- DL manuals

- Weber Mt

- Power Tool

- CR 7

- Operating And Maintenance Instructions Manual

Weber Mt CR 7 Operating And Maintenance Instructions Manual

Summary of CR 7

Page 1

Cr 7 lombardini 15 ld 440 0106-englisch operating and maintenance instructions weber maschinentechnik gmbh p. O. Box 21 53, d-57329 bad laasphe-rückershausen phone ++27 54 / 398-0 telefax (++ 27 54) 3 98-101 (switchboard) & 3 98-102 (spare parts).

Page 2

2 cr7.

Page 3: Preface

3 cr7 preface these operating and maintenance instructions describe the safe operation of the cr7 soil compactor. Please read this operation manual and familiarize yourself with all details of your soil compactor before operating the machine for the first time. Carefully follow all instructions and ...

Page 4: General Safety Instructions

4 cr7 general safety instructions general all safety notes (see also explanations of the pictogram meanings in the preface) must be read and observed (any lack of clarity must be dispelled before the soil compactor is put into operation), because otherwise the use of the machine may * constitute a r...

Page 5: Table of Contents

5 cr7 table of contents preface ....................................................................................................................................................................3 general safety instructions .............................................................................

Page 6: 1 Technical Description

6 cr7 1 2 3 4 6 7 8 9 14 10 12 1 technical description 1.1 illustration figure 1 overall view cr 7 1 engine 2 drive lever 3 handle 4 lifting lug 5 ignition lock (not shown) 6 base plate 7 protective frame 8 engine bracket 9 vibrator 10 v-belt guard 11 spring bar (not shown) 12 engine speed adjusting...

Page 7

7 cr7 1.2 machine description the cr 7 soil compactors are machines of the walk-behind type used for compaction work in road construction and landscape applications. Propulsion the cr 7 soil compactor is driven by a lombardini diesel engine. Important! Please refer to paragraph 1.3 (specifications) ...

Page 8

8 cr7 1.3 specifications cr 7 weight operating weight according to cece in kg 450 474 dimensions overall length (in mm) 1740 1740 width with extension plates (in mm) 600 800 height with handle folded down (in mm) 1135 1135 base plate length (contact area in mm) 440 440 propulsion engine manufacturer...

Page 9

9 cr7 1 2 weber maschinentechnik gmbh typ masch.-nr. Betriebsgewicht baujahr postfach 2153 57329 bad laasphe-rückershausen 4 3 cr 7 noise and vibration data* sound pressure level lpa (at the operator's place, according to 2000/14/eg, in db(a)) 98 sound power level lwa (according to 2000/14/eg, in db...

Page 10: 2 Operation

10 cr7 2 operation 2.1 safety precautions for the operation safety and protection devices before every shift, the operator must check the operativeness of all controls and safety elements as well as the proper installation of all protection devices. The soil compactor is only allowed to be operated ...

Page 11

11 cr7 - put the soil compactor out of operation as described in paragraph 2.7. - lock the handle (2/1) by means of the spring bar (2/2). Danger! Never use the handle (2/1) for lifting the machine by crane. The machine may overturn!! Danger! Only use a lifting tackle and a crane of a sufficient bear...

Page 12

12 cr7 - put the soil compactor out of operation as described in paragraph 2.7. - clean the area around the filler neck. - undo the cap (4/1) to open the fuel tank (3a/1). Caution! Fill the tank up with clean diesel fuel only. Refer to paragraph 3.4 for quantities and specifications. - fill the tank...

Page 13

13 cr7 caution! The engine oil level must be checked with the soil compactor standing horizontally on the ground. - pull out the oil dipstick (5/1), wipe it off with a clean, non- fluffing cloth and insert it again. Caution! -screw the oil dipstick (5/1) down. -undo the oil dipstick once again. Caut...

Page 14

14 cr7 - put the soil compactor out of operation as described in paragraph 2.7. - lift the soil compactor by means of a crane as described in paragraph 2.2.1. - put the damper plate beneath the machine. Caution! Do not enter the zone under the suspended load. - risk of injury! - attach the vulkollan...

Page 15

15 cr7 in case of any irregularity, turn off the engine immediately, localize and repair the malfunction.Let the engine idle for some minutes. In case of ambient temperatures of 5 degrees c below zero or less, the starting procedure must be carried out in accordance with the operation manual of the ...

Page 16

16 cr7 2.6 compaction work - put the soil compactor into operation (refer to paragraph 2.5). As soon as the engine reaches its operating temperature: - push the engine speed adjusting lever (9/1) into the full speed position. Caution! Compaction work is only allowed at full engine speed, otherwise t...

Page 17

17 cr7 2.7.1 stopping 1 1 figure 10 figure11 - push the speed adjusting lever (10/1) to the back and let the engine idle for some minutes. - turn the ignition key (11/1) from position "1" back in- to position "0". - take out the ignition key..

Page 18: 3 Maintenance

18 cr7 3 maintenance 3.1 safety precautions for maintenance work checks dependent upon the operating conditions, soil compactors must be made subject to an expert's check for operational safety as required, but at least once a year. The inspection results must be recorded in writing and kept at leas...

