- DL manuals

- Wayne

- Dispenser

- 3/VISTA series

- Service Manual

Wayne 3/VISTA series Service Manual

Summary of 3/VISTA series

Page 1

Se r v ic e 3/vista series blending and non-blending dispensers.

Page 2

Read this manual before you begin dispensers have both electricity and a hazardous, flammable and potentially explosive liquid. Failure to follow the below precautions and the warning and caution instructions in this manual may result in serious injury. Follow all rules, codes and laws that apply to...

Page 3: Service

June 2001 part no. 920525 rev a 3/vista series blending and non-blending dispensers service.

Page 4

Part no. 920525 rev a june 2001.

Page 5

1 june 2001 part no. 920525 rev a 1. Introduction this manual describes the service of wayne vista series blending and non-blending dispensers that have a "3" in the prefix of the model number. For example, 3/v390d1/gquy. Again, these dispensers can be iden- tified by their model which begins with “...

Page 6

2 part no. 920525 rev a june 2001 1.1. Regional service offices any service problems that cannot be solved should be refered to wayne technical support or to the appropriate regional service office. Wayne technical support 1-800-926-3737 austin, tx 24 hours/7 days northeast regional 410-546-6750 ser...

Page 7

3 june 2001 part no. 920525 rev a 2. Operation the operation for all 3/vista series dispensers is similar , except where distinguished below between lift-to-start and push-to-start models. Before the dispenser will reset unit prices must be set and an authorization signal must be received, and if a ...

Page 8

4 part no. 920525 rev a june 2001 • the computer performs a self test and flashes eights, blanks, then resets to zeros, on the main sale display. • after the dispenser resets, the proportional flow control valve (or valves if a blender model) is energized with just enough current to barely open the ...

Page 9

5 june 2001 part no. 920525 rev a at this point, pressing of next will advance the sub-function to the next sub-function, incrementing the value of n by (.01). For example, to access f3.02, press next. The unit price display will show 3.02, press next. The desired sub-function depends on the dispens...

Page 10

6 part no. 920525 rev a june 2001 2.4. Blend ratio setting function f18 is accessed to set the blend ratios, using the remote control interface. The sub-function f18.1n, where n is the logical nozzle number, is used to set the blend ratios for side 1 and the sub-function f18.2n is used to set the bl...

Page 11

7 june 2001 part no. 920525 rev a changing the value of the blend ratio 8. When the desired logical nozzle is shown on the unit price display, enter the desired value of the blend ratio by using up and down keys on the remote control interface or by typing the # sign followed by the value of the ble...

Page 12

8 part no. 920525 rev a june 2001 saving the new fpid 1. Press enter. The price display will show “– – – – – –“, the volume display will be blank and the unit price display will show the last sub-function accessed. 2. Press 00 (to access f00) 3. Press enter. The unit price should now display f00, th...

Page 13

9 june 2001 part no. 920525 rev a 3. Board layouts, indicators and pinouts.

Page 14

10 part no. 920525 rev a june 2001 3.1 computer board led indicators) processor activity indicator ds1: red (heartbeat) led indicates processor activity. It will be blinking on and off at a steady rate as long as the processor is running properly. Power indicators these leds only indicate the presen...

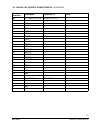

Page 15

11 june 2001 part no. 920525 rev a 3.2 computer board connector pinouts connector and pin # description connects to note j1 24 vdc in 24v dc distribution bd j4 typical reading 24v 1 24v 2 24v 3 gnd 4 gnd j2 sub pump relays relay board j1 typical readings 24v 1 24 vdc 2 pump motor 2 3 24 vdc 4 pump m...

Page 16

12 part no. 920525 rev a june 2001 3.2 computer board connector pinouts, continued connector and pin # description connects to note j4 nozzle switch inputs isb j7 typical reading 5v 1 gnd 2 nozz 4 3 gnd 4 nozz 3 5 gnd 6 nozz 2 7 gnd 8 nozz 1 9 gnd 10 nozz 8 11 gnd 12 nozz 7 13 gnd 14 nozz 6 15 gnd 1...

