- DL manuals

- Webasto

- Water Heater

- Thermo Pro 90

- Workshop Manual

Webasto Thermo Pro 90 Workshop Manual

Summary of Thermo Pro 90

Page 1

Water heaters workshop manual thermo pro 90 thermo pro 90 12 v diesel - adr thermo pro 90 24 v diesel - adr visit www.Butlertechnik.Com for more technical information and downloads. Www.Butlertechnik.Com.

Page 2

Improper installation or repair of webasto heating and cooling systems can cause fire or the leakage of deadly carbon monoxide leading to serious injury or death. To install and repair webasto heating and cooling systems you need to have completed a webasto training course and have the appropriate t...

Page 3

Visit www.Butlertechnik.Com for more technical information and downloads. Www.Butlertechnik.Com.

Page 4: Thermo Pro 90

Thermo pro 90 table of contents i table of contents 1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101 1.1 contents and purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 5: Table of Contents

Table of contents thermo pro 90 ii 6 operating tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 601 6.1 general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 6: Thermo Pro 90

Thermo pro 90 table of illustrations iii table of illustrations fig. 201 thermo pro 90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201 fig. 202 combustion air fan . . . . . . . . . . . . . . . . . . . . . . ....

Page 7: 1 Introduction

1 introduction thermo pro 90 101 1 introduction 1.1 contents and purpose this workshop manual serves to support instructed person- nel, which repairs the thermo pro 90 water heater. 1.2 meaning of signal words throughout this manual, the signal words warning, important and note have the following me...

Page 8: Thermo Pro 90

Thermo pro 90 1 introduction 102 warning the heater must not be operated: • in filling stations and tank farms. • at locations at which highly flammable gases or dusts can form, and at which highly flammable liquids or solid materials are stored (e.G. Near fuel, coal and wood dust, grain warehouses,...

Page 9: 2 General Description

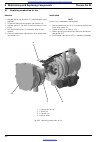

2 general description thermo pro 90 201 2 general description the thermo pro 90 water heater is used in conjunction with the original vehicle heating system in the parking heating mode for – cab and engine preheating, – utilisation of residual vehicle engine heat. The auxiliary heating mode can also...

Page 10: Thermo Pro 90

Thermo pro 90 2 general description 202 2.1 combustion air fan the combustion air fan feeds the air required for combus- tion to the burner unit. 2.2 heat exchanger the heat generated in the heat exchanger by combustion is transferred to the coolant circuit. 2.2.1 coolant temperature sensor the cool...

Page 11: 2 General Description

2 general description thermo pro 90 203 2.4 combustion pipe the combustion pipe supports the combustion of the fuel- air mixture, and as a result partially also the heating of the heat exchanger. 2.5 exhaust temperature sensor the exhaust temperature sensor (ats) is used to detect the flame and impe...

Page 12: Thermo Pro 90

Thermo pro 90 3 description of operation 301 3 description of operation 3.1 switching on and residual-heat utilisation phase the heater is switched on depending on the equipment variant by means of a switch or standard timer. Activating residual-heat utilisation phase the coolant temperature is chec...

Page 13: 3 Description of Operation

3 description of operation thermo pro 90 302 if the criterion b) is met during the activation of the residual- heat utilisation phase or during the residual-heat utilisation phase, then the heater is automatically started. 3.2 starting and control mode after combustion begins (start), controlled hea...

Page 14: Thermo Pro 90

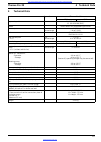

Thermo pro 90 4 technical data 401 4 technical data heater operation thermo pro 90 12 v 24 v approval symbol e1 122r 00 0320 (heater) e1 10r 03 6196 (emc) model water heater with evaporator-type burner heat output max. Control range 9.1 kw 1.8 to 7.6 kw fuel diesel din en 590 pme din en 14214 fuel c...

Page 15: 5 Faults, Troubleshooting

5 faults, troubleshooting thermo pro 90 501 5 faults, troubleshooting general this section describes troubleshooting on the thermo pro 90 heater. Important troubleshooting work demands precise knowledge of the structure and theory of operation of the various compo- nents and must be carried out by t...

Page 16: Thermo Pro 90

Thermo pro 90 5 faults, troubleshooting 502 elimination of faults with webasto thermo test pc diagnosis certain errors result in the errors being added up in the error memory. If the number of errors in the error memory has exceeded a limit, the heater changes over to the heater lock- out. The maxim...

Page 17: 5 Faults, Troubleshooting

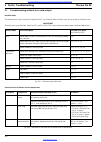

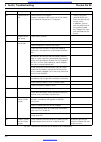

5 faults, troubleshooting thermo pro 90 503 5.1 troubleshooting without error code output possible faults the overview only shows some of the possible faults. The webasto service hotline must be contacted in individual cases. Important the error points specified from tables fig. 501 and fig. 502 do ...

Page 18: Thermo Pro 90

Thermo pro 90 5 faults, troubleshooting 504 4 combustion air fan combustion air fan short circuit/open circuit check fan wiring and replace component if neces- sary 5 u4840 circula- tion pump check wiring conduct component test to check function of circu- lation pump with webasto thermo test pc diag...

