- DL manuals

- WEG

- Inverter

- CFW08 Vector inverter

- User Manual

WEG CFW08 Vector inverter User Manual

Summary of CFW08 Vector inverter

Page 2: Frequency

08/2003 frequency inverter manual series: cfw-08 software: version 3.9x 0899.4690 e/5 attention! It is very important to check if the inverter software version is the same as indicated above..

Page 3

Summary of revisions the table below describes all revisions made to this manual. Revision description section 1 first edition - 2 item 3.3 - ce installation included see item 3.3 3 general revision - 4 external parallel keypad and see item 8.3 fixs kit included and and 8.12 general revision 5 gener...

Page 4

Contents quick parameter reference, fault and status messages 1 parameters ................................................................................. 07 2 fault messages .......................................................................... 14 3 other messages ...............................

Page 5

Contents chapter 5 keypad (hmi) operation 5.1 keypad (hmi) description ........................................................ 60 5.2 use of the keypad (hmi) .......................................................... 61 5.2.1 keypad operation ...........................................................

Page 6

Contents 8.8 cab-rs-1, cab-rs-2, cab-rs-3, cab-rs-5, cab-rs-7.5 cab-rs-10 ............................................................................ 121 8.9 kcs-cfw08 .......................................................................... 122 8.9.1 instruction and removing instructions for kcs-...

Page 7

Contents 8.20.2.1.2 rs-485 .......................................... 149 8.20.2.2 inverter configuration in the modbus-rtu network ..................................... 149 8.20.2.2.1 inverter address in the network ...... 149 8.20.2.2.2 transmission rate and parity ........ 149 8.20.2.3 access to ...

Page 8

7 cfw-08 - quick parameter reference software: v3.9x application: model: serial number: responsible: date: / / . 1. Parameters parameter function adjustable range factory user note page setting setting p000 parameter access 0 ... 4, 6 ... 999 = read 0 - 72 5 = alteration read only parameters (p002 ....

Page 9

8 cfw-08 - quick parameter reference speed limits p133 minimum frequency (f min ) 0.00 ... P134 3.00 76 p134 maximum frequency (f max ) p133 ... 300.0hz 66.00 76 v/f control p136 manual torque boost 0.0 ... 30.0% 5.0 or only available 76 (ixr compensation) 2.0 or in v/f control 1.0 (2) control mode ...

Page 10

9 cfw-08 - quick parameter reference (1) this parameter can be changed only with the inverter disabled (motor stopped). Only available in cfw-08 plus version local/remote definition p220 (1) local/remote 0 = always local 2 85 selection source 1 = always remote 2 = hmi-cfw08-p or hmi-cfw08-rp keypad ...

Page 11

10 cfw-08 - quick parameter reference only available in cfw-08 plus version. Analog output 0 = output frequency (fs) 1 = input reference (fe) 2 = output current (is) 3, 5, 8 = not used 88 p251 analog output 4 = motor torque 0 ao function 6 = process variable (pid) 7 = active current 9 = pid setpoint...

Page 12

11 cfw-08 - quick parameter reference according to the inverter model only available in cfw-08 plus version. In vector control mode (p202=2) it is not possible to set p297=7 (15khz). 3 = jog 4 = no extrernal fault 5 = decrease e.P. 6 = ramp #2 7 = multispeed (ms0) 8 = not used or start/stop 9 = star...

Page 13

12 cfw-08 - quick parameter reference serial communication interface i p308 (1) inverter address 1 ... 30 (serial weg) 1 98 1 ... 247 (modbus-rtu) flying start and ride-through p310 (1) flying start and ride-through 0 = inactive 0 99 1 = flying start 2 = flying start and ride-through 3 = ride-throug...

Page 14

13 cfw-08 - quick parameter reference only available in vector mode (p202=2). Only available in vector mode (p202=2). Only available in vector mode (p202=2). According to inverter model (1) this parameter can be changed only with the inverter disabled (motor stopped). Motor parameters (p399 ... P499...

Page 15

14 cfw-08 - quick parameter reference display description page e00 output overcurrent/short-circuit 110 e01 dc link overvoltage 110 e02 dc link undervoltage 110 e04 inverter overtemperature 111 e05 output overload (ixt function) 111 e06 external fault 111 e08 cpu error (watchdog) 111 e09 program mem...

Page 16: Chapter 1

15 chapter 1 safety notices this manual contains necessary information for the correct use of the cfw-8 variable frequency drive. This manual has been written for qualified personnel with suitable training and technical qualification to operate this type of equipment. The following safety notices wi...

Page 17

16 safety notices these personnel must follow all safety instructions included in this manual and/or defined by local regulations. Failure to comply with these instructions may result in personnel injury and/or equipment damage. Note! In this manual, qualified personnel are defined as people that ar...

Page 18: Chapter 2

This chapter defines the contents and purposes of this manual and describes the main characteristics of the cfw-08 frequency inverter. Identification, receiving inspections and storage requirements are also provided. This manual is divided into 10 chapter, providing infornation to the user on how re...

Page 19

18 general information 2.3 about the cfw-08 the cfw-08 is a high performance variable frequency drive that permits the control of speed and torque of a three-phase ac induction motor. Two types of control are available in the same product: programmable scalar (volts/hz) control; sensorless vector co...

Page 20

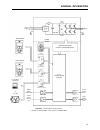

19 general information figure 2.1 - block diagram for the models: 1.6-2.6-4.0-7.0a/200-240v and 1.0-1.6-2.6-4.0a/380-480v power supply r s t p e pc-software superdrive or rs-485 miw-02 analog inputs (ai1 and ai2) digital inputs (di1 to di4) power control power supplies and control / power interfaces...

Page 21

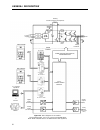

20 general information figura 2.2– block diagram for the models: 7.3-10-16a/200-240v and 2.7-4.3-6.5-10-13-16a/380-480v note: model 16a/200-240v is not fitted with rfi filter (optional). Power supply r s t rfi suppressor filter (optional) pc-software superdrive or rs-485 miw-02 analog inputs (ai1 an...