Page 17

13 june 2001 part no. 920525 rev a 3.2 computer board connector pinouts, continued connector and pin # description connects to note j6 totalizers from side1 outputs from tots 1-4 1 24v 2 tot 1 3 24v 4 tot 2 5 24v 6 tot 3 7 24v 8 tot 4 9 n/c 10 n/c j7 totalizers from side2 outputs from tots 5-8 1 24v...

Page 18

14 part no. 920525 rev a june 2001 j13 can bus i/o future use for harmony, evista, ovation 1 tx/rc + 2 tx/rc - 3 24v 4 gnd j14 euro datalink not used in us j15 display data cable bit bus side a (1) side 1 display j1 1 data in a 2 data out a 3 address bit a 4 clock a 5 buzzer a 6 stop a 7 8 vdc typ r...

Page 19

15 june 2001 part no. 920525 rev a 3.2 computer board connector pinouts, continued connector and pin # description connects to note j22 buzzer power side 1 1 8v 2 buzzer 1 j23 cat buzzer 1 gnd 2 buzz cat j24 wayne vac wayne vac bd j2 1 vac connected (yes/no) 2 freezing temp thermostat 3 wayne vac id...

Page 20

16 part no. 920525 rev a june 2001 3.3 isb board connector pinouts connector and pin # description connects to note j1 wip pulsers 1-4 computer j5 1 power 1 15v 2 gnd 3 rc 1 4 tx 1 5 gnd 6 rc 2 7 tx 2 8 gnd 9 gnd 10 rc 3 11 tx 3 12 gnd 13 rc 4 14 tx 4 15 gnd 16 power 2 15v j2 to pulser 1 1 tx 2 rc 3...

Page 21

17 june 2001 part no. 920525 rev a 3.3 isb board connector pinouts, continued connector and pin # description connects to note j4 to pulser 3 1 tx 2 rc 3 gnd 4 15v 5 n/c 6 n/c 7 n/c 8 n/c j5 to pulser 4 1 tx 2 rc 3 gnd 4 15v 5 n/c 6 n/c 7 n/c 8 n/c j7 nozz switch outputs computer j4 typ 5v 1 noz 1 2...

Page 22

18 part no. 920525 rev a june 2001 j6 nozz switch inputs nozzles 1 noz 1 2 noz 2 3 noz 3 4 noz 4 5 gnd 6 noz 5 7 noz 6 8 noz 7 9 noz 8 10 gnd.

Page 23

19 june 2001 part no. 920525 rev a 3.4 24v dc distribution board connector pinouts connector and pin # description connects to note j1 24v p/s j2 1 24v in 2 24v in 3 gdn 4 gdn j2 battery external 1 24v 2 24v 3 gdn 4 gdn j3 24v out wayne vac board j6 1 24v out 2 24v out 3 gdn 4 gdn j4 24v computer j1...

Page 24

20 part no. 920525 rev a june 2001 3.5 wayne vac control board pinouts connector and pin # description connects to note j1 is isb connection 1 5v 2 gnd 3 5v 4 5 5v 6 n/c 7 n/c 8 n/c 9 5v 10 gnd j7 vac motor a vac motor a 1 5v 2 5v 3 5v 4 5v 5 gnd 6 v motor 7 sw 24v 8 phase a 9 phase b 10 phase c j8 ...

Page 25

21 june 2001 part no. 920525 rev a 3.5 wayne vac control board pinouts, continued connector and pin # description connects to note j2 to computer j24 computer j24 pin 1 gnd 2 clock 3 gnd 4 reset 5 dir b 6 run b 7 dir a 8 run a 9 stat a0 10 stat a1 11 speed a 12 orvr a 13 stat b0 14 stat b1 15 speed ...

Page 26

22 part no. 920525 rev a june 2001 3.6 display board connector pinouts, continued 3.7 relay board connector pinouts 3.8 24v power supply board connector pinouts connector and pin # description connects to note j1 computer j15/j16 j15 side1 j16 side 2 j2 preset control bd j2 (optional) j3 pts buttons...

Page 27

23 june 2001 part no. 920525 rev a fi g ure 3- 1 . Co mputer bo ar d..

Page 28

24 part no. 920525 rev a june 2001 fi gure 3 -2. I s b bo ard assy ..

Page 29

25 june 2001 part no. 920525 rev a fi gu re 3- 3. Rela y bo ard ..

