- DL manuals

- Wayne-Dalton

- Garage Door Opener

- Confort

- Installation, User Operation & Maintenance Manual

Wayne-Dalton Confort Installation, User Operation & Maintenance Manual

NOTE: THIS NOTES MANUAL MUST BE ACCOMPANIED BY THE DRAWINGS MANUAL, PART NR. 324627.

© Copyright 2005 Wayne-Dalton Corp.

Part Nr. 324628 - ENGLISH NEW

11/10/2005

Notes Manual of Installation, Use, and Maintenance

In Between Jambs With Integrated Operator I-Drive™

Models: Wayne-Dalton Optimal, Wayne-Dalton Confort,

Wayne-Dalton Diffusion, Wayne-Dalton Prestige+/40mm/Pinnacle

Wayne-Dalton Europe

1 Rue Maurice Hollande

51100 Reims, France

www.waynedaltoneurope.com

NOTICE : THIS PRODUCT IS TO BE USED ONLY ON A SINGLE HOUSEHOLD DOMESTIC DOOR

Summary of Confort

Page 1

Note: this notes manual must be accompanied by the drawings manual, part nr. 324627. © copyright 2005 wayne-dalton corp. Part nr. 324628 - english new 11/10/2005 notes manual of installation, use, and maintenance in between jambs with integrated operator i-drive™ models: wayne-dalton optimal, wayne-...

Page 2: Table of Contents

2 table of contents notes of installation, use, and maintenance definition of symbols ..................................................................................................................................................................3. Important safety instructions for installation .....

Page 3: Definition of Symbols

3 definition of symbols warning attention - risk of injury warning it is vital for the safety of persons to follow all instructions. Save these instructions. 1. Read and follow all installation instructions. 2. Wear eye protection when using tools to install, repair or adjust door or opener, to prev...

Page 4: Opener Specifications

4 opener specifications input voltage ................................................................................................... 230 vac, 50hz, single phase max. Pull force ................................................................................................ 533 n power ............

Page 5: Package Contents

5 note: use these notes of installation, use, and maintenance in conjunction with the drawings of installation, use, and maintenance to perform the installation. The following letters & numbers in parenthesis, [example: (a1)] cross reference items listed in each diagram of the drawings of installati...

Page 6: Installation

6 installation important: stainless steel lag screws or pt2000 coated lag screws must be used when installing center bearing brackets, end bearing brackets, jamb brackets, operator mounting / support brackets and disconnect brackets on treated lumber (preservative-treated). Stainless steel or pt2000...

Page 7: Spreader Bar Pre-Mounting

7 3 spreader bar pre-mounting (see diagram 3 on page 5 of drawings of installation, use and maintenance manual) tools needed: 11mm (7/16”) wrench screw driver (flat head) attach the “l” bracket (a4.3) to the right side of the slider bar (a4.2) with one ø6x15mm (1/4” - 20 x 9/16”) track bolt (a6) and...

Page 8: Testing - Continued

8 4 back hanging horizontal track and spreader bar and manual door testing - continued (see diagram 4 on page 5 of drawings of installation, use and maintenance manual) tools needed: electric drill (with clutch) 5mm (3/16”) drill bit 11mm (7/16”) wrench tape measure screw driver (flat head) step lad...

Page 9: Electrical Connections

9 7 light fixture installation (if supplied, according to the model) (see diagram 7 on page 7 of drawings of installation, use and maintenance manual) tools needed: none select a lamp socket, preferably located on the ceiling and within 2m of the opener. If none is available, have one installed by a...

Page 10

10 9 wall station security code change and programming - continued (see diagram 9 on page 8 of drawings of installation, use and maintenance manual) tools needed: none testing the new wall station’s security code: - maintain pressure on the open / close button (2d) for several seconds. - the red led...

Page 11: Performing Install Routine

11 10 transmitter security code change and programming - continued (see diagram 10 on page 9 of drawings of installation, use and maintenance manual) tools needed: none note: the opener can be activated by up to six remote control devices (including wall station and keyless entry controls). If a sev...

Page 12: Tests

12 12 detent pin adjustment - continued (see diagram 12 on page 9 of drawings of installation, use and maintenance manual) tools needed: screw driver (flat head) a.) if the motor does not pivot down, or pivots down only partially, the detent pin (2g) is set too hard. Using a flat head screwdriver, t...

Page 13: Warning

13 important safety instructions for use warning it is vital for the safety of persons to follow all instructions. 1. Read and follow all instructions. 2. Never let children operate or play with door controls. Keep remote controls away from children. 3. Watch the moving door and keep people, and obj...

Page 14: Warning

14 wall station operation (if supplied). Wall station operation momentarily pressing up/down button (2d) activates the door. If a small out-of-balance condition causes door to stop while opening or reverse while closing, apply constant pressure to up/down button until door is fully opened or fully c...

Page 15: Warning

15 manual door operation - emergency disconnect (see diagram 16 on page 11 of drawings of installation, use and maintenance manual) warning the emergency disconnect should only be used when door is closed. Possible unexpected movement of the door could occur with door not fully closed. The opener is...

Page 16: Dismantle and Discardment

16 monthly maintenance - continued spring tension: to check spring tension: open the door halfway. The springs should hold the door in this position. Should the door slide down or raise on its own, contact a authorized, qualified door system service representative to adjust the spring tension. Fixin...

Page 17: Warning

17 spring adjustment (if required) (see diagram 18 on page 11 of drawings of installation, use and maintenance manual) note: the counterbalances system is pre-set at the factory, due to different materials and application a small adjustment may be needed. Warning counterbalance system and cables are...

Page 18

18 maintenance / painting instructions for pre-painted doors maintenance while factory-applied finishes on steel garage doors are durable, it is desirable to clean them on a routine basis. Some discoloration of the finish may occur when a door has been exposed to dirt-laden atmosphere for a period o...

Page 19: Control Board Wiring Diagram

19 control board wiring diagram available accessories light fixture, screw-in model no: 3940-cess part no: 295522 keyless entry rf transmitter model no: kep2-b433 part no: 298393 5 button wall station rf transmitter model no: 5bws-433 part no: 294394 3-button mini rf transmitter model no: 3btm-433 p...

Page 20: Troubleshooting

20 troubleshooting symptom probable cause corrective action opener does not respond to wall station or transmitter no power to opener controls not programmed check opener power cord to outlet connection see programming section opener works from wall station but not from transmitter transmitter is no...

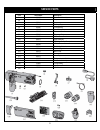

Page 21: Service Parts

21 service parts item part number description c1 296925 power head assembly c2 292358 bumper c3 296219 jumper c4 292403 finishing plug c5 293285 thrust bearing c6 305368 handle bracket c7 292382 disconnect handle c8 293286 disconnect cable c9 296976 3,048 m power cord c10 296412 roller assembly c11 ...

Page 22: Limited Warranty

22 wayne-dalton optimal, wayne-dalton confort, wayne-dalton diffusion, wayne-dalton prestige+/40mm/pinnacle, and i-drive opener system limited warranty 1. The manufacturer (wayne-dalton europe) warrants the above model steel garage door sections for a period of ten years from the time of installatio...

Page 23

23 manufacturer’s declaration of conformity garage door models: wayne-dalton optimal, wayne-dalton confort, wayne- dalton diffusion, wayne-dalton prestige+/40mm/pinnacle is in conformity to the applicable sections of door standards en 292, en 294, en 349, en 418, pren894, en 1037, en 1088, en 12424,...