Page 22

21 general information product appearance besides the internal electronics, also the exterrnal product appearance have changed, which are: - the frontal lettering on the plastic covers (formerly: µ line, now: cfw-08 vector inverter); - weg logo is now indicated on all accessories of the cfw-08 line ...

Page 23

22 general information expansion of the power range the power range of the old µ line (0.25-2hp) has been expanded to (0.25-10hp) with the new cfw-08 line. Control modes only the cfw-08 line has: - voltage vector control (vvc) that improves the inverter performance considerably - adding the paramete...

Page 24

23 general information i/o digital input di1 digital input di2 digital input di3 digital input di4 0v for digital inputs +10v analog input ai1 - voltage signal analog input ai1 - current signal 0v for analog input(s) analog input ai2 - voltage signal analog input ai2 - current signal saída analógica...

Page 25

24 general information b) automatic torque boost (automatic ixr compensation) and slip compensation in the µ line only the rated motor current (p401) was used in the automatic ixr compensation and the slip compensation functions. In the µ line the rated motor power factor of the motor was considered...

Page 26

25 general information 2.4 cfw-08 identification figure 2.4 - description and location of the nameplates software version hardware revision rated input data (voltage, number of phases current, frequency) manufacturing date weg part number serial number cfw-08 model rated output data (voltage, freque...

Page 27

26 general information cfw-08 0040 b 2024 p o 00 00 00 00 00 00 z rated output current for 200 to 240v : 0016=1.6a 0026=2.6a 0040=4.0a 0070=7.0a 0073=7.3a 0100=10a 0160=16a 380 to 480v : 0010=1.0a 0016=1.6a 0026=2.6a 0027=2.7a 0040=4.0a 0043=4.3a 0065=6.5a 0100=10a 0130=13a 0160=16a number of phases...

Page 28

27 general information 2.5 receiving and storing note! The option field (s or o) defines if the cfw-08 is a standard version or if it will be equipped with any optional devices. If the standard version is required, the specification code ends here. The model number has always the letter z at the end...

Page 29: Chapter 3

28 chapter 3 installation 3.1 mechanical installation this chapter describes the procedures for the electrical and mechanical installation of the cfw-08. These guidelines and suggestions must be followed for proper cfw-08 operation. 3.1.1 environment the location of the inverter installation is an i...

Page 30

29 installation and connection table 3.1 - recommended free spaces install the inverter in vertical position. Leave free space around the inverter as indicated in table 3.1. Do not install heat sensitive components immediately above the inverter. When inverters are installed side by side, maintain t...

Page 31

30 installation and connection figure 3.2 - dimensional drawings of the cfw-08 view of the mounting base frontal view lateral view.

Page 32

31 installation and connection inverter model 1.6a / 200-240v 2.6a / 200-240v 4.0a / 200-240v 7.0a / 200-240v 7.3a / 200-240v 10a / 200-240v 16a / 200-240v 1.0a / 380-480v 1.6a / 380-480v 2.6a / 380-480v 2.7a / 380-480v 4.0a / 380-480v 4.3a / 380-480v 6.5a / 380-480v 10a / 380-480v 13a / 380-480v 16...

Page 33

32 installation and connection (a) models 1.6-2.6-4.0-7.0a / 200-240v and 1.0-1.6-2.6-4.0a / 380-480v pe r s t power supply disconnect (*) pe t q1 r s t u v w pe pe w v u danger! Ac input disconnection: provide and ac input disconnecting switch to switch off the input power to the inverter. This dev...

Page 34

33 installation and connection note! Do not use the neutral conductor for grounding purposes. Figure 3.5 - grounding connections for more than one inverter grounding bar internal to the panel danger! The inverter must be grounded to a protective earth for safety purposes (pe). The earth or ground co...

Page 35

34 installation and connection table 3.3 - recommended wiring and circuit-breakers - use 70ºc copper wires only amp rating [ a ] 1.0 1.6 (200-240v) 1.6 (380-480v) 2.6 (200-240v) 2.6 (380-480v) 2.7 4.0 (200-240v) 4.0 (380-480v) 4.3 6.5 7.0 7.3 10.0 13.0 16.0 power cables [ mm 2 ] 1.5 1.5 1.5 1.5 1.5 ...

Page 36

35 installation and connection note! Supply line capacity: the cfw-08 is suitable for use in circuits capable of supplying not more than symmetrical 30.000arms (240/480v). The cfw-08 can be installed on power supplies with a higher fault level if an adequate protection is provided by fuses or circui...

Page 37

36 installation and connection 3.2.3 location of the power, grounding and control connections (a) models 1.6-2.6-4.0-7.0-7.3-10-16a/200-240v and 1.0-1.6-26-2.7-40- 4.3-65-10a/380-480v control (xc1) power grounding (b) models 7.3-10-16a/200-240v and 2.7-4.3-6.5-10a/380-480v u v w -ud br + ud (a) mode...

Page 38

37 installation and connection 3.2.4 control wiring the control wiring (analog inputs/outputs, digital inputs and relay outputs is made on the xc1 connector of control board (see location in figure 3.7, section 3.2.3). There are two configurations for the control board: standard version (cfw-08 line...

Page 39

38 installation and connection figure 3.9 - xc1 control terminal description of the control board 1 (cfw-08 plus) figure 3.10 - dip switch position for 0 ...10v/4 ... 20ma selection s1 2 1 off on conector xc1 1 di1 2 di2 3 di3 4 di4 5 gnd 6 ai1 7 +10v 8 ai2 9 ao 10 nf 11 comum 12 na description fact...

Page 40

39 installation and connection analog input ai1 ai2 factory deafult setting frequency / speed reference (remote mode) no function dip switch s1.1 s1.2 selection off: 0 ... 10v on: 4 ... 20ma or 0 ... 20ma off: 0 ... 10v on: 4 ... 20ma or 0 ... 20ma table 3.5 - dip switch configuration note! Jumpers ...

Page 41

40 installation and connection 5) relays, contactors, solenoids or eletromagnetic braking coils installed near inverters can generate interferences in the control circuit. To eliminate this interference, connect rc suppressor in parallel with the coils of ac relays. Connect free-wheeling diode in ca...

