen...

Page 63

Explanation of function seite 63 / 180 00 always on this function is effective on acceleration, constant speed, deceleration. 01 always off this function is ineffective on acceleration, constant speed, deceleration. A081 02 on decelerating off this increases a loss of motor and reduces the energy re...

Page 64

Explanation of function seite 64 / 180 3.7kw 15 100% 15 100% 5.5kw 15 100% 15 100% 7.5kw 15 100% 15 100% 11kw 15 100% 15 100% 15kw 12 95% (below 60.8a) 15 100% 18.5kw 8 80% (below 60.8a) 15 100% 22kw 5 65% (below 61.8a) 6 80% (below 38.4%).

Page 65

Explanation of function seite 65 / 180 external analog output (0, 02, 01) this inverter has three kinds of external analog ouput terminals. O-l terminal : 0 - 10v oi-l termminal : 4 - 20ma o2-l terminal : -10 - 10v the setting contents of this function is as follows. Setting item function code data ...

Page 66

Explanation of function seite 66 / 180 output frequency start/end external analog signal from the control terminals (frequency command) o-l terminal : 0 - 10v oi-l terminal : 4 - 20ma o2-l terminal : -10 - 10v set output frequency for one of the above (1)start, end of o-l terminal, oi-l terminal set...

Page 67

Explanation of function seite 67 / 180 (2) start, end of o2-l terminal set item functio n code data contents notes o2 start a111 -400.-400. Unit : hz set starting frequency o2 end a112 -400.-400. Unit : hz set ending frequency o2 start rate a113 -100.-100. Unit : % set starting rate for output frequ...

Page 68

Explanation of function seite 68 / 180 setting analog input filter set the internal filter of the frequency setting signal of voltage or current from the control terminals it is important to first remove the source of the noise to the system. When stable operation can not be achieved due to the effe...

Page 69

Explanation of function seite 69 / 180 control system (v/f characteristic) set v/f (output voltage/output frequency) characteristic. To change 1 st /2 nd /3 rd control system (v/f characteristic), set 08(set) / 17(set3) to an intelligent input terminal and switch it on. Function code data v/f charac...

Page 70

Explanation of function seite 70 / 180 period :the limit from 0 to 10% of basic frequency is the constant characteristic. (example) if the base frequency is 60hz, the limit from 0 to 6hz is constant characteristic. Period :the limit from 10% of base frequency to base frequency is reduced torque char...

Page 71

Explanation of function seite 71 / 180 (3) free v/f setting the free v/f setting sets optional v/f characteristics by setting the voltage and frequency in seven parts.(b100-b113) the setting of free v/f setting operates always to be 7 6 5 4 3 2 1 £ £ £ £ £ £ . Please set first free v/f setting 7 bec...

Page 72

Explanation of function seite 72 / 180 avr setting voltage. Torque boost a correctly installed motor and careful attention to voltage drop in the wiring will improve the motor torque at low speed. Setting of a041/a241 will select between manual torque boost and automatic torque boost, the level of t...

Page 73

Explanation of function seite 73 / 180 (2) automatic torque boost the output voltage is adjusted automatically by the condition of the load. When using automatic torque boost it is important that the following two parameters are set correctly. Set item function code setting limit contents motor capa...

Page 74

Explanation of function seite 74 / 180 direct current braking a dc voltage can be applied to the motor windings in order to lock the motor shaft and avoid overun at low speeds. There are two methods of activating the dc braking, outside which is through the intelligent input terminals and inside whi...

Page 75

Explanation of function seite 75 / 180 (2) outside dc braking set 07(db) to an intelligent input terminal. Dc braking is then switched by on/off of db terminal irrespective of dc braking selection a051. Set strength of dc braking power with a054. If dc braking late time a053 is set, the inverter out...

Page 76

Explanation of function seite 76 / 180 (3) inside dc braking when the inverter starts, and the db terminal is not on the inverter can operate dc braking. When using inside dc braking, the dc braking selection a051 should be set 01. Starting dc braking power is set with a057, dc braking time at start...

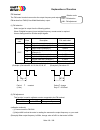

Page 77

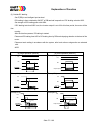

Explanation of function seite 77 / 180 (a) edge action (b) level action i) when starting (example 4-a) i) when starting (example 4-b) iii) when stopping (example 6-a) iii) when stopping (example 6-b) ii) when stopping (example 5-a) ii) when stopping (example 5-b) fw output frequency a053 free runnin...

