- DL manuals

- Weather-Rite

- Air Handlers

- TT Series

- Installation, Operation & Service Manual

Weather-Rite TT Series Installation, Operation & Service Manual - Warning

TT-S

ERIES

I

NSTALLATION

, O

PERATION

AND

S

ERVICE

M

ANUAL

10 of 198

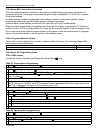

SECTION 3: CRITICAL CONSIDERATIONS

3.1 Required Clearances to Combustibles

Clearances are the required distances that

combustible objects must be away from the air

handler to prevent fire hazards. Combustibles are

materials that may catch on fire and include common

items such as wood, paper, rubber, fabric, etc.

Maintain clearances to combustibles at all times

for safety.

Check the clearances on each air handler being

installed to make sure the product is suitable for your

application and the clearances are maintained.

Minimum clearances for all models are as follows:

• 18" (45.7 cm) Above the top of the equipment

• 18" (45.7 cm) Along the sides of the equipment

• 18" (45.7 cm) Under the floor of the equipment

(when suspended)

Read and follow the safety guidelines below:

• Locate the air handler so that the air intakes are

not too close to any exhaust fan outlets (refer to

applicable codes for minimum distance to exhaust

fan outlets), gasoline storage, propane tanks or

other contaminants that could potentially cause

dangerous situations.

• Keep gasolines or other combustible materials

including flammable objects, liquids, dust or

vapors away from this air handler or any other

appliance.

• Maintain clearances from heat sensitive material,

equipment and workstations.

Clearances to combustibles do not denote

clearances for accessibility. Minimum clearance

for access is 48" (122 cm). Minimum clearance for

accessibility applies to the control enclosure,

blower access panel and filter access panel

(when equipped).

The stated clearances to combustibles represent

a surface temperature of 90 °F (50 °C) above

room temperature (90 °F [50 °C] plus ambient

temperature). Building materials with a low heat

tolerance (i.e. plastics, vinyl siding, canvas, tri-ply,

etc.) may be subject to degradation at lower

temperatures. It is the installer's responsibility to

assure that adjacent materials are protected from

degradation. Maintain clearances from heat

sensitive material, equipment and work stations.

• Maintain clearances from vehicles parked below

the air handler.

See Page 11, Section 4.4.

3.2 Purge of Supply Duct

If this heating unit is to be installed indoors, and its

outdoor air supply ducted from outdoors, ANSI

Standards Z83.4/CSA 3.7, Z83.18 and Z83.25/CSA

3.19 require that all supply duct shall be purged a

minimum of four times prior to any ignition attempt. If

the volume of the outdoor air supply duct exceeds

the heating unit's ability to complete the required four

air changes prior to ignition, you must contact the

factory to purchase an extended purge card of the

appropriate duration to meet this requirement.

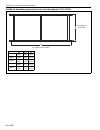

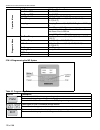

3.3 Hardware

Unless otherwise specified, all hardware must be

torqued to settings from

Page 10, Table 1.

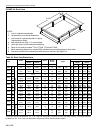

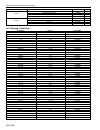

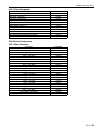

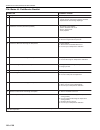

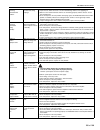

Table 1: Recommended Torque Settings

WARNING

Fire Hazard

Keep all flammable objects, liquids and

vapors the minimum required clearances to

combustibles away from equipment.

Some objects will catch fire or explode when

placed close to equipment.

Failure to follow these instructions can result

in death, injury or property damage.

Bolt Head

Grade Marking

Nut Grade

Marking

Bolt Size

Grade 2

Grade 5

10-24

27 in•lb

42 in•lb

1/4-20

65 in•lb

101 in•lb

5/16-18

11 ft•lb

17 ft•lb

3/8-16

19 ft•lb

30 ft•lb

Summary of TT Series

Page 1

Not for residential use weather-rite llc 1100 seven mile road nw comstock park, mi 49321 telephone: +1.612.338.1401 fax: +1.616.784.0435 toll free: 800.589.3691 www.Weather-rite.Com warning installation must be done by a registered installer/ contractor qualified in the installation and service of g...

Page 3: Attention

Conçus pour les applications non-résidentielles weather-rite llc 1100 seven mile road nw comstock park, mi 49321 téléphone: +1.612.338.1401 fax: +1.616.784.0435 numéro sans fraís: 800.589.3691 www.Weather-rite.Com attention linstallation doit être effectuée par un installateur éprouvé/contractant q...

Page 5

© 2017 weather-rite llc all rights reserved. No part of this work covered by the copyrights herein may be reproduced or copied in any form or by any means - graphic, electronic, or mechanical, including photocopying, recording, taping or information storage and retrieval systems - without the writte...

Page 6

Section 25: maintenance ................................................. 133 25.1 general .................................................................. 134 25.2 unit exterior ........................................................... 134 25.3 blower section ......................................

Page 7

Section 1: a ir h andler s afety 1 of 198 section 1: air handler safety your safety is important to us! This symbol is used throughout the manual to notify you of possible fire, electrical or burn hazards. Please pay special attention when reading and following the warnings in these sections. Instal...

Page 8

Tt-s eries i nstallation , o peration and s ervice m anual 2 of 198 1.3 safety labels and their placement product safety signs or labels should be replaced by product user if they are no longer legible. Please contact weather-rite llc or your weather-rite ™ independent distributor to obtain replacem...

Page 9

Section 1: a ir h andler s afety 3 of 198 figure 2: tt224-tt236 horizontal figure 3: tt112- 221 upright 13 12 11 7 1 3 6 2 4 5 10 8 9 item part number description 1 91070002 danger - severe injury 2 ref logo 3 91070001 danger - electric shock 4 91070004 warning - fire 5 91070006 warning - burn 6 910...

Page 10

Tt-s eries i nstallation , o peration and s ervice m anual 4 of 198 figure 4: tt224-tt236 upright 7 1 6 3 2 10 10 9 8 11 4 5 12 13 item part number description 1 91070002 danger - severe injury 2 ref logo 3 91070001 danger - electric shock 4 91070004 warning - fire 5 91070006 warning - burn 6 910700...

Page 11

Section 1: a ir h andler s afety 5 of 198 figure 5: tt118 upright figure 6: tt118 horizontal 7 1 10 9 8 11 2 1 3 6 4 5 12 13 item part number description 1 91070002 danger - severe injury 2 ref logo 3 91070001 danger - electric shock 4 91070004 warning - fire 5 91070006 warning - burn 6 91070005 war...

Page 12

Tt-s eries i nstallation , o peration and s ervice m anual 6 of 198 figure 7: 2" npt or smaller gas train control panel interior figure 8: 2.5" npt or larger gas train control panel interior exterior interior 22 21 3 2 6 23 24 10 item part number description 3 91070001 danger - electric shock 6 9107...

Page 13

Section 1: a ir h andler s afety 7 of 198 figure 9: remote panel figure 10: aux control panel item part number description 3 91070001 danger - electric shock 20a 91070032 danger - electric shock 20b 910700033 danger - electric shock item part number description 3 91070001 danger - electric shock 20a...

Page 14: Warning

Tt-s eries i nstallation , o peration and s ervice m anual 8 of 198 section 2: installer responsibility the installer is responsible for the following: • to install and commission the air handler, as well as the gas and electrical supplies, in accordance with applicable specifications and codes. Wea...

Page 15

Section 2: i nstaller r esponsibility 9 of 198 • pipe wrenches sized appropriately for the gas train components • drill motor and various drills • u-tube manometer or magnehelic ® gauge (0 to 1.0" w.C.) • u-tube manometer or gas pressure gauge (0 to 5# and 0 to 30" w.C.) • volt meter • clamp style a...

Page 16: Warning

Tt-s eries i nstallation , o peration and s ervice m anual 10 of 198 section 3: critical considerations 3.1 required clearances to combustibles clearances are the required distances that combustible objects must be away from the air handler to prevent fire hazards. Combustibles are materials that ma...