Page 42

41 installation and connection connection 3 - 3 wire start/stop function enabling (three wire control): set di1 to start: p263=14 set di2 to stop: p264=14 set p229=1 (command via terminals) if you want the 3-wire control in local mode. Set p230=1 (command via terminals) if you want the 3-wire contro...

Page 43

42 installation and connection connection 4 - fwd run / rev run parameter to be programmed: set di1 to forward run : p263 = 8 set di2 to reverse run: p264 = 8 make sure the inverter commands are via terminals, i.E., p229=1 to local mode or p230=1 to remote mode. Figure 3.14 - xc1 wiring for connecti...

Page 44

43 installation and connection 3.3 european emc directive - requirements for conforming installations the cfw-08 inverter series was designed considering safety and emc (electromagnetic compatibility) aspects. The cfw-08 units do not have an intrinsic function until connected with other components (...

Page 45

44 installation and connection 3.3.2 inverter models and filters table 3.6 below shows the inverter models and the respective rfi filter and the emc category number. A description of each emc category is given in item 3.3.3. The characteristics of the footprint and external input rfi filters are giv...

Page 46

45 installation and connection obs.: 1) category ii systems must be mounted inside a metallic cabinet in order to have radiated emissions below the limits for first environment and restricted distribution (see item 3.3.3). Category i systems do not require a metallic cabinet. Exception: models 7 and...

Page 47

46 installation and connection emc phenomenon emission: conducted emissions (mains terminal disturbance voltage - freq band 150khz to 30mhz) radiated emissions (electromagnetic radiation disturbance - freq band 30mhz to 1000mhz) immunity: electrostatic discharge (esd) fast transient-burst conducted ...

Page 48

47 installation and connection 3.3.4 emc filters characteristics filter table 3.7 - emc filters characteristics filter weg p/n rated current weight dimensions drawings (width x height x depth) fex1-cfw08 417118238 10a 0.6kg 79x190x51mm fig. 3.16 fex2-cfw08 417118239 5a fs6007-16-06 0208.2072 16a 0.9...

Page 49

48 installation and connection figure 3.17 - fs6007-16-06 external filter drawing figure 3.16 - fex1-cfw08 and fex2-cfw08 footprint filter drawing front view lateral right view bottom view terminal block for flexible and rigid cable of 4mm 2 or awg 10. Max. Torque: 0.8nm (a) footprint filter (b) foo...

Page 50

49 installation and connection figure 3.19 - fs3258-xx-xx external filter drawing type/45 terminal block for 6mm 2 solid cable, 4mm 2 flexible cable awg 12. Top view side view connector rated current type/47 terminal block for 16mm 2 solid wires, 10mm 2 flexible wires awg 8. Mechanical data front vi...

Page 51

50 installation and connection toroid: thornton nt35/22/22-4100-ip12r (weg p/n 0208.2102) plastic clamp: hellermanntyton nxr-18 (weg p/n 0504.0978) figure 3.20 - tor1-cfw08 drawing toroid: thornton nt52/32/20-4400-ip12e (weg p/n 0208.2103) figure 3.21 - tor2-cfw08 drawing.

Page 53

52 4.1 pre-power checks this chapter provides the following information: how to check and prepare the inverter before power-up; how to power-up and check for proper operation; how to operate the inverter when it is installed according to the typical connections (refer to section 3.2 - electrical ins...

Page 54

53 start-up 4.3 start-up 4.3.1 start-up operation via keypad (hmi)- type of control: linear v/f(p202=0) connections according to figure 3.4. Action hmi display description power-up the inverter press the key press the key and hold it depressed until 60 hz is reached press the key press the key press...

Page 55

54 start-up note! The last frequency reference (speed) vale set via the and keys is saved. If you wish to change this value before inverter enabling, change parameter p121 (keypad reference). Notes: (1) if the direction of rotation of the motor is not correct, switch off the inverter. Wait at least ...

Page 56

55 start-up 4.3.2 start-up operation via terminals - control mode: linear v/f (p202=0) connections are according to figures 3.4 and 3.12. Action hmi display description see figure 3.12 switch s1 (fwd / rev)=open switch s2 (reset)=open switch s3 (start/stop)=open potentiometer r1 (ref.)=totalzly ccw ...

Page 57

56 start-up 4.3.3 start-up operation via keypad - control mode: vector (p202=2) the sequence below is based on the following inverter and motor example: inveter: cfw080040s2024esz motor: weg-ip55 power: 0.75hp/0.55kw; frame size: 71; rpm: 1720; number of poles: iv; power factor (cos ϕ ): 0.70; effic...

Page 58

57 start-up action hmi display description press the key to save the selected option and to exit the programming mode press the key to go to the next parameter press the key and use the keys and to set the correct rated motor voltage press the key to save the selected option and exit the programming...

Page 59

58 start-up action hmi display description press the key to go to the next parameter press the key and use the key s and to set the the correct motor power. Press the key to save the selected option and exit the programming mode press the key to got to the next parameter press the key and use the ke...

Page 60

59 start-up note! The last speed reference value set via key and keys is saved. If you wish to change this value before enabling of inverter, change the value of the parameter p121 - keypad reference; the self-tuning routine can be cancelled by pressing the key. Notes: (1) if during the running of t...

Page 61: Chapter 5

60 keypad (hmi) operation this chapter describes the cfw-08 operation via standard keypad or human-machine interface (hmi), providing the following information: general keypad description (hm)i; use of the keypad; parameter programming; description of the status indicators. 5.1 keypad (hmi) descript...

Page 62

61 keypad (hmi) operation figure 5.2 - direction of rotation (fwd/rev) leds off on flashing basic functions of the keys: starts the inverter via acceleration ramp. Stops (disables) the inverter via deceleration ramp. Also resets inverter after a fault has occurred. Toggles the led display between pa...

Page 63

62 keypad (hmi) operation 5.2.1 keypad operation all functions relating to the cfw-08 operation (start/stop, direction of rotation, jog, increment/decrement of the speed (frequency) reference, and selection of local/remote mode) can be performed through the hmi selection. For factory default program...

