- DL manuals

- WEG

- Storage

- CFW100

- User Manual

WEG CFW100 User Manual

Summary of CFW100

Page 1

Motors i automation i energy i transmission & distribution i coatings modbus rtu cfw100 user’s manual phone: 800.894.0412 - fax: 888.723.4773 - web: www.Ctiautomation.Net - email: info@ctiautomation.Net.

Page 2

Modbus rtu user’s manual series: cfw100 language: english document number: 10002909455 / 00 publication date: 06/2014 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Ctiautomation.Net - email: info@ctiautomation.Net.

Page 3

Contents contents contents ......................................................................................................................... 3 about this manual ...................................................................................................... 5 abbreviations and definiti...

Page 4

Contents 5.1 available functions and response times ...................................................................... 17 5.2 memory map ................................................................................................................................. 17 6 detailed description of ...

Page 5

About this manual about this manual this manual supplies the necessary information for the operation of the cfw100 frequency inverter using the modbus rtu protocol. This manual must be used together with the cfw100 user manual. Abbreviations and definitions ascii american standard code for informati...

Page 6

Introduction to serial communication 1 introduction to serial communication in a serial interface the data bits are sent sequentially through a communication channel or bus. Several technologies use the serial communication for data transfer, including the rs232 and rs485 interfaces. The directions ...

Page 7

Interface description 2 interface description the interfaces for serial communication rs485 or usb available for the cfw100 frequency inverter depend on the selected communication module for the product. Following are presented information about the connection and installation of the equipment, usin...

Page 8

Interface description 2.1.3 terminating resistor it is necessary to enable a terminating resistor at both ends of the main bus for each segment of the rs485 network. If the equipment located at both ends of the bus does not have termination resistors, use active terminating to enable these resistors...

Page 9

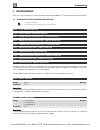

Programming 3 programming next, the cfw100 frequency inverter parameters related to the modbus rtu communication will be presented. 3.1 symbols for the properties description ro reading only parameter cfg parameter that can be changed only with a stopped motor. P0105 – 1 st /2 nd ramp selection p022...

Page 10

Programming p0311 – serial interface byte configuration range: 0 = 8 data bits, no parity, 1 stop bit default: 1 1 = 8 data bits, even parity, 1 stop bit 2 = 8 data bits, odd parity, 1 stop bit 3 = 8 data bits, no parity, 2 stop bits 4 = 8 data bits, even parity, 2 stop bits 5 = 8 data bits, odd par...

Page 11

Programming p0314 – serial watchdog range: 0.0 to 999.0s default: 0.0 properties: cfg description: it allows programming a time limit for the detection of serial interface communication error. If the frequency inverter remains without receiving valid telegrams longer than the time programmed in this...

Page 12

Programming table 3.3: p0680 parameter bit functions bits values bits 0 to 4 reserved. Bit 5 second ramp 0: the drive is configured to use the first ramp values, programmed in p0100 and p0101, as the motor acceleration and deceleration ramp times. 1: the drive is configured to use the second ramp va...

Page 13

Programming p0682 – serial control word range: 0000h to ffffh default: 0000h properties: - description: it is the device modbus rtu interface control word. This parameter can only be changed via serial interface. For the other sources (hmi, etc.) it behaves like a read-only parameter. In order to ha...

Page 14

Programming 60 hz => 8192 30 hz => 13 bit reference 13 bit reference = 30 × 8192 60 13 bit reference = 4096 this parameter also accepts negative values to revert the motor speed direction. The reference speed direction, however, depends also on the control word - p0682 - bit 2 setting: bit 2 = 1 and...

Page 15

Modbus rtu protocol 4 modbus rtu protocol the modbus rtu protocol was initially developed in 1979. Nowadays, it is a widely spread open protocol, used by several manufactures in many equipments. 4.1 transmission modes two transmission modes are defined in the protocol specification: ascii and rtu. T...

Page 16

Modbus rtu protocol received character represents the beginning of a new telegram. And in the same manner, the network elements will assume that the telegram has reached its end when after receiving the telegram elements, this time has elapsed again. If during the transmission of a telegram the time...

Page 17

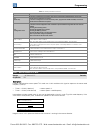

Operation in the modbus rtu network – slave mode 5 operation in the modbus rtu network – slave mode the cfw100 frequency inverter has the following characteristics when operated in modbus rtu network: network connection via rs485 serial interface. Address, communication rate and byte format defined ...

Page 18

Operation in the modbus rtu network – slave mode p0680 (holding register 680): status word p0681 (holding register 681): motor speed command (writing): p0682 (holding register 682): command word p0683 (holding register 683): speed reference refer to the programming manual for a complete parameter li...

Page 19

Detailed description of the functions 6 detailed description of the functions a detailed description of the functions available in the cfw100 frequency inverter for the modbus rtu is provided in this section. In order to elaborate the telegrams it is important to observe the following: the values ar...

Page 20

Detailed description of the functions example: writing of 30 hz as the speed reference (p0683) (assuming a motor frequency of 60 hz) for the slave at address 3. Address: 3 = 03h (1 byte) initial register address: 683 = 02abh (2 bytes) value for parameter: 1000h (2 bytes) request (master) response (s...

Page 21

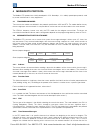

Detailed description of the functions 6.4 function 43 – read device identification it is an auxiliary function that allows the reading of the product manufacturer, model and firmware version. It has the following structure: request (master) response (slave) slave address slave address function funct...

Page 22

Detailed description of the functions when the master sends a message for an inverter configured in a specific network address, the product will not respond to the master if the following occurs: parity bit error. Crc error. Timeout between the transmitted bytes (3.5 times the transmission time of a...

Page 23

Faults and alarms related to the modbus rtu communication 7 faults and alarms related to the modbus rtu communication a128/f228 – timeout for serial communication description: it is the only alarm/fault related to the serial communication indicates that the equipment stopped receiving valid serial t...

Page 24

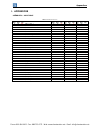

Appendices i. Appendices apÊndice a. Ascii table table i.1: ascii characters dec hex chr dec hex chr dec hex chr dec hex chr 0 00 nul (null char.) 32 20 sp 64 40 @ 96 60 ` 1 01 soh (start of header) 33 21 ! 65 41 a 97 61 a 2 02 stx (start of text) 34 22 " 66 42 b 98 62 b 3 03 etx (end of text) 35 23...

Page 25

Appendices apÊndice b. Crc calculation using tables next, a function using programming language “c” is presented, which implements the crc calculation for the modbus rtu protocol. The calculation uses two tables to supply pre-calculated values of the necessary displacement for the calculation. /* ta...