- DL manuals

- Webasto

- Heater

- Air Top Evo 40

- Workshop Manual

Webasto Air Top Evo 40 Workshop Manual

Summary of Air Top Evo 40

Page 1

Air heaters workshop manual air top evo 40 air top evo 55 air top evo 40 b / air top evo 55 b (petrol) air top evo 40 d / air top evo 55 d (diesel/pme) visit www.Butlertechnik.Com for more technical information and downloads. Www.Butlertechnik.Com.

Page 2

Improper installation or repair of webasto heating and cooling systems can cause fire or the leakage of deadly carbon monoxide leading to serious injury or death. To install and repair webasto heating and cooling systems you need to have completed a webasto training course and have the appropriate t...

Page 3: Table of Contents

Air top evo 40 / air top evo 55 i table of contents 1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101 1.1 contents and purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4

Air top evo 40 / air top evo 55 ii 6 functional checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 601 6.1 general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 5: Table of Illustrations

Air top evo 40 / air top evo 55 iii table of illustrations fig. 201 air top evo 40 / air top evo 55 air heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .201 fig. 202 air top evo 40 / air top evo 55 air heater without housing . . . . . . . . . ...

Page 6: Introduction

Introduction air top evo 40 / air top evo 55 101 1 introduction 1.1 contents and purpose this workshop manual is used to support instructed personnel when repairing the air top evo 40 / air top evo 55 petrol or diesel air heaters. 1.1.1 use of air heaters the webasto air top evo 40 / air top evo 55 ...

Page 7: Introduction

Air top evo 40 / air top evo 55 introduction 102 1.4.2 general safety precautions the repair and commissioning of the unit may only be carried out by personnel trained by webasto. The repair and installa- tion of the unit may only be carried out in accordance with the workshop manual and the install...

Page 8: Introduction

Introduction air top evo 40 / air top evo 55 103 note if damage to or leaks in the fuel line are determined, the heater may not be operated until the damage has been elim- inated by an authorised webasto specialist workshop. Put the heater out of action by removing the fuse. Overheating keep the col...

Page 9: General Description

Air top evo 40 / air top evo 55 general description 201 2 general description the air top evo 40 / air top evo 55 air heater designed ac- cording to the evaporator principle mainly consists of the fol- lowing: – the drive unit (drive motor with combustion and heating air fan) – the heat exchanger – ...

Page 10: General Description

General description air top evo 40 / air top evo 55 202 2.2 heat exchanger the heat generated by combustion in the heat exchanger is given off to the cold air transported by the heating air fan. 2.3 evaporator mount with combustion pipe the fuel is distributed via the metal fibre evaporator (fleece)...

Page 11: General Description

Air top evo 40 / air top evo 55 general description 203 2.5 exhaust temperature sensor the exhaust temperature sensor is a low-resistance ptc resis- tor which changes its resistance in dependence on the tem- perature change of the exhaust gases. This change in resistance is also used for flame monit...

Page 12: Function Description

Function description air top evo 40 / air top evo 55 301 3 function description 3.1 control element air top evo 40 / air top evo 55 can be activated either with suitable control elements, e.G. Rotary selector, combination timer, or an air top evo multi control (mc04). Operation is described in the o...

Page 13: Function Description

Air top evo 40 / air top evo 55 function description 302 in addition, the heating mode is briefly interrupted after every 8 hours and then automatically restarted in the same way as for a control break. This ensures controlled combustion oper- ation. 3.4 control mode in the control mode, the drive m...

Page 14: Function Description

Function description air top evo 40 / air top evo 55 303 after an adr switch-off, the control unit is in the "adr lock- out" position. For repeat start-up, the control element must be set to "off" and the auxiliary drive signal or the vehicle- specific safety mechanism must no longer be active. The ...

Page 15: Function Description

Air top evo 40 / air top evo 55 function description 304 3.10.2 reset a fault switch-off certain errors result in the errors being added up in the error memory. If the number of errors in the error memory has exceeded a limit, the heater changes over to the heater lock- out. The maximum number of er...

Page 16: Technical Data

Technical data air top evo 40 / air top evo 55 401 4 technical data except where limit values are specified, the technical data list- ed in the table refer to the usual heater tolerances of ±10% at an ambient temperature of +20 °c and at the rated voltage and in rated conditions. Electrical componen...

Page 17: Technical Data

Air top evo 40 / air top evo 55 technical data 402 setpoint values: 12 v 24 v glow plug at 25 °c test current: no marking 0.190 - 0.250 ohms green marking 0.740 - 0.940 ohms drive unit outside blow-out temperature sensor at 25 ºc 2,195 ohms external temperature sensor at 25 ºc 10,000 ohms exhaust te...