Page 78

Explanation of function seite 78 / 180 frequency limiter this function can set a maximum and minimum limit of the output frequency. Even if a frequency command exceeds the maximum and minimum limiter the inverter will ignore this value and stop at the values set. Set first maximum limiter on setting...

Page 79

Explanation of function seite 79 / 180 when using the minimum frequency limiter and 0v is inputted into o2 terminal, a062 applies to both forward and reverse directions. (a) when operation command is control terminal (terminal)(a002:01) terminal revolution when o2 is 0v fw(on) a062 on forward side r...

Page 80

Explanation of function seite 80 / 180 frequency jump function frequency jump can be used to avoid resonance points on machinery. Frequency jump is to jump the frquency command and avoid usual operation within the limit of the jump frequency. Output frequency changes continuously according to adjust...

Page 81

Explanation of function seite 81 / 180 pid function this integrated process control function can be used for controls such as constant flow and control for fan and pump applications. When using this function set a071 to 01 or assign an intelligent input terminal to 23(pid: valid / invalid). Set item...

Page 82

Explanation of function seite 82 / 180 [3] d action this is the action that the manipulated variable is in proportion to the changing rate of command. (4) the adjustment of gain please adjust each gain according to the state as the following, when the response on the functional operation pid is not ...

Page 83

Explanation of function seite 83 / 180 automatic energy-saving operation function this function regulates the inverter output power automatically to a minimum while operating at constant speed. This fits for the load of reduced torque characteristic of fans or pumps. In case of operating by this fun...

Page 84

Explanation of function seite 84 / 180 frequency two-stage deceleration frequency a096/a296 0.00-400.0 unit: hz it is valid when two-stage acceleration and deceleration selection (a094/a294) is 01. (example2) (example1) in to set a094/a294 to 00 case (example2) in to set a094/a294 to 01 case output ...

Page 85

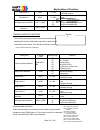

Explanation of function seite 85 / 180 acceleration and deceleration pattern (1) selection of pattern pattern of acceleration and deceleration speed is possible to set up corresponding to each system. Select the pattern of acceleration and deceleration with a097 and a098. Set value 00 01 02 03 curve...

Page 86

Explanation of function seite 86 / 180 there is the range which the midway adjustable-speed time becomes fast in the s character pattern. When an intelligent input terminal is allocated to lad cancel (lac) and the terminal is on ,output frequency is immediately controlled by setup frequency. Instant...

Page 87

Explanation of function seite 87 / 180 readings. Retry function (b001: 02): the timing chart in case of selection is following. After wait for t2 seconds according to t0 t0 t2 t1 free-run power supply inverter output revolving time of motor (example1) t0 t1 trip according to t0 > t1. Free-run power ...

Page 88

Explanation of function seite 88 / 180 (2) instantaneous power failure during stop alarm output during under-voltage select yes/no of alarm output when instantaneous power failure or under-voltage occurs with b004. Alarm outputs while control power of inverter remains. (example5) b004 : 00 (example6...

Page 89

Explanation of function seite 89 / 180 when an open phase occurs, there is a danger that the inverter could produce one of the following states; (1) ripple current of main capacitor increases, life of main capacitor shortens remarkably. (2) in case of load, there is danger that the capacitors or thy...

Page 90

Explanation of function seite 90 / 180 electrionic thermal function set the inverter according to motor rated current to protect the motor from overloading, overheating and damage. A warning signal is outputted before tripping on electronic thermal protection. (1) electronic thermal level function c...

Page 91

Explanation of function seite 91 / 180 reduced rated ratio inverter output frequency x1.0 0 60 x0.9 x0.8 5 2.5.

Page 92

Explanation of function seite 92 / 180 (3) free/thermal characteristic it is possible to set the electronic thermal characteristic freely according to the load in order to protect the motor and the inverter. Setting range is shown as follows; set item function code set range description free electro...

Page 93

Explanation of function seite 93 / 180 overload restriction (1) overload restriction the inverter monitors the motor current on acceleration and constant speed, when the inverter reaches the overload restriction level, the inverter will reduce the output frequency automatically to restrict the overl...