Page 30

26 pa rt n o . 920 525 r ev a jun e 200 1 figure 3-4. 24volt dist board..

Page 31

27 june 200 1 p art n o . 9 205 25 re v a figure 3-5. Wayne vac control board..

Page 32

28 part no. 920525 rev a june 2001 fi gure 3- 6. Du al ca t bo ard ..

Page 33

29 june 2001 part no. 920525 rev a.

Page 34

30 part no. 920525 rev a june 2001.

Page 35

31 june 2001 part no. 920525 rev a 4. Mechanical parts 4.1. Nozzle boot (proximity “reed” switch style boot) the nozzle boot assembly, used on the dispenser models covered in this manual, uses a proximity “reed” switch and magnet for on/off dispenser activation. The nozzle boot can be assembled in e...

Page 36

32 part no. 920525 rev a june 2001.

Page 37

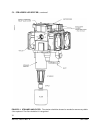

33 june 2001 part no. 920525 rev a 5. Hydraulic parts the following section describes the operation of those hydraulic parts in wayne dispensers which perform some “act”. Simple flow tubes will not be discussed. There are four basic hydraulic parts in the dispenser: • strainer and filter • proportio...

Page 38

34 part no. 920525 rev a june 2001 5.1. Strainer and filter , continued figure 5-1. Strainer and filter. The strainer should be cleaned as needed to remove any debris it has captured. The filter should be ul recognized..

Page 39

35 june 2001 part no. 920525 rev a 5.2. Proportional flow control valve the proportional flow control valve (see figure 5-2) is a pilot-operated, diaphragm sole- noid valve. It has three main functions in the dispenser: • positive shutoff • blend ratio control • flow rate regulation located between ...

Page 40

36 part no. 920525 rev a june 2001 5.3. Proportional flow control valve continued the pilot operated proportional solenoid valve performs three basic functions in the dispenser. It provides positive shutoff, regulates the ratio of blended feedstocks, and controls the flow rate through the hydraulic ...

Page 41

37 june 2001 part no. 920525 rev a 5.2.3. Flow control valve “on” full regulated flow flow control valve “on” full regulated flow occurs during the main portion of all sales. At this time, the coil is energized with bursts of current of longer duration, pulling the pilot further off it’s seat, relie...

Page 42

38 part no. 920525 rev a june 2001 5.3. Imeter , continued figure 5-3. Imeter cutaway. The magnetic disk affixed to the top of the meter valve is rotated by the meter crank shaft. As the disk rotates, the pulser converts the changing magnetic field into digital pulses..

Page 43

39 june 2001 part no. 920525 rev a 5.4. Double bump tubing on 3/vista dispensers, double bump product tubing is used between the imeter outlet, proportional valve, and hose outlet casting. The double bump connection eliminates the need to torque the compression fit- tings that were used on the flare...

Page 44

40 part no. 920525 rev a june 2001.

Page 45

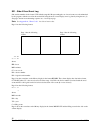

41 june 2001 part no. 920525 rev a 6. Programming functions and statistics the maintenance mode is used to access the functions and statistics in the 3/vista computer. Service technicians can access the maintenance mode by using the infrared remote (ir) remote control or by running the service termi...

Page 46

42 part no. 920525 rev a june 2001 the volume display window shows the current transaction count for side b. To view specific statistics, enter the statistic number and press enter. The statistic number appears in the unit price display. Figure 7-2 lists a quick step procedure on accessing the maint...

Page 47

43 june 2001 part no. 920525 rev a 6.2 sub entry level when you enter the sub entry level, the unit price display shows the function/statistic number in the two left-most digits and the sub level number in the two right-most digits separated with a decimal point. The f or s no longer appear. The fol...

Page 48

44 part no. 920525 rev a june 2001 f01 - filling modes sub-function numbers are in the format .0x where x = the selected configuration parameters defined as follows: .00 filling mode, 1 through 4 1 = serial mode, dispenser controlled by site controller via serial link 2 = stand alone mode, dispenser...

Page 49

45 june 2001 part no. 920525 rev a .06 manufacturing default for intelligent pulser .07 stop button configuration 1 = stop both sides 2 = stop side f08- side a dispenser type configuration part #1 sub-function numbers are in the format: .Xn where x = the selected configuration parameters and n = the...