Page 17

Section 4: n ational s tandards and a pplicable c odes 11 of 198 section 4: national standards and applicable codes all appliances must be installed in accordance with the latest revision of the applicable standards and national codes. This also refers to the electric, gas and venting installation. ...

Page 18

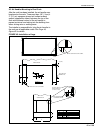

Tt-s eries i nstallation , o peration and s ervice m anual 12 of 198 section 5: specifications dimension and estimated weight tables apply to both upright and horizontal air handlers of the same model. The maximum total static pressure is listed by model in page 24, table 27. To calculate the availa...

Page 19

Section 5: s pecifications 13 of 198 figure 12: upright model dimensions (models tt112 and tt115) table 5: estimated shipping weights (models tt112 and tt115) table 6: estimated shipping weights - motors side view n end view e b l sd ra n h ad1 ad2 p n v f c g k d t s r d a x w s v m ce j y sd ra td...

Page 20

Tt-s eries i nstallation , o peration and s ervice m anual 14 of 198 figure 13: horizontal model dimensions (model tt118) table 7: cabinet dimensions (model tt118) table 8: filters (permanent, polyester, or pleated) ce bb y v t n u p q r k n u s n k m p x l ad2 j ad1 ad1 ad1 h g f e d c a b ee s dd ...

Page 21

Section 5: s pecifications 15 of 198 figure 14: upright model dimensions (model tt118) table 9: estimated shipping weights (models tt118) table 10: estimated shipping weights - motors n k r v t p u u q k n n m p x l g ce n y side view end view j h dd f b a c e d ad1 ad1 ad1 sd ra ad1 ad1 ra sd td oa...

Page 22

Tt-s eries i nstallation , o peration and s ervice m anual 16 of 198 figure 15: horizontal model dimensions (models tt212 - tt221) table 11: cabinet dimensions (models tt212 - tt221) table 12: filters (permanent, polyester or pleated) model a b c d e f g h j k l m n p q r s t u* v w x y z aa bb tt21...

Page 23

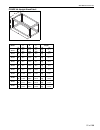

Section 5: s pecifications 17 of 198 figure 16: upright model dimensions (models tt212 and tt221) table 13: estimated shipping weights (models tt212 - tt221) table 14: estimated shipping weights - motors model burner/ blower section filter section inlet hood weatherizing roof curb legs stand service...

Page 24

Tt-s eries i nstallation , o peration and s ervice m anual 18 of 198 figure 17: horizontal model dimensions (models tt224 and tt230) table 15: cabinet dimensions (models tt224 and tt230) table 16: filters (permanent, polyester or pleated) model a b c d e f g h j k l m n p q r s t u v w x y z* tt224 ...

Page 25

Section 5: s pecifications 19 of 198 figure 18: upright model dimensions (models tt224 - tt230) table 17: estimated shipping weights (models tt224 - tt230) table 18: estimated shipping weights - motors model burner/ blower section filter section inlet hood weatherizing discharge/ inlet damper roof c...

Page 26

Tt-s eries i nstallation , o peration and s ervice m anual 20 of 198 figure 19: non-recirculating horizontal model dimensions (models tt233 and tt236) table 19: cabinet dimensions (models tt233 and tt236) table 20: filters (permanent, polyester or pleated) model a b c d e f g h j k l m n p q r s v w...

Page 27

Section 5: s pecifications 21 of 198 figure 20: non-recirculating upright model dimensions (models tt233 and tt236) table 21: estimated shipping weights (models tt233 and tt236) table 22: estimated shipping weights - motors w ce ad2 ad2 ad1 v d p b l a a k c q h r g m f g g f j h sd side view end vi...

Page 28

Tt-s eries i nstallation , o peration and s ervice m anual 22 of 198 figure 21: recirculating horizontal model dimensions (models tt-233 and tt-236) table 23: cabinet dimensions (models tt233 and tt236) table 24: filters (permanent, polyester or pleated) model a b c d e f g h j k l m n p q r s t u v...

Page 29

Section 5: s pecifications 23 of 198 figure 22: recirculating upright model dimensions (models tt233 and tt236) table 25: estimated shipping weights (models tt233 and tt236) table 26: estimated shipping weights - motors w ce ad2 ad2 ad1 v f p j z a b l a k c g x n u t h q s r e h h e m x ra sd side ...

Page 30

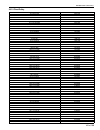

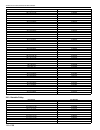

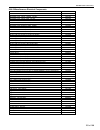

Tt-s eries i nstallation , o peration and s ervice m anual 24 of 198 table 27: blower motor horsepower selection mode l tt1 1 2 airflow cfm m 3 /h outlet velocity fpm m/s percent- age of capacity total static pressure .50 in wc / 1.25 mbar .75 in wc / 1.87 mbar 1.00 in wc / 2.49 mbar 1.25 in wc / 3....

Page 31

Section 5: s pecifications 25 of 198 mode l tt 21 5 airflow cfm m 3 /h outlet velocity fpm m/s percent- age of capacity total static pressure .50 in wc / 1.25 mbar .75 in wc / 1.87 mbar 1.00 in wc / 2.49 mbar 1.25 in wc / 3.11 mbar 1.50 in wc / 3.74 mbar 1.75 in wc / 4.36 mbar 2.00 in wc / 4.98 mbar...

Page 32

Tt-s eries i nstallation , o peration and s ervice m anual 26 of 198 mo del t t 230 airflow cfm m 3 /h outlet velocity fpm m/s percent- age of capacity total static pressure .50 in wc / 1.25 mbar .75 in wc / 1.87 mbar 1.00 in wc / 2.49 mbar 1.25 in wc / 3.11 mbar 1.50 in wc / 3.74 mbar 1.75 in wc / ...

Page 33: Warning

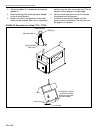

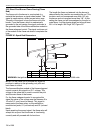

Section 6: l ifting an a ir h andler 27 of 198 section 6: lifting an air handler the air handler must be installed in compliance with all applicable codes. The qualified installer or service technician must use best building practices when installing the air handler and any optional equipment. This ...

Page 34

Tt-s eries i nstallation , o peration and s ervice m anual 28 of 198 3. The hook labeled #1 is attached to the eyebolt labeled #1. 4. Remove the lag bolts attaching the air handler to the skid and discard. 5. Begin to lift slowly; readjustment of the offset chain may be required. After unit is suspe...

Page 35

Section 6: l ifting an a ir h andler 29 of 198 6.1.3 lifting an upright air handler lift the air handler into place using all four 0.75" (1.9 cm) diameter lifting lugs on the unit base. Use spreader bars to ensure that the lifting cables clear the sides of the air handler. See page 29, figure 25. Us...

Page 36

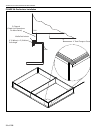

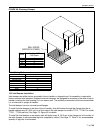

Tt-s eries i nstallation , o peration and s ervice m anual 30 of 198 section 7: air handler assembly all air handlers, except the tt118 and the recirculating tt233-tt236, have the blower and burner shipped as one piece. No field assembly is required. For tt118 and recirculating models tt233- tt236 f...

Page 37

Section 7: a ir h andler a ssembly 31 of 198 figure 27: air handler assembly - recirculating horizontal (models tt233 and tt236) typical for all connections bolt flat washer flat washer lock washer nut typical roof seam detail caulk end of seam & at intersections seam strip pitched roof (ref) instal...

Page 38

Tt-s eries i nstallation , o peration and s ervice m anual 32 of 198 figure 28: air handler assembly - recirculating upright (models tt233 and tt236) lock washer flat washer flat washer blower section burner section typical for all connections nut bolt model quantity of 1/2" nuts, bolts, flat/lock w...

Page 39

Section 8: vibration isolation 33 of 198 section 8: vibration isolation vibration isolation isolates the support / mounting structure / building from vibrations that the air handler equipment may generate. The type of isolation is determined by the application and or specifications of the equipment ...