Page 94

Explanation of function seite 94 / 180 (2) overload advance notice when the load is high, it is possible to adjust the load again by outputting an overload advance notice. It is used to prevent damage to the machine from too much load, i.E. Baggage on a conveyor, the inverter overload protection wil...

Page 95

Explanation of function seite 95 / 180 start frequency this frequency is the value the operator must set before the inverter will give an output. Mainly used when an operator adjusts the start torque. By setting the start frequency higher, direct starting is caused and the starting current increases...

Page 96

Explanation of function seite 96 / 180 brd (regenerative breaking) function this function only operates with the v3000 - 11kw and lower, as they have the built-in brd. This function is to consume regenerative energy from the motor as heat by the use of an external resistor. Regeneration occurs when ...

Page 97

Explanation of function seite 97 / 180 intelligent input terminal setting it is possible to operate functions by assigning those functions to the intelligent input terminals 1-8 (c001-c008). The intelligent input terminals 1-8 can be selected individually whether the contact input specification is e...

Page 98

Explanation of function seite 98 / 180 43 ppi:p/pi switching p/pi switching function 44 bok: brake confirmation brake control function 45 ort: orientation option function 46 lac: lad cancel lad cancel function 47 pclr: position deviation clear 48 stat: pulse train input permission option function no...

Page 99

Explanation of function seite 99 / 180 input terminal a/b (no/nc) selection it is possible to set a contact input or b contact input to intelligent input terminals 1-8 and fw terminals individually. Set item function code data description 00 a contact(no) intelligent input 1-8 a/b(no/nc)selecti on c...

Page 100

Explanation of function seite 100 / 180 11 speed on off on on 12 speed on on off off 13 speed on on off on 14 speed on on on off 15 speed on on on on (2) bit operation it is possible to set multi-speed 0 to 7 by assigning 32 to 38 (sf1-sf7) to the intelligent input terminals. Set frequency sf1-sf7 t...

Page 101

Explanation of function seite 101 / 180 jogging operation this function can be used to rotate the motor in small steps to allow fine-tuning. Set an intelligent input terminal to 06(jg). (1) jogging frequency the jogging operation does not use acceleration, therefore it would be advisable to set the ...

Page 102

Explanation of function seite 102 / 180 second/third control function (set, set3) this control function is used when the inverter is connected to two different types of motors. By assigning 08(set)/17(set3) to an intelligent input terminal and turning set/set3 terminal on/off you can switch between ...

Page 103

Explanation of function seite 103 / 180 h034/h234:1 st / 2 nd motor j (auto-tuning) h050/h250:1 st / 2 nd pi proportion gain h051/h251:1 st / 2 nd pi integration gain h052/h252:1 st / 2 nd p proportion gain h060/h260:1 st / 2 nd zero slv limitter display during setting isn’t differentiated between t...

Page 104

Explanation of function seite 104 / 180 software lock mode selection this function is used to prevent changing data by mistake. When you want to use an intellignent input terminal, assign 15(sft). Below is the software lock code selection. Function code data sft terminal description 00 on/off write ...

Page 105

Explanation of function seite 105 / 180 free-run stop (frs) by operating the free-run stop (frs) function, the inverter output is cut off. The motor will free wheel under its own momentum. This function is used when the motor is to be stopped by the use of a brake, like an electromagnetic brake. If ...

Page 106

Explanation of function seite 106 / 180 start 0hz regardless of the motor speed. On 0hz start, the retry wait time is disregarded. When 0hz start is used and the motor speed is still high there is the possibility of over-current trips. After frs terminal is switched off, the inverter reads the frequ...

Page 107

Explanation of function seite 107 / 180 commercial power source switching(cs) this function is used for systems with an excessive amount of starting torque requirements. The motor would be started direct-on-line and then when the motor had started the inverter would take over. This function is comon...

Page 108

Explanation of function seite 108 / 180 reset (rs) this function resets the inverter when a protective trip has occurred. The method of reset is to either push the stop/reset key on the digital operator or to switch the rs terminal on. To reset the inverter with the control terminal, assign 18(rs) t...

Page 109

Explanation of function seite 109 / 180 unattended start protection (usp) the usp function is designed as a fail safe to prevent accidental starting of the inverter if the run signal is on when the power is restored to the inverter. Either resetting the inverter or turning the run signal off can cle...