Page 18: Troubleshooting

Troubleshooting air top evo 40 / air top evo 55 501 5 troubleshooting 5.1 general information if a malfunction occurs, a flashing code is displayed on the operating indicator or a fault code f .. On the combination timer. In addition, the heater can be checked using a personal com- puter (see webast...

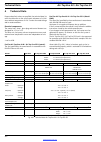

Page 19: Troubleshooting

Air top evo 40 / air top evo 55 troubleshooting 502 5.3 error symptoms during function the following table (fig. 502) lists the possible error symp- toms in the order in which they may occur during operation. In the event of a fault, the error is to be located using this ta- ble and rectified. It is...

Page 20: Troubleshooting

Troubleshooting air top evo 40 / air top evo 55 503 5.4 fault code displayed in control element if serious malfunctions, such as overheating or failure to start, occur with increasing frequency, then the heater is permanently locked out and can only be returned to operation following repairs by weba...

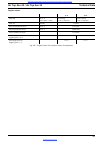

Page 21: Troubleshooting

Air top evo 40 / air top evo 55 troubleshooting 504 f 05 not available f 06 not available f 07 fuel pump defective 88 open circuit in fuel pump check electrical wiring and fuel pump and replace if necessary 08 short circuit in fuel pump f 08 open circuit/short circuit/ overloading/blockage in drive ...

Page 22: Troubleshooting

Troubleshooting air top evo 40 / air top evo 55 505 5.5 maintenance display in control element the maintenance signal is displayed when an operating period of more than 3,000 operating hours has been reached or the heater is in a restricted operating mode. In case of restricted operation, either the...

Page 23: Functional Checks

Air top evo 40 / air top evo 55 functional checks 601 6 functional checks 6.1 general information this section describes the tests conducted on the heater when it is installed and not installed to verify that it is in work- ing order. Warning the heater must not be operated in enclosed areas such as...

Page 24: Functional Checks

Functional checks air top evo 40 / air top evo 55 602 6.3 settings 6.3.1 factory settings the heater is set at the factory, based on an altitude of 0 m above sea level, to a specified nominal co 2 value in accord- ance with section 6.3.2. When used at altitudes above sea level, a higher co 2 content...

Page 25: Functional Checks

Air top evo 40 / air top evo 55 functional checks 603 6.4 tests of individual components important for function tests always disconnect the connection between the control unit and the component to be tested. Note if a fault occurs which cannot be detected with this proce- dure, the unit/component mu...

Page 26: Functional Checks

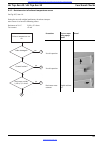

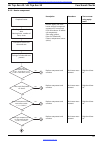

Functional checks air top evo 40 / air top evo 55 604 6.4.1 burner component assembly see fig. 907, item 3 and item 7 2 4 1 1 burner assembly (evaporator mount with combustion pipe) evaporator mount or combus- tion pipe mechanically dam- aged? No yes is fuel pipe freely passable? No check function o...

Page 27: Functional Checks

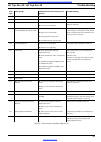

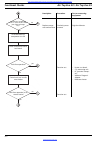

Air top evo 40 / air top evo 55 functional checks 605 6.4.2 resistance test of exhaust temperature sensor see fig. 907, item 10. During the test with a digital multimeter, the exhaust temper- ature sensor is to have the following values: resistance at 20 °c: 2,160 ± 3.2 ohms test current: 1 1 1 4 ex...

Page 28: Functional Checks

Functional checks air top evo 40 / air top evo 55 606 6.4.3 heating air fan component see fig. 903, item 1 6.4.4 glow plug component see fig. 907, item 8 note the resistance test must be carried out with an ohmmeter suitable for small resistance values. A resistance test with a simple digital multim...

Page 29: Functional Checks

Air top evo 40 / air top evo 55 functional checks 607 1 2 2 4 1 glow plug contacts detached? No yes procedure test or meas- uring equip- ment visual visual inspection visual inspection visual inspection resistance meas- urement digital multime- ter no yes no yes no yes cables damaged? Ceramic broken...

Page 30: Functional Checks

Functional checks air top evo 40 / air top evo 55 608 6.4.5 drive unit component see fig. 903, item 2 1 1 1 4 1 1 drive unit externally damaged? No yes procedure test or meas- uring equip- ment visual visual inspection continuity meas- urement digital multime- ter drive motor start- up voltage sourc...

Page 31: Functional Checks

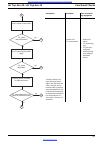

Air top evo 40 / air top evo 55 functional checks 609 6.4.6 blow-out temperature sensor component see fig. 903, item 9 during the resistance test with a digital multimeter, the blow- out temperature sensor must have values in accordance with the following chart: fig. 604 characteristic resistance va...

Page 32: Functional Checks

Functional checks air top evo 40 / air top evo 55 610 6.4.7 control unit component see fig. 701 and fig. 903, item 4 2 1 4 control unit externally damaged? No yes procedure test or meas- uring equip- ment visual visual inspection – housing broken? – all clips engaged? – clips torn? Conduct function ...

