Burne sc80 electr installat regulati all loca incorrec and coul a qualif the equi codes an b er model rical powe tion of the ons of the l codes and ct installa ld result in ied installe pment and w nd ordinanc burner is light wayne co 801 fort www.Wa r supply – 12 man note: d in burner mus national ...

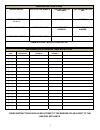

2 these instructions should be affixed to the burner or adjacent to the heating appliance. Installation log burner model: specification number: fuel (natural or propane): gas orifice drilled size: inlet gas pressure (in. W.C.): co 2 (%): o 2 (%): co (ppm): installer’s name: contractor name: contract...

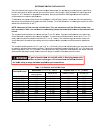

F for yo vapo what t open do no do no extin imme supp if you sprea elec high vo equipment use on fault in do not turn o read t c ur saft rs and l o do if yo n windows ot try to lig ot touch e nguish any ediately ca plier’s instr u cannot re ader adjustm ctric sh oltages a t. Follow t electri nly a p...

4 contents section i: installation and setup………………………………………………................................……….………......5 a. Installation of mounting flange ……………………………………………………….….................................5 b. Determine orifice size and rate …………………………………………………………….…............................6 c. Chang...

This natur maki burne not adjus posit appli note the fl inser manual is a g ral gas or lp ng the sc80 er is supplied e: the burne stment and re tion the moun ance allows t the orientatio ange. Tighten rt the burner t guide for the i fired burner c as simple an as a comple er must be ins epairs. Ntin...

As com for leak once the burners co burners o orifices siz to determ the prope drilled wit note: nu been pro bit size. The corre should be mbar) and should be range. The corre be made maximum pressure a btu/hr( 20,0 25,0 30,0 35,00 40,00 45,00 50,00 55,00 60,00 65,00 70,00 75,00 80,00 mbustion ch ks...

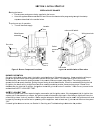

Not show 1) tu 2) th 3) di depe 4) mu exam there of 10 impo whe to in size. Befo nuts e: the btu/hr wn. To determ urn off all othe he hand with t vide 3,600 by ending on size ultiply the num mple: time efore 50 x 2 is 07,500 btu/hr ortant: the the valve n leaving the ncrease the b to determine re re...

Pull t the o to dr lining and s man not the b the gas train o orifice with a 9 rill the orifice, g up the drill b secure the ga ual. E: numbered burner is now out of the bur 9/16” wrench place it face bit easier. Deb as pipe train to d and lettered w ready to be rner. The orific (figure 3). Down in ...

All pi sedim upstr plugg conn in the the g and l be du alum male it is r build other be be the g freez not b from mbar valve gaug 2 impe threa ping must co ment trap or d ream from the ged tapping p ection for the e gas supply gas line shou ocated so tha urable, substa minum tubing s e threads only ...

10 table 2: pipe sizing chart for natural gas (0-0.5 psi) with straight schedule 40 metal pipe the following chart is based on 0-0.5 psi inlet pressure, specific gravity of 0.6 , and a pressure loss of 0.5” w.C.. Maximum capacity of pipe size in btu per hour length of pipe (ft) 1/2” 3/4” 1” 1 1/4” 1...

11 table 4: pipe sizing chart for liquid propane (11” w.C.) with copper tubing the following chart is based on 11” w.C. Inlet pressure and a pressure drop of 0.5” w.C. Maximum capacity of tube size in btu per hour pipe size 1/2” 5/8” 3/4” 7/8” length (feet) maximum capacity in btu/hr 10 110,000 206,...

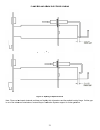

T‐t jumpe warm air hot water or vapor b dangerou t terminal er wire furnaces (gra r boilers (force boilers should sly low. Inspe avity and force ed or gravity) d be provided ction of l ed air) should should be eq with means t figure 7: t-t connect line voltage 12 imit contr d be equipped quipped wit...

The s gas v sc80 natur mode press the h the l same requi sepa energ conn be co sc80 low/hi valve marked 0 low/high m ral and propa e. Low fire mo sure required high rate requ low/high sc e as the stand ires a separat arate thermost gized which is ected to the h onnected to th gh model ope “lo hi” ne...

S t bur on e purge simu spark for ig detec sectio safe the t expir contr be re “on” if nor gas v starting the bu ensur have seque to put burner turn o figure 9: rner opera every call for h e, the ignition ultaneously, th k at the burne gnition, the bu cted after the on titled saf ety lock-o trial fo...