Page 40

Tt-s eries i nstallation , o peration and s ervice m anual 34 of 198 figure 30: pad isolator installation unit waffle pad isolator 2" (5.08 cm) x 2" (5.08 cm) curb angle curb c-channel (check unit dimensions for more detail) 2” duct flange or case.

Page 41

Section 8: vibration isolation 35 of 198 8.2 neoprene or spring isolators for hanging- mounted air handler the hanger style isolator, available in neoprene or spring, and is used to suspend the air handler from any overhead support. (i.E. Hanger rod) it is supplied with a rectangular steel housing w...

Page 42

Tt-s eries i nstallation , o peration and s ervice m anual 36 of 198 figure 33: hanger rods’ installation instructions (model tt112-tt218) lock washer (hardware by others) nut flat washer.

Page 43

Section 8: vibration isolation 37 of 198 figure 34: hanger rods’ installation (model tt221) flat washer lock washer nut (hardware by others).

Page 44

Tt-s eries i nstallation , o peration and s ervice m anual 38 of 198 figure 35: hanger rods’ installation instructions (model tt224-tt236) nut lock washer flat washer (hardware by others).

Page 45

Section 8: vibration isolation 39 of 198 8.3 neoprene or spring isolators for pad- mounted air handlers the pad style isolator, which is available in either a neoprene version or spring version, is used to support the air handler from a base pad or structural frame. 8.3.1 neoprene mount isolator the...

Page 46

Tt-s eries i nstallation , o peration and s ervice m anual 40 of 198 figure 37: pad mounting installation instructions for neoprene isolator (models tt112-tt218).

Page 47

Section 8: vibration isolation 41 of 198 figure 38: pad mounting installation instructions for neoprene isolator (model tt221).

Page 48

Tt-s eries i nstallation , o peration and s ervice m anual 42 of 198 figure 39: pad mounting installation instructions for neoprene isolator (models tt224-tt236).

Page 49

Section 8: vibration isolation 43 of 198 8.3.2 spring mount isolator the spring mount isolator includes a rectangular steel housing which incorporates the spring and load tensioning adjustment bolt. It is equipped with neoprene stabilizers to provide lateral control without binding. See page 43, fig...

Page 50

Tt-s eries i nstallation , o peration and s ervice m anual 44 of 198 figure 41: pad mounting installation instructions for spring isolator (models tt112-tt218).

Page 51

Section 8: vibration isolation 45 of 198 figure 42: pad mounting installation instructions for spring isolator (model tt221).

Page 52

Tt-s eries i nstallation , o peration and s ervice m anual 46 of 198 figure 43: pad mounting installation instructions for spring isolator (model tt224-tt236).

Page 53: Warning

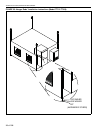

Section 9: r oof c urb 47 of 198 section 9: roof curb roof curbs support roof mounted horizontal air handlers and accessory sections, roof curbs are available in 24" (61.0 cm). Roof curbs are shipped knocked down and require field assembly. Note: before installation, verify that you have the correct...

Page 54

Tt-s eries i nstallation , o peration and s ervice m anual 48 of 198 figure 44: roof curb table 29: roof curb dimensions *the length indicated by dimension “b1” is for a roof curb designed to support the burner and blower sections. The length indicated by dimension “b2” is for a roof curb designed t...

Page 55

Section 9: r oof c urb 49 of 198 9.2 air handler mounting to roof curb after the curb has been installed, the air handler may be placed on the curb. There must be a 1/8" (.3 cm) x 2" (5.1 cm) neoprene closed cell, adhesive-back gasket (supplied by others) between the top of the curb and the base sur...

Page 56: Warning

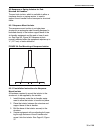

Tt-s eries i nstallation , o peration and s ervice m anual 50 of 198 section 10: upright stand 10.1 upright stand a stand can be used on an upright air handler which will be installed on a concrete slab or on the floor. For models tt112 - tt221 stand height is 36" (91.4 cm); for model tt224 stand he...

Page 57

Section 10: u pright s tand 51 of 198 figure 46: upright stand detail model a b c weight tt112 & tt115 in cm 36.0 91.4 36.0 91.4 28.0 71.1 lb kg 125 56.7 tt118 in cm 36.0 91.4 60.0 152.4 30.0 76.2 lb kg 140 63.5 tt212 in cm 36.0 91.4 60.0 152.4 28.0 71.1 lb kg 140 63.5 tt215 in cm 36.0 91.4 72.0 182...

Page 58

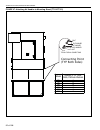

Tt-s eries i nstallation , o peration and s ervice m anual 52 of 198 figure 47: attaching air handler to mounting stand (tt112-tt221) quantity of 1/2" nuts, bolts, flat/lock washers 115 118 212 215 112 model 4 4 4 4 221 4 218 4 4 connecting point (typ both sides) typical for all connections bolt fla...

Page 59

Section 10: u pright s tand 53 of 198 figure 48: attaching air handler to mounting stand (tt224-tt236) connecting point (typ both sides) 17 17 8 236 230 233 8 224 model quantity of 1/2" nuts, bolts, flat/lock washers typical for all connections bolt flat washer flat washer lock washer nut.

Page 60

Tt-s eries i nstallation , o peration and s ervice m anual 54 of 198 figure 49: stand mounting hole detail for floor/slab (models tt221-tt236) b a short sides of air handler long sides of air handler model a b tt221 (in) (cm) 43.5 110.5 101.5 257.8 tt224 (in) (cm) 53.5 135.9 113.0 287.0 tt230 (in) (...

Page 61: Warning

Section 11: v ertical mounting l egs 55 of 198 section 11: vertical mounting legs legs can be used when mounting an air handler on a concrete slab or directly on the floor. Legs are available for models tt112 - tt221 in the upright configuration.They cannot be used if the optional inlet damper is su...

Page 62

Tt-s eries i nstallation , o peration and s ervice m anual 56 of 198 figure 51: mounting legs installation instructions weather-rite unit bolt legs to the section thru the lifting lugs. 1/2" 13nc x 1.5" bolts. Drill screw mountins leg to underside of section. A model 28.000 tt 112, 115, 212, 215 36....

Page 63: Warning

Section 12: f ilter s ection 57 of 198 section 12: filter section all filter sections are shipped assembled. The tt118 filter section is an integral part of the burner section. Note: check to be sure that all required components are present. If any are missing, contact your weather-rite ™ independen...

Page 64

Tt-s eries i nstallation , o peration and s ervice m anual 58 of 198 12.1 filter section installation - horizontal air handlers for installation directly onto the inlet of the air handler, use the supplied hardware and bolt the filter section to the air handler through the pre-drilled holes. Supplie...

Page 65

Section 12: f ilter s ection 59 of 198 12.2 filter section installation - upright air handlers for installation directly onto the inlet of the air handler, use the supplied hardware and bolt the filter section to the air handler through pre-drilled holes. If the air handler and filter section are to...

Page 66: Warning

Tt-s eries i nstallation , o peration and s ervice m anual 60 of 198 section 13: inlet hoods inlet hoods are available with permanent filters or birdscreen mounted on the inet face. For models tt112 - tt215, inlet hoods are shipped as one piece. For models tt218 and tt221 the inlet hood is shipped i...

Page 67

Section 13: i nlet h oods 61 of 198 13.1 inlet hood installation (models tt112 - tt215) inlet hoods for models tt112 - tt215 are shipped in one piece. To install the inlet hood on the cabinet of the air handler, use the supplied hardware. See page 61, figure 54. To install the inlet hood on an exter...

Page 68

Tt-s eries i nstallation , o peration and s ervice m anual 62 of 198 13.2 inlet hood assembly (models tt218 and tt221) inlet hoods for standard tt218 and tt221 are shipped in two pieces. To install the inlet hood on the cabinet of the air handler, use the supplied hardware. See page 62, figure 55. T...

