- DL manuals

- Webasto

- Heater

- Air Top 2000 STC

- Workshop Manual

Webasto Air Top 2000 STC Workshop Manual

Summary of Air Top 2000 STC

Page 1

Luft-heizgeräte air heaters 03/2003 workshop manual air top 2000 stc trade names: air top 2000 stc b (petrol) air top 2000 stc d (diesel).

Page 2

Improper installation or repair of webasto heating and cooling systems can cause fire or the leakage of deadly carbon monoxide leading to serious injury or death. To install and repair webasto heating and cooling systems you need to have completed a webasto training course and have the appropriate t...

Page 3: Air Top 2000 Stc

Air top 2000 stc table of contents i table of contents 1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101 1.1 contents and purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4: Table Of Contents

Table of contents air top 2000 stc ii 6.4.1 component: burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 605 6.4.2 testing resistance of flame monitor (petrol heater only) . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 5: Air Top 2000 Stc

Air top 2000 stc table of contents iii 9 repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 901 9.1 general information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 6: Table Of Illustrations

Table of illustrations air top 2000 stc iv table of illustrations fig. 201 air heater air top 2000 stc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201 fig. 202 air top 2000 stc air heater without casing. . . . . . . . . . . ...

Page 7: Air Top 2000 Stc

Air top 2000 stc 1 introduction 101 1 introduction 1.1 contents and purpose this workshop manual is designed to assist trained personnel in repairing both the petrol and the diesel versions of the air top 2000 stc air heaters. 1.1.1 use of air heaters the webasto air top 2000 stc air heaters are des...

Page 8: 1 Introduction

1 introduction air top 2000 stc 102 in the event of prolonged smoke accumulation, unusual com- bustion noise or smell of fuel, the heater must be shut down by removing the fuse and must not be started again until it has been examined by webasto-trained personnel. Liability claims can only be asserte...

Page 9: Air Top 2000 Stc

Air top 2000 stc 1 introduction 103 page for notes.

Page 10: 2 General Description

2 general description air top 2000 stc 201 2 general description the air top 2000 stc air heater is based on the evaporator principle and essentially consists of: – drive unit (combustion air fan, heating air fan and drive motor) – heat exchanger – burner with combustion chamber – control unit – glo...

Page 11: Air Top 2000 Stc

Air top 2000 stc 2 general description 202 2.2 heat exchanger in the heat exchanger, the heat generated by the combustion process is transferred to the air delivered by the heating air fan. Fig. 204 heat exchanger 2.3 burner with combustion chamber in the burner, the fuel is distributed over the met...

Page 12: 2 General Description

2 general description air top 2000 stc 203 2.6 glow plug the fuel/air mixture is ignited by the glow plug when the heater is started. The glow plug is designed as an electrical resistor and is positioned in the burner on the side opposite the flame. Fig. 208 glow plug 2.7 overheating sensor the over...

Page 13: Air Top 2000 Stc

Air top 2000 stc 2 general description 204 page for notes.

Page 14: 3 Function Description

3 function description air top 2000 stc 301 3 functional description 3.1 control element the control element is used to: • switch the heater on and off. • set the required room temperature (intake temperature between approx. 5 °c and 35 °c). • reset the heater after a malfunction. • display fault co...

Page 15: Air Top 2000 Stc

Air top 2000 stc 3 function description 302 if, at minimum heating capacity, the intake temperature set on the control element is exceeded, the fuel pump will be shut down and combustion stops. To allow the flame to burn out properly, the speed of the heating and combustion air fan drops to partial ...

Page 16: 3 Function Description

3 function description air top 2000 stc 303 3.8.1 fault monitoring overheating, incorrect start and flame failure faults are counted and, after the maximum number of permissible faults have been exceeded, result in heater lock-out. The incorrect start counter is incremented by 1 each time the heater...

Page 17: Air Top 2000 Stc

Air top 2000 stc 3 function description 304 page for notes.

Page 18: 4 Technical Data

4 technical data air top 2000 stc 401 4 technical data wherever no limit values are specified, the technical data in the table refer to the standard heater tolerances of ±10% at an ambient temperature of +20 °c and at rated voltage under standard conditions. Electrical components: the control unit, ...

