Weed Eater 178704 Owner's Manual - Safety Rules

3

•

Be sure the area is clear of other people before mowing. Stop

machine if anyone enters the area.

•

Never carry passengers or children even with the blades off.

•

Do not mow in reverse unless absolutely necessary. Always

look down and behind before and while backing.

•

Never carry children. They may fall off and be seriously

injured or interfere with safe machine operation.

•

Keep children out of the mowing area and under the watchful

care of another responsible adult.

•

Be alert and turn machine off if children enter the area.

•

Before and when backing, look behind and down for small

children.

•

Mow up and down slopes (15° Max), not across.

•

Remove obstacles such as rocks, tree limbs, etc.

•

Watch for holes, ruts, or bumps. Uneven terrain could over-

turn the machine. Tall grass can hide obstacles.

•

Use slow speed. Choose a low gear so that you will not have

to stop or shift while on the slope.

•

Avoid starting or stopping on a slope. If tires lose traction,

disengage the blades and proceed slowly straight down the

slope.

•

If machine stops while going uphill, disengage blades, shift

into reverse and back down slowly.

•

Do not turn on slopes unless necessary, and then, turn slowly

and gradually downhill, if possible.

Safe Operation Practices for Ride-On Mowers

SAFETY RULES

SAFETY RULES ........................................................ 2-3

PRODUCT SPECIFICATIONS ....................................... 4

CUSTOMER RESPONSIBILITIES ...................... 4, 15-18

ASSEMBLY ................................................................ 6-8

OPERATION ............................................................. 9-14

MAINTENANCE SCHEDULE ....................................... 15

SERVICE AND ADJUSTMENTS ............................. 19-23

STORAGE ................................................................... 24

TROUBLESHOOTING ............................................. 25-26

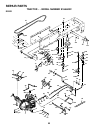

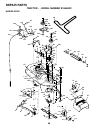

REPAIR PARTS - TRACTOR .................................. 28-41

WARRANTY ................................................................ 42

TABLE OF CONTENTS

Look for this symbol to point out im-

portant safety precautions. It means

CAUTION!!! BECOME ALERT!!! YOUR

SAFETY IS INVOLVED.

CAUTION: In order to prevent acciden-

tal starting when setting up, transport-

ing, adjusting or making repairs, al-

ways disconnect spark plug wire and

place wire where it cannot contact spark

plug.

CAUTION: Do not coast down a hill in

neutral, you may lose control of the

tractor.

CAUTION: Tow only the attachments

that are recommended by and comply

with specifications of the manufacturer

of your tractor. Use common sense

when towing. Operate only at the low-

est possible speed when on a slope.

Too heavy of a load, while on a slope,

is dangerous. Tires can lose traction

with the ground and cause you to lose

control of your tractor.

WARNING

Engine exhaust, some of its constituents, and cer-

tain vehicle components contain or emit chemicals

known to the State of California to cause cancer and

birth defects or other reproductive harm.

WARNING

Battery posts, terminals and related accessories

contain lead and lead compounds, chemicals known

to the State of California to cause cancer and birth

defects or other reproductive harm. Wash hands

after handling.