Page 64

63 keypad (hmi) operation inverter is ready to be started. Line voltage is too low for inverter operation (undervoltage condition). Inverter is in a fault condition. Fault code is flashing on the display. In our example we have the fault code e02 (refer to chaper maintenance). Inverter is applying a...

Page 65

64 keypad (hmi) operation note! (1) for parameters that can be changed with the motor running, the inverter will use the new value immediately after it has been set. For parameters that can be changed only with motor stopped, the inverter will use this new value only after the key is pressed. (2) by...

Page 66

65 keypad (hmi) operation table 5.1 - incompatibility of parameters - e24 p265=3 (jog) and other(s) di(s) ≠ start/stop or forward run and reverse or fwd run and rev run using ramp #2 p266=3 (jog) and other(s) di(s) ≠ start/stop or forward run and reverse or fwd run and rev run using ramp #2 two or m...

Page 67: Chapter 6

66 this chapter describes in detail all cfw-08 parameters and functions. 6.1 symbols please find below some symbols used in this chapter: aix = analog input number x. Ao = analog output. Dix = digital input number x. F* = frequency reference. This is the frequency value that indicates the desired mo...

Page 68

67 detailed parameter description there is still a variation of the linear v/f control: the quadratic v/f control. This control mode is suitable for applications like centrifugal pumps and fans (loads with quadratic torque x speed characteristics), since it enables a motor loss reduction, resulting ...

Page 69

68 detailed parameter description figure 6.1 - block diagram of the frequency reference note! Ai2 is only available in cfw-08 plus version. Dis on when connected to 0v (xc1:5). When f* rotation (if this is possible - p231=2 and if the selected control is not forward run/reverse run. Rs-232 pc, clp, ...

Page 70

69 detailed parameter description fe command via digital input (di) acceleration& deceleration ramp #2 acceleration & deceleration ramp p102 p103 p100 p101 dc link regulation p151 p151 u d p133 p134 frequency reference limits p202 p295 inverter control (v/f or vector) p136, p137, p138, p142, p145 mo...

Page 71

70 detailed parameter description 6.2.5 commands 6.2.6 local/remote operation modes the inverter has the following commands: pwm pulse enabling/disabling, definition of the direction of rotation and jog. As the reference, the inverter commands can de defined in several ways. The command sources are ...

Page 72

71 detailed parameter description read-only parameters variables that can be viewed on the display, but can not be changed by the user. Regulation parameters programmable values used by the cfw-08 functions. Configuration parameters they define the inverter characteristics, the functions to be execu...

Page 73

72 detailed parameter description range [factory setting] parameter unit description / notes p000 0...999 access parameter [ 0 ] 1 6.3.1 access and read only parameters - p000 ... P099 p002 0...6553 frequency [ - ] proportional value 0.01 ( 0.1 ( 1 (>999.9) p003 0...1.5 x i nom output current [ - ] ...

Page 74

73 detailed parameter description range [factory setting] parameter unit description / notes p023 x.Yz software version [ - ] - p040 0...P528 process [ - ] variable (pid) 1 p100 0.1...999s acceleration [ 5.0s ] time #1 0.1s ( 1s (>99.9) p101 0.1...999s deceleration [ 10.0s ] time #1 0.1s ( 1s (>99.9...

Page 75

74 detailed parameter description range [factory setting] parameter unit description / notes p120 0...2 digital reference [ 1 - ativo ] backup - defines if the inverter should save or not the last used digital reference. This backup function is only applicable to the keypad reference. P120 0 1 2 ref...

Page 76

75 detailed parameter description multispeed is used when the selection of a number up to 8 pre- programmed speeds is desired. It allows the control of the output speed by relating the values programmed by the parameters p124...P131, according to the logical combination of the digital inputs program...

Page 77

76 detailed parameter description range [factory setting] parameter unit description / notes p133 (1) 0.00...P134 minimum frequency [ 3.00hz ] (f min ) 0.01hz ( 0.1hz (>99.99) p134 (1) p133...300.0 maximum frequency [ 66.00hz ] (f max ) 0.01hz ( 0.1hz (>99.99) defines the maximum and minimum output ...

Page 78

77 detailed parameter description range [factory setting] parameter unit description / notes figure 6.7 - block diagram of the automatic torque boost function compensation zone maximum (p142) output voltage output frequency field weakening (p145) 4hz 0 figure 6.8 - v/f curve with automatic torque bo...

Page 79

78 detailed parameter description range [factory setting] parameter unit description / notes figure 6.10 - v/f curve with slip compensation output voltage (function of the motor load) output frequency to set the parameter p138 use the following procedure: - run the motor without load up to approxima...

Page 80

79 detailed parameter description range [factory setting] parameter unit description / notes p151 325...410v dc link voltage (line 200-240v) regulation level [ 380v ] 1v 564...820v (line 380-480v) [ 780v ] 1v the dc link voltage regulation (ramp holding) avoids overvoltage trips (e01) during deceler...

Page 81

80 detailed parameter description range [factory setting] parameter unit description / notes figure 6.13 - ixt function – overload detection 3,0 2,0 1,5 1,0 15 30 60 90 time (s) motor current (p003) overload current prevents motor stalling during an overload. If motor load increases its current will...

Page 82

81 detailed parameter description range [factory setting] parameter unit description / notes defines the inverter control mode. Item 4.3 gives some guidelines relating to the selection of control type. P202 (1) 0...2 type of control [ 0 - v/f linear ] - as shown in table above, there are 2 v/f contr...

Page 83

82 detailed parameter description range [factory setting] parameter unit description / notes selects or not the special function of the pid regulator. P203 (1) 0...1 special function [ 0 - none ] selection - p203 0 1 special function none pid regulator see detailed description of pid regualator para...

Page 84

83 detailed parameter description range [factory setting] parameter unit description / notes motor pole number ii poles iv poles vi poles p208 to p002 indicate the speed in rpm 60 30 20 always when programmed to vector mode (p202=2), the parameter p208 is set according to the value of p402 (motor sp...

Page 85

84 detailed parameter description range [factory setting] parameter unit description / notes parameters parameters eeprom eeprom inverter b inverter a hmi → keypad (paste) p215 = 2 press inv → keypad (copy) p215 = 1 press keypad figure 6.16 - copying the parameters from the inverter a to the inverte...