Page 110

Explanation of function seite 110 / 180 up/down selection the inverter output frequency can be changed with the up and dwn intelligent input terminals. Assign 27(up) and 28(dwn) to two of the intelligent inputs 1-8. This function is valid only when the frequency command selection a001 is set to 01 o...

Page 111

Explanation of function seite 111 / 180 external trip (ext) this function can be used to force the inverter into a trip situation which is switched by an external input, i.E. Plc or relay contact. When the ext terminal is switched on, the inverter trips on an e12 error and the outputis switched off....

Page 112

Explanation of function seite 112 / 180 a044/a244/a 344 : control method c001 - c008 : intelligent input selection h005/h205 : speed response h050/h250 : pi proportion gain h051/h251 : pi integration gain h052/h252 : p proportion gain h070 : pi proportion gain for it hi a044/a244/a 344 : control met...

Page 113

Explanation of function seite 113 / 180 setting item function code setting range contents control method selection a044/a244 /a344 03 04 05 slv (a344 is not) 0 hz domain slv (a344 is not) v2 (a344) intelligent input selection c001 - c008 43 ppi : p/pi switching speed response h005/h205 0.01 - 99.99 ...

Page 114

Explanation of function seite 114 / 180 output terminal setting any of the following functions can be assigned to the intelligent output terminals (11 - 15) or the alarm relay. Both intelligent output terminals 11 - 15 and the alarm relay are all relay outputs. All three output relays can be selecte...

Page 115

Explanation of function seite 115 / 180 output terminal a/b (no/nc)selection this sets the intelligent output terminal 11-15 and alarm relay output terminal contact condition to either no or nc, (a or b). Each output is changeable individually. Both intelligent output terminals 11 and 12 and the ala...

Page 116

Explanation of function seite 116 / 180 (2) specification of the alarm relay output terminal the specifications of the alarm relay output terminal is a changeover contact. Action is as follows. Example on using as alarm state of output terminal c036 set value power source state of inverter al1-al 0 ...

Page 117

Explanation of function seite 117 / 180 signal during run (run) this function is to provide an output signal when the inverter is in a running condition. Assign 00(run: signal during run) to an intelligent output terminal 11 - 15 or the alarm relay output terminal. The signal is still outputted when...

Page 118

Explanation of function seite 118 / 180 (1) output on constant speed arrival (01:fa1) when the inverter arrives at the set frequency with frequency setting (f001, a020) or multi-speed (a021-a035), the output relay is switched. (2) output over setting frequency (02:fa2, 24:fa4) when the output is ove...

Page 119

Explanation of function seite 119 / 180 run time / power on time over (rnt/ont) when the accumulated operation time reaches or is over the setting time in b034, run time/power on time over (rnt/ont) output is switched. Function code data description b034 0. 1. -9999. 1000-6553 don’t operate. Set by ...

Page 120

Explanation of function seite 120 / 180 a044/a244 /a344 : first/second/third contro method selection c021 - c025 : intelligent output selection c055 : over torque level (forward driving) c056 : over torque level (reverse regenerating) c021 - c025 intelligent output selectio c062 alarm code selection...

Page 121

Explanation of function seite 121 / 180 setting item function code setting range contents alarm code selection c062 00 01 02 invalid 3bit code 4bit code.

Page 122

Explanation of function seite 122 / 180 fm terminal the fm control terminal can monitor the output frequency and output current. Fm terminal is a pwm (pulse width modulation) output. (1) fm selection select a signal to output from the following options. When 03(digital frequency) is set a digital fr...

Page 123

Explanation of function seite 123 / 180 am terminal, ami terminal the am terminal and the ami terminal can monitor the output frequency or the output current. The am terminal has an analog output of 0-10v. The ami terminal has an analog output of 4-20ma. (1) am, ami selection select a signal to outp...

Page 124

Explanation of function seite 124 / 180 thermistor error level b099 0. -9999. Units:ohm set the resistance value of temperature for trip according to thermistor methods. Thermistor adjustment c085 0.0-1000. Use this as gain adjustment..

Page 125

Explanation of function seite 125 / 180 initialization setting it is possible at any time to reinitialize the inverter parameters back to their factory default. The trip history can also be cleared at any time, however, if problems occur it will be difficult to fault find without the trip history fo...

Page 126

Explanation of function seite 126 / 180 display selection this function can be used to limit what the digital operator can display. Set item function code data description 01 function individual display (display, no display by item set)(example1) display selection b037 02 user setting and b037 only ...