Page 50

46 part no. 920525 rev a june 2001 sub-function numbers are in the format: .Xn where x = the selected configuration parameters and n = the logical nozzle number 1-8. .0n octane number assignment, 00-99, 00 = none assigned .1n product select button input number assignment, 0-8, 0 = none assigned .2n ...

Page 51

47 june 2001 part no. 920525 rev a .06 suppress display of leading zeros in normal mode 1 = yes 2 = no .07 totals and totalizers amount display digits right of the decimal point, 0-4 .08 totals and totalizers volume display digits right of the decimal point, 0-4 f15 - dispenser annunciator configura...

Page 52

48 part no. 920525 rev a june 2001 .08 maximum volume amount/filling, 1-6 digits f18 - blend ratio configuration sub-function numbers are in the format: sn where s = the side number (1=a, 2=b) and n = the logical nozzle number 1-8. Sn. Blend ratio (the allowed range for data is 0-101, where 101 = di...

Page 53

49 june 2001 part no. 920525 rev a 1 = on at end of display test 2 = on at start of display test 3 = on at product selection .01 lock on filling mode configuration 1 = access to filling mode configuration restricted 2 = access allowed. .02 standalone indication enabled (show four digits right of dec...

Page 54

50 part no. 920525 rev a june 2001 1 = calculate the closest volume from the money and the unit price but show the preset money amount at the end of sale as long as the sale hasn’t reached the maximum overrun volume. 2 = calculate a volume amount that will ensure a money amount that is greater than ...

Page 55

51 june 2001 part no. 920525 rev a f25 - local preset by button configuration sub-function numbers are in the format .0x where x = the selected configuration parameters defined as follows: .00 preset button #1 operation mode 1 = money 2 = volume .01 preset button #2 operation mode 1 = money 2 = volu...

Page 56

52 part no. 920525 rev a june 2001 .2n maximum fast flow rate, 3-48 (units of gallons/min.) .3n minimum fast flow rate, 03-48 (units of gallons/min.), 0 = no minimum n logical nozzle f32 - side b gallon flow rate configuration .0n maximum slow flow rate, 1-10 (units of 1/10 gallons/min.) .1n minimum...

Page 57

53 june 2001 part no. 920525 rev a f35 - side a wayne vac a/l calibration data this function provides a way to calibrate the wayne vac a/l ratio. There is an adder and a multiplier that can be used to change the ratio. The adder has more effect at the low flow rates (lower rpms) and the multiplier h...

Page 58

54 part no. 920525 rev a june 2001 f96 - upload flash memory programming this function requires the service terminal, not the remote control. This function has no subfunctions. Press enter to transmit the flash program data. The service terminal program requests a filename to upload the data to. Sel...

Page 59

55 june 2001 part no. 920525 rev a when the download is complete, the software executes a warm start which is just like a power cycle. If the laptop is still connected and the laptop program is still running, the computer will re-enter maintenance mode prompting for the passwords to be entered. At t...

Page 60

56 part no. 920525 rev a june 2001 s04 - side b error/event counter totals the money display is in the form of dashes and sub-statistic displays on the unit price display in the range 1-99 representing the set of error/events detectable by the program. The allowed range for the counter value is 0-25...

Page 61

57 june 2001 part no. 920525 rev a the money display shows dashes and the volume display shows the statistic data. The unit price display shows the statistic and sub-statistic numbers in the format 13.Xx where .Xx is in the range 0-99 representing the set of error/ events detectable by the program. ...

Page 62

58 part no. 920525 rev a june 2001 s21 - side a error/event log sub-statistic numbers in the format ’.Xx’ with the range 01-50 representing the set of error/events records maintained by the program, with the record in sub-statistic 01 being the most recent. Display error log data by using the two (2...

Page 63

59 june 2001 part no. 920525 rev a s22 - side b error/event log sub-statistic numbers in the format ’.Xx’ with the range 01-50 representing the set of error/events records maintained by the program, with the record in sub-statistic 01 being the most recent view statistic data on the two (2) data ’pa...

Page 64

60 part no. 920525 rev a june 2001 s25 - total number of power cycles the money display is blank and the power cycle counter value appears on the volume display. Sub-statistic numbers are displayed in the format ’0x’ where x = the selected configuration parameter defined as follows: 0. Number of pow...

