- DL manuals

- Weed Eater

- Lawn Mower

- 186843

- Owner's Manual

Weed Eater 186843 Owner's Manual

Summary of 186843

Page 1

Model no. Wet1742sta 17.0 hp 42 inch lawn tractor 186843 rev. 1 6.9.03 jh/mh printed in u.S.A. ® for parts and service, contact our authorized distributor: call 1-800-849-1297 for technical assistance: call 1-800-829-5886.

Page 2: Safety Rules

2 • avoid starting or stopping on a slope. If tires lose trac- tion, disengage the blades and proceed slowly straight down the slope. Do not: • do not turn on slopes unless necessary, and then, turn slowly and gradually downhill, if possible. • do not mow near drop-offs, ditches, or embankments. The...

Page 3: Safety Rules

3 warning: in order to prevent ac- ci den tal starting when setting up, trans port ing, ad just ing or making re- pairs, al ways dis con nect spark plug wire and place wire where it can not contact spark plug. Warning: do not coast down a hill in neutral, you may lose control of the tractor. Warning...

Page 4: Table of Contents

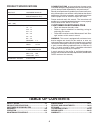

4 table of contents safety rules ......................................................... 2-3 product specifications ....................................... 4 customer responsibilities................................. 4 assembly ................................................................. 6-8 ...

Page 5: Contents of Hardware Pack

5 contents of hardware pack steering wheel seat keys slope sheet (1) oil drain tube (1) bolt (1) washer 17/32 x 1-3/16 x 12 gauge (1) lock washer 1/2 (1) large flat washer (1) hex bolt 1/4-28 x 1-1/4 (1) locknut 1/4-28 (1) locknut 1/2-20 (2) keys steering wheel adapter steering wheel insert steering...

Page 6: Assembly

6 assembly tools required for assembly a socket wrench set will make assembly easier. Stan dard wrench sizes are listed. (2) 7/16" wrenches utility knife (2) 3/4" wrench tire pres sure gauge pliers when right or left hand is mentioned in this man ual, it means when you are in the operating po si tio...

Page 7: Assembly

7 assembly fig. 2 to roll tractor off skid (see op- er a tion section for location and func tion of con trols) • press lift lever plunger and raise attachment lift lever to its highest po si tion. • release parking brake by depressing clutch/brake ped al. • place gearshift lever in neutral (n) po si...

Page 8: Assembly

8 assembly ✓checklist before you operate and enjoy your new trac- tor, we wish to assure that you receive the best per for mance and satisfaction from this quality prod uct. Please review the following checklist: ✓ all assembly instructions have been completed. ✓ no remaining loose parts in carton. ...

Page 9: Operation

9 operation these symbols may appear on your tractor or in literature supplied with the product. Learn and understand their mean- ing. Danger, keep hands and feet away free wheel (automatic models only) over temp light keep area clear slope hazards 15 15 15 (see safety rules section) battery reverse...

Page 10: Operation

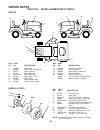

10 operation know your tractor read this owner's manual and safety rules before operating your tractor compare the illustrations with your tractor to familiarize yourself with the locations of various controls and ad just ments. Save this manual for future reference. Attachment clutch lever - used t...

Page 11: Operation

11 note: under certain conditions when tractor is standing idle with the engine running, hot engine exhaust gases may cause “brown ing” of grass. To eliminate this possibility, al- ways stop engine when stopping tractor on grass areas. Caution: always stop tractor com- plete ly, as described above, ...

Page 12: Operation

12 to operate on hills warning: do not drive up or down hills with slopes great er than 15° and do not drive across any slope. • choose the slowest speed before starting up or down hills. • avoid stopping or changing speed on hills. • if slowing is necessary, move throttle control lever to slower po...

Page 13: Operation

13 operation to start engine (see fig. 5) when starting the engine for the fi rst time or if the engine has run out of fuel, it will take extra cranking time to move fuel from the tank to the engine. • sit on seat in operating position, depress clutch/brake pedal and set parking brake. • place gear ...

Page 14: Maintenance

14 maintenance befo re eac h use t r a c t 0 r inspect muffler/spark arrester lubrication chart check brake operation clean air filter change engine oil (with oil filter) replace air filter paper cartridge replace spark plug check battery level check tire pressure clean battery and terminals fill in...

Page 15: Maintenance

15 maintenance fig. 9 fig. 8 battery your tractor has a battery charging system which is suf fi cient for normal use. However, periodic charging of the battery with an automotive charger will extend its life. • keep battery and terminals clean. • keep battery bolts tight. • keep small vent holes ope...

Page 16: Maintenance

16 maintenance v-belts check v-belts for deterioration and wear after 100 hours and replace if necessary. The belts are not adjustable. Re place belts if they begin to slip from wear. Transaxle cooling keep transaxle free from build-up of dirt and chaff which can restrict cooling. Fig. 11 fig. 10 to...

Page 17: Maintenance

17 maintenance cleaning • clean engine, battery, seat, fi nish, etc. Of all foreign matter. • keep fi nished surfaces and wheels free of all gasoline, oil, etc. • protect painted surfaces with automotive type wax. We do not recommend using a garden hose or pressure washer to clean your tractor unles...

