- DL manuals

- Webasto

- Water Heater

- DBW 2010

- Workshop Manual

Webasto DBW 2010 Workshop Manual

Summary of DBW 2010

Page 1

Water heaters 03/2003 workshop manual dbw 2010 dbw 2016 visit www.Butlertechnik.Com for more technical information and downloads. Www.Butlertechnik.Com.

Page 2

Improper installation or repair of webasto heating and cooling systems can cause fire or the leakage of deadly carbon monoxide leading to serious injury or death. To install and repair webasto heating and cooling systems you need to have completed a webasto training course and have the appropriate t...

Page 3

Visit www.Butlertechnik.Com for more technical information and downloads. Www.Butlertechnik.Com.

Page 4: Dbw 2010 / 2016

Dbw 2010 / 2016 table of contents i table of contents 1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101 1.1 contents and purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 5: Table of Contents

Table of contents dbw 2010 / 2016 ii 5.4 malfunction symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 504 5.4.1 heater does not start up when switched on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 6: Dbw 2010 / 2016

Dbw 2010 / 2016 table of contents iii 9 repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 901 9.1 general information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 7: Table of Illustrations

Table of illustrations dbw 2010 / 2016 iv table of illustrations fig. 201 dbw 2010 heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202 fig. 202 dbw 2010 heaters with sensor technology . . . . . . . . . . . ...

Page 8: Dbw 2010 / 2016

Dbw 2010 / 2016 1 introduction 101 1 introduction 1.1 contents and purpose this workshop manual serves to support instructed personnel, which repairs the water heater dbw 2010/2016. The heater may only be operated with the predetermined fuel (diesel in accordance with din en 590, el fuel oil, f34, f...

Page 9: 1 Introduction

1 introduction dbw 2010 / 2016 102 the heater may only be installed in motor vehicles or in inde- pendent heating systems with a minimum coolant quantity of 10 litres. The heater may not be installed in the cab or the passenger compartment of vehicles. If the heater is nevertheless installed in an a...

Page 10: Dbw 2010 / 2016

Dbw 2010 / 2016 1 introduction 103 5.3.4 exhaust system 5.3.4.1 the exhaust outlet must be located so as to prevent emissions from entering the vehicle through ventilators, heated air inlets or opening windows. 5.3.5 combustion air inlet 5.3.5.1 the air for the combustion chamber of the heater must ...

Page 11: 1 Introduction

1 introduction dbw 2010 / 2016 104 all fuel tanks offered in the webasto accessories catalogue are individually subjected to a pressure test of at least 0.3 bar gauge pressure at the factory. • the respective operating mode of the heater, at least switched on or off, must be easily recognisable. For...

Page 12: Dbw 2010 / 2016

Dbw 2010 / 2016 2 general description 201 2 general description the webasto dbw 2010 and dbw 2016 water heaters are used in conjunction with the original vehicle heating system – to heat the passenger compartment, – to defrost the windows and – for preheating water-cooled engines. The water heater o...

Page 13: 2 General Description

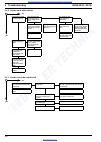

2 general description dbw 2010 / 2016 202 fig. 201 dbw 2010 heaters 1 burner head 2 ignition spark generator 3 coolant, outlet 4 control thermostat * 5 thermal fuse * 6 control thermostat * 7 temperature limiter * 8 fan thermostat * 9 heat exchanger 10 exhaust outlet 11 control unit * for components...

Page 14: Dbw 2010 / 2016

Dbw 2010 / 2016 2 general description 203 fig. 202 dbw 2010 heaters with sensor technology 1 burner head 2 ignition spark generator 3 coolant, outlet 4 temperature sensor * 5 thermal fuse * 6 temperature limiter * 7 heat exchanger 8 exhaust outlet 9 control unit * for components installed in accorda...

Page 15: 2 General Description

2 general description dbw 2010 / 2016 204 fig. 203 dbw 2016 standard / rail heaters 1 burner head 2 ignition spark generator 3 coolant, outlet 4 heat exchanger 5 exhaust outlet 6 control unit 4 1 2 3 5 6 visit www.Butlertechnik.Com for more technical information and downloads. Www.Butlertechnik.Com.

Page 16: Dbw 2010 / 2016

Dbw 2010 / 2016 2 general description 205 2.1 combustion air fan the combustion air fan transports the air required for com- bustion out of the combustion air inlet into the combustion chamber. The following fan models are installed in the heaters: dbw 2010 / 2016 – radial fan. 2.2 motor the motor d...