Page 19: 5 Faults, Troubleshooting

5 faults, troubleshooting thermo pro 90 505 10 combustion air fan combustion air fan sluggish. Conduct component test on function of fan motor with webasto thermo test pc diagnosis. – specify a set-point speed of 6,000 rpm – listen for rubbing and friction noises. In addition, start-up must be audib...

Page 20: Thermo Pro 90

Thermo pro 90 5 faults, troubleshooting 506 17 vehicle fan check fuse f1 observe coolant temperature ( k5 switches at approx. 25 °c) check switching signal on the relay k5 , ground on pin 85 and positive on pin 86 (audible, also see wiring diagram in general installation instructions) check coolant ...

Page 21: 5 Faults, Troubleshooting

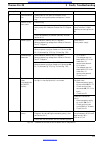

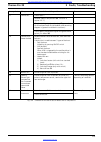

5 faults, troubleshooting thermo pro 90 507 5.2 troubleshooting with error code output the error code is displayed via: – the operation indicator or – the "on/off" switch or – reading out of the error memory with webasto thermo test pc diagnosis. 5.2.1 error code output with webasto thermo test pc d...

Page 22: Thermo Pro 90

Thermo pro 90 5 faults, troubleshooting 508 3 supply voltage too high/operat- ing voltage too low power supply check battery check electrical connections 4 flame was detected prior to combustion exhaust temperature sensor defective functional check of exhaust temperature sensor; replace exhaust temp...

Page 23: 5 Faults, Troubleshooting

5 faults, troubleshooting thermo pro 90 509 16 exhaust gas tem- perature too high exhaust temperature sensor defective check wiring for damage, open circuit and short circuit functional check of exhaust temperature sensor; replace exhaust temperature sensor if necessary heater sooted visual inspecti...

Page 24: Thermo Pro 90

Thermo pro 90 5 faults, troubleshooting 510 5.3 visual inspection for evaluation of burner unit observe the specific features of the burner unit if it needs to be replaced or no source of error is apparent. The criteria for proper checking are listed in the following. First, the burner unit is check...

Page 25: 5 Faults, Troubleshooting

5 faults, troubleshooting thermo pro 90 511 • fasteners (3x) of metal fibre evaporator are deformed or missing. Therefore, metal fibre evaporator is not pressed on correctly. Remedy replace burner unit. 5.3.3 entire burner unit • the cover and the combustion chamber (fig. 505) must be permanently co...

Page 26: Thermo Pro 90

Thermo pro 90 6 operating tests 601 6 operating tests 6.1 general this section describes the tests and adjustments of the heater and its components in the installed and the removed state. Warning the heater may not be operated in closed rooms, such as garages or workshops, without exhaust extraction...

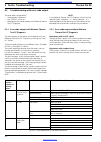

Page 27: 6 Operating Tests

6 operating tests thermo pro 90 602 6.4 checking individual components 6.4.1 resistance test of coolant temperature sensor during an electrical test with a digital multimeter, the tem- perature sensor is to have the following values: resistance at 25 °c: 990 to 1,010 ohms test current: 6.4.2 resista...

Page 28: Thermo Pro 90

Thermo pro 90 6 operating tests 603 rubbing and friction noises must be listened for. In addition, start-up must be audible up to the specified speed. In the event of the fan rubbing the fault message would be "slug- gish fan start". 6.4.5 testing dp42 metering pump during an electrical test with a ...

Page 29: 7 Circuit Diagrams

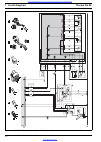

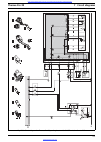

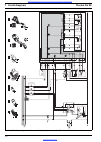

7 circuit diagrams thermo pro 90 701 7 circuit diagrams fig. 703 shows the circuit of the thermo pro 90 heater, parking heater with standard timer without adr. Fig. 704 shows the circuit of the thermo pro 90 heater, parking heater with on/off switch without adr. Fig. 705 shows the circuit of the the...

Page 30: Thermo Pro 90

Thermo pro 90 7 circuit diagrams 702 table 3 legend for wiring diagrams item description comment 1 temperature coding d+ signal (vehicle engine on/off) for determination of the control temperature 2 standard clock p2 – with ignition (terminal 15) on connection 10: continuous operation with immediate...

Page 31: 7 Circuit Diagrams

7 circuit diagrams thermo pro 90 703 fig. 703 wiring diagram for thermo pro 90, parking heater with standard timer without adr. Visit www.Butlertechnik.Com for more technical information and downloads. Www.Butlertechnik.Com.

Page 32: Thermo Pro 90

Thermo pro 90 7 circuit diagrams 704 fig. 704 circuit diagram for thermo pro 90, parking heater with on/off switch without adr. Visit www.Butlertechnik.Com for more technical information and downloads. Www.Butlertechnik.Com.