Page 33: Functional Checks

Air top evo 40 / air top evo 55 functional checks 611 6.4.8 heater component complete heater testing of all electrical com- ponents description procedure test or meas- uring equip- ment remove upper shell from heater and pull component connector off control unit pcb. Wire colours of individ- ual com...

Page 34: Functional Checks

Functional checks air top evo 40 / air top evo 55 612 check function on heater test bench description procedure test or measuring equipment replace compo- nent and continue continuity meas- urement function test digital multimeter – heater test bench – co 2 measuring unit – pc (personal compu- ter) ...

Page 35: Functional Checks

Air top evo 40 / air top evo 55 functional checks 613 2 2 3 2 c reinstallation of control unit in heater to be tested description procedure test or measur- ing equipment conduct function test with reference heater. Adjust the reference unit after 5 minutes to co 2 nominal value in accord- ance with ...

Page 36: Wiring Diagrams

Wiring diagrams air top evo 40 / air top evo 55 701 7 wiring diagrams 7.1 general information the air top evo 40 / air top evo 55 heaters can be operated with the rotary selector, a combination timer or the air top evo multi control (mc04) control element. The wiring diagrams (fig. 702 to fig. 707) ...

Page 37: Wiring Diagrams

Air top evo 40 / air top evo 55 wiring diagrams 702 fig. 702 wiring diagram for air top evo 40 and air top evo 55, 12 v/24 v with rotary selector and vehicle fan fig. 703 wiring diagram for air top evo 40 and air top evo 55, 24 v for adr operation with rotary selector visit www.Butlertechnik.Com for...

Page 38: Wiring Diagrams

Wiring diagrams air top evo 40 / air top evo 55 703 fig. 704 wiring diagram for air top evo 40 and air top evo 55, 12 v/24 v with 1531 combination timer and electr. Battery isolation switch fig. 705 wiring diagram for air top evo 40 and air top evo 55, 12 v/24 v with air top evo multicomfort (mc04) ...

Page 39: Wiring Diagrams

Air top evo 40 / air top evo 55 wiring diagrams 704 fig. 706 wiring diagram for air top evo 40 and air top evo 55 "master heater", 12 v/24 v with rotary selector fig. 707 wiring diagram for air top evo 40 and air top evo 55 "slave heater", 12 v/24 v x3/x4/x5/x6/x8 x1/x2 x7 x15 x13 9 10 12 4 11 1 8 6...

Page 40: Wiring Diagrams

Wiring diagrams air top evo 40 / air top evo 55 705 fig. 708 connection diagram fir air top evo 40 and air top evo 55 with 1531 combination timer fig. 709 connection diagram for air top evo 40 and air top evo 55 with air top evo multi control (mc04) control element 1. 1531 combination timer 2. Grey:...

Page 41: Wiring Diagrams

Air top evo 40 / air top evo 55 wiring diagrams 706 7.2 legend for wiring diagrams cable cross-sections cable colours 7.5 - 15 m 0.75 mm 2 1.0 mm 2 1.0 mm 2 1.5 mm 2 1.5 mm 2 2.5 mm 2 2.5 mm 2 4.0 mm 2 4.0 mm 2 6.0 mm 2 abbreviation colour bl blue br brown ge yellow gn green gr grey or orange rt red...

Page 42: Wiring Diagrams

Wiring diagrams air top evo 40 / air top evo 55 707 note numbers (1) with plus from terminal 15/75 to connection 10: continuous operation with immediate heating as long as ignition is switched on. (2) all heater variants: w bus pc diagnostics connection. Heater variants with air top evo multi contro...

Page 43: Service Work

Air top evo 40 / air top evo 55 service work 801 8 service work 8.1 general information this section describes the servicing work that can be carried out on the heater when it is installed. 8.2 work on heater disconnect the main power cable from the vehicle’s battery before carrying out any work on ...

Page 44: Service Work

Service work air top evo 40 / air top evo 55 802 air outlet side if it is used in an air circulation system. A short circuit of the cold and hot air flow must be avoided. Minimum inside diameter of main branch of hot air line: 80 mm for air top evo 40 90 mm for air top evo 55 the cold and hot air ho...

Page 45: Service Work

Air top evo 40 / air top evo 55 service work 803 8.6.2.2 fuel filter if soiled fuel is to be expected, a suitable fuel filter (e.G. We- basto fuel filter) must be installed. Install vertically if possible, however at least horizontally (see fig. 802). Note: observe installation position and flow dir...

Page 46: Service Work

Service work air top evo 40 / air top evo 55 804 warning if the exhaust pipe ends is other than as shown in the fig. 804 it will pose a fire risk. 8.6.6 electrical connections 8.6.6.1 heater connection, control element the electrical connection is to be made as shown in the ap- propriate wiring diag...