Page 17: 2 General Description

2 general description dbw 2010 / 2016 206 2.4 heat exchanger the heat generated in the heat exchanger by combustion is transferred to the coolant circuit. 2.5 combustion chamber the fuel-air mixture is distributed in the combustion chamber and burned there. The heat exchanger is heated in the proc- ...

Page 18: Dbw 2010 / 2016

Dbw 2010 / 2016 2 general description 207 2.7 flame monitor the flame state is monitored during the entire combustion operation with the flame monitor. The flame monitor is a photo resistor for standard device or a photo transistor for sensor technology variant, which reacts depending on the light s...

Page 19: 2 General Description

2 general description dbw 2010 / 2016 208 2.10 temperature limiter/thermal fuse temperature limiter the temperature limiter (bi-metal) protects the heater against impermissibly high operating temperatures. The temperature limiter reacts at a temperature above 107 °c or 117 °c and switches off the he...

Page 20: Dbw 2010 / 2016

Dbw 2010 / 2016 2 general description 209 2.12 fan thermostat the fan thermostat switches the original vehicle heater fan off or on when the coolant temperature is between 30 °c and 40 °c. The thermostat closes at 40 ± 3 °c and opens at 30 ± 5 °c. 2.13 circulation pump the heater must be operated wi...

Page 21: 3 Description of Operation

3 description of operation dbw 2010 / 2016 301 3 description of operation 3.1 general information the heaters equipped with a high-pressure atomizing burner operate in the intermittent mode. Control is carried out either – thermostatically (heaters with 1553 control unit) or – with temperature senso...

Page 22: Dbw 2010 / 2016

Dbw 2010 / 2016 3 description of operation 302 fault switch-off only for heaters with sensor technology with 1563/64 control unit – 12 seconds after start-up due to detection of extraneous light or in case of undervoltage – during combustion operation as the result of undervolt- age for at least 12 ...

Page 23: 3 Description of Operation

3 description of operation dbw 2010 / 2016 303 fig. 302 operating sequence (heaters with 1563/1564 control unit) 12 s 90 s* 12 s 90 s* * adr heaters: 20 s (a) switch-on indicator (b) circulation pump (c) combustion air fan (d) ignition spark generator (e) solenoid valve (f) flame monitor (1) switch-...

Page 24: Dbw 2010 / 2016

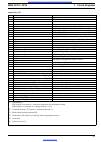

Dbw 2010 / 2016 4 technical data 401 4 technical data the technical data listed in the table refer to the usual heater tolerances of ±10 % at an ambient temperature of +20 °c and at nominal voltage. 4.1 electrical components control unit, motors for combustion air fan and circulation pump, solenoid ...

Page 25: 4 Technical Data

4 technical data dbw 2010 / 2016 402 circulation pump u 4840 volume flow rate [l/h] 1,600 (against 0.1 bar) rated voltage [v] 12 or 24 operating voltage range [v] 9 to 15 or 16 to 30 rated power consumption [w] 30 dimensions - length - width - height [mm] [mm] [mm] 135 95 48 weight [kg] 0,4 visit ww...

Page 26: Dbw 2010 / 2016

Dbw 2010 / 2016 5 troubleshooting 501 5 troubleshooting 5.1 general information this section describes troubleshooting on the dbw 2010/ 2016/2016 rail heaters. Important troubleshooting work demands precise knowledge of the structure and theory of operation of the various components and must be carr...

Page 27: 5 Troubleshooting

5 troubleshooting dbw 2010 / 2016 502 malfunction in water system heater shuts off, as heat exchangers (heater and vehicle) do not give off sufficient heat. Flow rate insufficient, as • air or gas in heater, in heat exchangers or in system sections. • valves (flow controller) throttled, soiled or cl...

Page 28: Dbw 2010 / 2016

Dbw 2010 / 2016 5 troubleshooting 503 5.3 troubleshooting – rapid diagnosis heater types: all heaters only heaters with sensor technology with 1563/1564 control unit description of malfunction check and repair or replace if necessary s after switching on – no function switch-on check – goes out afte...

Page 29: 5 Troubleshooting

5 troubleshooting dbw 2010 / 2016 504 5.4 malfunction symptoms 5.4.1 heater does not start up when switched on no yes is voltage connected to terminals b1, b2 and b4? (with 1563/1564 control unit: termi- nals a1, a2, a3, a4). Are both fuses f2/ f3 defective? (with 1563/1564 control unit: f1/ f2). Do...