Page 127

Explanation of function seite 127 / 180 21 01, 02 h020-h024 / h220-h224 motor constant 22 h002/h202 00 h030-h034 / h230-h234 motor constant (auto-tunning).

Page 128

Explanation of function seite 128 / 180 stabilized factor when the motor is hunting or unstable, this function can be adjusted to help stabilize the motor. When the motor is unstable, check the allowable motor selection (h003/h203) and motor pole selection (h004/h204) with your motor. If their code ...

Page 129

Explanation of function seite 129 / 180 fazzy most suitable acceleration and deceleration fazzy acceleration and deceleration function eliminates setting of acceleration and deceleration time in using inverter. Inverter acceleration time should be set every time before, but this function applies the...

Page 130

Explanation of function seite 130 / 180 braking control function this is a function that the inverter controls external braking used in systems like elevators. By braking control function selection(b120) is set to valid(01), this function is performed as the following below. (1) when running command...

Page 131

Explanation of function seite 131 / 180 when braking control function is used, if necessary, assign the following functions to intelligent input / output terminals. When signal outputted from external braking during releasing braking is inputted to intverter, one of intelligent output terminals (c00...

Page 132

Explanation of function seite 132 / 180 stopping of deceleration at power off this is a function that decelerates and stops not to exceed over voltage level (ov-ladstop : 052) after power turns off during running. When selection of non-stop function at instanteneaous power failure is valid (b050), i...

Page 133

Explanation of function seite 133 / 180 offline autotuning function this is a function for measuring and automatically setting the motor circuit constant necessary for the sensorless vector control and 0hz domain sensorless vector control. When the sensorless vector control and the 0hz domain sensor...

Page 134

Explanation of function seite 134 / 180 precautions (1) fit motor base frequency (a003/a203) and motor voltage selection (a082) to the specification of the motor measued. (2) motor capacity to be measured is one frame or less maximum applicable motors. If not within this range, correct constant is n...

Page 135

Explanation of function seite 135 / 180 moter constant selection motor constant used in sensorless vector control and 0hz domain sensorless vector control can be selected from the following the three. (1) watt general purpose motor constant (2) motor constant measured in offline autotuning (3) optio...

Page 136

Explanation of function seite 136 / 180 online autotuning function online autotuning can revise the motor constant by increase of temperature, and stabilize running. Setting item function code setting range contents motor constant selection h002/h202 00 01 02 watt general purpose motor data autotuni...

Page 137

Explanation of function seite 137 / 180 a001 frequency commanding method a044 control method f001 output frequency setting b040 selection of torque limit b041-b044 torque limit of 4zone h002 h202 selection of first, second motor constant h003 h203 selection of first, second motor capacity h004 h204 ...

Page 138

Explanation of function seite 138 / 180 a001 : frequency command selection a044 : control method f001 : frequency command setting b040 : torque limit selection b041-b044 : 4zone torque limit h002/h202 : first / second motor constant selection h003/h203 : first / second motor capacity selection h004/...

Page 139

Explanation of function seite 139 / 180 a044/a244 first / second control method c027 fm selection c028 am selection c029 am`selection h003/h203 first / second motor capacity selection h004/h204 first / second motor pole selection torque monitor function this is a function for monitoring motor presum...

Page 140

Explanation of function seite 140 / 180 a044/a244 : first / second control method b040 : torque limit selection b041 - b044 : torque limit 1 - 4 c001 - c008 : intelligent input selection c021 - c025 : intelligent output selection torque limit function this function limits motor output torque when se...

Page 141

Explanation of function seite 141 / 180 a044/a244/a344 control method b040 torque limit selection b041 ^b044 4 zone torque limit b045 torque ladstop selection setting item function code setting range contents control method selection a044/a244/a34 4 00 01 02 03 04 05 vc vp 1.7power vf free setting s...

Page 142

Explanation of function seite 142 / 180 torque limit 4 b044 0 - 200 unit : %(forward regenerating in4 zone individual setting torque ladstop selection b045 00 01 valid invalid intelligent input selection c001 - c008 40 41 42 torque control valid / invalid torque limit switching 1 torque limit switch...

Page 143

Explanation of function seite 143 / 180 a044/a244 first / second control method c027 fm selection c028 am selection c029 am`selection h003/h203 first / second motor capacity selection h004/h204 first / second motor pole selection torque monitor function this is a function for monitoring motor presum...

