- DL manuals

- Webasto

- Electric Heater

- Air Top 2000 S B

- Service And Repair Manual

Webasto Air Top 2000 S B Service And Repair Manual

List of Contents

Air Top 2000

– Improper installation or repair of Webasto heating and cooling systems can cause

fire or the leakage of deadly carbon monoxide leading to serious injury or death.

– Installation and repair of Webasto heating and cooling systems requires special

Webasto training, technical information, special tools and special equipment.

– NEVER attempt to install or repair a Webasto heating or cooling system unless you

have successfully completed the factory training course and have the technical skills,

technical information, tools and equipment required to properly complete the

necessary procedures.

– ALWAYS carefully follow Webasto installation and repair instructions and heed all

WARNINGS.

– Webasto rejects any liability for problems and damage caused by the system being

installed by untrained personnel.

Air Heater

Air Top 2000 S D (Diesel)

Air Top 2000 S B (Gasoline)

Service and Repair Manual

Summary of Air Top 2000 S B

Page 1

List of contents air top 2000 – improper installation or repair of webasto heating and cooling systems can cause fire or the leakage of deadly carbon monoxide leading to serious injury or death. – installation and repair of webasto heating and cooling systems requires special webasto training, techn...

Page 3

I list of contents 1. Introduction 1.1 scope and purpose.................................................................................................................................101 1.1.1 use of air heaters..........................................................................................

Page 4

Ii 7. Circuit diagrams 7.1 general....................................................................................................................................................701 8. Servicing 8.1 general.............................................................................................

Page 5

Iii air top 2000 s list of figures list of figures 501 general failure symptoms .............................................................................................................................501 502 failure symptoms during operation ........................................................

Page 6

List of figures air top 2000 s iv.

Page 7

1. Introduction 1.1 scope and purpose this repair shop manual is intended to support famil- iarized personnel in the repair of the air top 2000 s. 1.1.1 use of air heaters the air heater air top 2000 s is used to - heat the cabin - defrost the windscreens. They are not cleared for heating a transpor...

Page 8

The heater must not be installed in the passenger or driver compartments of busses. Should the heater never- theless be installed in such a compartment, the installa- tion box must be sealed tight against the vehicle interior. There must be sufficient ventilation of the installation box from the ext...

Page 9

Metal lines must be used. These may not heat to more than 110 °c should there be the possibility of contact within the room interior. Protective devices against con- tact may be fitted. Should exhaust pipes be routed through rooms accom- modating persons, these pipes shall be renewed after 10 years ...

Page 10

2. General description the air heater air top 2000 s operates under the evaporator principle and basically consists of: - combustion and heating air fan - heat exchanger - burner insert with combustion tube - control unit air heater air top 2000 s for control and monitoring a - control unit/control ...

Page 11

2.2 heat exchanger the heat exchanger dissipates the heat provided by combustion to the air delivered by the combustion and heating air fan. Heat exchanger 2.3 burner insert with combustion tube within the burner insert fuel is distributed in the combus- tion tube across the burner cross-section. In...

Page 12

2.7 temperature limiter the temperature limiter protects the air heater against excessive operating temperatures. Overheat protection is activated at a temperature higher than 150 °c to inter- rupt the electrical circuit of the dosing pump and switch off the heater with run-down operation. After coo...

Page 13

3. Functional description 3.1 functional description air top 2000 s 301 air top 2000 s 3 functional description 3.1.1 control element the control element is used to switch the air heater on and off, set the desired room temperature (air intake tem- perature between 10 °c and 45 °c), and to unlock a ...

Page 14

302 3 functional description air top 2000 s 3.1.4 heating operation during operation the combustion exhaust gasses flow through the heat exchanger charging its walls with com- bustion heat, which in turn is taken up by the heating air delivered by the heating air fan to be routed to the ve- hicle in...

Page 15

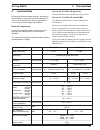

4. Technical data as long as no threshold values are given, the following technical data are understood to include tolerances of ± 10% usual for heaters at an ambient temperature of +20 °c and at nominal voltage and conditions. Electrical components: control unit, combustion air fan, dosing pump, ti...

Page 16

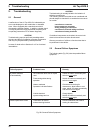

5. Troubleshooting 5.1 general a malfunction of the air top 2000 s is indicated by an error code displayed on the combination or standard timer. When equipped with a standard control dial the operating indicator flashes. In addition a heater check out may be performed using a personal computer (refe...

Page 17

5.3 failure symptoms during operation the following table (fig. 502) lists the possible failure symptoms as they might occur during the functional sequence of operation. In case of malfunction the failure is to be isolated and removed using this table. It is important to accurately identify the fail...

