- DL manuals

- Weed Eater

- Tiller

- WET6500A

- Owner's Manual

Weed Eater WET6500A Owner's Manual

186100 Rev. 3 06.17.03 TR

PRINTED IN U.S.A.

•

Assembly

•

Operation

•

Maintenance

•

Service and Adjustments

•

Storage

•

Troubleshooting

•

Repair Parts

OWNER'S MANUAL

MODEL NO. WET6500A

6.5 HP 17 Inch

Tiller

For Parts and Service, contact our authorized distributor: call 1-800-849-1297

For Technical Assistance: call 1-800-829-5886

®

01029-weedeater

Summary of WET6500A

Page 1

186100 rev. 3 06.17.03 tr printed in u.S.A. • assembly • operation • maintenance • service and adjustments • storage • troubleshooting • repair parts owner's manual model no. Wet6500a 6.5 hp 17 inch tiller for parts and service, contact our authorized distributor: call 1-800-849-1297 for technical a...

Page 2: Safety Rules

2 • never operate the tiller without proper guards, plates, or other safety protective devices in place. • keep children and pets away. • do not overload the machine capacity by attempting to till too deep at too fast a rate. • never operate the machine at high speeds on slippery surfaces. Look behi...

Page 3: Table of Contents

3 maintenance ..................................................... 12-14 service & adjustments ................................. 15-18 storage .................................................................... 19 troubleshooting ................................................. 20 repair parts-ti...

Page 4: Assembly

4 assembly your new tiller has been assembled at the factory with exception of those parts left unassembled for shipping purposes. To ensure safe and proper operation of your tiller, all parts and hardware you assemble must be tightened securely. Use the correct tools as necessary to insure proper t...

Page 5: Assembly

5 assembly viewed from r.H. Side of tiller • grasp handle assembly. Hold in “up” position. Be sure handle lock remains in gearcase notch. Slide handle assembly into position. Handle assembly "up" position fig. 4 unpacking carton (see fig. 2) caution: be careful of exposed sta ples when handling or d...

Page 6: Assembly

6 assembly attach clutch cable (see fig. 6) • hook end of clutch cable through hole in control bar bracket if necessary. Control bar bracket clutch cable control bar fig. 6 end of clutch cable control bar bracket shift rod hairpin clip shift lever indicator fig. 7 connect shift rod (see fig. 7) • in...

Page 7: Operation

7 operation know your tiller read this owner's manual and safety rules before operating your tiller. Compare the illustrations with your tiller to familiarize yourself with the location of various controls and adjustments. Save this manual for future reference. These symbols may appear on your tille...

Page 8: Operation

8 operation how to use your tiller know how to operate all controls before adding fuel and oil or attempting to start engine. Stopping (see fig. 9) tines and drive • release drive control bar to stop movement. • move shift lever to “n” (neutral) position. Engine • move throttle control to “stop” pos...

Page 9: Operation

9 operation fig. 12 turning • release the drive control bar. • move throttle control to “slow” position. • place shift lever indicator in “f” (forward) position. Tines will not turn. • lift handle to raise tines out of ground. • swing the handle in the opposite direction you wish to turn, being care...

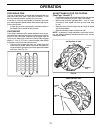

Page 10: Operation

10 operation fig. 14 3 2 1 5 4 6 7 fig. 13 tilling hints caution: until you are accustomed to handling your tiller, start actual fi eld use with throttle in slow position (mid-way between “fast” and “idle”). • tilling is digging into, turning over, and breaking up packed soil before planting. Loose,...

Page 11: Operation

11 operation fig. 16 outer view of tire adjust wheels for cultivating (see figs. 16 and 17) • place blocks under right hand side of tiller and remove hairpin clip and clevis pin from right hand wheel. • move wheel outward approximately 1 inch (2.5 cm) until hole in inner wheel hub lines up with inne...

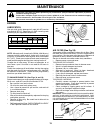

Page 12: Maintenance

12 maintenance general recommendations the warranty on this tiller does not cover items that have been subjected to operator abuse or negligence. To receive full value from the warranty, the operator must main tain tiller as instructed in this manual. Some adjustments will need to be made periodical...

Page 13: Maintenance

13 maintenance fig. 18 disconnect spark plug wire before performing any maintenance (except car bu re tor adjustment) to prevent accidental start ing of engine. Prevent fi res! Keep the engine free of grass, leaves, spilled oil, or fuel. Re move fuel from tank before tipping unit for maintenance. Cl...

Page 14: Maintenance

14 maintenance muffler do not operate tiller without muffl er. Do not tamper with exhaust system. Damaged muffl ers or spark arresters could create a fi re hazard. Inspect pe ri odi cally and re place if nec es sary. If your engine is equipped with a spark arrester screen assembly, re move every 50 ...

Page 15: Service And Adjustments

15 tiller to adjust handle height (see fig. 22) select handle height best suited for your tilling conditions. Handle height will be different when tiller digs into soil. • first loosen handle lock lever. • handle can be positioned at different settings between “high” and “low” positions. • retighten...