Page 144

Explanation of function seite 144 / 180 a044/a244 : first / second control method b040 : torque limit selection b041 - b044 : torque limit 1 - 4 c001 - c008 : intelligent input selection c021 - c025 : intelligent output selection torque limit function this function limits motor output torque when se...

Page 145

Explanation of function seite 145 / 180 a044/a244/a344 control method b040 torque limit selection b041 ^b044 4 zone torque limit b045 torque ladstop selection torque limit 3 b043 0 - 200 unit : %(reverse driving in 4 zone individual setting torque limit 4 b044 0 - 200 unit : %(forward regenerating i...

Page 146

Explanation of function seite 146 / 180 (1) communication specification use tm2 of control terminal pcb for rs485 communication function. Item specification notes transmission speed 2400/4800/9600/19200 bps selection with operator communication methods half duplex communication methods synchronizing...

Page 147

Explanation of function seite 147 / 180 connect each inverter in parallel as shown below. It is necessary to short terminals rp and sn on the last inverter in the link (even if communication is to only one inverter the link should still be made). By shorting between rp and sn, the terminal resistanc...

Page 148

Explanation of function seite 148 / 180 (3) communication protocol the method of the communication protocol is shown below in the time diagram. The following is indicated. (1):frame transmitted from external control machines to the inverter (2):frame replied from inverter to the external control mac...

Page 149

Explanation of function seite 149 / 180 explanation of each command is the following. ( i ) 00 command : this controls the forward, backward and stop command. Transmission frame frame format explanation data size value stx control code (start of text) 2 byte stx (0x02) code station number of inverte...

Page 150

Explanation of function seite 150 / 180 note) the data is 100 times as big as set value. Example) 5(hz) 500 000500 30 30 30 35 30 30 reply frame on normal reply : (4) - (i) reference on abnormal reply : (4) - (ii) reference ascii.

Page 151

Explanation of function seite 151 / 180 (iii) 02 command: this sets the state of the intelligent terminals. Transmission frame frame format (note3) data (sixteenth) of intelligent terminal and contents (the details refer to intelligent input terminal function.) example) when you make (forward), (mul...

Page 153

Explanation of function seite 153 / 180 (note4) each monitor value (note5) intelligent input terminal monitor (note6) intelligent output terminal monitor (v) 04 command: this reads the state of the inverter. Transmission frame frame format explanation data size value stx control code(start of text) ...

Page 154

Explanation of function seite 154 / 180 explanation data size value stx control code(start of text) 1 byte stx (0x02) code station number of inverter 2 byte 01-32 data data on trip 8 byte (note7) reference bcc block check code 2 byte exclusive or of code, command and data (5) reference cr control co...

Page 155

Explanation of function seite 155 / 180 code status 00 on stopping 01 on running 02 on tripping (vi) 05 command: this reads trip history data. Transmission frame frame format replay frame frame format: (note8) the monitor data (trip history) on trip memorizes the last six errors with an accumulated ...

Page 156

Explanation of function seite 156 / 180 (vii) 06 command: this reads 1 set item. Transmission frame frame format explanation data size value stx control code(start of text) 1 byte stx (0x02) code station number of inverter 2 byte 01-32 comman d transmission command 2 byte 06 paramete r parameter num...

Page 157

Explanation of function seite 157 / 180 comman d transmission command 2 byte 07 paramete r parameter number of data 4 byte (note9) data data of parameter (tenth ascii code) 8 byte (note10) bcc block check code 2 byte exclusive or of code, command and data (5) reference cr control code(carriage retur...

Page 158

Explanation of function seite 158 / 180 (ix) 08 command: this returns each set value to initial value. This works in conjunction with initial selection (b084). If b084 is 00, the trip history is cleared. Transmission frame frame format explanation data size value stx control code(start of text) 1 by...

Page 159

Explanation of function seite 159 / 180 return) on normal reply : (4) - (i) reference (xi) 0a command: this stores the set value to the eeprom. Transmission frame frame format explanation data size value stx control code(start of text) 1 byte stx (0x02) code station number of inverter 2 byte 01-32 c...

Page 160

Explanation of function seite 160 / 180 reply frame on normal reply : (4) - (i) reference on abnormal reply : (4) - (ii) reference (i) affirmative reply reply frame frame format explanation data size value stx control code(start of text) 1 byte stx (0x02) code station number of inverter 2 byte 01-32...