Page 69

Section 13: i nlet h oods 63 of 198 13.3 inlet hood installation (models tt224 and tt230) inlet hoods for standard tt224 and tt230 are shipped in five pieces. To install the inlet hood on the cabinet of the air handler, use the supplied hardware. See page 63, step 13.3.1. To install the inlet hood o...

Page 70

Tt-s eries i nstallation , o peration and s ervice m anual 64 of 198 step 13.3.2 step 13.3.3 lock washer and washer washer 1/2" nut 1/2" bolt caulk mating surfaces model quantity of 1/2" nuts, bolts, flat/lock washers tt224 tt230 8 sets 10 sets step 1: attach assembly made on page 63, step 13.3.1 to...

Page 71

Section 13: i nlet h oods 65 of 198 step 13.3.4 drill screws caulk mating surfaces step 1: use supplied drill screws to attach assembly made on page 64, step 13.3.3 to the larger section of the inlet hood that was attached to the air handler on page 64, step 13.3.2..

Page 72

Tt-s eries i nstallation , o peration and s ervice m anual 66 of 198 step 13.3.5 step 13.3.6 note: this view shown with half of the hood hidden to show support. Drill screws step 1: drill screw factory supplied hood support channel through side of support and side flanges of inlet hood. Note: this v...

Page 73

Section 13: i nlet h oods 67 of 198 13.4 inlet hood installation (models tt233 and tt236) inlet hoods for standard tt233 - tt236 are shipped in two sections. To install the inlet hood on the cabinet of the air handler, use the supplied hardware. See page 67, figure 56. To install the inlet hood sect...

Page 74: Warning

Tt-s eries i nstallation , o peration and s ervice m anual 68 of 198 section 14: service platform all service platforms are shipped assembled and attached. Upright air handlers supplied with both a stand and a service platform will have the service platform factory-mounted as an integral part of the...

Page 75

Section 14: s ervice p latform 69 of 198 figure 57: service platform table 30: service platform note: service platform will be located on the same side as the control panel. *dimension "b" only applies to service platforms on upright units. For horizontal units, dimension "b" can be determined by ad...

Page 76: Warning

Tt-s eries i nstallation , o peration and s ervice m anual 70 of 198 section 15: dampers 15.1 discharge damper installation discharge dampers are either factory mounted to the air handler or shipped loose. No assembly is required for factory mounted discharge dampers. Shipped loose discharge dampers...

Page 77

Section 15: d ampers 71 of 198 figure 58: discharge damper table 31: lag bolts 15.2 inlet damper installation inlet dampers are either factory mounted to the air handler or shipped loose. No assembly is required for factory mounted inlet dampers. Shipped loose inlet dampers are designed for mounting...

Page 78

Tt-s eries i nstallation , o peration and s ervice m anual 72 of 198 figure 59: inlet damper drill screws or lag bolts (supplied by others).

Page 79: Warning

Section 16: d ischarge plenum and d ischarge l ouvers 73 of 198 section 16: discharge plenum and discharge louvers 16.1 four-way discharge plenum installation all discharge heads are shipped assembled. The discharge head is designed for mounting to the cabinet of the air handler (covering the discha...

Page 80

Tt-s eries i nstallation , o peration and s ervice m anual 74 of 198 16.2 double deflection discharge louver installation all discharge louvers are shipped assembled. The discharge louvers are designed for mounting to the cabinet of the air handler (covering the discharge opening) or to an interior ...

Page 81: Warning

Section 17: d uct c onsiderations 75 of 198 section 17: duct considerations the air handler has been designed to operate at the specific air volume and external static pressure that was ordered. This static pressure is generated by any additional components that are added to the heater (i.E. Inlet h...

Page 82

Tt-s eries i nstallation , o peration and s ervice m anual 76 of 198 17.1 inlet air duct inlet duct work height and width must be no smaller than the air handler inlet height and width and supply only uncontaminated air to the air handler. See page 12, figure 11 through page 23, figure 22 for inlet ...

Page 83

Section 18: g as p iping 77 of 198 section 18: gas piping 18.1 gas manifolds all gas piping to the air handler must comply with: united states: refer to nfpa 54/ansi z223.1 - latest revision, national fuel gas code. Canada: refer to csa b149.1 - latest revision, natural gas and propane installation ...

Page 84

Tt-s eries i nstallation , o peration and s ervice m anual 78 of 198 18.3 gas manifold venting vent valves fitted on xl-compliant manifolds on indoor installed air handlers must be piped to the atmosphere outside the structure. This is the responsibility of the installer. 18.3.1 vent line installati...

Page 85

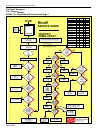

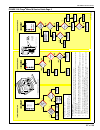

Section 18: g as p iping 79 of 198 figure 63: ansi manifold 1000 - 5000 mbh - 1"-2" npt figure 64: ansi manifold above 3000 mbh - 2 ½" to 3" npt pilot gas regulator controls the amount of gas flow to the burner's pilot tube. Main gas solenoid valve. Opens & closes allowing gas to flow to the burner....

Page 86

Tt-s eries i nstallation , o peration and s ervice m anual 80 of 198 figure 65: fm manifold 700 mbh less than 1000 mbh 1" npt figure 66: fm manifold 1000 - 5000 mbh - 1"-2" npt pilot gas regulator controls the amount of gas flow to the burner's pilot tube. Position indicating block gas solenoid valv...

Page 87

Section 18: g as p iping 81 of 198 figure 67: fm manifold above 3000 mbh 2 ½" to 3" npt figure 68: xl manifold less than 1000 mbh - 1" npt honey well fluid power gas val ve fluid power gas val ve honey well m axitrol selec tra pilot gas regulator controls the amount of gas flow to the burner's pilot...

Page 88

Tt-s eries i nstallation , o peration and s ervice m anual 82 of 198 figure 69: xl manifold 1000 - 5000 mbh 1" - 2" npt pilot gas regulator controls the amount of gas flow to the burner's pilot tube. Position indicatingmain gas solenoid valve. Opens & closes allowing gas to flow to the burner. Pilot...

Page 89

Section 18: g as p iping 83 of 198 figure 70: xl manifold above 3000 mbh 2 ½" - 3" npt 18.4 gas piping the gas manifold extends through the side of the control cabinet. The factory piping terminates with a female pipe connection. The manual main gas shutoff valve is shipped loose for field installat...

Page 90

Tt-s eries i nstallation , o peration and s ervice m anual 84 of 198 figure 71: gas pressure taps (manifold) 18.5.2 burner gas pressure - 1/8" npt a pressure tap is used to measure negative airflow at the burner and to set high fire gas pressure. The pressure tap is located on an elbow between the m...

Page 91: Danger

Section 19: e lectrical 85 of 198 section 19: electrical each air handler is equipped with a wiring diagram which will vary depending on the type of controls and options supplied. Note: spark testing or shorting of the control wires by any means will render the transformers inoperative. 19.1 wiring ...

Page 92

Tt-s eries i nstallation , o peration and s ervice m anual 86 of 198 19.5 safety systems safety systems are required for proper performance of the air handler. The air handler shall not be permitted to operate with any safety system disabled. If a fault is found in any of the safety systems, then th...

Page 93: Danger

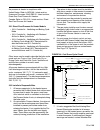

Section 20: s equence of o peration 87 of 198 section 20: sequence of operation 20.1 air handler configuration based on the air handler application, the air handler may be configured in any of the following styles to achieve the described functionality. These configurations are available on all air ...

Page 94

Tt-s eries i nstallation , o peration and s ervice m anual 88 of 198 20.1.1 make-up air (mua) style the mua style air handler has a constant speed blower that is designed to deliver a constant volume of air to the heated space. This style air handler supplies 100% outside air to the heated space and...

Page 95

Section 20: s equence of o peration 89 of 198 flame failure indicator: the burner control module has experienced a fault and will need to be reset. The burner control module must be reset at the air handler. Refer to the maintenance and trouble shooting sections of this manual to determine the cause...