Page 30: Dbw 2010 / 2016

Dbw 2010 / 2016 5 troubleshooting 505 5.4.2 heater switches into fault mode repeatedly after approx. 30 s (20 s with 1563/1564 control unit) when switched on no yes has thermal fuse f1 blown? Has temperature lim- iter been tripped? Is the buzzing of the (mechanical) ignition spark generator audi- bl...

Page 31: 5 Troubleshooting

5 troubleshooting dbw 2010 / 2016 506 5.4.3 heater does not start until after several starting attempts 5.4.4 heater goes out by itself during operation no yes does smoke exit from the exhaust pipe during the failed starting attempts? No fuel level has dropped while heater was stopped: press off int...

Page 32: Dbw 2010 / 2016

Dbw 2010 / 2016 5 troubleshooting 507 5.4.5 heater emits black smoke no yes is the combustion-air intake pipe or the exhaust connec- tion piece soiled? No are the gas paths of the heat exchanger heavily soiled? Does vacuum or gauge pressure result at the combustion air inlet, possibly also while dri...

Page 33: 5 Troubleshooting

5 troubleshooting dbw 2010 / 2016 508 5.4.6 heater emits white smoke 5.4.7 heater cannot be switched off no yes does the heater smoke for longer than 20 s? Does the heater emit smoke during opera- tion (including at inter- vals)? Does the heater emit smoke after being switched off? Yes is the electr...

Page 34: Dbw 2010 / 2016

Dbw 2010 / 2016 6 operating tests 601 6 operating tests 6.1 general information this section describes the tests and settings carried out on the heater when it is installed and not installed to verify that it is in working order. Warning the heater must not be operated in enclosed areas such as gara...

Page 35: 6 Operating Tests

6 operating tests dbw 2010 / 2016 602 – loosen locking screw (see fig. 604) and move adjust- ment ring with locking screw until setpoint value is reached. – tighten locking screw to 1.0 + 0.5 nm and lock with sealing paint. Note the co 2 setting is dependent on the fuel (viscosity) and the geodetic ...

Page 36: Dbw 2010 / 2016

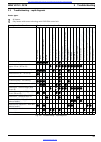

Dbw 2010 / 2016 6 operating tests 603 6.3 checking individual components 6.3.1 resistance test of temperature sensor (only heaters with 1563/1564 control unit) during an electrical test with a digital multimeter, the tem- perature sensor is to have the values in accordance with the following graph. ...

Page 37: 6 Operating Tests

6 operating tests dbw 2010 / 2016 604 6.3.2.2 checking flame monitor with 1563/1564 control unit when installed – connect voltmeter to connections d6 (+) and d7 (–) of control unit – switch on heater – the measured voltage must be 5 v. After approx. 15 s to 26 s, the voltage must drop to when remove...

Page 38: Dbw 2010 / 2016

Dbw 2010 / 2016 6 operating tests 605 6.3.4 checking ignition spark generator warning high voltage; a voltage of approx. 8,000 v jumps across at ignition electrodes. Important do not charge ignition spark generator without ignition elec- trodes with voltage. Test note connect direct current supply w...

Page 39: 6 Operating Tests

6 operating tests dbw 2010 / 2016 606 6.3.6 checking burner motor note the combustion air fan is checked when installed. If the set- point states are not reached, then the fan motor must be replaced. Test – examine bearing condition (stickiness) of burner motor. – measure input voltage on heater – s...

Page 40: Dbw 2010 / 2016

Dbw 2010 / 2016 7 circuit diagrams 701 7 circuit diagrams the wiring diagrams or application examples (fig. 701 to fig. 705) show the possible circuits of the dbw 2010, dbw 2016 and dbw 2016 railheaters. Cable cross-sections vehicle’s own cable 7.5 m–15 m 0.75 mm² 1.0 mm² 0.75 mm² 1.0 mm² 1.0 mm² 1....

Page 41: 7 Circuit Diagrams

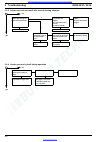

7 circuit diagrams dbw 2010 / 2016 702 fig. 701 system wiring diagram for dbw 2010 with 1553 control unit and switch, 12 and 24 v version with thermal fuse only version with temperature limiter and thermal fuse version with thermal fuse and fan thermostat version with thermal fuse, temperature limit...