Page 18: Service and Adjustments

18 service and adjustments warning: to avoid se ri ous in ju ry, before performing any service or adjust- ments: • depress clutch/brake pedal fully and set parking brake. • place gearshift lever in neutral (n) position. • place attachment clutch in “disengaged” position. • turn ignition key to “stop...

Page 19: Service and Adjustments

19 to replace mower blade drive belt (see fig. 18) the mower blade drive belt may be replaced without tools. Park the tractor on level surface. Engage parking brake. Belt removal - • remove mower from tractor (see “to remove mow er” in this section of this manual). • work belt off both mandrel pulle...

Page 20: Service and Adjustments

20 service and adjustments fig. 18 to replace motion drive belt (see fig. 20) park the tractor on level surface. En gage parking brake. For as sis tance, there is a belt installation guide decal on bottom side of left footrest. Belt removal - • remove mower (see “to re move mower” in this section of...

Page 21: Service and Adjustments

21 fig. 20 adjustment bolt neutral lock gate gearshift lever fig. 21 service and adjustments transaxle pulley sta tion ary idler clutching idler engine pulley center span keeper transaxle gear shift lever neu tral- adjustment (see fig. 21) the transaxle should be in neutral when the gear shift lever...

Page 22: Service and Adjustments

22 fig. 23 service and adjustments replacing battery (see figs. 24 and 25) warning: do not short battery ter mi nals by allowing a wrench or any other object to contact both terminals at the same time. Before connect- ing battery, remove metal bracelets, wristwatch bands, rings, etc. Positive termin...

Page 23: Service and Adjustments

23 service and adjustments engine to ad just throttle con trol cable the throttle control has been preset at the factory and ad just ment should not be necessary. If adjustment is nec- es sary, see engine manual. To ad just choke con trol the choke control has been preset at the factory and ad- just...

Page 24: Storage

24 storage immediately prepare your tractor for storage at the end of the season or if the tractor will not be used for 30 days or more. Warning: never store the trac tor with gas o line in the tank inside a building where fumes may reach an open fl ame or spark. Allow the engine to cool before stor...

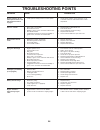

Page 25: Troubleshooting Points

25 troubleshooting points will not start 1. Out of fuel. 1. Fill fuel tank. 2. Engine not “choked” properly. 2. See “to start engine” in operation section. 3. Engine fl ooded. 3. Wait several minutes before attempting to start. 4. Bad spark plug. 4. Replace spark plug. 5. Dirty air fi lter. 5. Clean...

Page 26: Troubleshooting Points

26 troubleshooting points problem cause correction engine continues to run 1. Faulty operator-safety presence control system. 1. Check wiring, switches and connections. If not when operator leaves seat corrected, contact an authorized service center/ with attachment clutch department. Engaged poor c...

Page 27: Repair Parts

27 repair parts tractor - - model number wet1742sta schematic battery fuse ignition switch red red red black ignition unit headlights removable connections black black black white white white red black orange black brown black black black starter m seat switch (not occupied) grounding connector att'...

Page 28: Repair Parts

28 repair parts tractor - - model number wet1742sta electrical 28 29 26 24 42 43 27 27 25 41 27 27 40 33 90 30 8 2 1 27 16 16 52 48 22 21.

Page 29: Repair Parts

29 repair parts tractor - - model number wet1742sta electrical 1 163465 battery 12 volt 28 amp 2 74760412 bolt hex hd 1/4-20unc x 3/4 8 176689 box battery 16 176138 switch interlock push -in 21 175685 harness asm light w/4152j 22 4152j bulb light #1156 24 108432x cable battery 6 ga 16”red 25 146147 ...

Page 30: Repair Parts

30 repair parts tractor - - model number wet1742sta chassis and enclosures 26 25 64 208 13 208 11 1 3 2 9 208 209 209 209 5 5 207 3 3 3 142 3 3 3 142 17 29 28 12 51 57 53 52 54 55 145 37 3 37 24 26 25 31 24 30 35 3 26 33 10 26 34 35 18 14 38 14 206 212 chassis-pl.Lt_stlt_50

Page 31: Repair Parts

31 repair parts tractor - - model number wet1742sta chassis and enclosures 1 174619 chassis 2 176554 drawbar 3 17060612 screw 3/8-16x.75 5 155272 bumper hood/dash 9 168336x010 dash p/l 10 72140608 bolt carriage 3/8-16 x 1 11 174996 panel dash lh 12 145660 clip tinnerman 13 172105x010 panel dash rh 1...

Page 32: Repair Parts

32 repair parts tractor - - model number wet1742sta drive 29 28 112 14 41 38 39 57 51 74 75 78 76 77 1 25 19 24 2 53 35 34 37 36 35 62 36 59 212 55 77 61 22 27 26 6 113 18 51 5 18 6 85 52 30 32 32 30 52 11 85 80 4 3 13 81 84 82 64 65 145 79 16 96 26 27 51 48 150 151 202 49 47 50 120 21 8 10 156 165 ...

