Wayne Classicdrive 3014 Owner Installation And User Manual - Installation Instructions

11

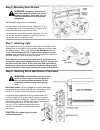

Step 1: Attaching Motor Power Head Unit to Rail

Before assembly, align sprocket/coupling cogs to match notches

of driver gear. Rotate the Motor Spline to position Driver Gear so

that the nearest notch in Driver Gear is directly behind Motor

Spline, as illustrated. Note: Do not rotate more than ½ turn.

Place opposite end of rail on temporary support approximately 6”

in height.

Proceed to attach rail to motor Power

Head Unit making sure that pre-

alignment allows proper engagement

between sprocket/coupling cog and

driver gear notches. Realign as

necessary, making sure to keep any

rotation only to the nearest notch. Using

four (4) supplied 1/4”-20 x 5/8” hex head

bolts, assemble Motor Power Head Unit

to rails with a 3/8” socket. Tighten

securely.

Do not plug the opener power cord into electrical outlet until fully installed and instructed to do so in

this manual. Door springs, pulleys and cables are under extreme tension and can cause severe injury.

Do not attempt to adjust or repair. Call a professional door service company.

Do not wear rings, watches or loose clothing when installing or servicing a garage door system. Use a

sturdy, non-metallic step ladder. Remove all ropes or cords attached to the garage door. Failure to do

so may result in personal injury due to entanglement. Disable all existing locking devices on the garage

door, by securing lock/latch to inside face of door with suitable screw.

Install only on a properly balanced garage door. An improperly balanced door could cause severe

injury. Have a qualified service person make repairs to cables, spring assemblies and other hardware

before installing opener.

READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS

Step 2: Positioning and Installing Front Wall Bracket

WARNING:

Do not attempt to loosen or remove any portion of door spring system in order to rein-

force header wall or to mount wall bracket. If these are necessary, call a professional garage door ser-

vice person.

Note: it is recommended that the door opener be installed 7 feet or more above the door.

REINFORCE THE HEADER WALL

Reinforce the header wall (wall above door opening) as

required, to ensure rigid mounting of the front wall bracket.

Locate the vertical center line of the garage door and mark it

on the header above the door and on the top rail of the door.

Raise the door slightly until the top rail reaches the highest

point of travel (see illustration); using a carpenter’s level,

transfer and mark the highest point of travel on the header

wall.

Mount the front wall bracket with its lower edge

approximately 1/2” (room permitting) above the mark show-

ing the highest point of travel centered on the vertical center

line. Mark the two mounting holes and pre-drill with a 3/16”

drill. Mount wall bracket using the lag screws supplied (1/4” x

1-1/2”) to ensure rigid mounting.