Page 161

Explanation of function seite 161 / 180 (note11) error code list inverter doesn’t reply on all code communication. Error code contents 01h parity error 02h sum check error 03h framing error 04h overrun error 05h protocol error 06h ascii code error 07h reception buffer overrun error 08h reception tim...

Page 162

Explanation of function seite 162 / 180 (5) about the calculation method of bcc (the block check cord) (example) 5hz is set up by using 01 commands (the setting of the frequency command). (when the code of the inverter of the object is ‘01' ) bcc is the result that transforms the code ^data into asc...

Page 163

Explanation of function seite 163 / 180 (6) communication test mode the communication test mode checks the communication line of rs485. The communication test mode procedure 1. Please remove the wiring of terminal unit tm2 of the control terminal unit foundation, to do the loop back check. 2. Please...

Page 164

Explanation of function seite 164 / 180 4.4 protection function list 4.4.1 protection function name description display of digital panel e digital operator display of remote operator/ copy unit err1*** at constant speed oc. Drive on deceleration speed oc. Decel on acceleration speed oc. Accel over-c...

Page 165

Explanation of function seite 165 / 180 name description display of digital panel e digital operator display of remote operator/ copy unit err1*** abnormal brake when inverter cannot detect switching of the brake(on/ff) after releasing the brake ,and for waiting for signal condition(b124) (when the ...

Page 166

Explanation of function seite 166 / 180 4.4.2 trip monitor display (1) factor of trip, explanation of (2) output frequency on trip. (3) output current on trip (a) (4) dc link voltage on trip. (v) (5) accumulated time that the inverter has been running. (hr) (6) accumulated time that the inverter has...

Page 167

Explanation of function seite 167 / 180 4.4.3 warning monitor display warning messages will appear when the data set is contradicting to others. Program lamp (prg) turns on during the warning (until the data is changed). Below is the description of the warnings. Warning codes basic code 001/ 201 fre...

Page 168

Explanation of function seite 168 / 180 free electronic thermal frequency 1, 2 b015, b017 > free electronic thermal frequency 3 b019 warning is cleared when the setting fulfils the above condition. Data will be changed automatically to the basic code. (note 1)the jump frequency will be automatically...

Page 169

Explanation of function seite 169 / 180 5.1 precautions for maintenance/inspection 5.1.1 daily inspection every day before operation check the following; [1] does the motor operate according to the settings? [2] is there any trouble with the surroundings of the installation? [3] is there any trouble...

Page 170

Explanation of function seite 170 / 180 5.2 daily inspection and regular inspection inspection cycle regular inspec-ti on parts inspection item inspection item inspection methods decision standard meter surroundings check temperature of surrounding, humidity, dust. Refer to 2.1 installing. Temperatu...

Page 171

Explanation of function seite 171 / 180 5.3 megger test when executing a megger test on the inverter remove all wires to r, s, t, pd, p, n, rb, u, v and w. Do not use a megger or buzzer on the control circuit only use a digital multi-meter. (megger voltage 500v dc) execute megger test of main circui...

Page 172

Explanation of function seite 172 / 180 5.5 the method to check inverter, converter part a test is possible to check quality. (preparation) [1] take out the power lines (r, s and t) connected to the inverter, the motor connection lines (u, v and w) and the regenerative control resistance (p and rb)....

Page 173

Explanation of function seite 173 / 180 rb n no-conduct n rb no-conduct.

Page 174

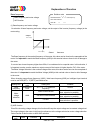

Explanation of function seite 174 / 180 5.6 capacitor life curve (note1) ambient temperature means the surrounding temperature of the inverter. In case the inverter is installed in a cabinet, ambient temperature is the temperature of the internal air of the cabinet. (note2) dc bus capacitors are rec...