Page 33: Repair Parts

33 repair parts tractor - - model number wet1742sta drive key part no. No. Description key part no. No. Description 1 - - - - - - transaxle peerless (206-545c) (order parts from transaxle manu- facturer) 2 146682 spring return brake t/a zinc 3 123666x pulley transaxle 18" tires 4 12000028 ring retai...

Page 34: Repair Parts

34 repair parts tractor - - model number wet1742sta steering assembly 44 51 54 5 9 5 7 7 9 4 3 32 43 6 43 8 10 40 11 8 6 9 46 46 8 6 9 2 47 47 26 30 28 1 41 42 37 36 37 38 12 39 68 67 67 67 13 65 85 85 68 15 15 15 29 29 82 88 71 17 29 43 91.

Page 35: Repair Parts

35 repair parts tractor - - model number wet1742sta steering assembly 1 140044x428 wheel steering auto black 2 175131 axle asm front 3 169840 spindle asm lh 4 169839 spindle asm rh 5 6266h bearing race thrust harden 6 121748x washer 25/32 x 1 5/8 x 16ga 7 19272016 washer 27/32 x 1 1/4 x 16 ga 8 1200...

Page 36: Repair Parts

36 repair parts tractor - - model number wet1742sta engine 2 1 optional equipment spark arrester 29 44 46 32 31 33 37 33 40 62 13 4 85 78 78 81 3 16 23 45 14 38.

Page 37: Repair Parts

37 repair parts tractor - - model number wet1742sta engine note: all component dimensions given in u.S. Inches 1 inch = 25.4 mm 1 170551 control throt /ch flag 2 17720408 screw hex thd cut 1/4-20x1/2 3 - - - - - - engine briggs model ohv170 (order parts from engine manufacturer) 4 137351 muffl er 13...

Page 38: Repair Parts

38 repair parts tractor - - model number wet1742sta seat assembly key part no. No. Description key part no. No. Description 14 72050412 bolt rdhd sht nk 1/4-20 x 1-1/2 15 134300 spacer split 28 x 96 yel zinc 16 121250x spring cprsn 1 27 blk pnt 17 123976x nut lock 1/4 lge flg gr 5 zinc 21 171852 bol...

Page 39: Repair Parts

39 5 11 16 6 9 12 3 10 7 14 wheels & tires key part no. No. Description key part no. No. Description 6 2 1 5,8 4,10 3,9 11 7 repair parts tractor - - model number wet1742sta decals 20 1 4 4 key part no. No. Description 1 59192 cap valve tire 2 65139 stem valve 3 106222x tire f ts 15 x 6 0 - 6 servic...

Page 40: Repair Parts

40 repair parts tractor - - model number wet1742sta mower lift 15 20 16 17 18 20 20 15 20 4 5 6 2 3 1 6 5 4 7 8 12 11 31 32 31 32 19 19 13 13 13 13.

Page 41: Repair Parts

41 repair parts tractor - - model number wet1742sta mower lift 1 159460 wire asm inner/sprg w/plunger 2 159471 shaft asm lift 3 105767x pin groove 4 12000002 e ring #5133-62 5 19211621 washer 21/32 x 1 x 21 ga. 6 120183x bearing nylon 7 109413x grip handle 8 124526x button plunger 11 139865 link lif...

Page 42: Repair Parts

42 repair parts tractor - - model number wet1742sta mower deck 15 14 13 11 10 9 8 16 68 37 184 30 31 32 33 146 148 145 150 45 144 147 147 142 149 142 54 52 53 55 56 34 1 46 44 21 24 25 26 27 2 28 29 23 21 21 21 18 18 20 2 48 59 19 4 3 5 6 21 40 143 36 40 37 40 159 42_deck_man-t-path_3 152 151 153 15...

Page 43: Repair Parts

43 repair parts tractor - - model number wet1742sta mower deck 1 165892 mower deck assembly, 42" 2 72140506 bolt 3 138017 bracket asm fr. Sway bar 3/42 4 165460 bracket asm deck 42" sway bar 5 4939m retainer spring 6 178024 bar sway deck 8 850857 bolt 3/8-24 x 25 grade 8 patched 9 10030600 washer, l...

Page 44: Service Notes

44 service notes.

Page 45: Limited Warranty

45 limited warranty the manufacturer warrants to the original consumer purchaser that this product as manufactured is free from defects in materi- als and work man ship. For a period of two (2) years from date of purchase by the original consumer purchaser, we will repair or replace, at our option, ...

Page 46: Service

46 t e c u m s e h ® issued january 1980 revised january 1991 t e c u m s e h ® service policy policy warranty limited warranties for new peerless gear power train components a. Products warranted peerless gear and machine division of tecumseh products company (“tecumseh”), subject to the limitation...

Page 47

47 15 degrees max. Fold along dotted line this is a 15 degree slope only ride up and down hill, not across hill suggested guide for sighting slopes for safe operation warning: to avoid serious injury, operate your tractor up and down the face of slopes, never across the face. Do not mow slopes great...

Page 48

®.