Page 47: Service Work

Air top evo 40 / air top evo 55 service work 805 8.6.6.3 rotary selector connection the wiring harness is prepared for connection to the rotary selector. Simply pull on connector housing to unplug the con- nector (see fig. 808). Note the fibre optic cable (fig. 807, "a") must be in contact with the ...

Page 48: Service Work

Service work air top evo 40 / air top evo 55 806 fig. 809 installation example for heater in re-circulated air mode 1 7 8 6 5 4 2 3 1. Control element 2. Heater 3. Fuse 4. Fuel standpipe 5. Fuel filter (optional) 6. Fuel pump 7. Exhaust silencer (optional) 8. Maximum permissible water passage height...

Page 49: Service Work

Air top evo 40 / air top evo 55 service work 807 8.7 removal and installation important when the heater is installed it must not be dismantled. 8.7.1 heater, removal and installation 8.7.1.1 removal 1. Disconnect vehicle battery. 2. Pull cover off top shell as described in section 9.2.1.1. 3. Discon...

Page 50: Repair

Repair air top evo 40 / air top evo 55 901 9 repair 9.1 general information this section describes the repair work that can be carried out on the air top evo 40 / air top evo 55 heater after it has been removed from the vehicle. Any further dismantling will invalidate the warranty. Only use the spar...

Page 51: Repair

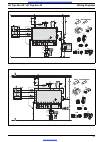

Air top evo 40 / air top evo 55 repair 902 9.2 dismantling and assembling 9.2.1 remove housing parts 9.2.1.1 cover for electrical connection the cover (1, fig. 902) can be carefully levered off using a blunt blade in the areas marked “x”. 9.2.1.2 grilles (optional) for cold air inlet and hot air out...

Page 52: Repair

Repair air top evo 40 / air top evo 55 903 fig. 902 removing/fitting housing parts y y x x x 1 2 3 5 4 6 6 7 8 7 7 1. Cover, electrical connection 2. Top shell 3. Cover, hot air outlet 4. Bottom shell 5. Cover, cold air inlet 6. Grille (on hot air outlet side not shown) 7. Insulators (4 pc.). 8. Wid...

Page 53: Repair

Air top evo 40 / air top evo 55 repair 904 9.2.3 replacing control unit 9.2.3.1 removal 1. Remove heater (see 8.7.1.1). 2. Remove housing parts (see 9.2.1). 3. Remove screws (5, fig. 903). 4. Disconnect connectors on control unit (4). 5. Pull out control unit (4) upward. Note no repairs may be carri...

Page 54: Repair

Repair air top evo 40 / air top evo 55 905 9.2.6.2 installation 1. Make sure that sealing surfaces on drive unit (2, fig. 903) and on heat exchanger (8) are not damaged. 2. Lay new flat seal (7) on flange of drive unit (2). 3. Move drive unit (2) into assembly position and secure it with screws (3)....

Page 55: Repair

Air top evo 40 / air top evo 55 repair 906 9.2.7 replacing exhaust temperature sensor 9.2.7.1 removal 1. Remove heater (see 8.7.1.1). 2. Remove housing parts (see 9.2.1). 3. Remove control unit (see 9.2.3.1). 4. Remove drive unit (see 9.2.6.1). 5. Remove 2 screws (1, fig. 907) and take off spring cl...

Page 56: Repair

Repair air top evo 40 / air top evo 55 907 9.2.8 replacing evaporator mount and glow plug 9.2.8.1 removal 1. Remove heater (see 8.7.1.1). 2. Remove housing parts (see 9.2.1). 3. Remove control unit (see 9.2.3.1). 4. Remove drive unit (see 9.2.6.1). 5. Remove 2 screws (1, fig. 907) and take off sprin...

Page 57: Repair

Air top evo 40 / air top evo 55 repair 908 fig. 907 replacing evaporator mount, glow plug, exhaust temperature sensor, combustion pipe and heat exchanger 1 2 3 6 5 4 7 9 10 8 detail a 1. Torx screw (4 pc.) 2. Spring clip 3. Evaporator mount (diesel) 4. Combustion pipe 5. Round sealing ring 6. Heat e...

Page 58

Packaging, storage and shipping 1001 10 packaging, storage and shipping 10.1 general information the heater or its components which are sent to webasto for testing or repair must be cleaned and packaged so that they are protected against damage when handled, transported and stored. An ambient temper...

Page 59

Id ent-nr . 90303 49a • 05/14 • err ors a n d o mis sio n s ex cepted • © w e b a st o therm o & co mfort se, 2014 webasto thermo & comfort se postfach 1410 82199 gilching germany visiting address: friedrichshafener str. 9 82205 gilching germany technical extranet: http://dealers.Webasto.Com the tel...