Page 86

85 detailed parameter description range [factory setting] parameter unit description / notes p220 0 1 2 3 4 5 6 local/remote selection always local mode always remote mode key of the keypad (hmi-cfw08-p or hmi-cfw08-rp) key of the keypad (hmi-cfw08-p or hmi-cfw08-rp) di2...Di4 key of the keypad (hmi...

Page 87

86 detailed parameter description range [factory setting] parameter unit description / notes p230 (1) 0...2 remote command [ 1 - terminals ] selection - the direction of rotation is the only operation control that depends on other parameter for operation - p231. For more details, refer to items 6.2....

Page 88

87 detailed parameter description range [factory setting] parameter unit description / notes where: - x = 1, 2; - aix is given in v or ma, according to the used signal (see parameters p235 and p239); - gain is defined by the parameters p234 and p238 for ai1 and ai2 respectively; - offset is defined ...

Page 89

88 detailed parameter description range [factory setting] parameter unit description / notes p251 0...9 analog output ao [ 0 - f s ] function - p252 0.00...9.99 analog output ao [ 1.00 ] gain 0.01 p251 defines the variable to be indicated at the analog ouput. P251 0 1 2 3, 5 and 8 4 6 7 9 ao functio...

Page 90

89 detailed parameter description p263 (1) 0...14 digital input di1 [ 0 - not used function or general enabling] - p264 (1) 0...14 digital input di2 [ 0 - fwd/rev ] function - p265 (1) 0...15 digital input di3 [ 10 - reset ] function - p266 (1) 0...15 digital input di4 [ 8 - not used function [start...

Page 91

90 detailed parameter description range [factory setting] parameter unit description / notes notes! 1) local/remote = open/0v at the digital input respectively. 2) p263=0 (not used or general enable) operates as follows: - if the comand source are the terminals, i.E., if p229=1 for the local mode or...

Page 92

91 detailed parameter description open motor speed motor runs freely time time 0v accel. Ramp general enable 0v motor speed decel. Ramp time time accel. Ramp open start/stop open time 0v time time 0v open di2 - rev di1 - fwd motor speed cw ccw foward run / reverse run time tempo 0v 0v open di2 - sto...

Page 93

92 detailed parameter description open 0v time time motor speed di - fwd/rev cw ccw fwd/rev open open 0v time 0v time p102 p100 di - start/stop di - ramp #2 ramp #2 motor speed p103 p101 time time motor speed 0v open di - start/stop minimum frequency (p133) reset di4 - decrease pe di3 - increase pe ...

Page 94

93 detailed parameter description flying start disable time disabled open enabled inverter status di - flying start disable motor speed open 0v time time motor speed di - no external fault no external fault motor runs freely figure 6.19 - time diagrams of the digital input functions (cont.) reset fa...

Page 95

94 detailed parameter description range [factory setting] parameter unit description / notes p277 (1) 0...7 relay output rl1 [ 7 - no fault ] function - p279 (1) 0...7 relay output rl2 [ 0 - fs > fx ] function - check possible options on table below and details about each function operation on figur...

Page 96

95 detailed parameter description (1) this parameter can be changed only with the inverter disabled (motor stopped). Range [factory setting] parameter unit description / notes when the definition in the function name is true, the digital output will be activated, i.E., the relay coil is energized. W...

Page 97

96 detailed parameter description range [factory setting] parameter unit description / notes thus, p297=4 (5khz) results in an audible motor noise corresponding to 10khz. This is due to the used pwm technique . The reduction of the switching frequency also contributes to the reduction of instability...

Page 98

97 detailed parameter description range [factory setting] parameter unit description / notes p300 0.0...15.0s dc braking [ 0.0 ] time 0.1s p301 0.00...15.00hz dc braking [ 1.00hz ] start frequency 0.01hz p302 0.0...130% dc braking [ 0.0% ] current 0.1% the dc braking feature provides a motor fast st...

Page 99

98 detailed parameter description range [factory setting] parameter unit description / notes p304 p133...P134 skip frequency 2 [ 30.00hz ] 0.01hz ( 0.1hz (99.99hz) p306 0.00...25.00hz skip band range [ 0.00 ] 0.01hz figure 6.23 - skip frequency" curves the passage through the skip speed band (2xp306...

Page 100

99 detailed parameter description range [factory setting] parameter unit description / notes p311 t t disabled. >t dead time enabled disabled dc link voltage undervoltage level (e02) pwm pulses output voltage 0v output frequency (motor speed) 0hz p310 (1) 0...3 flying start and [ 0 - inativas ] ride...

Page 101

100 detailed parameter description range [factory setting] parameter unit description / notes if the inverter does not receive any valid message (via serial interface) during the interval programmed at p314, the action set at p313 will be performed and error e28 is shown on the display. The differen...

Page 102

101 detailed parameter description range [factory setting] parameter unit description / notes p401 0.3xpi nom ...1.3xpi nom rated motor [ according to current the inverter model ] 0.01a ( 0.1a (>9.99a) rated motor current indicated on the motor nameplate. It is the rms-value of the rated motor line ...

Page 103

102 detailed parameter description range [factory setting] parameter unit description / notes p407 (1) 0.50...0.99 rated motor [ according to power factor the inveter model ] 0.01 set this parameter according to motor nameplate. If this value is not available: - if the rated motor efficiency is know...

Page 104

103 detailed parameter description range [factory setting] parameter unit description / notes p409 0.00...9.99 motor resistance [ according to the inverter type ] 0.01 this parameter is shown of the display only when in vector control (p202=2) value estimated by the self-tuning routine. The table in...

Page 105

104 detailed parameter description 6.3.5 special function parameters - p500 ... P599 6.3.5.1 pid introduction cfw-08 is fitted with the pid regulator that can be used for closed loop process control. This function acts as a proportional, integral and derivative regulator, superimposed on the normal ...