Page 96

Tt-s eries i nstallation , o peration and s ervice m anual 90 of 198 figure 76: 8.3ls remote panel rmtc 20.2.4 ddc - ready option the ddc-ready option provides inputs to receive control signals from a customer determined control system and outputs to provide sequence status to the same. A 24vac tran...

Page 97

Section 20: s equence of o peration 91 of 198 compliance requirements (ansi, csa, fm and xl). 20.4.1 fireye ® microm flame safeguard this control is located in the center of the main control panel. Figure 77: fireye components microm family the cover of this control is red and it has a reset button ...

Page 98

Tt-s eries i nstallation , o peration and s ervice m anual 92 of 198 4. Flame on - this indicator comes on after the flame safeguard has proven out the flame sig- nal. It also shows that the main valves have been activated in the equipment. On the safe- guard control, terminal #5 is powered up. 5. A...

Page 99

Section 20: s equence of o peration 93 of 198 provided in the flame safeguard control. There is a specified time for pre-purge, trial for ignition, and non recycle. Figure 81: fireye mep 230 programmer 1. Timed pre-purge this must be a separate purge from the rest of the system. The trial for igniti...

Page 100

Tt-s eries i nstallation , o peration and s ervice m anual 94 of 198 network. • all interlocks, control relays and safety limits are closed. Power is supplied to terminals #1 and #7 of the flame safeguard. • the operating control led illuminates. • the electronic network is now powered up which illu...

Page 101

Section 20: s equence of o peration 95 of 198 3. Ptfi - this acronym stands for pilot trial for ignition. This indicator is on only during the trial for ignition period. It indicates that terminal #3 (pilot valve) and terminal #4 (ignition module), in the flame safeguard, have been turned on. 4. Fla...

Page 102

Tt-s eries i nstallation , o peration and s ervice m anual 96 of 198 tinuing activating the spark electrode if a haz- ardous malfunction takes place. 3. Non recycle this feature prevents the flame safeguard con- trol from trying to re-light the burner if it should fail during the ignition cycle or f...

Page 103

Section 20: s equence of o peration 97 of 198 • all interlocks, control relays and safety limits are closed. Power is supplied to terminal #7 of the flame safeguard. • the operating control led illuminates. • the electronic network is now powered up which illuminates the air flow led. Note: the airf...

Page 104

Tt-s eries i nstallation , o peration and s ervice m anual 98 of 198 2. Pilot - this indicator comes on when power is present at terminals #8 and #10 of the flame safeguard. It indicates that the pilot circuit has been turned on. 3. Flame - this indicates that a flame signal has been proven. 4. Main...

Page 105

Section 20: s equence of o peration 99 of 198 options; see page 98, figure 85 and page 98, table 39. If necessary, clip the site-configurable jumpers with side cutters and remove the resistors from the relay module. Important clipping and removing a jumper after 200 hours of operation causes a non-r...

Page 106

Tt-s eries i nstallation , o peration and s ervice m anual 100 of 198 (master/slave operation). As the vfd speeds the blower up, the profile damper opens proportionally to maintain the proper pressure drop across the burner. As the vfd slows the blower down, the profile damper closes. 20.5.3 two pos...

Page 107

Section 20: s equence of o peration 101 of 198 20.5.6 space pressure controller with minimum air this option uses a building pressure sensor (for ddc controls) or differential pressure switch [photohelic optional] (for conventional relay logic controls) to monitor differential pressure between the o...

Page 108

Tt-s eries i nstallation , o peration and s ervice m anual 102 of 198 20.7 other control options 20.7.1 exhaust fan interlock - exhaust fan starts air handler this option provides an interlock between an exhaust fan and an air handler. It includes a break in the control circuitry to which wiring fro...

Page 109

Section 20: s equence of o peration 103 of 198 this option provides a service receptacle. It includes ground-fault interrupter (gfi) receptacle (mounted on the air handler). Power to the receptacle is supplied by a 7a power source from the air handler itself. 20.7.14 ul-listed flame control panel th...

Page 110: Danger

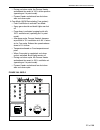

Tt-s eries i nstallation , o peration and s ervice m anual 104 of 198 section 21: temperature controls the standard temperature controls supplied with the air handler are manufactured by maxitrol company®. The type of controls are identified by a "series" type the ones used on weather-rite llc equip...

Page 111

Section 21: t emperature c ontrols 105 of 198 figure 86: series 14 components 21.1.2 system components for series 44 • space temperature sensors / selectors these are combined temperature sensing / selection devices used to control the space to the temperature desired during heating operations. It i...

Page 112

Tt-s eries i nstallation , o peration and s ervice m anual 106 of 198 21.1.3 system components for series 94 • dual temperature selectors with led display these are non-temperature-sensing controls which set the temperature required in the spray cycle and in the dry cycle, while displaying the actua...

Page 113

Section 21: t emperature c ontrols 107 of 198 that its resistance increases as its temperature increases. Rtd is an acronym for resistance temperature detector. As its name implies, the sensor is located such that the averaging tube protrudes into the discharge duct. Note: this is a field-installed ...

Page 114: Warning

Tt-s eries i nstallation , o peration and s ervice m anual 108 of 198 section 22: direct fired burner the burner used by weather-rite is manufactured by midco international ® , inc., model hma-2a. The hma- 2a is used for natural gas and propane (lp). The burner combines the two main ingredients need...

Page 115

Section 22: d irect f ired b urner 109 of 198 figure 90: midco hma-2a burner 22.1 direct fired burner ignition the burner that is used in the weather-rite llc unit is equipped with a pilot assembly. The pilot assembly consists of a pilot gas tube, spark electrode or rod and either a flame rod with g...

Page 116

Tt-s eries i nstallation , o peration and s ervice m anual 110 of 198 22.2 direct fired burner flame proving (flame rod) the flame rod in the burner is constructed of a material that produces a signal when heated. This signal is measured as a direct current micro amp. The path of the signal is from ...

Page 117

Section 22: d irect f ired b urner 111 of 198 22.3 direct fired burner flame proving (ultra violet scanner) the uv tube is made of quartz and is filled with a gas that ionizes when struck by uv radiation from the flame. In the absence of uv radiation, the gas acts as an insulator between two electro...

Page 118: Danger

Tt-s eries i nstallation , o peration and s ervice m anual 112 of 198 section 23: direct fired process air heaters this section applies to direct gas-fired process air heaters of the recirculating or non-recirculating type. During the process heating cycle (bake or cure) excess carbon monoxide is pr...

Page 119

Section 23: d irect fired process air heaters 113 of 198 the process air heater in compliance with: united states: refer to nfpa 86 - latest revision, ovens and furnaces /ansi z83.25 - latest revision, direct gas-fired process air heaters. Canada: refer to csa 3.19 - latest revision, direct gas-fire...

Page 120: Warning

Tt-s eries i nstallation , o peration and s ervice m anual 114 of 198 llc or weather-rite ™ independent distrib- utor. Figure 95: burn hazard 8. The space serviced by the process heater, during the bake cycle mode must have its light- ing turned off. If not supplied by the process heater, then the i...

Page 121

Section 23: d irect fired process air heaters 115 of 198 figure 97: exhaust interlock circuit 2. If a purge cycle between ventilation cycle mode and the bake cycle mode is not supplied with the process heater, then the installer must supply a purge timer that delays the bake cycle from operating for...

Page 122

Tt-s eries i nstallation , o peration and s ervice m anual 116 of 198 • booth lighting on/off switch, fusing and contactor (supply power for lights by others). 2.Operation: • switch in "summer" position for fan only or "winter" position for fan and burner. • process heater's discharge damper (if equ...

Page 123

Section 23: d irect fired process air heaters 117 of 198 figure 101: wrp-2 23.4.3 wrp - 3 remote control station - 100% ventilation air / reduced airflow dry cycle - vfd exhaust 1. Description: • nema1 hinged control panel. • summer-off-winter switch. • three system indicating lights; blower, burner...

