- DL manuals

- Weed Eater

- Lawn Mower

- 532 43 32-03

- Operator's Manual

Weed Eater 532 43 32-03 Operator's Manual

Summary of 532 43 32-03

Page 1

Operator’s manual 532 43 32-03 rev. 10 26" riding mower side discharge electric start important: read and follow all safety rules and instructions before operating this equipment. Catalog no. We261 patents pending.

Page 2: Table of Contents

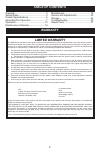

2 table of contents warranty warranty ................................................. 2 safety rules ........................................... 3 product specifications ............................ 6 assembly/pre-operation ........................ 7 operation ........................................

Page 3: Safety Rules

3 safety rules danger: this cutting machine is capable of amputating hands and feet and throwing objects. Failure to observe the following safety instructions could result in serious injury or death. I. General operation • read, understand, and follow all instruc- tions on the machine and in the man...

Page 4: Safety Rules

4 safety rules ii. Slope operation slopes are a major factor related to loss of control and tip-over accidents, which can result in severe injury or death. Operation on all slopes requires extra caution. If you cannot back up the slope or if you feel uneasy on it, do not mow it. • mow up and down sl...

Page 5: Safety Rules

5 safety rules • never fill containers inside a vehicle or on a truck or trailer bed with plastic liner. Always place containers on the ground away from your vehicle when filling. • remove gas-powered equipment from the truck or trailer and refuel it on the ground. If this is not possible, then refu...

Page 6: Unassembled Parts

6 unassembled parts product specifications customer responsibilities • read and observe the safety rules. • follow a regular schedule in maintaining, caring for and using your riding mower. • follow the instructions under “mainte- nance” and “storage” sections of this owner’s manual. Warning: this r...

Page 7: Assembly/pre-Operation

7 your new riding mower has been assembled at the factory with the exception of those parts left unassembled for shipping purposes. To ensure safe and proper operation of your riding mower all parts and hardware you assemble must be tightened securely. Use the correct tools as necessary to insure pr...

Page 8: Check Tire Pressure

8 note: you may now roll your riding mower off the skid. Follow the appropriate instruction below to remove the riding mower from the skid. Check tire pressure the tires on your riding mower were overinflated at the factory for shipping pur- poses. Correct tire pressure is important for best cutting...

Page 9: Checklist

9 checklist before you operate your new riding mower, we wish to assure that you receive the best performance and satisfaction from this quality product. Please review the following checklist: all assembly instructions have been completed. No remaining loose parts in carton. Battery is properly conn...

Page 10: Operation

10 operation these symbols may appear on your riding mower or in literature supplied with the prod- uct. Learn and understand their meaning. Danger, keep hands and feet away over temp light keep area clear slope hazards 15 15 (see safety rules section) battery reverse forward fast slow engine on eng...

Page 11: Know Your Riding Mower

11 know your riding mower read this owner's manual and safety rules before operating your riding mower compare the illustrations with your riding mower to familiarize yourself with the locations of various controls and adjustments. Save this manual for future reference. Our riding mowers conform to ...

Page 12: How to Use Your Riding

12 the operation of any riding mower can result in foreign objects thrown into the eyes, which can result in severe eye damage. Always wear safety glasses or eye shields while operating your riding mower or performing any adjustments or repairs. We recommend a wide vision safety mask over spectacles...

Page 13

13 to operate mower your riding mower is equipped with an operator presence sensing switch. Any attempt by the operator to leave the seat with the engine running and the deck clutch engaged will shut off the engine. You must remain fully and centrally positioned in the seat to prevent the engine fro...

Page 14: To Start Engine

14 add gasoline • fill fuel tank to bottom of filler neck. Do not overfill. Use fresh, clean, regular unleaded gasoline with a minimum of 87 octane. (use of leaded gasoline will increase carbon and lead oxide deposits and reduce valve life). Do not mix oil with gasoline. Purchase fuel in quantities ...

Page 15: Mowing Tips

15 mowing tips • mower should be properly leveled for best mowing performance. See “to level mower housing” in the service and adjustments section of this manual. • the left hand side of mower should be used for trimming. • drive so that clippings are discharged onto the area that has already been c...