Page 106

105 detailed parameter description setpoint definition (reference of the process variable) ai2 p239 ai2 signal p240 (ai2 offset) ai2 gain p525 2, 3 - ai2 0-key p221 (local) or p222 (remote) pid setpoint (key) setpoint pid regulator pid ramp p526 process v ariable filter p528 process v ariable scale ...

Page 107

106 detailed parameter description 6.3.5.3 pid start-up guide please find below a start-up procedure for the pid regulator: initial definition 1) process - definition of the pid action type that the process requires: direct or reverse. The control action must be direct (p527=0) when it is required t...

Page 108

107 detailed parameter description set p234 and p236 according to the variation range of the used feedback signal (for more details, see description of the parameters p234 to p240). Example: suppose the following application: - full scale of the transducer (maximum value at the transducer output) = ...

Page 109

108 detailed parameter description figure 6.26 - application example of an inverter with pid regulator note! The inverter setting must be correct in order to obtain a good performance of the pid regualtor. Ensure the following settings: torque boosts (p136 and p137) and slip compensation (p138) in t...

Page 110

109 detailed parameter description range [factory setting] parameter unit description / notes p520 0.000...7.999 pid proportional [ 1.000 ] gain 0.001 p521 0.000...9.999 pid integral [ 1.000 ] gain 0.001 p522 0.000...9.999 pid differential [ 0.000 ] gain 0.001 the integral gain can be defined as bei...

Page 111: Chapter 7

110 diagnostics and troubleshooting this chapter assists the user to identify and correct possible faults that can occur during the cfw-08 operation. Also instructions about required periodical inspections and cleaning procedures are also provided. When a fault is detected, the inverter is disabled ...

Page 112

111 diagnostics and troubleshooting note: (1) in case of e04 fault due to inverter overtemperature, allow the inverter to cool down before trying to reset it. In the types 10a/200-240 and 10a/380-480v fitted with internal class a rfi-filters, the fault e04 can be caused by internal airflow overtempe...

Page 113

112 diagnostics and troubleshooting note! The faults act as follows: e00 ... E06: switches off the relay that has been programmed to “no fault”, disables the pwm pulses, displays the fault code on the display and the “error” led flashes. Some data are saved on the eeprom memory: keypad reference and...

Page 114

113 diagnostics and troubleshooting problem point to be corrective action checked motor speed loose connections 1.Disable the inverter, switch off the power supply and tighten all varies connections. (oscillates) defective speed 1.Replace the defective speed potentiometer. Potentiometer variation of...

Page 115

114 diagnostics and troubleshooting attention! Electronic boards have components sensitive to electrostatic discharges. Never touch the components or connectors directly. If this is unavoidable, first touch the metallic frame or use a suitable ground strap. Never apply a high voltage test on the inv...

Page 116: Chapter 8

115 chapter 8 cfw-08 options and accessories this chapter describes the optional devices that can be used internal or external with the cfw-08 . Table below shows a list of existing optional devices and the types to which they are applied. Are also given information about the optional devices and th...

Page 117

116 cfw-08 options and accessories name fil1 fil2 fil4 fex1-cfw08 fex2-cfw08 fs6007-16-06 fn3258-7-45 fs6007-25-08 fs6007-36-08 fn3258-16-45 fn3258-30-47 tor1-cfw08 tor2-cfw08 function internal class a suppressor filter rfi - a - 7.3a/200-240v internal class a suppressor filter rfi- a - 2.7-4.3-6.5-...

Page 118

117 cfw-08 options and accessories 1. Unlock the keypad by using a screwdriver as shown above. 2. Remove the keypad by pulling on the lateral sides. (b) removing figure 8.2 - instructions for hmi-cfw-08-p insertion and removing 8.2 tcl-cfw08 dummy panel to be inserted in the place of the parallel ke...

Page 119

118 cfw-08 options and accessories figure 8.4 - dimensions of the hmi-cfw08-rp 8.3.1 hmi-cfw08-rp installation the hmi-cfw08-rp can be installed directly on the panel door (0,12in), as shown in the figures below: figure 8.5 - installation of the hmi-cfw08-rp 8.4 mip-cfw08-rp isolation interface: iso...

Page 120

119 cfw-08 options and accessories 8.5 cab-rp-1 cab-rp-2 cab-rp-3 cab-rp-5 cab-rp-7.5 cab-rp-10 cables used to connect the inverter to the external parallel interface keypad (hmi-cfw08-rp). There are 6 cables options ranging in lenghts from 1m (39in) to 10m (394in). The user must select among these ...

Page 121

120 cfw-08 options and accessories 8.5 cab-hmi08-rp-1 cab-hmi08-rp-2 cab-hmi08-rp-3 cab-hmi08-rp-5 cab-hmi08-rp-7.5 cab-hmi08-rp-10 cables used to connect the inverter to the external parallel interface keypad (hmi-cfw08-rp). There are 6 cables options ranging in lenghts from 1m (39in) to 10m (394in...

Page 122

121 cfw-08 options and accessories 8.6.3 keypad copy function the hmi-cfw08-rs keypad still has an additional function: the keypad copy function.This function is useful when one wants to copy the settings of one inverter (source inverter) to another (target inverter) or one needs to program several ...

Page 123

122 cfw-08 options and accessories 8.9 kcs-cfw08 serial communication module rs-232: is inserted in the place of the parallel keypad, enabling the rs-232 connection (connector rj-6). The rs-232 serial interface enables the point-to-point connection (inverter - master). It is gavanically isolated and...

Page 124

123 cfw-08 options and accessories 8.9.1 instructions for kcs-cfw08 insertion/removal -connect the cable of the communication module to xc5 - place the communication module as shown in figure above. - press it. (a) insertion - use a screwdriver to unlock the communication module. - remove the module...

Page 125

124 cfw-08 options and accessories to install the rs-232 communication kit on the pc, proceed as follows: - remove the parallel keypad (hmi-cfw08-p) from the inverter. - install the serial communication module rs-232 (kcs-cfw08) in the place of the keypad. - install the software “superdrive” in the ...