Page 42: Dbw 2010 / 2016

Dbw 2010 / 2016 7 circuit diagrams 703 fig. 702 system wiring diagram dbw 2016 with 1553 control unit and switch, 24 v version with thermal fuse only version with temperature limiter and thermal fuse version with thermal fuse and fan thermostat version with thermal fuse, temperature limiter and fan ...

Page 43: 7 Circuit Diagrams

7 circuit diagrams dbw 2010 / 2016 704 fig. 703 system wiring diagram dbw 2010 with 1553 control unit, 12 and 24 v, switch, nozzle holder pre-heating unit and altitude control fig. 704 system wiring diagram dbw 2016 with 1553 control unit, 24 v, switch, nozzle holder pre-heating unit and altitude co...

Page 44: Dbw 2010 / 2016

Dbw 2010 / 2016 7 circuit diagrams 705 legend fig. 701 to fig. 704: item description comment a b c d 1 heater not earthed 2 control unit sg 1553 4 ignition spark generator 5 thermostat control thermostat (internal) 7 thermostat fan thermostat 8 thermostat temperature limiter thermostat 10 ignition e...

Page 45: 7 Circuit Diagrams

7 circuit diagrams dbw 2010 / 2016 706 fig. 705 automatic switching, dbw 2010 with 1563 control unit, 12 and 24 v visit www.Butlertechnik.Com for more technical information and downloads. Www.Butlertechnik.Com.

Page 46: Dbw 2010 / 2016

Dbw 2010 / 2016 7 circuit diagrams 707 legend fig. 705: item description comment a1 heater not earthed a2 control unit sg 1563 b1 flame monitor ensure proper polarity b2 temperature sensor polarity as desired b3 fan thermostat in water circuit, for vehicle fan (on - off) f1 20 a fuse flat fuse sae j...

Page 47: 8 Servicing Work

8 servicing work dbw 2010 / 2016 801 8 servicing work 8.1 general information this section describes the servicing work that can be carried out on the heaters when they are installed. 8.2 work on heater the main battery power must not be disconnected whilst the heater is operating or slowing down as...

Page 48: Dbw 2010 / 2016

Dbw 2010 / 2016 8 servicing work 802 8.5.1 swinging burner head away and in warning the ignition spark generator is operated with high voltage. Before being swung away, the connectors of the wiring har- ness in the vehicle must be disconnected, as otherwise there is a danger of incurring life-threat...

Page 49: 8 Servicing Work

8 servicing work dbw 2010 / 2016 803 8.6 visual inspections and installation instructions 8.6.1 connection to the vehicle cooling system the heater should be installed as low as possible to permit automatic bleeding of the heater and circulation pump. This is particularly important as the circulatio...

Page 50: Dbw 2010 / 2016

Dbw 2010 / 2016 8 servicing work 804 fig. 802 installation example for heater in bus water heating circuit – wall radiator 1 wall radiator with fan 2 heater 3 circulation pump 4 motor vehicle engine 5 driver's seat heating 6 control element run-up return line visit www.Butlertechnik.Com for more tec...

Page 51: 8 Servicing Work

8 servicing work dbw 2010 / 2016 805 when installing a shut-off device in the return line, a notifica- tion sign must be mounted in a highly visible location. Important operation with a closed return line will result in damage to the fuel pump. Fuel can escape. Danger of fire! Unsupported fuel lines...

Page 52: Dbw 2010 / 2016

Dbw 2010 / 2016 8 servicing work 806 the combustion air inlet and exhaust-gas outlet location must be chosen so that no air pressure difference results in any vehicle operating mode. Rigid pipes of unalloyed or alloyed steel with a minimum wall thickness of 1.0 mm or flexible piping of alloyed steel...

Page 53: 8 Servicing Work

8 servicing work dbw 2010 / 2016 807 8.7.4 replacing thermal fuse note the procedure for replacing the thermal fuse with the heater installed or removed is identical. Replacing must be carried out according to 9.2.3. Warning before replacing the thermal fuse on heaters with the 1563/ 1564 control un...

Page 54: Dbw 2010 / 2016

Dbw 2010 / 2016 8 servicing work 808 8.8 start-up after the heater has been installed, the coolant circuit and the fuel supply system must be carefully bled. The specifica- tions of the vehicle manufacturer must be observed when doing so. All coolant and fuel connections must be checked for leaks an...