Page 18

5.4 error code output when equipped with a combination or standard timer a malfunction will cause an error code output to the dis- play of the timer for indication. Note when equipped with a control dial, the error code output is indicated by flashing of the operating indica- tor/error code indicati...

Page 19

6. Functional tests 6.1 general this section describes the on-vehicle and off-vehicle testing of the air heater to check its proper operation. Warning the air heater shall not be operated in enclosed areas like garages or workshops not provided with exhaust venting facilities. 6.2 adjustments 6.2.1 ...

Page 20

6.3 components testing caution during electrical testing always ensure that the control unit and the component under test are electrically discon- nected from each other. 6.3.1 glow plug resistance test during electrical testing of the glow plug using a digital multimeter, the following readings sho...

Page 21

7. Circuit diagrams 7.1 general the air heater air top 2000 s may be operated using the control dial (rated value transmitter/switch) or with the control dial and a combination or standard timer. The circuit diagrams (figs. 702 to 704) show the possible circuits 12 or 24 volt with control element co...

Page 22

702 7 circuit diagrams air top 2000 s ? ? ? K r a m e r e r u t a l c n e m o n m e ti 0 s 0 0 2 p o t r i a r e t a e h r i a 1 a a2 control unit b1 flame sensor b2 temperature sensor b3 temperature limiter e glow plug 4 8 2 1 j e a s e s u f t a l f a 5 1 v 2 1 / a 0 1 v 4 2 e s u f 2 f n o it a c...

Page 23

703 air top 2000 s 7 circuit diagrams wire gauges 7.5 - 15 m 0.75 mm 2 1.0 mm 2 1.5 mm 2 2.5 mm 2 4.0 mm 2 1.5 mm 2 1.5 mm 2 2.5 mm 2 4.0 mm 2 6.0 mm 2 bl br ge gn gr or rt sw vi ws wire colours blue brown yellow green grey orange red black violet white fig. 703 circuit diagram automatic control air...

Page 24

704 7 circuit diagrams air top 2000 s wire gauges 7.5 - 15 m 0.75 mm 2 1.0 mm 2 1.5 mm 2 2.5 mm 2 4.0 mm 2 1.5 mm 2 1.5 mm 2 2.5 mm 2 4.0 mm 2 6.0 mm 2 bl br ge gn gr or rt sw vi ws wire colours blue brown yellow green grey orange red black violet white fig. 704 circuit diagram automatic control air...

Page 25

705 air top 2000 s 7 circuit diagrams fig. 705 connection diagram, air top 2000 s with combination timer 3 2 1 6 5 4 9 8 7 12 11 10 12v 24v combination timer 1531 adapter harness p/n 9008440a brown battery negative (12, 4) red battery positive (11) black battery positive or ignition signal (10) grey...

Page 26

706 7 circuit diagrams air top 2000 s.

Page 27

8. Servicing 8.1 general this section describes the servicing procedures that may be performed with the air heater installed. 8.2 work on the air heater prior to performing any work it is mandatory to discon- nect the vehicle battery main lead. As long as the air heater is in operation or in run-dow...

Page 28

8.6.2 fuel supply 8.6.2.1 fuel tapping vehicles with a diesel engine fig. 801 fuel supply 802 8 servicing air top 2000 s iØ2mm iØ2mm iØ2mm iØ2mm i2 i2 i1 i1 max. 3m (9.8 ft.) h s i 2 i 1 + ≤ 10 m (32.8 ft.) ≤ 1.2 m (3.9 ft.) ≤ 8.8 m (28.8 ft.) i 1 i 2 vehicles with an injection engine when installin...

Page 29

803 hole pattern fig. 802 webasto fuel tank tap * use fuel tank tap only on metal fuel tanks fig. 803 fuel tapping from plastic tank (tapping via fuel drain plug) plastic tank gasket fuel tank tap gaskets tank fitting plate fig. 804 fuel tapping from plastic tank (tapping via fitting plate) note the...

Page 30

Connection of 2 pipes with hose the proper connection of fuel lines with hoses is shown in fig. 805. Fig. 805 pipe/hose connection 8.6.3 dosing pump the dosing pump is a combined delivery, dosing, and shut-off system and is subject to certain installation crite- ria (see figs. 801 and 806). At 2000 ...

Page 31

8.6.5 combustion air supply combustion air must under no circumstances be ex- tracted from rooms with persons. The combustion air inlet must not point towards the forward direction of mo- tion. It must be located so that no clogging by contamina- tion is to be expected. Note for fuel operated heater...

Page 32

8.6.8 electrical connections 8.6.8.1 connection air heater, control dial electrical connection is according to circuit diagram automatic control (see section 7). For connection of the cable loom the cover (see 9.2.1.1) of the air heater has to be removed for connecting the cable loom plug(s) to the ...