Page 126

125 cfw-08 options and accessories this kit must be used when a better access to the screw hole of the inverter is needed. Models that used this kit: kfix-cfw08-m1 1,6 - 2,6 - 4,0 - 7,0a/200-240v; 1,0 - 1,6 - 2,6 - 4,0a/380-480v kfix-cfw08-m2 7,3 - 10 - 16a/200-240v; 2,7 - 4,3 - 6,5 - 10a/380-480v 8...

Page 127

126 cfw-08 options and accessories (a) kn1-cfw08-m1 (b) kn1-cfw08-m2 figure 8.17 - dimensions of the nema1/ip20 kits 68 75 89 106 115 86 (a) inverters 1.6-2.6- 4.0-7.0/220-240v; 1.0-1.6-2.6-4.0/380-480v with kn1-cfw08-m1 (b) inverters 7.3-10-16a/200-240v; 2.7-4.3-6.5-10a/380-480v with kn1-cfw08-m2 f...

Page 128

127 cfw-08 options and accessories figure 8.19 - connection of the cfw-08 to a standard rs-485 communication network cfw-08 rs-485 rs-232 miw-02 pow ser weg network rs-485 8.15 rfi filter the installation of frequency inverters requires some care in order to prevent electromagnetic interferences (em...

Page 129

128 cfw-08 options and accessories power supply ground filter cfw-08 driving panel conduit or shielded cable motor motor ground (frame) pe pe figure 8.20 - connection of the external rfi filter - class b 8.16 line reactor due to the input circuit characteristic, common to the most inverters availabl...

Page 130

129 cfw-08 options and accessories [ µ h] l = 1592 x ∆ v x v e f i s, nom where: ∆ v - desired line voltage drop, in percentage (%); v e - phase voltage at inverter input (line voltage), given in volts (v); i s,nom - rated inverter output current; f - line frequency. L pe p e r u v w p e q1 s t u v ...

Page 131

130 cfw-08 options and accessories (b) three-phase power supply models figure 8.21 - power connection with line reactor at the input shield p e u v w r s t r p e s t u v w p e line pe as an alternative criterion, we recommend to add a line reactor always the transformer that supplies the inverter ha...

Page 132

131 cfw-08 options and accessories figure 8.22 - load reactor connection 8.18 dynamic braking the dynamic braking is used where short deceleration times are required or where high inertia is present. For the correct sizing of the braking resistor, application data such as, deceleration time, load in...

Page 133

132 cfw-08 options and accessories inverter model 1.6a / 200-240v 2.6a / 200-240v 4.0a / 200-240v 7.0a / 200-240v 7.3a / 200-240v 10a / 200-240v 16a / 200-240v 1.0a / 380-480v 1.6a / 380-480v 2.6a / 380-480v 2.7a / 380-480v 4.0a / 380-480v 4.3a / 380-480v 6.5a / 380-480v 10a / 380-480v 13a / 380-480...

Page 134

133 cfw-08 options and accessories figure 8.23 - braking resistor connection (only for models 7.3-10-16a/200-240v e 2.7-4.3-6.5-10-13-16/380-480v) 8.19 serial communication motor power supply contactor control power supply overload relay thermostat braking resistor u v w r s t br +ud master pc, plc,...

Page 135

134 cfw-08 options and accessories - identification network address; inverter; software version. - control general enabling/disabling; enabling/disabling by ramp; direction of rotation; frequency/speed reference; local/remote; jog; error and fault reset. - status recognition ready; sub; run; local/r...

Page 136

135 cfw-08 options and accessories address (p308) 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 ascii char dec hex @ 64 40 a 65 41 b 66 42 c 67 43 d 68 44 e 69 45 f 70 46 g 71 47 h 72 48 i 73 49 j 74 4a k 75 4b l 76 4c m 77 4d n 78 4e o 79 4f p 80 50 q 81 51 r...

Page 137

136 cfw-08 options and accessories in this case we have the connection of a master to an inverter (point-to- point). The data can be exchanged in a bi-directional way, but not simultaneously (half duplex). The logical levels meet the eia rs-232c standard, that specifies the use of balanced signals. ...

Page 138

137 cfw-08 options and accessories reading message: for inquiring of the inverter variable content; writing message: to change the inveter variable content or to send comands to the inverters. Note: no transmission between two inverters is possible. The master has the bus access control. 8.19.3.4.1 ...

Page 139

138 cfw-08 options and accessories this message sends data to the inverter variables. The inverter will answer by indicating if the data have been accepted or not. 8.19.3.4.2 writing message format of the writing message: eot: control character of the end of transmission; adr: inverter address; stx:...

Page 140

139 cfw-08 options and accessories the messages are processed in the inverter in determined intervals. Therefore, a pause larger than the sum of the times t proc + t di + t txi should be ensured between two messages addressed to the same inver- ter (refer to section 8.18.6.). 8.19.3.6 message sequen...

Page 141

140 cfw-08 options and accessories 3) master: eot reading of the output current from the inverter 10 (supposing the the same was at 7.8a at the moment of the enquiry). 1) master: eot j 0 1 7 0 3 enq p003 code addr.10 2) inverter: p003 code p003=30ch=780=7.8/0.01 addr.10 3) master: eot 8.19.5 variabl...

Page 142

141 cfw-08 options and accessories el8: 0 = ramp enabling (start/stop) inactive 1 = ramp enabling el9: 0 = general enabling inactive 1 = general enabling active el10: 0 = reverse 1 = forward el11: 0 = jog inactive 1 = jog active el12 0 = local 1 = remote el13: 0 = without undervoltage 1 = with under...

Page 143

142 cfw-08 options and accessories cl5: not used cl6: not used cl7: the transition in this bit from 0 to 1 causes the inverter “reset” when any error condition is present. Note: disabling via dix has priority over this disabling. To disable the inverter via serial interface, set cl0=cl1=cl8=cl9=1, w...

Page 144

143 cfw-08 options and accessories 8.19.5.2 parameters related to the serial communication parameter description local/remote selection local reference selection remote reference selection local command selection remote command selection forward/reverse selection inverter address on the serial commu...

Page 145

144 cfw-08 options and accessories they act as follows: they do not disable the inverter; they do not disable the fault relay; they inform in the word the logical status (v02). Fault types: e22: longitudinal parity fault (bcc); e24: parametrization fault (when some of the situations occurs as indica...