Page 55: 9 Repair

9 repair dbw 2010 / 2016 901 9 repair 9.1 general information this section describes the repair work that can be carried out on the heaters when they are installed. Any further disman- tling will invalidate the warranty. During assembly only the spare parts from the corresponding spare parts kit may...

Page 56: Dbw 2010 / 2016

Dbw 2010 / 2016 9 repair 902 9.1.1 works on components when dismantled important all sealing elements between the dismantled components must always be removed and replaced. 9.1.1.1 general visual inspection • check all components for damage (cracks, deformation, wear, etc.) and fit new ones if neces...

Page 57: 9 Repair

9 repair dbw 2010 / 2016 903 9.1.2.1 installation of nozzle holder pre-heating unit for dbw 2010 / dbw 2016 with 1553 control unit general information the fuel to the atomiser nozzle is heated with the nozzle holder pre-heating unit. At extremely low temperatures, mal- functions can occur without no...

Page 58: Dbw 2010 / 2016

Dbw 2010 / 2016 9 repair 904 retrofitting works dbw 2010 / dbw 2016 note on dbw 2010 / dbw 2016 heaters, the washer and the nut in the retrofit kit are not required. 1. Swing away burner head as described in 8.5.1. 2. Remove ignition electrodes as described in 9.2.14.1. 3. Remove snap ring and pull ...

Page 59: 9 Repair

9 repair dbw 2010 / 2016 905 fig. 904 electrical connection item description comment a1 heater a2 control unit sg 1553 b plug connector, 6-pin b5 thermostat for nozzle holder pre-heating unit f1 10 a fuse flat fuse sae j 1284 f2 20 a fuse flat fuse sae j 1284 f3 16 a (12 v); 8 a (24 v) fuse flat fus...

Page 60: Dbw 2010 / 2016

Dbw 2010 / 2016 9 repair 906 9.1.2.2 installation of nozzle holder pre-heating unit for dbw 2010 / dbw 2016 with 1563/1564 control unit general information the fuel to the atomiser nozzle is heated with the nozzle holder pre-heating unit. At extremely low temperatures, mal- functions can occur witho...

Page 61: 9 Repair

9 repair dbw 2010 / 2016 907 retrofitting works dbw 2010 note on dbw 2010 heaters, the washer and the nut in the retrofit kit are not required. 1. Swing away burner head as described in 8.5.1. 2. Remove ignition electrodes as described in 9.2.14.1. 3. Remove snap ring and pull disc with flame monito...

Page 62: Dbw 2010 / 2016

Dbw 2010 / 2016 9 repair 908 fig. 907 electrical connection item description comment a1 heater a2 control unit sg 1563/1564 a plug connector, 6-pin b3 thermostat for nozzle holder pre-heating unit f2 fuse flat fuse sae j 1284 f3 fuse flat fuse sae j 1284 f4 16 a (12 v); 8 a (24 v) fuse flat fuse sae...

Page 63: 9 Repair

9 repair dbw 2010 / 2016 909 9.2 dismantling and assembling 9.2.1 replacing temperature limiter note with the sensor technology device, release pressure from cooling system according to manufacturer's instructions before replacement. Important danger of injury from escaping hot coolant. 9.2.1.1 remo...

Page 64: Dbw 2010 / 2016

Dbw 2010 / 2016 9 repair 910 fig. 908 replacing temperature limiter, temperature sensor, thermal fuse, fusible link and control thermostat 1 control thermostat 2 terminal block 3 protective cap 4 nut 5 angle bracket 6 screw plug 7 thermal fusible link 8 temperature limiter 9 fan thermostat 10 heat e...

Page 65: 9 Repair

9 repair dbw 2010 / 2016 911 9.2.5 replacing fan thermostat 9.2.5.1 removal 1. Remove nut (4, fig. 908) and take off protective cap (3). 2. Disconnect electrical connection to fan thermostat (9). 3. Screw fan thermostat off angle bracket (5) and remove. 4. Carry out works on stripped down components...

Page 66: Dbw 2010 / 2016

Dbw 2010 / 2016 9 repair 912 fig. 909 replacing control unit 1 1553 control unit 2 retaining clip 3 1563/1564 control unit 4 burner head fig. 910 replacing burner head 1 screw (2) 2 cotter pin 3 nut (2) 4 burner head note • the cotter pin can be positioned on the other side in accordance with the sw...