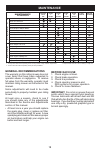

Page 16: Maintenance

16 maintenance important: do not oil or grease the pivot points which have special nylon bearings. Viscous lubricants will attract dust and dirt that will shorten the life of the self-lubricating bearings. If you feel they must be lubricated, use only a dry, powdered graphite type lu- bricant sparin...

Page 17

17 riding mower always observe safety rules when performing any maintenance. Brake operation if riding mower requires more than four (4) feet to stop at highest speed in highest gear on a level, dry concrete or paved surface, then brake must be serviced. (see “to adjust brake” in the service and adj...

Page 18: V-Belt

18 battery your riding mower has a battery charging system which is sufficient for normal use. • keep battery and connectors clean. • only recharge battery with charger approved for a 12v 2.8 amp. Hour battery. • charging with any other charger or an automotive style charger can cause per- manent da...

Page 19: Air Filter

19 muffler inspect and replace corroded muffler and spark arrester (if equipped) as it could create a fire hazard and/or damage. Spark plug(s) replace spark plug(s) at the beginning of each mowing season or after every 100 hours of operation, whichever occurs first. Spark plug type and gap setting a...

Page 20: Service and Adjustments

20 service and adjustments warning: to avoid serious injury, before performing any service or adjustments: 1. Depress clutch/brake pedal fully and set parking brake. 2. Place motion control lever in neutral (n) position. 3. Place deck clutch in “disengaged” position. 4. Turn ignition key to “stop” a...

Page 21

21 to level mower housing adjust the mower while riding mower is parked on level ground or driveway. Make sure tires are properly inflated (see side of tire for proper psi). If tires are over or underinflated, you will not properly adjust your mower. Side-to-side adjustment • raise mower to its high...

Page 22

22 to adjust brake your riding mower is equipped with an adjustable brake system which is mounted on the right side of the transaxle. If riding mower requires more than (4) feet stop- ping distance in highest gear on a lever dry concrete or paved surface, then brake must be adjusted. 1. Park riding ...

Page 23

23 fender battery battery bracket 1. Lift seat for bolt access. 2. Disconnect black battery cable then red battery cable. 3. Remove battery bracket bolt. 4. Install new battery with terminals facing to the right, and away from seat as shown. 5. Reinstall battery bracket and bolt. 6. First connect re...

Page 24: Storage

24 storage immediately prepare your riding mower for storage at the end of the season or if the riding mower will not be used for 30 days or more. Warning: never store the riding mower with gasoline in the tank inside a building where fumes may reach an open flame or spark. Allow the engine to cool ...

Page 25: Troubleshooting Chart:

25 problem cause correction will not start 1 out of fuel. 1 fill fuel tank. 2 bad spark plug. 2 replace spark plug. 3 dirty air filter. 3 clean/replace air filter. 4 water in fuel. 4 empty fuel tank and carburetor, refill tank with fresh gasoline and replace fuel filter. 5 loose or damaged wiring. 5...

Page 26: Troubleshooting Chart:

26 problem cause correction engine continues to run when operator leaves seat with atta- chment clutch engaged 1 faulty operator-safety presence control system. 1 check wiring, switches and connections. If not corrected, contact a qualified service center. Poor cut - uneven cutting 1 worn, bent or l...

Page 27

27 riding mower - -catalog no. We261 schematic battery fuse-40a red red white black/white red green yellow black/white black black gray black relay m starter clutch / brake (pedal up) seat switch (not occupied) ignition unit s m b g a1 a2 l reverse switch spark plug gap not in reverse shorting conne...

Page 28

28 riding mower - -catalog no. We261 electrical 11 lrv1 10 9 8 12 13 7 1 2 3 4 6 5.

Page 29

29 riding mower - -catalog no. We261 electrical 1 532 43 70-70 battery 2 532 42 54-16 foam, polyurethane 3 532 19 33-50 switch, ign, dlta, p-in, ros 4 532 41 19-33 key, molded english/spanish - - 532 41 19-35 key, molded english/french/international 5 532 43 33-30 fuse, 5a 6 532 42 59-37 fuse, 40a 7...

