User's manual questions? As a manufacturer, we are committed to providing complete customer satisfaction. If you have questions, or if there are missing parts, we will guarantee complete satisfaction through direct assistance from our factory. To avoid unnecessary delays, please call direct to our t...

2 table of contents important precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

3 1. Read all instructions in this manual and in the accompanying literature before using the training system. Use the training system only as described in the literature. 2. It is the responsibility of the owner to ensure that all users of the training system are ade- quately informed of all precau...

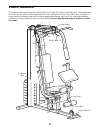

4 before you begin foot plate low pulley station high pulley station lat bar leg lever butterfly arm curl pad curl frame press arm weight stack backrest shroud seat thank you for selecting the versatile weider ® 245 training system. The weider ® 245 offers a selection of weight stations designed to ...

1/4" nylon locknut (2) 1/2" x 1/2" spacer (61) 5/16" nylon jamnut (87) 1/4" washer (78) 5/16" sae washer (88) 5/8" x 1/2" spacer (82) 3/8" nylon jamnut (67) cable clip (53) 1" retainer (68) 1/2" nylon locknut (81) 5/8" x 3/4" spacer (40) 3/8"washer (9) 5/16" washer (70) 3/8" nylon locknut (21) 5/16"...

5/16" x 2 3/4" shoulder bolt (85) 1/4" x 2 1/4" carriage bolt (38) 5/16" x 6" bolt (60) 3/8" x 5" bolt (75) 3/8" x 4 1/4" bolt (64) 3/8" x 4" bolt (16) 3/8" x 3 1/4" bolt (8) 5/16" x 3 1/4" bolt (14) 1/4" x 3" bolt (43) 3/8" x 2 1/2" bolt (7) 5/16" x 2 1/2" bolt (22) 3/8" x 2 1/4" carriage bolt (1) ...

7 assembly make sure you have the following tools: • two (2) adjustable wrenches • one (1) standard screwdriver • one (1) phillips screwdriver • one (1) rubber mallet • you will also need grease or petroleum jelly, a small amount of soapy water, and clear tape or masking tape. Note: assembly will be...

3 4 frame assembl y 8 1 21 42 4 19 25 pin groove 62 3. Attach the front upright (42) to the base (4) using two 3/8” x 2 1/4” bolts (1) and two 3/8” nylon locknuts (21). Do not tighten the nylon locknuts yet. 4. Slide a weight bumper (19) down over each weight guide (62). Slide the weights (25) onto ...

5. Insert the weight tube cap (72) into the indi- cated end of the weight tube (63). Slide the weight tube into the center holes in the weights (25). Slide the top weight (56) down onto the weight guides (62) as shown. 6. Press four 1 1/2” x 2 1/2” inner caps (27) into the top frame (55). Press two ...

Arm assembl y frame assembl y 8. Attach the top frame (55) to the weight guides (62) using a 5/16” x 6” bolt (60), two 1/2” x 1/2” spacers (61), and a 5/16” nylon locknut (3) as shown. Tighten all nylon locknuts used in steps 3 through 8. 9. Lubricate a 3/8” x 4” bolt (16). Attach the press frame (1...

11 arm assembl y 11. Attach the seat plate (37) to the seat frame (36) using a 1/4” x 2 1/4” carriage bolt (38), a 1/4” flat washer (78), and a 1/4” nylon locknut (2). 12. Attach a bumper (11) to the seat frame (36) using a #10 x 1” screw (80). 13. Attach the seat frame (36) to the front upright (42...

18 15 48 47 bracket lubricate axle 55 65 68 45 44 47 16 17 cable assembl y arm assembl y 12 15. Press a 1 3/4” square inner cap (44) into the lower end of the left arm (47). Using a small amount of soapy water, slide a large foam pad (45) onto the left arm. Assemble the right arm (48, not shown) in ...

19. Route the short cable (23) around two “v”- pulleys (6). Attach the pulleys and two long cable traps (50) to the left arm (47) and the right arm (48) as shown, using two 3/8” x 2 1/2” bolts (7) and two 3/8” nylon locknuts (21). Do not overtighten the nylon locknuts; the pulleys must be able to tu...

26 23 24 25 23. Locate the long cable (69). Route the long cable between the base (4) and the press frame (17) as shown. Lay the long cable in the bracket on the base. Attach the pro-pulley (77) to the bracket using a 3/8” x 2” bolt (12) and a 3/8” nylon locknut (21). Do not overtighten the nylon lo...

27. Route the long cable (69) behind the press frame (17) and under the seat frame (36) as shown. Route the long cable around two 3 1/2” pulleys (15). Slide the 3/8” x 5” bolt (75) through the 3 1/2” pulleys (15), two cable traps (66), and the press frame (17) as shown. Tighten a 3/8” nylon locknut ...

31. Attach the seat (13) to the seat frame (36) using two 1/4” x 3/4” bolts (18), a 1/4” x 2 1/4” bolt (33), and a 1/4” washer (78). 32. Attach the backrest (41) to the front upright (42) using two 1/4” x 3” bolts (43) and two 1/4” washers (78). 33. Insert the four 3/4” round inner caps (34) into th...

35. Attach the shroud (59) to the brackets on the top frame (55) and the base (4) using four #8 x 1/2” screws (79). 17 35 79 79 59 55 79 4 sea t assembl y 36. Make sure that all parts have been properly tightened. The use of the remaining parts will be explained in adjustment, beginning on page 18 o...

18 54 39 53 53 52 23 25 26 changing the weight setting to change the weight setting of the weight stack, insert the weight pin (26) under the desired weight (25). Be sure to insert the weight pin until the bent end of the weight pin is touching the weights, and turn the bent end downward. The weight...

19 this chart shows the approximate weight resistance at each exercise station. “top” refers to the 6.5 lb. Top weight. The other numbers refer to the 10 lb. Weight plates. The butterfly arm resistance listed is the resistance for each butterfly arm.The actual resistance at each weight station may v...

20 trouble-shooting and maintenance make sure all parts are properly tightened each time you use the training system. Replace any worn parts immedi- ately. The training system can be cleaned using a damp cloth and mild non-abrasive detergent. Do not use solvents. Tightening the cables woven cable, t...

21 cable diagram the diagram below shows the proper routing of the short cable (23) and the long cable (69). Use the diagram to be sure that the cables and the cable traps have been assembled correctly. If the cables have not been cor- rectly routed, the training system will not function properly an...

Note: “#” indicates a non-illustrated part. Specifications are subject to change without notice. Part list—model no. Wesy19002 r0303a key no. Qty. Description 1 4 3/8” x 2 1/4” carriage bolt 2 2 1/4” nylon locknut 3 9 5/16” nylon locknut 4 1 base 5 1 stabilizer 6 5 “v”-pulley 7 4 3/8” x 2 1/2” bolt ...

2 21 66 15 64 9 21 21 8 43 21 68 65 48 42 45 44 79 79 79 79 3 61 62 60 23 86 57 56 63 26 25 73 14 73 5 21 58 15 15 12 58 1 4 3 3 21 21 21 19 19 77 12 27 53 21 21 15 17 16 52 39 22 3 15 75 46 46 31 49 44 34 30 28 29 32 31 49 44 34 30 64 8 21 66 15 2 3 18 6 21 66 9 50 33 21 38 37 18 36 11 80 32 22 28 ...

Ordering replacement parts to order replacement parts, simply call our customer service department toll-free at 1-800-999-3756, monday through friday, 6 a.M. Until 6 p.M. Mountain time (excluding holidays). To help us assist you, please be pre- pared to give the following information: • the model nu...