Page 16: Service And Adjustments

16 service and adjustments fig. 26 tine replacement (see figs. 24, 25 and 26) caution: tines are sharp. Wear gloves or other protection when han- dling tines. A badly worn tine causes your tiller to work harder and dig more shallow. Most important, worn tines cannot chop and shred organic matter as ...

Page 17: Service And Adjustments

17 service and adjustments to replace ground drive belt (see figs. 27 and 28) • remove belt guard as described in “to remove belt guard”. • remove old belt by slipping off engine pulley fi rst then remove from transmission pulley. • place new belt in groove of transmission pulley and into engine pul...

Page 18: Service And Adjustments

18 service and adjustments engine to adjust throttle control ca ble (see fig. 29) the throttle control has been preset at the factory and ad just ment should not be necessary. If adjustment is necessary, proceed as follows: • with engine not running, move remote throttle control lever to “fast” posi...

Page 19: Storage

19 immediately prepare your tiller for storage at the end of the season or if the unit will not be used for 30 days or more. Warning: never store the tiller with gasoline in the tank inside a build ing where fumes may reach an open fl ame or spark. Allow the engine to cool before storing in any en c...

Page 20: Troubleshooting Points

20 will not start 1. Out of fuel. 1. Fill fuel tank. 2. Engine not “choked” properly. 2. See “to start engine” in operation section. 3. Engine fl ooded. 3. Wait several minutes before attempting to start. 4. Dirty air cleaner. 4. Clean or replace air cleaner cartridge. 5. Water in fuel. 5. Drain fue...

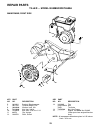

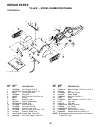

Page 21: Repair Parts

21 key part no. No. Description key part no. No. Description 1 175769 control, throttle 2 150744 grip, handle 4 159227 bar, control 8 71191008 screw, pan hd. #10-24 10 8389j grip, handle 11 4497h clip, hairpin 15 108281x rod, shift 16 72110608 bolt, carriage 3/8-16 x 1 gr. 5 17 109229x lock, handle ...

Page 22: Repair Parts

22 key part no. No. Description 1 73510500 nut, keps 5/16-18 2 10040600 washer, lock 3/8 3 73220600 nut, hex 3/8-16 4 170127 shield, inner, belt guard 5 164329 pin spirol flared 6 110111x lever, shift 7 72110404 bolt, carriage 1/4-20 x 1/2 gr. 5 8 8700j plate, shift indicator 9 86777 screw, hex, was...

Page 23: Repair Parts

23 5 10 7 8 9 11 12 13 15 14 key part no. No. Description key part no. No. Description 5 102332x bracket, reinforcement 7 102173x counter weight, r.H. 8 10040600 washer, lock 3/8 9 73220600 nut, hex 3/8-16 10 74760524 bolt, hex 5/16-18 x 1-1/2 11 4497h clip, hair pin 12 126875x rivet, drilled 13 102...

Page 24: Repair Parts

24 29 102134x chain #35-50 pitch 30 150737 ground shaft assembly 31 143008 bearing, shaft, ground drive 32 106388x spacer 0.70 x 1.00 x 1.150 33 102121x sprocket and gear assembly 34 102112x shaft, re duc tion (2nd) 35 102101x screw, whiz, lock 5/16-18 x 3-1/2 36 154355 sprocket assembly w/bearing (...

Page 25: Repair Parts

25 key part no. No. Description 2 29 29 15 1 11 11 12 12 13 14 14 24 23 26 27 11 12 16 11 12 25 33 32 16 3 4 7 8 9 5 23 23 28 24 18 6 5 5 12 11 10 tine_shield_13_in(sears) 22 21 20 19 1 key part no. No. Description 1 73900500 nut, flange 5/16-18 2 161415x550 shield, side, outer l. H. 3 8393j pin, st...

Page 26: Repair Parts

26 key part no. No. Description 8 74610616 bolt, hex 3/8-24 x 1 9 4460j tine, outer, r.H. 10 132728 assembly, hub and plate, r.H. 11 6555j tine, inner, r.H. Key part no. No. Description 1 4459j tine, outer, l.H. 2 132673 clevis pin 3 6554j tine, inner, l.H. 4 3146r clip, hairpin 5 132727 assembly, h...

Page 27: Repair Parts

27 key part no. No. Description 1 162846 decal, logo 3 186761 decal, logo 4 143678 decal, instruction, tilling 5 141907 decal, hand placement 6 102180x decal, shift indicator 9 141906 decal, warning, rotating tines 10 156199 deal, reverse 12 162215 decal, tine shield wrng dom - - 186100 manual, owne...

Page 28: Limited Warranty

Limited warranty the manufacturer warrants to the original consumer purchaser that this product as manufactured is free from de- fects in materials and work man ship. For a period of two (2) years from date of purchase by the original consumer purchaser, we will repair or replace, at our option, wit...