Weider Club 16.6st User Manual - Assembly

4

ASSEMBLY

1

8

8

11

51

27

1

4

3

1

51

5

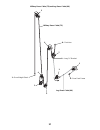

1.

Before beginning assembly, be sure that

you have read and understand the infor-

mation in the box above.

Locate and open the parts bag labeled

“FRAME ASSEMBLY.”

Press two 50mm Square Outer Caps (51)

onto the Stabilizer (5). Press a 50mm

Square Inner Cap (27) into the Base (4).

Insert six M8 x 65mm Carriage Bolts (1) up

through the Stabilizer (5). Insert two M8 x

65mm Carriage Bolts up through the Base

(4).

Attach the Base (4) to the Stabilizer (5) with

two M8 x 70mm Bolts (11), two M8 Washers

(8), and two M8 Nylon Locknuts (3). Do not

tighten the Nylon Locknuts yet.

FRAME ASSEMBL

Y

Before beginning assembly, carefully read the

following information and instructions:

• Place all parts of the weight system in a cleared

area and remove the packing materials; do not

dispose of the packing materials until assembly is

completed.

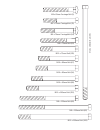

• The assembly is broken into four stages: 1) frame

assembly, 2) arm assembly, 3) cable assembly,

and 4) seat and backrest assembly. The hard-

ware for each stage is packaged separately.

• Wait until you begin each assembly stage to open

the parts bag labeled for that assembly stage.

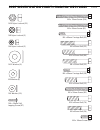

• For help identifying the small parts used in

assembly, use the PART IDENTIFICATION

CHART located in the center of this manual.

Note: Some small parts may have been pre-

attached for shipping. If a part is not in the parts

bag, check to see if it has been pre-attached.

• As you assemble the weight system be sure that

all parts are oriented as shown in the drawings.

• Tighten all parts as you assemble them, unless

instructed to do otherwise.

THE FOLLOWING TOOLS (NOT INCLUDED) ARE

REQUIRED FOR ASSEMBLY:

• Two (2) adjustable wrenches

• One (1) standard screwdriver

• One (1) phillips screwdriver

• One (1) rubber mallet

• Lubricant, such as grease or petroleum jelly,

and soapy water will also be needed.

Assembly will be more convenient if you have the

following tools: A socket set, a set of open-end or

closed-end wrenches, or a set of ratchet wrenches.

1