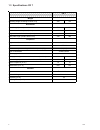

Page 19

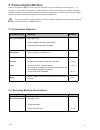

19 cr7 3.2 maintenance survey 3.2.1 maintenance any maintenance work required on the soil compactor must be repeated at regular intervals. The column „maintenance point´“ refers to the assembly group on which the work indicated in the column „maintenance work“ must be carried out. The column „remark...

Page 20

20 cr7 - put the soil compactor out of operation as described in paragraph 2.7. Caution! Drain off the engine oil at operating temperature and with the soil compactor in horizontal position only. - put a drain pan under the outlet. Environment hazard! Choose a drain pan having a sufficient capacity ...

Page 21

21 cr7 3.3.1.1 cleaning the engine oil filter figure 15 figure 16 1 - put the soil compactor out of operation as described in paragraph 2.7. - drain the engine oil according to paragraph 3.3.1. - undo the screws (15/1) and remove the lid (15/2) of the filter body. - pull the oil filter (16/1) out of...

Page 22

22 cr7 3.3.2 cleaning/replacing the air filter cartridge - loosen the fastening screw (17/2) and remove the cover (17/1) from the air filter body. - pull the air filter element (18/1) out of the air filter body(18/2) and blow or knock it clean. Caution! If this procedure does not provide a sufficien...

Page 23

23 cr7 3.3.3 replacing the fuel filter figure 19 - put the soil compactor out of operation as described in paragraph 2.7. - undo the clips (19/2), remove the diesel fuel lines (19/1) from the fuel filter (19/3) and completely drain the tank. - remove the clip (19/4) from the fuel filter (19/3) and r...

Page 24

24 cr7 3.3.4checking the condition and tension of the vibrator v-belt - put the soil compactor out of operation as described in paragraph 2.7. - undo the screws (20/1) to remove the v-belt guard (20/2). - check the condition of the v-belt (21/1) (cracks, broken out flanks, wear). - in case of excess...

Page 25

25 cr7 3.3.6 changing the vibrator oil - put the soil compactor out of operation as described in paragraph 2.7. Caution! Change the oil at operating temperature only. When working on the machine, always protect the soil compactor against slipping out of control. - risk of injury - - thoroughly clean...

Page 26

26 cr7 3.3.7 hydraulic control the switch head (24/2) is filled with hydraulic oil. Switching is effected upon actuation of the switch lever (24/1). A hydraulic line connects the reaction end socket (26/1) and the switch head. Important! In case of switching problems, proceed as follows: - remove th...

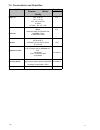

Page 27

27 cr7 assembly group consumable quantity summer winter cr 7 quality engine engine oil sae 10 w 40 1,2 l (-10 ~ + 50 °c) api - cd ce-cf-cg or shpd or ccmc - d4 - d5 - pd2 5,0 l fuel tank vibrator initial filling fuchs titan 5 speed 1,25 l sl 75 w 90 hydraulic control initial filling as required fuch...

Page 28

28 cr7 4 malfunctions during operation 4.1 general if a malfunction occurs on the soil compactor, proceed as follows: - put the soil compactor out of operation as described in paragraph 2.7. - determine the source of the malfunction (refer to paragraph 4.2 - trouble shooting). - repair the failure (...

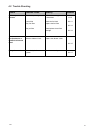

Page 29

29 cr7 4.2 trouble shooting failure possible cause remedy remarks soil compactor does not start mistake in operating the unit perform the starting procedure as described # 2.5 lack of fuel check the fuel level # 2.4.1 dirty fuel filter replace the fuel filter # 3.3.3 dirty air filter clean/replace t...

Page 30

30 cr7 4.3 repair and replacement work 4.3.1 replacing the battery - put the soil compactor out of operation as described in paragraph 2.7. - undo the fastening screws (27/1) and remove the battery cover (27/2). - disconnect the cable plug (28/3). - disconnect the terminals (28/1). At first, disconn...

Page 31: 5 Preserving The Machine

31 cr7 5 preserving the machine 5.1 preservation measures if the soil compactor is planned to be put out of operation for an extended period of time (approx. 1 ... 6 months), e. G. During the winter season, it must be stored in a frost-proof and dry room. Before storing the machine, however, the pre...

Page 32

6 addresses, weber maschinentechnik gmbh for problems, questions and further information refer to one of the following addresses: in germany weber maschinentechnik gmbh postfach 2153 57329 bad laasphe - rückershausen telefon telefax e-mail + 49 (0) 2754 - 398-0 + 49 (0) 2754 - 398101-switchboard + 4...

Page 33

> vibratory plate compactors > vibratory soil compactors > vibratory rollers > joint cutters > internal vibrators and converters > vibrating motors > stone saws > rotary trowels > and many others weber maschinentechnik gmbh im boden d- 57334 bad laasphe - rückershausen p. O. Box 2153 d - 57329 bad l...