Page 19: Air Top 2000 Stc

Air top 2000 stc 4 technical data 402 4.1 setpoints heater operation air top 2000 stc b and air top 2000 stc d 12 volt 24 volt glow plug at 25 ºc test current: red mark 0.263 - 0.323 ohm green mark 1.125 - 1.375 ohm drive motor outside overheating temperature sensor at 25 ºc 2 - 2.5 ohm undervoltage...

Page 20: 4 Technical Data

4 technical data air top 2000 stc 403 page for notes.

Page 21: Air Top 2000 Stc

Air top 2000 stc 5 troubleshooting 501 5 troubleshooting 5.1 general information this section describes how to identify and remedy faults in the air top 2000 stc heater. If a malfunction occurs, a fault code will be shown on the display or the on indicator lamp will flash (on control elements with n...

Page 22: 5 Troubleshooting

5 troubleshooting air top 2000 stc 502 5.3 fault symptoms during operation the following table (fig. 502) lists the possible fault symptoms during operation which should be checked first. In the event of a malfunction, the fault is to be located and rectified with the aid of this table. It is import...

Page 23: Air Top 2000 Stc

Air top 2000 stc 5 troubleshooting 503 5.4 fault code output (hexadecimal / webasto thermo test) fault code output: fault message fault details recommended measures hex 00 no error no error no action necessary 01 defective control unit defective control unit, wrong end- of-line programming or coolan...

Page 24: 5 Troubleshooting

5 troubleshooting air top 2000 stc 504 12 w-bus communication failure w-bus communication failure 1) check for fault in area of w-bus communication/w-bus control element/w-bus telestart 2) replace control unit 14 temperature sensor short circuit (internal, external) temperature sensor has short circ...

Page 25: Air Top 2000 Stc

Air top 2000 stc 5 troubleshooting 505 1b overheat sensor short circuit the overheat sensor has a short circuit to ground electrical check of overheating sensor 8 a glow plug / electronic ignition unit interruption glow plug/flame monitor interrupted or short circuit to supply voltage ub electrical ...

Page 26: 5 Troubleshooting

5 troubleshooting air top 2000 stc 506 5.5 fault code output (flashing or fxx output) fault code output: fault message fault details recommended measures flashing / fxx f00 defective control unit control unit defective eol programming error 1) check for fault in area of w-bus communication/w-bus con...

Page 27: Air Top 2000 Stc

Air top 2000 stc 5 troubleshooting 507 f12 heater lock-out heater lock-out was activated 1) reset heater lock-out and attempt restart 2) read out further fault messages and work through instructions reset heater lock-out: switch on heater. Pull fuse f1 for at least 10 s. Switch off heater. Reinsert ...

Page 28: 5 Troubleshooting

5 troubleshooting air top 2000 stc 508 page for notes.

Page 29: Air Top 2000 Stc

Air top 2000 stc 6 function checks 601 6 function checks 6.1 general information this section describes the checks conducted on the heater in installed and uninstalled state to verify that it is in working order. Caution the heater must not be operated in enclosed areas such as garages and workshops...

Page 30: 6 Function Checks

6 function checks air top 2000 stc 602 a schematic diagram of the components necessary to operate a heater is shown below. Application-specific interfaces must be taken into account. A calibrated fuel pump, which is continually monitored, must be used for testing. The technical requirements are spec...

Page 31: Air Top 2000 Stc

Air top 2000 stc 6 function checks 603 6.3 settings 6.3.1 setting the co 2 content the co 2 content in the exhaust gas is set using the adjustment knob on the control element. At a constant fan speed, the volume of fuel is controlled by changing the fuel pump cycle. Attention the co 2 measuring inst...

Page 32: 6 Function Checks

6 function checks air top 2000 stc 604 6.4 testing individual components attention when carrying out function tests, always disconnect the connection between the control unit and the component to be tested. Note if this procedure is not able to detect the fault, the heater/ component must be sent in...

Page 33: Air Top 2000 Stc

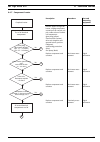

Air top 2000 stc 6 function checks 605 6.4.1 component: burner see fig. 904, item 5 2 1 1 2 1 1 burner combustion chamber mechanically damaged? No yes starting air hole open? No check function on heater test bench can co 2 value be set within tolerance? No yes procedure test and measuring equipment ...

Page 34: 6 Function Checks

6 function checks air top 2000 stc 606 6.4.2 testing resistance of flame monitor (petrol heater only) see abb. 904, item 1 when testing with a digital multimeter, the flame monitor must show the following values: cold test: resistance at 25 °c: 2.6 - 3.4 ohms test current: hot test: resistance at 80...