Page 65

61 june 2001 part no. 920525 rev a l the money display contains the current counter value showing how many times this products blend ratio has changed. L the volume display contains the current blend ratio if you press one of the following keys while you are in this mode, the corresponding action oc...

Page 66

62 part no. 920525 rev a june 2001 l liters liters volume unit l us gal u.S. Gallons volume unit l ip gal imperial gallons volume unit if you press one of the following keys while in this mode, the corresponding action happens: clear the system exits the weights and measures mode. Enter the system e...

Page 67

63 june 2001 part no. 920525 rev a 7. Troubleshooting guide warning electric shock hazard! Some of the following corrective actions in this section may require the electrical power to the equip- ment be on. Use wiring diagrams, connector drawings and other information in this manual to iden- tify th...

Page 68

64 part no. 920525 rev a june 2001 table 6-1. Error codes and solutions error code description probable cause corrective action 1 flash program crc error corrupt flash program area bootstrap & re-flash program or replace computer base 2 flash template crc error corrupt or incompatible flash template...

Page 69

65 june 2001 part no. 920525 rev a 21 reserved 22 reserved 23 reserved 24 reserved 25 sale cannot start - zero unit price unit price not set set unit price 26 sale cannot start - no unit price downloaded pos has not set a unit price set unit price on pos 27 sale cannot start - unit price changed – f...

Page 70

66 part no. 920525 rev a june 2001 45 reserved 46 vapor recovery motor turning wrong direction defective wayne vac motor or cables defective wayne vac control board replace replace 47 illegal sensor states from vapor recovery sys defective wayne vac motor or cables defective wayne vac control board ...

Page 71

67 june 2001 part no. 920525 rev a 67 pulser calibration ok bit status changed pulser has been calibrated 68 pulser calibration door status changed pulser cal door was opened or closed 69 pulser last calibration status changed pulser last calibration successful. 70 timeout limit reached for no flow ...

Page 72

68 part no. 920525 rev a june 2001 see board layouts in section 9 for for identification and location of connector assignments and led indicators. Table 6-2 symptoms and solutions symptom probable cause corrective action sale and unit price displays are out 1 no ac power to dispenser check control p...

Page 73

69 june 2001 part no. 920525 rev a table 6-2 symptoms and solutions, continued symptom probable cause corrective action unit price displays read 0.000 1 control system unit price set at 0.000. Set correct unit price in control system. 2 unit price not set at dispenser. If a control system is con- ne...

Page 74

70 part no. 920525 rev a june 2001.

Page 75

71 june 2001 part no. 920525 rev a 8. Procedures for uploading and downloading files.

Page 76

72 part no. 920525 rev a june 2001 figure 8-1. Service terminal screens that appear on the laptop..

Page 77

73 june 2001 part no. 920525 rev a 1. If this process is now interrupted for any reason, the bootstrap procedure then must be used to download to dispenser. 2. After briefly displaying “download complete”, the laptop will display “enter password” assuming you may want to proceed to other functions, ...

Page 78

74 part no. 920525 rev a june 2001 the bootstrap procedure listed below must be performed if: 1) after selecting filename or template in function 98 or 99, the process of downloading to the pump computer is interrupted, or 2) a pump computer is installed that does not have pump software code already...

Page 79

Written by s. G. Martin this manual was produced using adobe® framemaker® on a power macintosh® 8100/80. Page design uses times 12 and helvetica 10 fonts. Manuals were electronically produced on a xerox docutech 135 publishing system at 600 dpi. Art was produced using aldus® freehand® and adobe® pho...

Page 80

Copyright © 2001 dresser, inc. All rights reserved. Printed in the united states of america. Framemaker® is a trademark of frame technology. Power macintosh® is a trademark of apple computer, inc. Adobe® photoshop® is a trademark of adobe systems, inc. This manual and the software described within a...

Page 81

Warranty and limitation of remedy and liability seller warrants that new products and parts of its own design and manufacture when shipped, will be of good quality and will be free from defects in material and workmanship and will conform to applicable specifications. Work, when performed by seller,...

Page 82

"note: this equipment has been tested and found to comply with the limits for a class a digital device, pursuant to part 15 of the fcc rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a com- mercial environment. This equ...