Page 124

Tt-s eries i nstallation , o peration and s ervice m anual 118 of 198 23.4.4 wrp - 3r remote control station - 100% ventilation air and 90/10 recirculating cure sys- tem - vfd exhaust 1. Description: • nema1 hinged control panel. • summer-off-winter switch. • three system indicating lights; blower, ...

Page 125

Section 23: d irect fired process air heaters 119 of 198 adjusts exhaust fans to maintain booth pressure. 2.Operation - paint mode: • switch in "summer" position for fan only or "winter" position for fan and burner. • process heater discharge damper opens to 100% open position. • exhaust fan starts ...

Page 126

Tt-s eries i nstallation , o peration and s ervice m anual 120 of 198 • dry mode: • activate switch to either "summer" or "winter" position • turn dry cycle start timer to desired time (activates the dry cycle) • spray gun solenoid and booth lights are shut off • purge timer is activated, purging bo...

Page 127

Section 23: d irect fired process air heaters 121 of 198 • during cool-down cycle, the process heater and exhaust fan revert to 100% airflow position (operating as if in paint mode). • process heater and exhaust fan shut down after cool-down cycle. 4.Cure mode (90/10 recirculating cure system): • pu...

Page 128: Danger

Tt-s eries i nstallation , o peration and s ervice m anual 122 of 198 section 24: start-up procedures electrical shock hazard disconnect electric before service. More than one disconnect switch may be required to disconnect electric from equipment. Equipment must be properly grounded. Severe injury ...

Page 129

Section 24: s tart - up p rocedures 123 of 198 installation code and annual inspections: all installation and service of weather-rite ™ equipment must be performed by a contractor qualified in the installation and service of equipment sold and supplied by weather-rite llc and conform to all requirem...

Page 130

Tt-s eries i nstallation , o peration and s ervice m anual 124 of 198 v-belt and a motor sheave measuring between 5.8" (1.59 cm) and 8.6" (21.84 cm), the belt will have proper tension if a 5/8" deflection can be achieved with a minimum of 6-3/8 inch lbs. And a maximum of 8-3/4 inch lbs. Of pressure ...

Page 131

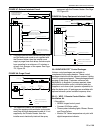

Section 24: s tart - up p rocedures 125 of 198 24.4.1.1 differential pressure adjustment manual profiles to adjust the differential pressure that was measured in the step above, use the profile damper adjustment quadrants located above and below the burner access panel for horizontal configuration o...

Page 132

Tt-s eries i nstallation , o peration and s ervice m anual 126 of 198 note: open the burner observation port and examine the burner flame. The flame should be a brilliant blue with short (approx. 1" to 2") yellow finger tips. If there is too much yellow in the flame then the air pressure drop, or ve...

Page 133

Section 24: s tart - up p rocedures 127 of 198 finger tips. 24.5 gas piping and initial pressure settings 1. Perform a pressure test on all gas supply lines to the air handler per applicable codes. Make sure to isolate all gas controls before pressure testing the system. 2. Verify supply pressure do...

Page 134

Tt-s eries i nstallation , o peration and s ervice m anual 128 of 198 figure 112: pilot pressure tap pilot gas regulator controls the amount of gas flow to the burner's pilot tube. Pilot shut-off cock manual shut off that isolates the pilot gas assembly from the main gas supply. Pilot pressure tap. ...

Page 135

Section 24: s tart - up p rocedures 129 of 198 figure 113: maxitrol mr212 valve t n e v r 2a0 4 1 12a06 r low fire adjustment (loosen locking screw before adjustment) high fire adjustment.

Page 136

Tt-s eries i nstallation , o peration and s ervice m anual 130 of 198 figure 114: regulator rv61.

Page 137

Section 24: s tart - up p rocedures 131 of 198 figure 115: maxitrol m611 valve 24.6 safety shut off valve check after the initial start up and gas pressure adjustment, verify gas soundness of each ssov (safety shut off valve). This check must be repeated after the first 100 hours of operation. 24.7 ...

Page 138

Tt-s eries i nstallation , o peration and s ervice m anual 132 of 198 • recheck air pressure drops across burner on high and low airflow settings. • minimum motor speed is factory set and should not be adjusted unless specifically directed to do so by the factory. 24.7.3 two position volumatic • air...

Page 139: Danger

Section 25: m aintenance 133 of 198 section 25: maintenance prior to any maintenance or service to the air handler, shut off, lockout and tagout the electrical disconnect and fuel valve that supplies the unit in accordance with osha regulations and allow ample time for the air handler to cool. After...

Page 140

Tt-s eries i nstallation , o peration and s ervice m anual 134 of 198 installation code and annual inspections: all installation and service of weather-rite ™ equipment must be performed by a contractor qualified in the installation and service of equipment sold and supplied by weather-rite llc and ...

Page 141

Section 25: m aintenance 135 of 198 drive belts and sheaves check for belt ride in the groove. In multiple groove drives, belt ride should be uniform. Check groove wear area for wear. Side wall of groove should be straight, not dished out. Bottom of groove should show no signs of belt con- tact. She...

Page 142

Tt-s eries i nstallation , o peration and s ervice m anual 136 of 198 motors inspection: 1. Inspect motor every 3 months or 500 hours of operation, which ever occurs first. Keep the motor clean and vent openings clear. Lubrication: 1. Motors with grease fittings must be lubricated based on the table...

Page 143

Section 25: m aintenance 137 of 198 25.4 motor and drive components figure 116: supply blowers gain access to the blower and motor by removing the belt guard or weather- proof cover. First, release tension on the belts by adjusting the motor base closer to the blower pulley. Remove the belts. To rem...

Page 144

Tt-s eries i nstallation , o peration and s ervice m anual 138 of 198 25.5 supply blower 25.6 manifold and controls the supply air is handled by dwdi (double width, double inlet) blower wheel(s) mounted on either a solid or tubular shaft. The blower wheel(s) are attached to this shaft via two setscr...

Page 145

Section 25: m aintenance 139 of 198 25.7 burner an annual inspection of the burner and components must be made to ensure proper and safe operation. For the most part, the burner is self cleaning. However, if the application is extremely dirty or dusty, it may become neces- sary to periodically clean...

Page 146

Tt-s eries i nstallation , o peration and s ervice m anual 140 of 198 table 42: burner orifice sizes 12. If your flame sensor is a scanner, clean the lens with a clean damp soft rag. A flame rod's metal rod should be clean and free of dirt and carbon. Like the spark rod igniter, the porcelain on the...

Page 147: Warning

Section 26: r eplacement p arts 141 of 198 section 26: replacement parts see warnings and important information before removing or replacing parts. After any maintenance or repair work, always test fire the heater in accordance with the start-up instructions on page 122, section 24 to help ensure al...

Page 148

Tt-s eries i nstallation , o peration and s ervice m anual 142 of 198 26.1.2 bushing, fixed pulley model description part number quantity tt233 bearing 81900000 1 bearing drive end 81900110 1 shaft 30315702 1 wheel 82000073 2 tt236 bearing 81900000 1 bearing drive end 81900116 1 shaft 30315900 1 whe...

Page 149

Section 26: r eplacement p arts 143 of 198 26.1.3 fixed pulley description part number 1b x 11.0 1-3/16 82105120 1b x 11.0 pd sds 14093210 1b x 12.4 1-3/16 82105140 1b x 12.4 pd sds 14189300 1b x 13.6 1-3/16 82105150 1b x 13.6 pd sds 82105160 1b x 16.0 pd sds 82100270 1b x 18.4 pd sk 82100280 1b x 2...

Page 150

Tt-s eries i nstallation , o peration and s ervice m anual 144 of 198 26.1.4 variable pulley description part number 3b x 20.0 pd sf 82100950 3b x 25.0 pd sf 82100960 3b x 30.0 pd sf 82100970 3b x 31.5 pd sh 14120900 3b x 4.4 pd sd 82100700 3b x 4.6 pd sd 82100710 3b x 4.8 pd sd 82100720 3b x 5.0 pd...