Page 35: Air Top 2000 Stc

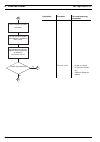

Air top 2000 stc 6 function checks 607 a 2 2 2 1 2 1 a flame monitor contacts detached? No yes procedure test and measuring equipment visualisation visual inspection visual inspection visual inspection resistance meas- urement digital multime- ter visual inspection no yes no yes no yes cables damage...

Page 36: 6 Function Checks

6 function checks air top 2000 stc 608 6.4.3 component: glow plug see abb. 904, item 6 note the resistance must be measured with a ohmmeter suitable for low resistance. Measuring the resistance with a simple digital multimeter is too inaccurate to determine the exact values. A new glow plug can be m...

Page 37: Air Top 2000 Stc

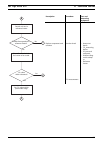

Air top 2000 stc 6 function checks 609 a 2 2 2 1 2 1 a glow plug contacts detached? No yes procedure test and measuring equipment visualisation visual inspection visual inspection visual inspection resistance meas- urement digital multime- ter visual inspection no yes no yes no yes cables damaged? C...

Page 38: 6 Function Checks

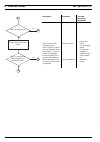

6 function checks air top 2000 stc 610 6.4.4 component: drive unit see abb. 903, item 5 1 1 1 4 1 1 drive unit externally damaged? No yes procedure test and measuring equipment visualisation visual inspection continuity meas- urement digital multimeter drive motor start- up voltage source subjective...

Page 39: Air Top 2000 Stc

Air top 2000 stc 6 function checks 611 6.4.5 component: overheating temperature sensor see abb. 903, item 8 when measuring the resistance with a digital multimeter, the overheating temperature sensor must return values as shown in the diagram (fig. 601). Overheating temperature sensor pt 2000 in tem...

Page 40: 6 Function Checks

6 function checks air top 2000 stc 612 6.4.6 component: control unit see abb. 701 and abb. 903, item 3 2 1 2 control unit externally damaged? No yes procedure test and measuring equipment visualisation visual inspection check function with reference heater. Install control unit to be tested in the r...

Page 41: Air Top 2000 Stc

Air top 2000 stc 6 function checks 613 6.4.7 component: heater 3 3 3 3 a complete heater test of all electrical components description procedure test and measuring equipment remove upper casing from heater, unplug component connector from control unit pcb, cable colour of individ- ual components: gl...

Page 42: 6 Function Checks

6 function checks air top 2000 stc 614 2 b a check function on heater test bench description procedure test and measuring equipment function check – heater test bench – pc (personal compu- ter) – webasto diagnostics adapter control unit data readout: operating hours, number of starts, faults send di...

Page 43: Air Top 2000 Stc

Air top 2000 stc 6 function checks 615 3 2 c b reinstall control unit in the heater to be tested description procedure test and measuring equipment replace component and continue function check – heater test bench – co 2 measuring device – pc (personal computer) – webasto diag- nostics adapt- er – r...

Page 44: 6 Function Checks

6 function checks air top 2000 stc 616 2 2 3 c description procedure test and measuring equipment check function with reference heater. After 5 minutes of opera- tion, set reference heater to nominal co 2 value as shown in the graphic, install the burner to be tested in the reference heater and meas...

Page 45: Air Top 2000 Stc

Air top 2000 stc 6 function checks 617 page for notes.

Page 46: 7 Wiring Diagrams

7 wiring diagrams air top 2000 stc 701 7 wiring diagrams 7.1 general information the air top 2000 stc heater can be operated with the control element (rotary switch or switch), combination timer or multicontrol/smartcontrol. The wiring diagrams (fig. 702 to fig. 705) show the possible connections fo...

Page 47: Air Top 2000 Stc

Air top 2000 stc 7 wiring diagrams 702 7.2 system wiring diagrams fig. 702 system wiring diagram air top 2000 stc, 12 v/24 v with rotary switch fig. 703 systems wiring diagram air top 2000 stc, 12 v/24 v with multicontrol 9032487a01 9032412a02.