Air s to ad open shutt for n co s for p and c stack the lo up in once durin conta all adjustm 1. Draft g 2. O 2 or c shutter adjust djust the air s nings. Increas ter adjustmen natural gas ap should be min propane gas a co should be k temperature ock nut to sec formation and e adjustments ng setup, ...

16 section iii: gas conversion natural gas and lp conversion instructions in order to allow sc80 burners to be converted from natural gas to lp gas operation, or from lp to natural gas operation, wayne combustion systems has created gas conversion kits that contain all the parts necessary for any bu...

17 section v: service and troubleshooting normal operation check of burner 1. Appliance calls for heat by raising the thermostat to the desired setting. Note the transformer is always energized with 120 volts. 2. When the thermostat circuit is complete, this allows 24 volts to coil side of the fan r...

18 preliminary checks, diagnosis and service hints although the following tests can be made using standard volt meter, it is quicker and more convenient to use a fenwal model 05-125539-001 test adapters. 1. Input polarity if a spark is present and the gas valve opens for the flame establishing perio...

19 once the flame is established, assure that the flame current is above the minimum specified. If not, assure that the system has the proper input voltage. During service, a scale may build up on the flame sensing rod, which may also reduce flame current readings. Do not use liquids to clean. Use s...

20 more service hints thermostat calls for heat and the following conditions occur: 1. Problem: the combustion fan motor is not operating. Possible reasons: a. Power is not on. B. Circuit breaker tripped. C. Thermostat in the off position. D. Thermostat connections to t-t terminals on junction box h...

Note is ou : flame rod a t of the tolera and spark elec ances noted a flame r fig f ctrode positio above, contac rod and sp gure 12: spac figure 13: spa ons are fixed b ct wayne com 21 park elect cing of flame s acing of spark by their dimen mbustion syst trode spac sensor rod k electrode nsions and...

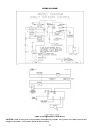

Cau dang tion: label gerous operat all wires prior tion. Verify pro figu r to disconnec oper operatio wirin ure 14: wiring ction when se on after servic 22 ng diagram g diagram for ervicing contro cing. Ms sc80 burner ols. Wiring errrors can caus se improper aand.

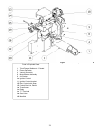

F s igure 15: rig ection vi ght side exp i: parts l expl loded view o 23 list and e loded view of sc80 exploded ws 1. Tu 2. Fl 4. Ve 8. M 9. Ai 10. Ig 11. Ig 12. Bo 13. Co 14. Tr 15. Re 16. T- 18. Ga 19. M d views parts in exp ube/flange w ame spreade enturi assem otor/blower a ir shutter nition con...

1. 2. 4. 8. 9. 10 11 12 13 14 15 16 18 19 parts in tube/flang flame spre venturi ass motor/blow air shutter 0. Ignition con . Ignition con 2. Box, contro 3. Control box 4. Transforme 5. Relay 6. T-t termin 8. Gas valve 9. Manifold exploded vie ge weldment eader sembly wer assembly ntrol ntrol bracke...

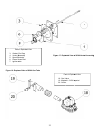

Figu re 18: explod parts 3. Gasket, 4. Venturi a 5. Spark el 6. Flame s 7. Ignition w ded view of s in exploded end cap assembly ectrode ense rod wire sc80 gas tr view rain 25 figu ure 17: explo pa 18. Gas v 19. Manif 20. Orifice oded view o arts in explod valve fold – sc80 s e of sc80 ventu ded vie...

Par 12. Box, c 13. Contro 14. Transfo 15. Relay 16. T-t te rts in explode control with st ol box lid, pla ormer erminal ed view trap ated 26 figure 19: e exploded vieew of sc80 jjunction box x.

27 sc80 parts list orifice chart *drill out in the field from a smaller sized orifice or a blank orifice (p/n 62815-000). Item part no. Description qty 1 64504‐001 tube/flange weldment – painted 1 2 63622‐001 flame spreader 1 3 63620‐001 gasket, end cap 1 4 63693‐001 venturi assembly 1 5 63696‐001 s...

Wa wa for tha wo (36 bu wa ma gre wa co qu lic pr su of acc an def rep 1. 2. 3. Ayne com arrants to tho resale or fo at its burner orkmanship un 6) months fro urners man arranted for anufacture ex eater warranty arranties overed by ualified, c censed wh revail, and uch install the nationa cordance w...

N 29 notes.