Page 67: 9 Repair

9 repair dbw 2010 / 2016 913 9.2.9 replacing motor 9.2.9.1 removal 1. Remove ignition spark generator (see 9.2.12.1). 2. Remove screws (17, fig. 911) from protective cap (4) and pull off protective cap towards front. 3. Disconnect electrical connection to motor (16). 4. Remove screws (10) and take o...

Page 68: Dbw 2010 / 2016

Dbw 2010 / 2016 9 repair 914 9.2.10 replacing high-pressure nozzle 9.2.10.1 removal 1. Swing away burner head (see 8.5.1). 2. Screw off high-pressure nozzle (11, fig. 912) and remove. 3. Carry out works on stripped down components (see 9.1.1). 9.2.10.2 installation 1. Screw in high-pressure nozzle (...

Page 69: 9 Repair

9 repair dbw 2010 / 2016 915 fig. 912 replacing nozzle holder, nozzle holder pre-heating unit, high-pressure nozzle and flame monitor 1 solenoid valve 2 heating cartridge 3 clamping yoke 4 ignition cable (2) 5 retaining clip (2) 6 clip 7 washer 8 screw 9 ignition electrode (2) 10 flame monitor 11 hi...

Page 70: Dbw 2010 / 2016

Dbw 2010 / 2016 9 repair 916 9.2.15 replacing fuel pump 9.2.15.1 removal 1. Swing away burner head (see 8.5.1). 2. Remove ignition electrodes (see 9.2.14.1). 3. Remove banjo bolts (22, fig. 912) and washers (21), take off fuel lines (20) and remove. 4. Loosen screw fittings on pressure line (16), ta...

Page 71: 9 Repair

9 repair dbw 2010 / 2016 917 fig. 913 replacing thermostat of nozzle holder pre-heating unit fig. 914 replacing solenoid valve 1 disc 2 serrated lock washer 3 nut 4 thermostat 5 screw 6 lug 7 nozzle holder plate dbw 2010 / dbw 2016 1 nut 2 washer 3 solenoid valve head 4 solenoid valve body 5 “o” rin...

Page 72: Dbw 2010 / 2016

Dbw 2010 / 2016 9 repair 918 9.2.19 replacing heat exchanger 9.2.19.1 removal 1. If necessary, remove nut (6, fig. 915) from cover (5) and take off cover and remove. 2. Remove temperature limiter or thermal fuse (see 9.2.1.1 or 9.2.3.1). 3. Remove temperature sensor (see 9.2.2.1). 4. Remove thermal ...

Page 73: 9 Repair

9 repair dbw 2010 / 2016 919 9.2.20 replacing nozzle holder 9.2.20.1 removal 1. Swing away burner head (see 8.5.1). 2. Remove ignition electrodes (see 9.2.14.1). 3. Remove high-pressure nozzle (see 9.2.10.1). 4. If necessary, remove nozzle holder pre-heating unit (see 9.2.11.1). 5. Remove solenoid v...

Page 74: Dbw 2010 / 2016

Dbw 2010 / 2016 9 repair 920 fig. 916 replacing combustion air fan 1 screw (3) 2 washer (3) 3 motor carrier 4 combustion air fan 5 nozzle holder plate 6 screw (4) dbw 2010 / dbw 2016 visit www.Butlertechnik.Com for more technical information and downloads. Www.Butlertechnik.Com.

Page 75

10 packing, storage and shipping 1001 10 packing, storage and shipping 10.1 general information if the heater or its components are sent to webasto for test- ing or repair, it must be cleaned and packed in such a way that it is protected against damage during handling, trans- port and storage. Impor...

Page 76: Dbw 2010 / 2016

Dbw 2010 / 2016 appendix a a-1 appendix a periodic heater maintenance the heater should be checked at regular intervals, however at the latest at the start of the heating period (point in time of weather-dependent increased use of heater). The maintenance intervals specified in the following refer t...

Page 77

Visit www.Butlertechnik.Com for more technical information and downloads. Www.Butlertechnik.Com.

Page 78

P a rt no. 132 130 2a • 10 /13 • err o rs and omissions ex cepted • print e d in germany • © w e bast o ther mo & comfor t se, 2013 webasto thermo & comfort se postfach 1410 82199 gilching germany visitors’ address: friedrichshafener str. 9 82205 gilching germany internet: www.Webasto.Com technical ...