Page 48: 7 Wiring Diagrams

7 wiring diagrams air top 2000 stc 703 fig. 704 system wiring diagram air top 2000 stc d, 12 v/24 v adr operation with smartcontrol fig. 705 system wiring diagram air top 2000 stc d, 12 v/24 v adr operation with rotary switch 9032489a01 9032488a01.

Page 49: Air Top 2000 Stc

Air top 2000 stc 7 wiring diagrams 704 7.3 legends to system wiring diagrams fig. 706 system wiring diagram air top 2000 stc, 12 v/24 v with combination timer 9032490a01 cable cross-sections 7.5 - 15 m 0.75 mm 2 1.0 mm 2 1.0 mm 2 1.5 mm 2 1.5 mm 2 2.5 mm 2 2.5 mm 2 4.0 mm 2 4.0 mm 2 6.0 mm 2 cable c...

Page 50: 7 Wiring Diagrams

7 wiring diagrams air top 2000 stc 705 7.4 pin assignments plug connection x6, 18-pin h2 led red (in item p) lighting:quick heating button, ready indicator, on indicator h3 heating symbol on display (in item p) on indicator, ready indicator h4 bulb/led (in item p) display and button lighting h5 bulb...

Page 51: Air Top 2000 Stc

Air top 2000 stc 7 wiring diagrams 706 page for notes.

Page 52: 8 Servicing

8 servicing air top 2000 stc 801 8 servicing 8.1 general information this section describes the servicing jobs that can be carried out on the heater when installed. 8.2 working on the heater always disconnect the main power cable from the vehicle battery before carrying out any work on the heater. T...

Page 53: Air Top 2000 Stc

Air top 2000 stc 8 servicing 802 attention in vehicles used to transport persons, the air outlet opening is to be arranged such that it is at least 20 cm away from any parts of the body. When switched on, the heater automatically checks the internal rise in temperature. If the rise in temperature is...

Page 54: 8 Servicing

8 servicing air top 2000 stc 803 8.6.2.3 fuel take-off via tank drain plug (from plastic or metal fuel tank) fig. 802 fuel take-off via tank drain plug (plastic or metal fuel tank) 8.6.2.4 webasto tank extracting device for plastic fuel tank fig. 803 webasto tank extracting device (plastic fuel tank...

Page 55: Air Top 2000 Stc

Air top 2000 stc 8 servicing 804 8.6.2.7 connecting 2 fuel lines with a hose fig. 805 shows the correct connection of fuel lines with a hose. Fig. 805 pipe/hose connections 8.6.3 fuel pump the fuel pump is a combined delivery, metering and a shut- off system and is subject to certain installation cr...

Page 56: 8 Servicing

8 servicing air top 2000 stc 805 8.6.4 fuel filter installation location of fuel filter: between fuel tank and fuel pump. Only a webasto filter, ident. No. 487 171, is to be fitted if poor-quality fuel is used. Install vertically if possible, maximum deviation not exceeding 90° (ensure correct direc...

Page 57: Air Top 2000 Stc

Air top 2000 stc 8 servicing 806 8.6.8 combustion air intake and exhaust pipes to avoid damaging the fuel pump cable, exhaust pipe must not be used to extend the combustion air supply line. Length of combustion air intake line and exhaust pipes: with exhaust silencer: max.2.0 m without exhaust silen...

Page 58: 8 Servicing

8 servicing air top 2000 stc 807 8.6.9.3 control element connection the wiring harness is prepared for connection to the control element (rotary switch). Only pull on the connector housing to unplug the connector (fig. 813). Fig. 813 rotary switch control element note the fibre optic cable must make...

Page 59: Air Top 2000 Stc

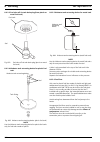

Air top 2000 stc 8 servicing 808 1 2 3 4 5 6 7 10 9 8 1 control element 2 heater 3 fuse 4 tank extracting device 5 fuel filter (accessory) 6 fuel pump 7 exhaust silencer (accessory) 8 combustion air intake line 9 combustion air intake silencer (accessory) 10 maximum permissible fording level fig. 81...

Page 60: 8 Servicing

8 servicing air top 2000 stc 809 8.7 removing and installing attention the heater must not be dismantled when installed. 8.7.1 removing and installing heater 8.7.1.1 removal 1. Disconnect vehicle battery. 2. Detach cover from upper casing as shown in 9.2.1.1. 3. Disconnect wiring harness connector f...

Page 61: Air Top 2000 Stc

Air top 2000 stc 8 servicing 810 page for notes.