Page 30

30 riding mower - -catalog no. We261 chassis 10 11 3 4 5 7 9 8 1 2 12 13 49 14 15 16 17 18 19 20 21 22 23 24 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 39 40 40 41 41 42 43 44 45 45 50 50 45 45 45 45 45 45 6 46 46 45 45 45 46 48 46 48 46 46 47 lrv-chassis_1_r2.

Page 31

31 riding mower - -catalog no. We261 chassis 1 532 42 80-48 weldment, chassis 2 532 42 82-47 support, axel lh 3 532 42 82-44 support, axel rh 4 532 42 83-46 shield, transaxle front 5 532 42 81-10 brace, axle cross 6 532 42 81-09 cover, friction drive 7 532 42 80-40 plate, engine 8 532 42 85-76 brack...

Page 32

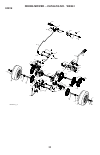

32 riding mower - -catalog no. We261 drive lrv-drive_1_r3 10 11 11 3 1 2 2 3 4 5 6 7 72 8 8 1 2 2 3 4 5 6 7 8 73 8 12 13 13 70 70 14 14 15 71 15 16 17 18 19 20 21 22 23 24 24 25 26 27 28 29 30 31 32 33 34 35 36 37 37 38 38 38 39 40 41 42 43 70 45 46 47 48 49 50 51 52 53 54 55 56 57 58 58 58 70 70 70...

Page 33

33 key part no. No. Description key part no. No. Description note: all component dimensions given in u.S. Inches 1 inch = 25.4 mm riding mower - -catalog no. We261 drive – – 532 43 61-44 service kit, transaxle 1 532 43 64-98 wheel asm (rear) 2 532 12 17-48 washer, 16 ga. 3 812 00 00-01 e-clip 4 532 ...

Page 34

34 riding mower - -catalog no. We261 steering 10 11 2 2 4 6 6 7 7 9 9 9 1 2 30 3 1 2 30 3 4 4 5 29 8 8 8 12 13 14 15 16 17 18 19 19 20 21 22 28 23 24 25 26 27 lrv-steering_1_r2.

Page 35

35 riding mower - -catalog no. We261 steering 1 532 43 65-00 wheel asm (front) 2 812 00 00-01 e-clip 3 532 18 89-67 washer, hardened 4 532 12 17-49 washer, 1/4 x 3/4 5 532 42 80-34 spindle, rh 6 532 12 49-31 washer, hardened thrust 7 532 12 49-37 bushing, steering column 8 532 42 10-76 pin, 5/64 x 3...

Page 36

36 riding mower - -catalog no. We261 mower deck 10 11 1 2 3 4 5 7 9 8 12 13 41 14 15 16 16 17 17 17 40 17 45 18 18 19 19 19 19 20 20 21 22 23 42 24 25 26 27 27 28 29 30 31 32 33 34 35 36 37 37 38 39 39 lrv-deck_1_r4 44 43 46 6 36.

Page 37

37 riding mower - -catalog no. We261 mower deck 1 532 42 81-93 deck, 26" 2 532 19 28-70 mandrel asm 3 532 43 25-20 keeper, belt 4 532 43 25-94 pulley, mandrel 5 532 42 85-78 belt 6 532 42 82-42 cover, mandrel 7 532 42 93-95 lift asm, deck 8 532 42 91-95 link, deck lift 9 532 42 93-97 link, adjustabl...

Page 38

38 riding mower - -catalog no. We261 decals 1 532 43 05-88 decal, steering wheel 2 532 43 35-96 decal, v-belt sch 30" 3 532 42 51-13 decal, warn. Deflect/ctfgr 4 532 43 05-89 decal, deck/deflector 5 532 43 44-57 decal, warning engineguard 6 532 43 53-48 decal, strbrckt install boot - - 532 43 24-79 ...

Page 39

39 15 degrees max. Fold along dotted line this is a 15 degree slope only ride up and down hill, not across hill suggested guide for sighting slopes for safe operation warning: to avoid serious injury, operate your tractor up and down the face of slopes, never across the face. Do not mo w slopes grea...

Page 40: Parts and Service

10.04.10 cl printed in the u.S.A. This product has been expertly engineered and carefully manufactured to rigid quality standards. As with all mechanical products, some adjustments or part replacement may be necessary during the life of your unit. For parts and service, contact our authorized distri...