Page 151

Section 26: r eplacement p arts 145 of 198 description part number 1b x 5.0-6.5 1-3/8" 82105930 1b x 6.0-7.4 1-1/8" 82101630 1b x 6.3-7.3 1-1/8" 14128900 2b x 3.5-4.9 1-3/8" 82101810 2b x 3.5-4.9 7/8" 82101790 2b x 4.3-5.3 1-3/8" 82101890 2b x 4.3-5.4 1-3/8 14228905 2b x 4.5-5.9 1-5/8" 82101930 2b x...

Page 152

Tt-s eries i nstallation , o peration and s ervice m anual 146 of 198 26.1.5 belts description part number b-036 33689436 b-040 33689440 b-041 33689441 b-042 33689402 b-043 33689443 b-044 33689444 b-045 33689445 b-046 33689446 b-047 33689447 b-048 33689448 b-050 33689450 b-052 33689452 b-053 3368945...

Page 153

Section 26: r eplacement p arts 147 of 198 26.2 damper components 26.2.1 actuators description part number b-120 33689420 b-128 33689428 b-150 33689411 b-154 33689413 bx-49 33689549 bx-50 33689550 bx-51 33689551 bx-52 33689552 bx-62 33689562 bx-64 33689564 bx-65 33689565 bx-67 33689567 bx-70 3368957...

Page 154

Tt-s eries i nstallation , o peration and s ervice m anual 148 of 198 26.2.2 actuators accessories 26.3 burner components note: for complete natural gas or lp burner assemblies - contact factory description part number modulating foot mount with end switch 83400051 24v no sw spring return 14321500 2...

Page 155

Section 26: r eplacement p arts 149 of 198 26.4 manifold components 26.5 combustion components 26.5.1 combustion components description part number solenoid valve - 3/8" (pilot) 14036400 solenoid valve - 1" 82500031 solenoid valve - 1.25" 82500040 solenoid valve - 1.5" 10762900 solenoid valve - 2" 8...

Page 156

Tt-s eries i nstallation , o peration and s ervice m anual 150 of 198 high gas pressure switch 83100070 ignition cable (per foot) 81400400 ignition cable boot 81150420 ignition cable snap fitting 81150440 fireye ultra violet scanner 83500022 honeywell ultra violet scanner 15159701 pilot off timer 14...

Page 157

Section 26: r eplacement p arts 151 of 198 26.5.2 flame safeguards 26.6 electrical components 26.6.1 motor protectors description part number flame safeguard relay module 15159600 flame relay sub-base 15160001 amplifier - flame rod 15159802 amplifier - ultraviolet 15159801 purge timer 7 sec 15159701...

Page 158

Tt-s eries i nstallation , o peration and s ervice m anual 152 of 198 26.6.2 contactors 26.6.3 overloads 26.6.4 temperature controls description part number 18 amps 14320703 25 amps 14320704 32 amps 14320705 40 amps 14320706 50 amps 14320707 65 amps 14320708 80 amps 14320709 115 amps 14320710 150 am...

Page 159

Section 26: r eplacement p arts 153 of 198 26.6.5 miscellaneous electrical components description part number clogged filter pressure switch 8024206082 83100006 indicator light - neon - amber - 120 vac 14297311 indicator light - neon - green - 120 vac 14297313 indicator light - neon - red - 120 vac ...

Page 160

Tt-s eries i nstallation , o peration and s ervice m anual 154 of 198 26.7 miscellaneous mechanical components 26.7.1 filters description part number door handle - control panel, slotted, compression 14303506 door handle - cabinet doors, latch 10500401 profile quadrants #640 81100030 volumatic outdo...

Page 161

Section 26: r eplacement p arts 155 of 198 tt224 permanent 2 x 20 x 20 82400160 18 2 x 20 x 25 82400170 12 disposable 2 x 20 x 20 82400070 18 2 x 20 x 25 82400080 12 30% pleated 2 x 20 x 20 82402870 18 2 x 20 x 25 82402860 12 30% poly flat panel 20 x 20 14074201 18 20 x 25 14074202 12 optional fresh...

Page 162: Danger

Tt-s eries i nstallation , o peration and s ervice m anual 156 of 198 section 27: troubleshooting electrical shock hazard disconnect electric before service. More than one disconnect switch may be required to disconnect electric from equipment. Equipment must be properly grounded. Severe injury haza...

Page 163

Section 27: t roubleshooting 157 of 198 the following is divided into two basic categories - fan problems and burner problems. In some cases, they interrelate. In order to use this effectively, you should familiarize yourself with both categories. 27.1 initial checks when encountering any abnormal o...

Page 164

Tt-s eries i nstallation , o peration and s ervice m anual 158 of 198 27.3 burner problem possible cause solution flame control does not try for ignition auxiliary contact "m1" not closed? Properly mount contact or replace replace switch high temp limit switch tripped? Manually reset or replace low ...

Page 165

Section 27: t roubleshooting 159 of 198 burner (continued) 27.4 temperature controls if temperature control problems occur and are not remedied in the troubleshooting procedure, refer to the trouble shooting table for the unit specific temperature control amplifier. 1. For units with the maxitrol se...

Page 166

Tt-s eries i nstallation , o peration and s ervice m anual 160 of 198 5. After test, remove the test resistor and recon- nect the discharge air sensor to terminals 3 and 4. If remote temperature selector has been moved return it to its original position. 27.5.1 series 14 - low fire start time adjust...

Page 167

Section 27: t roubleshooting 161 of 198.

Page 168

Tt-s eries i nstallation , o peration and s ervice m anual 162 of 198 27.5.4 series 14 - field service checklist symptom possible cause a. No gas flow 1. Modulating valve improperly installed. B. Continuous low fire (electronics problem). 2. Short circuit or no voltage to the amplifi er. 3. Open cir...

Page 169

Section 27: t roubleshooting 163 of 198 field test remedy 1. Arrow on side of valve should point in direction of gas fl ow. 1. Install properly. 2. Check for 24vac at amplifi er terminals 7 & 8. 3. Inspect for loose or broken wires between amplifi er terminals 1 & 2, and td114 terminals 1 & 2, and t...

Page 170

Tt-s eries i nstallation , o peration and s ervice m anual 164 of 198 27.6 series 44 - preliminary circuit analysis this preliminary circuit analysis will provide identification of faulty components, improper wiring or calibration, and other difficulties. Note: all voltages and resistance readings a...

Page 171

Section 27: t roubleshooting 165 of 198 • if hunting is encountered (rapid oscillation), rotating the sensitivity control counterclockwise may dampen the oscillation, stabilizing the flame. • do not adjust unless necessary, because decreasing the sensitivity will increase the temperature "droop" of ...

Page 172

Tt-s eries i nstallation , o peration and s ervice m anual 166 of 198 27.6.4 series 44 - field service checklist symptom possible cause a. No gas fl ow. 1. Valve improperly installed. B. Continuous low fi re (electronics ok). 2. Open circuit in modulator coil. 3. Plunger missing, jammed or improperl...

Page 173

Section 27: t roubleshooting 167 of 198 field test remedy 1. Arrow on side of valve should point in direction of gas fl ow. 1. Install properly. 2. Remove wires connected to amplifi er terminals 6 & 7 and mea- sure resistance. Mr212 (60-80 ohms), m611 (45-55 ohms). 3. Inspect - plunger should be ins...

Page 174

Tt-s eries i nstallation , o peration and s ervice m anual 168 of 198 27.7 series 94 - preliminary circuit analysis in order to diagnose the cause of problems in this system it is necessary to determine certain values. It is helpful to have a volt/ohm multimeter. Modulation function: if sensed tempe...

Page 175

Section 27: t roubleshooting 169 of 198.

Page 176

Tt-s eries i nstallation , o peration and s ervice m anual 170 of 198 27.7.2 series 94 - field service checklist.