Page 62: 9 Repair

9 repair air top 2000 stc 901 9 repair 9.1 general information this section describes the repair jobs that can be carried out on the air top 2000 stc heater after it has been removed from the vehicle. Any further dismantling will invalidate the warranty. For assembling the heater only use the spare ...

Page 63: Air Top 2000 Stc

Air top 2000 stc 9 repair 902 5. Plug connector x12 of the external room temperature sensor into connector x11 of the wiring harness. 6. Plug both connectors on the external room temperature sensor line into the external room temperature sensor. 7. Mount external room temperature sensor. 6. Carry ou...

Page 64: 9 Repair

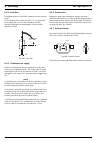

9 repair air top 2000 stc 903 . Fig. 902 removing / fitting casing parts 1 2 3 4 5 6 1 cover, electrical connection 2 upper casing 3 cover, heating air outlet 4 lower casing 5 grille 6 cover, heating air inlet 7 insulator 5 7 widening of corner fin insulator positioning insulator.

Page 65: Air Top 2000 Stc

Air top 2000 stc 9 repair 904 9.2.3 replacing control unit 9.2.3.1 removal 1. Remove heater (see 8.7.1.1). 2. Remove casing parts (see 9.2.1). 3. Spread apart heating air fan retainer. 4. Pull off the heating air fan (1, fig. 903) from the motor shaft by hand. 5. Disconnect plug connections at contr...

Page 66: 9 Repair

9 repair air top 2000 stc 905 9.2.6 replacing flame monitor (petrol heater only) 9.2.6.1 removal 1. Remove heater (see 8.7.1.1). 2. Remove casing parts (see 9.2.1). 3. Remove control unit (see 9.2.3.1). 4. Remove drive unit (see 9.2.5.1). 5. Remove two screws (2, fig. 903) and air baffle (3). 6. Pre...

Page 67: Air Top 2000 Stc

Air top 2000 stc 9 repair 906 fig. 903 replacing control unit, combustion air fan and overheating temperature sensor 5 1 heating air blower 2 torx screw (3) 3 control unit 4 torx screw (5) 5 drive motor, combustion air fan and intake housing 6 gasket 7 heat exchanger 8 overheating temperature sensor...

Page 68: 9 Repair

9 repair air top 2000 stc 907 9.2.7 changing glow plug 9.2.7.1 removal 1. Remove heater (see 8.7.1.1). 2. Remove casing parts (see 9.2.1). 3. Remove control unit (see 9.2.3.1). 4. Remove combustion air fan (see 9.2.5.1). 5. Press cable grommet (10, fig. 904) inwards and out of heat exchanger (9). 6....

Page 69: Air Top 2000 Stc

Air top 2000 stc 9 repair 908 fig. 904 changing glow plug, replacing flame monitor, burner and heat exchanger 1 flame monitor (petrol heater only) 2 torx screw (4) 3 air baffle 4 retaining clip 5 burner 6 glow plug 7 screw 8 grommet 9 heat exchanger 10 cable grommet 11 cable grommet (petrol heater o...

Page 70: 9 Repair

9 repair air top 2000 stc 909 9.2.8 replacing burner, combustion chamber and heat exchanger 9.2.8.1 removal 1. Remove heater (see 8.7.1.1). 2. Remove casing parts (see 9.2.1). 3. Remove control unit (see 9.2.3.1). 4. Remove overheating temperature sensor (see 9.2.4.1). 5. Remove combustion air fan (...

Page 71: Air Top 2000 Stc

Air top 2000 stc 9 repair 910 fig. 905 starting air hole in burner starting air hole.

Page 72: Air Top 2000 Stc

10 packaging / storage / shipping air top 2000 stc 1001 10 packaging/storage and shipping 10.1 general information if the heater or its components are to be sent to webasto thermo & comfort se for testing or repair, they must be cleaned and packed in such a way that they are protected from damage du...

Page 73: Air Top 2000 Stc

Air top 2000 stc 10 packaging / storage / shipping 1002 page for notes.

Page 74

Webasto thermo & comfort se postfach 1410 82199 gilching germany visiting address: friedrichshafener str. 9 82205 gilching germany internet: www.Webasto.Com technical extranet: http://dealers.Webasto.Com the telephone number of each country can be found in the webasto service center leaflet or the w...