Page 146

145 cfw-08 options and accessories 8.19.7 physical connection rs-232 and rs-485 note: the wiring of the rs-232 must be laid separately from the power cables and the control wiring in 110/220v. Note! You can not use rs-232 and rs-485 simultaneously. Figure 8.24 - cfw-08 network connection through rs-...

Page 147

146 cfw-08 options and accessories figure 8.26 - message structure master query message address (1 byte) function code (1 byte) data (n bytes) crc (2 bytes) address (1 byte) function code (1 byte) data (n bytes) crc (2 bytes) slave answer message start b0 b1 b2 b3 b4 b5 b6 b7 parity or stop stop 8.2...

Page 148

147 cfw-08 options and accessories 8.20.1.2.1 address the master initiates the communication by sending one byte with the address of the slave to which the message is addressed. The slave with the right slave address initiates the message with its own address. The master can also send a message dest...

Page 149

148 cfw-08 options and accessories 8.20.1.2.5 times between messages in the rtu mode there is no specific character that indicates the beginning or the end of a message. Thus the only indication for the beginning or the end of a new message is the data transmission absence in the network by 3.5 time...

Page 150

149 cfw-08 options and accessories 8.20.2.1.1 rs-232 the interface is used for the point-to-point connection (between a single slave and the master). Max. Distance: 10 meters. Signal levels according to eia standard rs-232c. Three wires: transmission (tx), reception (rx) and return (0v). The rs-232 ...

Page 151

150 cfw-08 options and accessories 8.20.2.3.1 available functions and response times in the modbus rtu protocol specification is defined the functions used for accessing different types of registers described in the specification. In the cfw-08 both parameters and basic variables are defined as bein...

Page 152

151 cfw-08 options and accessories ... ... ... ... ... ... ... ... ... Basic variables modbus address decimal hexadecimal v00 5000 1388h v01 5001 1389h v05 5005 138dh number of the basic variable note: all registers (parameters and basic variables) are considered as holding type registers, reference...

Page 153

152 cfw-08 options and accessories bit number bit 3 bit 4 bit 5 bit 6 bit 7 status bits function 0 = jog inactive 1 = jog active 0 = local mode 1 = remote mode 0 = no undervoltage 1 = with undervoltage not used 0 = no fault 1 = with fault the command bits are available to read and write and they hav...

Page 154

153 cfw-08 options and accessories 8.20.3.1 function 01 - read coils it reads the content of an internal group of bits that must compulsorily in a numerical sequence. This function has the following structure for the read and response messages (the values are always hexadecimal, and each filed repre...

Page 155

154 cfw-08 options and accessories 8.20.3.3 function 05 - write single coil this function is used to write a value to a single bit. The bit value is represented by using two bytes, where ff00h represents the bit that is equal to 1, and 0000h represents the bit that is equal to 0 (zero). It has the f...

Page 156

155 cfw-08 options and accessories 8.20.3.5 function 15 - write multiple coils this function allows writing values for a bit group that must be in numerical sequence. This function can be also used to write a single bit (the values are always hexadecimal, and each field represents one byte). Example...

Page 157

156 cfw-08 options and accessories query (master) slave address function initial bit address (byte high) initial bit address (byte low) number of bits (byte high) number of bits (byte low) byte count field (number of data bytes) byte 1 byte 2 byte 3 etc... Crc- crc+ response (slave) slave address fu...

Page 158

157 cfw-08 options and accessories query (master) slave address function initial register address (byte high) initial register address (byte low) number of registers (byte high) number of registers (byte low) byte count field (number of data bytes) data 1 (high) data 1 (low) data 2 (high) data 2 (lo...

Page 159

158 cfw-08 options and accessories query (master) slave address function mei type read code object number crc- crc+ response (slave) slave address function mei type conformity level more follows next object number of objects object code* object length* object value* crc- crc+ the fields are repeated...

Page 160

159 cfw-08 options and accessories in the example the object value has not been represented as hexadecimal value, but with corresponding ascii characters. For instance, for the object 00, the ´weg‘ value has been transmitted as being three ascii characters, that as hexadecimal have the values 57h (w...

Page 161

160 cfw-08 options and accessories query (master) field value slave address 01h function 06h register (high) 00h register (low) 59h value (high) 00h value (low) 00h crc- 59h crc+ d9h response (slave) field value slave address 01h function 86h error code 02h crc- c3h crc+ a1h.

Page 162: Chapter 9

161 technical specifications this chapter describes the technical specifications (electrical and mechanical) of the cfw-08 inverter series. 9.1 power data ac input specifications: voltage: + 10%, -15% (with loss of motor efficiency) frequency : 50/60hz (± 2 hz) phase unbalance: 3% overvoltage: categ...

Page 163

162 technical specifications note! (1) the power rating in va is determined by the following equation: the values shown in the table were calculated by considering the rated inverter current, input voltage of 220v for the 220-240v models and input voltage of 440vfor the 380-480 models. (2) rated cur...

Page 164

163 technical specifications voltage source inverter v/f control or sensorless vector control (vvc - voltage vector control). Pwm svm (space vector modulation). 0 ... 300hz, resolution of 0.01hz. Speed regulation: 1% of the rated speed. Speed regulation: 0.5% of the rated speed. Cfw-08: 1 isolated i...

Page 165

164 technical specifications the inverters are delivered with factory setting to drive weg three-phase, iv-pole, ip55 motors, frequency of 60hz, voltage of 220v for 200-240v models or 380v for 380-480v models and with power as indicated in the tables of sections 9.1.1 and 9.1.2. The data of the appl...

Page 166: Chapter 10

165 warranty weg warrants its frequency inverters against defects in workmanship and materials under the following conditions: 1.0 for the effectiveness of this warranty it is essential that the purchaser inspects carefully the purchased inverter, immediately after receipt, checking its characterist...

Page 167

166 warranty 9.0 this warranty does not cover parts or components that are considered consumer goods, such as rubber or plastic parts, incandescent bulbs, fuses, etc. 10.0 this warranty will be cancelled automatically, independently of any previous written notice or not, when the purchaser , without...