Page 175

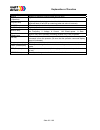

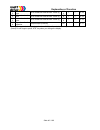

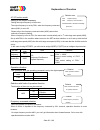

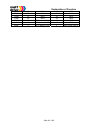

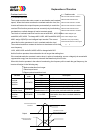

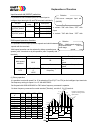

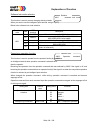

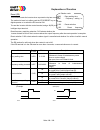

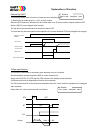

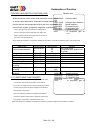

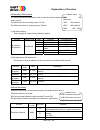

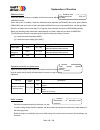

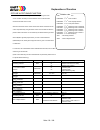

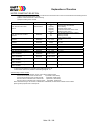

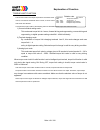

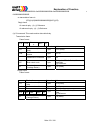

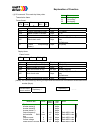

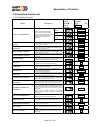

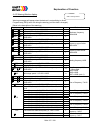

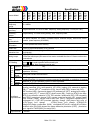

Specification seite 175 / 180 6.1 standard specification list (1) 200v class inverter model v30 00- 015 nf v30 00- 022 nf v30 00- 037 nf v30 00- 055 nf v30 00- 075 nf v30 00- 110 nf v30 00- 150 nf v30 00- 185 nf v30 00- 220 nf v30 00- 300 nf v30 00- 370 nf v30 00- 450 nf v30 00- 550 nf max. Applicad...

Page 176

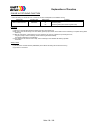

Specification seite 176 / 180 inverter model v30 00- 015 nf/ hf v30 00- 022 nf/ hf v30 00- 037 nf/ hf v30 00- 055 nf/ hf v30 00- 075 nf/ hf v30 00- 110 nf/ hf v30 00- 150 nf/ hf v30 00- 185 nf/ hf v30 00- 220 nf/ hf v30 00- 300 nf/ hf v30 00- 370 nf/ hf v30 00- 450 nf/ hf v30 00- 550 nf/ hf control ...

Page 177

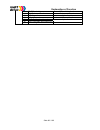

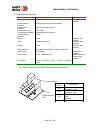

Specification seite 177 / 180 intelligent output terminal signal during run(run), frequency arrival type 1 signal(fa1) frequency arrival type 2 signal (fa2) overload advance notice signal(ol)output deviation for pid control(od) alarm signal(al) arrival signal for only setting frequency(fa3),over tor...

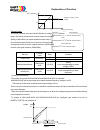

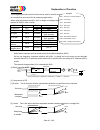

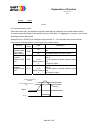

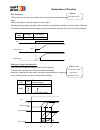

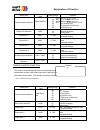

Page 178

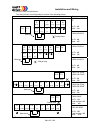

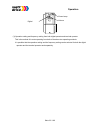

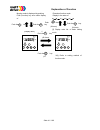

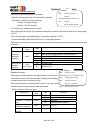

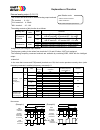

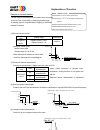

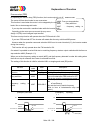

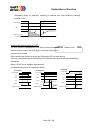

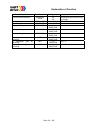

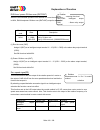

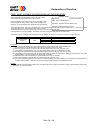

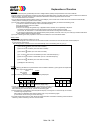

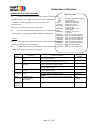

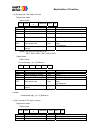

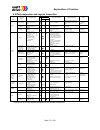

Specification seite 178 / 180 6.2 dimension ûv3000-015^055nf/hf ûv3000-075011nf/hf 15 2- ö 25 24 6 13 14 14 69 2- ö 26 24 18 7 20 17 89 7.

Page 179

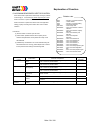

Specification seite 179 / 180 ûv3000-150^220nf/hf ûv3000-300nf/hf 2- ö 31 26 54 51 10 19 25 22 2- ö 39 37 7 22 9. 24 19 92.

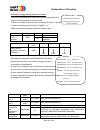

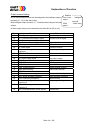

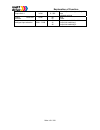

Page 180

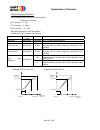

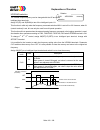

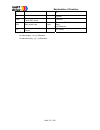

Specification seite 180 / 180 ûv3000-370450nf/hf ûv3000-550nf/hf 25 55 52 10 39 30 2- ö 25 70 67 12 48 38 2- ö.