Page 177

Section 27: t roubleshooting 171 of 198.

Page 178

Tt-s eries i nstallation , o peration and s ervice m anual 172 of 198 27.8 series mp - trouble shooting the mp2 and mp2+ have built in diagnostics; refer to the following programming guides for setup and troubleshooting information. Thoroughly read entire mp section to guarantee proper usage of mp2 ...

Page 179

Section 27: t roubleshooting 173 of 198 the feature has a range of -10 °f (-5.6 °c) to +10 °f (5.6 °c) and is available for each pro- cess. Ramping this feature is used to step the input rate when changing from one process set point to another. It is available for each process. The ramping rate dete...

Page 180

Tt-s eries i nstallation , o peration and s ervice m anual 174 of 198 27.8.1.2 operation menu max proc temp this feature limits the maximum temperature for each process. It has a range of 60 °f (15 °c) to 240 °f (115 °c). It does not allow the process set point to be set in excess of the maximum pro...

Page 181

Section 27: t roubleshooting 175 of 198 27.8.1.3 menus looping mode (tm02 applications only) the looping mode feature is used to select the controllers default position on startup and after the last process of a program is completed. Note: global setting for mp2+ system. Note: for mp2+ system, on "p...

Page 182

Tt-s eries i nstallation , o peration and s ervice m anual 176 of 198 27.8.1.4 programming the mp system table 45: programming buttons oper ati on me n u soft start off, slow, medium, fast max valve vdc 7 to 25 vdc max ramp vdc 5 to 24 vdc total bandwidth 5 °f(2.8 °c) to 15 °f (8.3 °c) offset temp o...

Page 183

Section 27: t roubleshooting 177 of 198 table 46: screen indicators 27.8.2 series mp2 select user information 27.8.2.1 program indication output terminal #8 is used to indicate the controller is operating within a program. The following voltage will be measured across the #8 terminals. Press and rel...

Page 184

Tt-s eries i nstallation , o peration and s ervice m anual 178 of 198 27.8.3 series mp2+ select user information the initial programming has a maximum of 8 programs available. Each program has a maximum of 8 processes set points. The program and process set point in use is displayed as p(1-8) s#(1-8...

Page 185

Section 27: t roubleshooting 179 of 198 table 49: diagnostics menu programming max valve vdc (global setting for mp2+ system) 2 scroll to max valve vdc, press . 3 max valve vdc, set voltage value (7 v to 25 v), press . 4 **stored** will flash 4 times to confirm entry. Max ramp vdc 2 scroll to max ra...

Page 186

Tt-s eries i nstallation , o peration and s ervice m anual 180 of 198 27.8.4.2 mp2+ system initial menu programming, press once. Programs appears, press or scroll to global settings and press . Programs selected: • scroll to desired program #, press . • after program loads, scroll to process menu, o...

Page 187

Section 27: t roubleshooting 181 of 198 27.8.5 series mp operation 27.8.5.1 mp2 process control system 27.8.5.2 mp2 process control system w/ tm02 multifunctional timer control switching to the next programmed process: 27.8.5.3 mp2+ multiple program processes temperature controller 27.8.5.4 mp2+ mul...

Page 188

Tt-s eries i nstallation , o peration and s ervice m anual 182 of 198 27.8.6 switching to the next programmed process: table 50: mp2 and mp2+ field service guide timed processes nothing is required. The mp2+ system will immediately proceed to the next programmed process after timing out. Note: if th...

Page 189

Section 27: t roubleshooting 183 of 198 e continuous high fire (electronic problem) 1 short circuit in ts194(q) dis- charge air sensor circuit or wir- ing. 1 check ts194(q) for internal short cir- cuit. See temperature sensor function of preliminary circuit analysis. 2 faulty mp2 2 perform remedy fo...

Page 190

Tt-s eries i nstallation , o peration and s ervice m anual 184 of 198 observed problem possible cause remedy h 1 hunting 1 increase bandwith setting. See opera- tion menu programming in mp2(+) user's programming guide. If flame stabilizes, reduce bandwith to the mini- mum setting where a stable flam...

Page 191

Section 27: t roubleshooting 185 of 198 l control inoperable; dis- play reads "ready…" 1 bad cable connection between dial and amplifier. 1 remove power. Disconnect and recon- nect cable securely. Restore power. If "ready…" remains, replace or consult maxitrol company. 2 dial cable disconnected and ...

Page 192

Tt-s eries i nstallation , o peration and s ervice m anual 186 of 198 27.9 flame ® safeguard 27.9.1 fireye ® microm figure 117: fireye ® micro m service guide page 1 lockout message op ctrl intrlck ptfi flame line frequency noise ● ❍ ❍ ● flame fail - ptf1 ❍ ● ● ● fault unknown ● ● ● ● amplifier coun...

Page 193

Section 27: t roubleshooting 187 of 198 figure 118: fireye ® micro m service guide page 2 troubleshooting tips 1. V erify that there is a solid earth ground wire brought to the panel that the fireye base is mounted to. 2. In a rectifi cation system, verify that terminal s1 is solidly earth grounded,...

Page 194

Tt-s eries i nstallation , o peration and s ervice m anual 188 of 198 27.9.2 fireye ® m4rt1 the fireye ® m4rt1 is a self contained version of the microm flame safeguard. It is only used on flame rod applications and does not have separate programming boards or flame signal amplifiers. Refer to page ...

Page 195

Section 27: t roubleshooting 189 of 198 code 3-1 *running/ interlock switch problem* running or lockout interlock fault during prepurge. 1. Check wiring; correct any errors. 2. Inspect the fan; make sure there is no air intake blockage and that it is supplying air. 3. Make sure the lockout interlock...

Page 196

Tt-s eries i nstallation , o peration and s ervice m anual 190 of 198 code 5-3 *man-open sw.; start sw. Or control on* man-open switch, start switch or control on in the wrong operational state. 1. Check wiring and correct any errors. 2. Make sure that the manual open valve switch, start switch and ...

Page 197

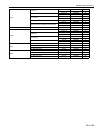

Section 27: t roubleshooting 191 of 198 27.10 weather-rite ™ tt-series start-up procedure model: serial no: phone no: type of gas: nat: lp: yes no 1 inspect for shipping damage. 2 check packing list against items received. 3 4 5 6 check installation site to ensure all codes and engineering specifica...

Page 198

Tt-s eries i nstallation , o peration and s ervice m anual 192 of 198.

Page 199

Section 27: t roubleshooting 193 of 198 yes no 27 28 29 ` 30 d.C. Volts flame rod: 6 - 18 vd.C. U.V. Scanner: 4 - 5.5 vd.C 31 32 record pressure drop inches w.C. - range is .50" w.C. ± .1" 33 34 record the inlet gas pressure while the unit is on high fire inches w.C. 35 36 37 38 39 40 41 series mp2 ...

Page 200

Tt-s eries i nstallation , o peration and s ervice m anual 194 of 198 42 yes no if no, explain: if no, explain: if no, explain: if no, explain: if no, explain: if no, explain: 43 if no, explain: if no, explain: 44 if no, explain: if no, explain: date date operation of the temperature control in the ...

Page 201

Section 28: t he weather-rite ™ tt-s eries w arranty 195 of 198 section 28: the weather-rite ™ tt-series warranty weather-rite llc will pay for: within 24 months from date of purchase by buyer or 27 months from date of shipment by weather-rite llc (whichever occurs first), replacement parts will be ...

Page 202

Tt-s eries i nstallation , o peration and s ervice m anual 196 of 198.

Page 203

Section 28: t he weather-rite ™ tt-s eries w arranty 197 of 198.

Page 204

Tt-s eries i nstallation , o peration and s ervice m anual 198 of 198.

Page 205: Warning

Section 28: t he weather-rite ™ tt-s eries w arranty 199 of 198 warning read the installation, operation and service manual thoroughly before installation, operation or service. Operating instructions 1. Stop! Read all safety instructions on this information sheet. 2. Open the manual gas valve in th...