Page 33: 7 Circuit Diagrams

7 circuit diagrams thermo pro 90 705 fig. 705 circuit diagram for thermo pro 90, parking heater with on/off switch with adr with auxiliary drive. Visit www.Butlertechnik.Com for more technical information and downloads. Www.Butlertechnik.Com.

Page 34: Thermo Pro 90

Thermo pro 90 7 circuit diagrams 706 fig. 706 circuit diagram for thermo pro 90, parking heater with on/off switch with adr without auxiliary drive. Visit www.Butlertechnik.Com for more technical information and downloads. Www.Butlertechnik.Com.

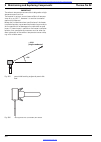

Page 35: 8 Servicing Work

8 servicing work thermo pro 90 801 8 servicing work this section describes the servicing work that can be carried out on the heater and its components while installed. 8.1 work on heater the power supply must always be disconnected at the vehicle battery before carrying out any work on the heater, o...

Page 36: Thermo Pro 90

Thermo pro 90 8 servicing work 802 8.5.2 installation 1 position heater in installation position and fasten with 3 screws and washers. 2 mount fuel line and secure with hose clamp. 3 mount coolant hoses and tighten hose clamps with 8 nm. 4 restore all electrical connections. The 12-pin vehicle speci...

Page 37: Thermo Pro 90

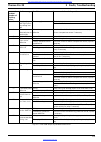

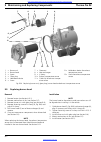

9 maintaining and replacing components thermo pro 90 901 9 maintaining and replacing components 9.1 general this section describes the permissible repair work on the heater when removed. Any and all warranty claims shall be voided if the heater is dismantled further. During assembly only the spare p...

Page 38: Thermo Pro 90

Thermo pro 90 9 maintaining and replacing components 902 9.4 replacing circulation pump removal 1. Remove heater (see section 8.5.1). 2. Disconnect electrical connections (see section 9.3). 3. Remove screws (4, fig. 901). 4. Remove clamp (3) and circulation pump (2). 5. Carry out measures on compone...

Page 39: Thermo Pro 90

9 maintaining and replacing components thermo pro 90 903 9.5 replacing overheating protection removal note the overheating protection may only be removed if it is replaced with a new one. The operating test must be carried out while installed. 1. Remove heater (see section 8.5.1), depending on space...

Page 40: Thermo Pro 90

Thermo pro 90 9 maintaining and replacing components 904 fig. 902 replacing overheating protection and coolant temperature sensor 1 2 1 = protective cap 2 = clamp 3 = overheating protection 4 = heat exchanger 5 = round sealing ring 6 = coolant temperature sensor 3 4 5 6 visit www.Butlertechnik.Com f...

Page 41: Thermo Pro 90

9 maintaining and replacing components thermo pro 90 905 9.7 replacing combustion air fan removal 1. Remove heater (see section 8.5.1), depending on space required. 2. Disconnect electrical connections (see section 9.3). 3. Remove screws (2, fig. 903). Pull off control unit if nec- essary. 4. Pull c...

Page 42: Thermo Pro 90

Thermo pro 90 9 maintaining and replacing components 906 9.8 replacing burner unit and glow plug removal 1. Remove heater (see section 8.5.1), depending on space required. 2. Remove combustion air fan (see section 9.7). 3. Remove screw (3, fig. 904). 4. Pull grommet (7) and burner unit (1) out of bu...

Page 43: Thermo Pro 90

9 maintaining and replacing components thermo pro 90 907 fig. 904 replacing burner unit, glow plug, burner head and exhaust temperature sensor 9.9 replacing burner head removal 1. Remove heater (see section 8.5.1). 2. Remove combustion air fan (see section 9.7). 3. Remove burner unit with glow plug ...

Page 44: Thermo Pro 90

Thermo pro 90 9 maintaining and replacing components 908 9.10 replacing heat exchanger removal 1. Remove heater (see section 8.5.1). 2. Remove circulation pump (see section 9.4). 3. Remove overheating protection (see section 9.5). 4. Remove coolant temperature sensor (see section 9.6). 5. Remove bur...

Page 45: Thermo Pro 90

9 maintaining and replacing components thermo pro 90 909 important the exhaust-temperature sensor cable is designed as a high- temperature-resistant line. The material is resistant to continuous effects of tempera- tures of up to 185 °c, however it is sensitive to external mechanical influences. Bef...

Page 46: Thermo Pro 90

Thermo pro 90 10 packing, storage and shipping 1001 10 packing, storage and shipping 10.1 general if the heater or its components are sent to webasto for testing or repair, it must be cleaned and packed in such a way that it is protected against mechanical damage, soiling and environmental influence...

Page 47

Id en t- no. 131 720 1b • 01/ 1 2 • err o rs an d omis sion s except ed • prin ted in ger m any • © w e b a st o ther mo & co mfo rt se, 2 0 1 2 webasto thermo & comfort se postfach 1410 82199 gilching germany visitors’address: friedrichshafener str. 9 82205 gilching germany internet: www.Webasto.Co...