Page 33

807 fig. 813 example of an installation 1 c on tro l d ia l 2 ai r h ea te r 3 d os in g pu m p an d d am pe r 4 fu el f ilt er (a cc es so ry ) 5 fu el c on ne ct or 6 ex ha us t m uf fle r 7 fu se air top 2000 s 8 servicing 1 2 3 4 5 6 7.

Page 34

8.7 removal and installation caution when the heater is installed it must not be dismantled. 8.7.1 air heater, removal and installation 8.7.1.1 removal 1. Disconnect battery terminal leads. 2. Withdraw cover from upper housing shell according to 9.2.1. 3. Disconnect the wire harness plug from contro...

Page 35

9. Repair 9.1 general this section describes the repairs that may be per- formed on the air heater air top 2000 s after it has been removed from the vehicle. Any further disassembly will void the warranty. For reassembly, only components of the proper spare parts and kits are to be used. 9.1.1 work ...

Page 36

9.2 disassembly and assembly 9.2.1 removal of housing components/covers 9.2.1.1 cover for electrical connection dependent on the type of installation the cable loom exits the air heater either on the left or right. The cover (1, fig. 901) may be levered off using a blunt blade in the areas marked x ...

Page 37

903 air top 2000 s 9 repair 9.2.2 replacement of control unit 9.2.2.1 removal during removal avoid the build-up of static charge (i.E. Do not touch strip conductors). 1. Remove heater from vehicle (see 8.7.1.1). 2. Remove covers for heating air inlet and outlet (6 and 3, fig. 901) according to 9.2.1...

Page 38

904 9 repair air top 2000 s fig. 902 replacement of control unit and temperature limiter 1 plug connections 2 control unit 3 screw (2) 7 screw 4 screw (2) 5 temperature limiter 6 bracket 3 1 7 x6 2 4 5 6.

Page 39

9.2.4 replacement of combustion air fan 9.2.4.1 removal 1. Remove air heater (see 8.7.1.1). 2. Remove control unit (see 9.2.2.1). 3. Remove seal (2 fig. 903) from lower housing shell and discard. 4. Remove air heater from lower housing shell. 5. Remove insulation (1, fig. 903) 6. Remove screws (1, f...

Page 40

906 9 repair air top 2000 s 1 3 2 fig. 904 replacement of combustion air fan (assembly) 1 screw (5) 2 gasket 3 combustion air fan before assembly always renew gasket. Combustion air fan must not be disassembled any further 9.2.4.2 installation 1. Ensure that sealing surfaces on combustion air fan an...

Page 41

907 air top 2000 s 9 repair 9.2.5 replacement of flame sensor 9.2.5.1 removal 1. Remove air heater (see 8.7.1.1). 2. Remove control unit (see 9.2.2.1). 3. Remove combustion air fan (see 9.2.4.1). 4. Remove screws (3, fig. 905) and spoiler (2) for cable protection. 5. Push out cable grommet (10) towa...

Page 42

908 fig. 905 disassembly of heat exchanger (sheet 1 of 2) 9 repair air top 2000 s 8 7 6 3 1 2 12 5 4 10 9 11 13 1 flame sensor 2 spoiler 3 screw (4) 4 locking tab 5 burner insert 6 combustion tube 7 gasket 8 heat exchanger 9 cable grommet 10 cable grommet 11 glow plug 12 grommet 13 screw.

Page 43

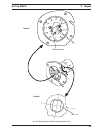

909 fig. 906 disassembly of heat exchanger (sheet 2 of 2) air top 2000 s 9 repair detail a detail b starting air bore twist lock.

Page 44

910 9 repair air top 2000 s 9.2.7 replacement of burner insert, combustion tube, and heat exchanger 9.2.7.1 removal 1. Remove air heater (see 8.7.1.1). 2. Remove control unit (see 9.2.2.1). 3. Remove combustion air fan (see 9.2.4.1). 4. Remove flame sensor (see 9.2.5.1). 5. Remove glow plug (see 9.2...

Page 45

10. Packaging/storage and shipping 10.1 general in storage an ambient temperature of +85 °c and -40 °c must not be exceeded. 06/2008 1001 air top 2000 s 10 packaging/storage and shipping when it is necessary to ship the heater and its components to a webasto repair center for inspection or repair, t...

Page 46

Notes air top 2000 s.

Page 48

W ebasto p roduct n.A., i nc . 15083 north road fenton, mi 48430 technical assistance hotline usa: (800) 860-7866 canada: (800) 667-8900 www.Techwebasto.Com www.Webasto.Us org. 06/2008 rev. N/a p/n lit9000557a © 2008 webasto product n.A., inc..